Daewoo Solar S010 Excavator Service Manual

$31.00

Format: PDF

Language: English

Publication No: 2022-7153E

Daewoo Solar S010 Excavator Service Repair Manual – 268 Pages

- Description

- Reviews (0)

Description

Daewoo Solar S010 Excavator Service Manual

Daewoo Excavator Solar S010

Format: PDF

Language: English

Publication No: 2022-7153E

Daewoo Solar S010 Excavator Service Manual – 268 Pages

How to Use The Daewoo Solar S010 Excavator Guide Manual:

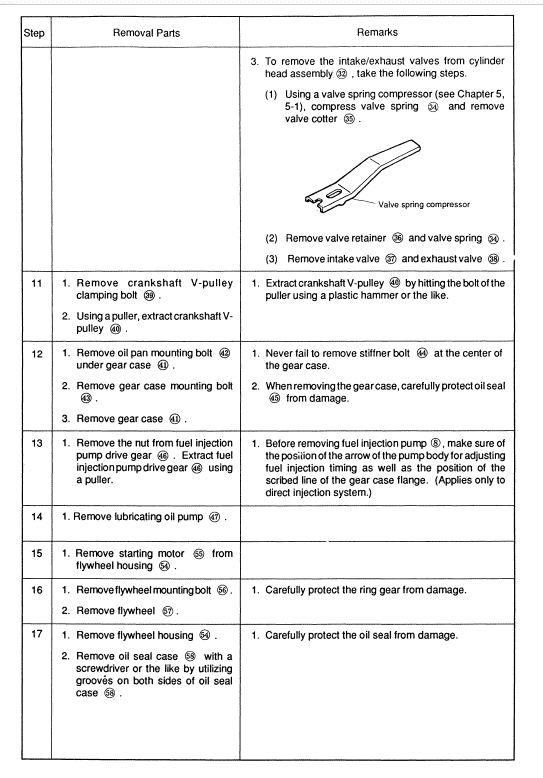

This manual provides information for servicing the Solar S010 Daewoo Excavator. All service procedures are broken down into detailed steps, listed in their recommended sequence. The manual uses both photographs and drawings to help locate and itemize components. The table of Contents on the preceding pages is your best tool for finding the service procedure you need. Be certain to observe all Safety information included in these pages.

A schematic of each of the major engine systems is provided at the beginning of the section of the manual devoted to troubleshooting and repairing that particular system.

Basic safety precautions are list in the Safety section of the Daewoo Solar S010 Excavator Service Manual. Additional safety precautions are list in the Safety section of the owner/operation/maintenance publication. Specific safety warnings for all these publications are provided in the description of operations where hazards exist. WARNING labels have also been put on the product to provide instructions and to identify specific hazards.

HYDRAULIC SYSTEM OPERATION

Hydraulic oil from Pump 1 is directed to port P1 of the control valve and operates the travel(right), boom swing, boom and bucket. See Figure 3-1

Hydraulic oil Pump 2 is directed to port P2 of the control valve to operate swing, arm, travel(left) and the dozer blade.

An overload relief valve protects the boom, arm and bucket.

A return oil filter protects components by removing impurities from hydraulic oil as it returns to the hydraulic oil tank.

A hydraulic circuit diagram is shown in Figure 3-1.

Be the first to review “Daewoo Solar S010 Excavator Service Manual”

You must be logged in to post a review.

Reviews

There are no reviews yet.