Kubota 05-E2B, 05-E2BG Engine Workshop Service Manual

$25.00

Publication: 9Y011-02754

Format: PDF

Language: English

Kubota 05-E2B, 05-E2BG Engines Workshop Manual – 125 Pages

- Description

- Reviews (0)

Description

Kubota 05-E2B, 05-E2BG Engine Workshop Service Manual

Kubota Engines Model 05-E2B, 05-E2BG

Publication: 9Y011-02754

Format: PDF

Language: English

Kubota 05-E2B, 05-E2BG Engines Workshop Manual – 125 Pages

Table of Content of the Workshop Service Manual

This Workshop Manual has been prepared to provide servicing personnel with information on the mechanism, service and maintenance of 05-E2B and 05-E2BG series. It is divided into three parts, General, Mechanism and Servicing.

General

Information on the engine identification, the general precautions, maintenance check list, check and maintenance and special tools are described.

Mechanism

Information on the construction and function are included. This part should be understood before proceeding with troubleshooting, disassembling and servicing.

Refer to Diesel Engine Mechanism Workshop Manual (Code No. 9Y021-01870) for the one which has not been described to this workshop manual.

Servicing 05-E2B, 05-E2BG Engine

Information on the troubleshooting, servicing specification lists, tightening torque, checking and adjusting, disassembling and assembling, and servicing which cover procedures, precautions, factory specifications and allowable limits.

All information illustrations and specifications contained in this manual are based on the latest product information available at the time of publication.

Your KUBOTA dealer is always ready to help so that your Engines offers the best performance. After having carefully read this manual, you will realize that much of the routine maintenance can be done by yourself. Machines must be disassembled and assembled efficiently and safely. It is very important to thoroughly understand the construction and function of the machine, to make all appropriate preparations, and start operations according to the specified working procedures in 05-E2B, 05-E2BG Engines workshop service manual.

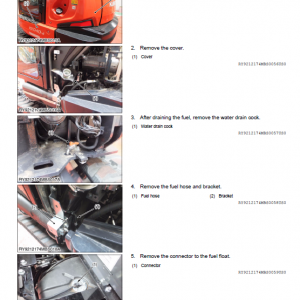

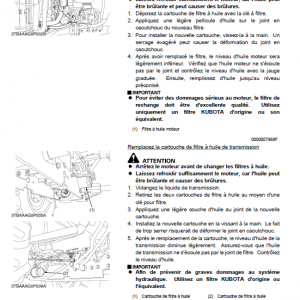

Checking Engine Oil Level

1. Level the engine.

2. To check the oil level, draw out the dipstick (1), wipe it clean, reinsert it, and draw it out again.

Check to see that the oil level lies (A) between the two notches.

3. If the level is too low, add new oil to the specified level.

IMPORTANT When using an oil of different maker or viscosity from the previous, drain old oil. Never mix two different types of oil.

NOTE Be sure to inspect the engine, locating it on a horizontal place. If placed on gradients, accurately, oil quantity may not be measured.

• Be sure to keep the oil level between upper and lower limits of the dipstick. Too much oil may cause a drop in output or excessive blow-by gas. On the closed breather type engine in which mist is sucked through port, too much oil may caused oil hammer. While too little oil, may seize the engines rotating and sliding parts.

Be the first to review “Kubota 05-E2B, 05-E2BG Engine Workshop Service Manual”

You must be logged in to post a review.

Reviews

There are no reviews yet.