Timberjack 404 Skidder Service Repair Manual (Year 1967-1975, SN 444001-446249)

$39.00

Model: Timberjack 404 Skidder

Type: Skidders

Language: English

Format: PDF

- Timberjack 404 Skidder Service Repair Manual – 466 Pages

- Description

- Reviews (0)

Description

Timberjack 404 Skidder Service Repair Manual (Year 1967-1975, SN 444001-446249)

Model: Timberjack 404 Skidder

Type: Skidders

Language: English

Format: PDF

- Timberjack 404 Skidder Service Repair Manual – 466 Pages

This manual contains instructions for the operation, maintenance and repair of the 404 – Heavy Duty – Powershift -TIMBERJACK Skidder.

The life of your TIM:BERJACK Skidder will be extended by the proper operation, maintenance and repair of each machine. This manual outlines the proper procedures for executing these functions.

Each Serviceman involved with these machines should familiarize himself with the sub-assemblies and individual parts with which he is concerned before attempting to carry out any maintenance or repair work.

The information, specifications and illustrations in the manual are based on material available at the time of publication and are, therefore, subject to change and amendment at any time.

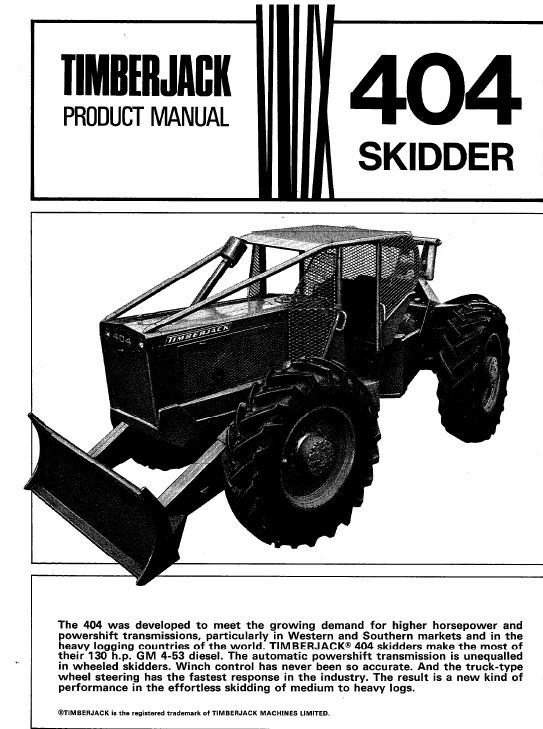

The big-performance 130 h.p. Model 404 has inherited the tradition of engineering excellence that has made TIMBERJACK Skidders the industry standard in 47 countries. Your first glance at the 404 tells you that this powerful skidder is built on years of experience in the toughest of logging conditions. The frames, dozer blade, canopy, fairlead and butt pan are solidly constructed using only premium grade alloy steels. Equally important, the extra heavy duty axles and walking beam will last as long as the machine itself.Protected by the frames are the vital components. The powershift transmission with its twin turbine torque converter develops an overall drive train multiplication of 433:1 in a virtually infinite number of speeds, in both forward and reverse. All components of the hydraulic, cooling and electrical systems were engineered as much for their long life as for their performance characteristics.

A single step puts you into the low, plush seat. The operator is relatively unaffected by machine sway. His controls are conveniently located for minimum physical effort. His wheel-controlled steering – with the fastest response in the industry- is “cushioned” to prevent front and rear frames jarring together. The narrow hood tapers in towards the operator, giving him excellent visibility in key areas.

A central lubrication system, with grease nipples located beside the operator, encourages regular lubrication of vital bearings while the 404 is moving. Planned preventive maintenance and planned service access have helped build for TIMBERJACK skidders their reputation as the skidder with Staying Power.

Be the first to review “Timberjack 404 Skidder Service Repair Manual (Year 1967-1975, SN 444001-446249)”

You must be logged in to post a review.

Reviews

There are no reviews yet.