John Deere 7430, 7430 E, 7530, 7530 E (Premium) Tractors Repair Manual

$75.00 – $85.00

Language: English

Format: PDF

Region & Publication: Tractors built in North America. TM400319 & TM400019

- John Deere 7430 Premium , 7530 Premium Tractors Service Repair Manual – 1612 Pages

- John Deere 7430 Premium , 7530 Premium Diagnostic Technical Manual – 8978 Pages

- Operators Manual – 350 Pages

Region & Publication: Tractors built in Europe. TM8042 & TM8060

- John Deere 7430, 7430 E, 7530, 7530 E Premium (EU) Tractors Service Repair Manual – 1737 Pages

- John Deere 7430, 7430 E, 7530, 7530 E Premium (EU) Diagnostic Technical Manual – 4314 Pages

- Operators Manual – 306 Pages

- Description

- Additional information

- Reviews (0)

Description

John Deere 7430, 7430 E, 7530, 7530 E (Premium) Tractors Repair Manual

Language: English

Format: PDF

Region & Publication: Tractors built in North America. TM400319 & TM400019

- John Deere 7430 Premium , 7530 Premium Tractors Service Repair Manual – 1612 Pages

- John Deere 7430 Premium , 7530 Premium Diagnostic Technical Manual – 8978 Pages

- Operators Manual – 350 Pages

Region & Publication: Tractors built in Europe. TM8042 & TM8060

- John Deere 7430, 7430 E, 7530, 7530 E Premium (EU) Tractors Service Repair Manual – 1737 Pages

- John Deere 7430, 7430 E, 7530, 7530 E Premium (EU) Diagnostic Technical Manual – 4314 Pages

- Operators Manual – 306 Pages

Table of Content of the 7430, 7530 Premium Tractors

Repair Manuals

Foreword

Safety

Safety Measures

General Information

Technical Information

Tests and Adjustments

Predelivery Inspection

Engine

Removal and Installation of Components

Fuel, Air Intake, Cooling and Exhaust System

Speed Control

Fuel System

Air Intake System

Cooling System

Cold-Weather Starting Aids

Exhaust system

Electrical System

Connector Information

Charging Circuit

Starting Circuit

Electrical Components

Electronic Control Units

Removal and Installation of Electronic Control Units

Removal and Installation of Terminating Resistors

AutoPowr/IVT transmission

Removal and Installation of AutoPowr/IVT Transmission

Transmission Shift Units

Input Housing 2.0

Output Housing 2.0

Differential Drive Shaft Assembly

PowrQuad Transmission

Removal and Installation of Components

Transmission Shift Unit

PowrQuad Module

Range transmission

Drive Train (without Transmission)

Removal and Installation of Components

U.J. Shaft and Torsion Damper

Front-wheel drive clutch

Differential

Hydraulic pump drive

Final Drives

Rear PTO

Steering and Brakes

Hydrostatic Steering

Brake valve

Rear Brakes

AutoTrac

Hydraulic System

Operator Controls

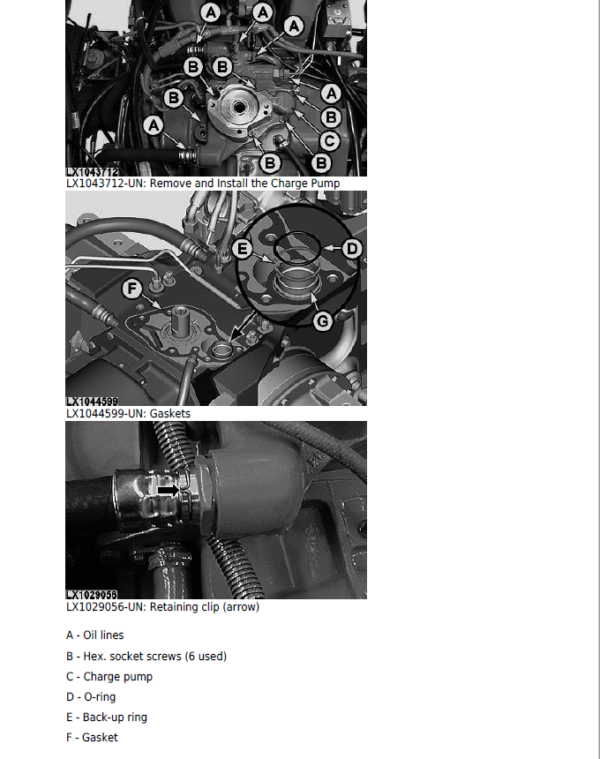

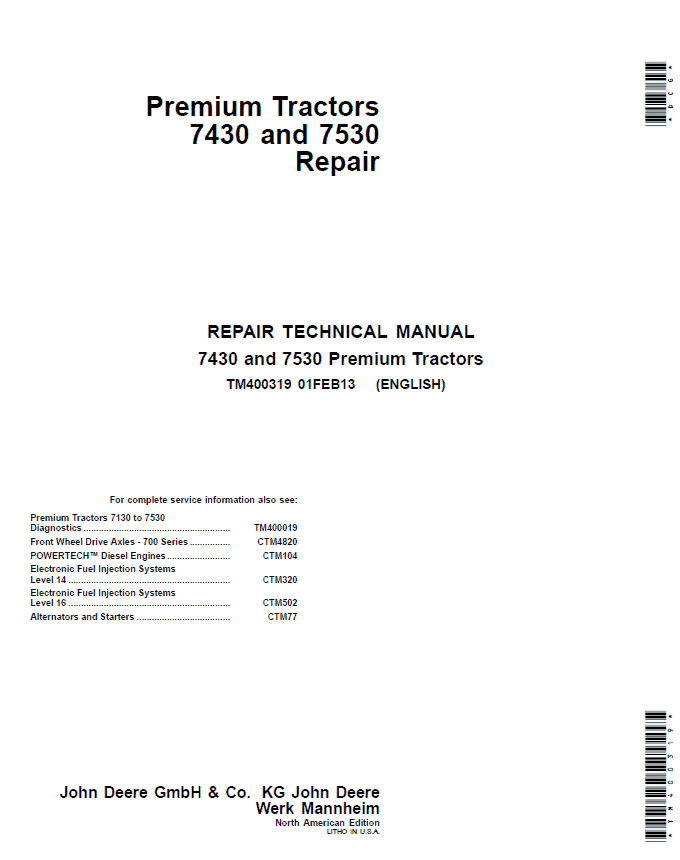

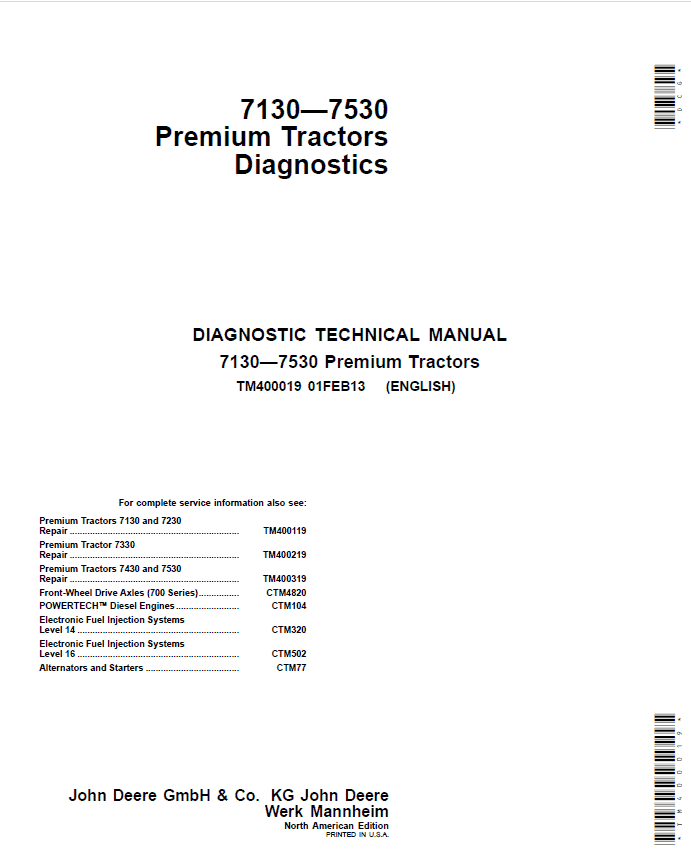

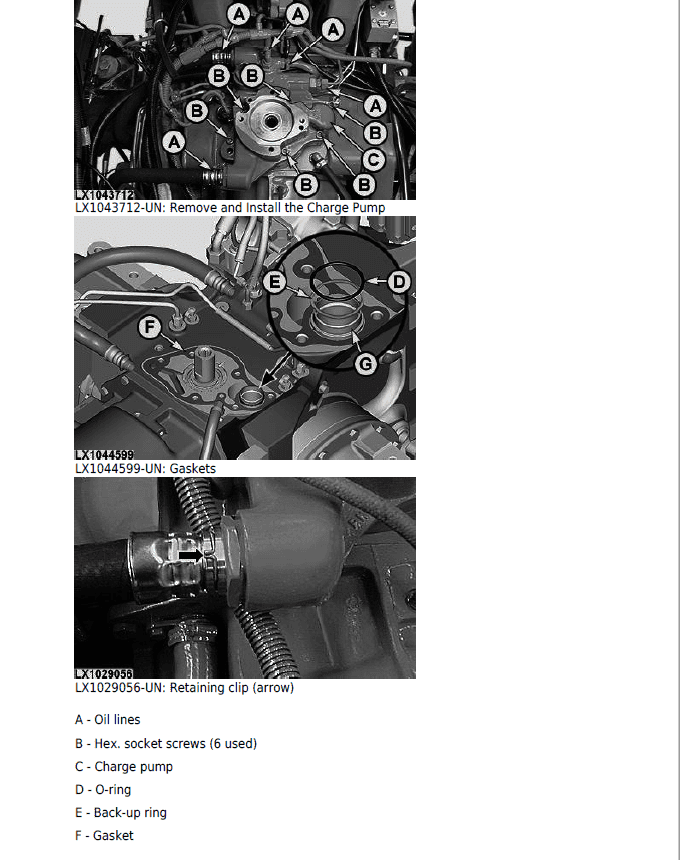

Oil Filter, Charge Pump and Hydraulic Pump

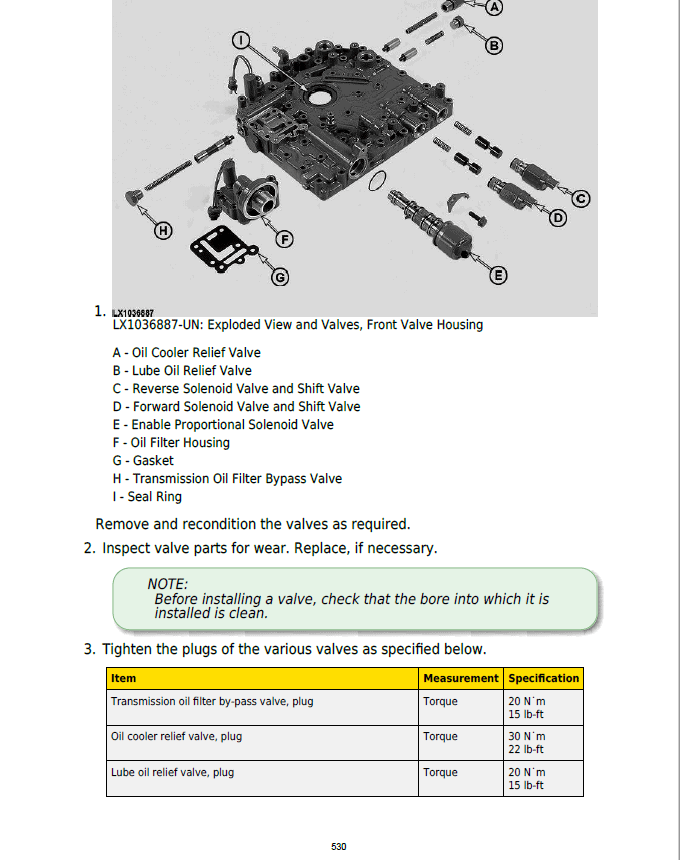

Valves

Hitch

Selective Control Valves (SCVs) and Couplers

Independent Control Valves (ICVs)

Miscellaneous

Removal and Installation of Components

Main Frame

Front Wheels and Rear Wheels

Trailer Mounting and Swinging Drawbar

Triple Link Suspension (TLS) of Front-Wheel Drive Axle

Triple Link Suspension (TLS) of Front-Wheel Drive Axle – 3D Animation

Operator`s Cab

Removal and Installation of Components

Controls and Instruments

Air Conditioning System

ClimaTrak

Heating System

Seats

Operator`s Cab

Cab Suspension

Special Tools

Special Tools (Dealer-Fabricated)

Special Tools (Available from the Dealer)

Operation and Tests

Foreword

Serial Number Break 2008

General Information

Safety Measures

General References

Diagnostic Trouble Codes

ATC Control Unit

BCU Control Unit

BIF Control Unit

DSM Control Unit

DTI Control Unit

ECU Control Unit

EPC Control Unit

ETC Control Unit

JDL Control Unit

PLC Control Unit

SIC Control Unit

SSU Control Unit

TCU Control Unit

TEC Control Unit

TEI Control Unit

TSC Control Unit

UIC Control Unit

UIM Control Unit

VTI Control Unit

Observable Symptoms

Electrical System

Electronic Control Units

AutoPowr/IVT Transmission

PowrQuad Transmission

Drive Train (without Transmission)

Steering and Brakes

Hydraulic System

Miscellaneous

Operator`s Cab

System Diagnostics

Electronic Control Units

PowrQuad Transmission

Hydraulic System

JDL – System Diagnostics

VTI (GreenStar) – System Diagnostics

Engine

General Information

Operational Checks

Tests and Adjustments

Fuel, Air Intake and Cooling Systems

Tests and Adjustments

Fuel System

Air Intake System

Cooling System

Cold-Weather Starting Aids

Electrical System

Starting Motor and Charging Circuit

Fuel Preheater

Electrical Starting Aid

BIF Control Unit (Basic Informator)

Horn

Operator`s Seat and Cigarette Lighter

Lights

Connector for Accessories

Radio Light, Dome Light, Console Light and Access Step Lights

ATC/ETC/HTC Control Units (Air Conditioning, Fan and Heater)

3- and 7-Terminal Power Outlet Sockets

BCU Control Unit (Electronic Hitch Control)

BCU Control Unit (Basic Functions)

Signal Socket and Service Socket

TSC Control Unit (Suspension)

SIC Control Unit (Selective Control Valves)

CAN BUS Terminating Resistor

Level 14 ECU Control Unit (Electronic Engine Control) for 4-Valve Engine with HPCR

Level 16 ECU Control Unit (Electronic Engine Control) for 2-Valve Engine with HPCR

TCU Control Unit (Transmission Control with AutoPowr/IVT Transmission)

EPC Control Unit (Transmission Control with PowrQuad Plus or AutoQuad Plus Transmission)

UIC Control Unit (Transmission Control with AutoPowr/IVT Transmission)

PLC Control Unit (Electronic Park Lock with AutoPowr/IVT Transmission)

Electrical Outside Mirrors

JDL Control Unit (JDLink)

TEC Control Unit (ISOBUS)

GreenStar (AMS)

SSU Control Unit (AutoTrac)

UIM/VTI Control Units (GreenStar Display)

Electro-Hydraulic Pick-Up Hitch

PC6 Power Module (HF)

PC0 Power Module

PC5 Power Module

DTI Control Unit (CommandCenter)

Component Information – Connectors and Contacts

Component Information – Connectors (X001 to X249)

Component Information – Connectors (X250 to X499)

Component Information – Connectors (X500 to X749)

Component Information – Connectors (X750 to X999)

Component Information – Connectors (XGND)

Component Information – Wiring Harnesses

Component Information – Electrical Parts/Components

Component Information – Electrical Parts/Components (Actuators)

Component Information – Electrical Parts/Components (Sensors/Switches/Potentiometers)

Component Information – Electrical Parts/Components (Fuses/Relays/Diodes)

Component Information – Electrical Parts/Components (Headlamps/Lights)

Component Information – Electrical Parts/Components (Other)

Component Information – Ground Connections

Component Information – CAN BUS Systems

Electronic Control Units

Operation and General Information on Diagnostics

Interactive Tests

Interactive Calibrations

Information on How to Reprogram Control Units

Data BUS Systems

ATC Control Unit

BCU Control Unit

BIF Control Unit

DSM Control Unit

DTI Control Unit

ECU Control Unit

EPC Control Unit

ETC Control Unit

JDL Control Unit

PC0 Power Module

PC5 Power Module

PC6 Power Module (HF)

PLC Control Unit

SIC Control Unit

SSU Control Unit

TCU Control Unit

TEC Control Unit

TSC Control Unit

UIC Control Unit

UIM Control Unit

VTI Control Unit

AutoPowr/IVT Transmission

Operational Checks

Tests and Adjustments

Theory of Operation

PowrQuad Transmission

Operational Checks

Tests and Adjustments

Theory of Operation

Drive Train (without Transmission)

Operational Checks

Tests and Adjustments

Front-Wheel Drive Clutch

Differential

Final Drives

Rear PTO Options

Steering and Brakes

Introductory Checks

Operational Checks

Tests and Adjustments

Hydrostatic Steering

Brake Valve

Rear Brakes

AutoTrac

Hydraulic System

Operational Checks

Tests and Adjustments

Theory of Operation

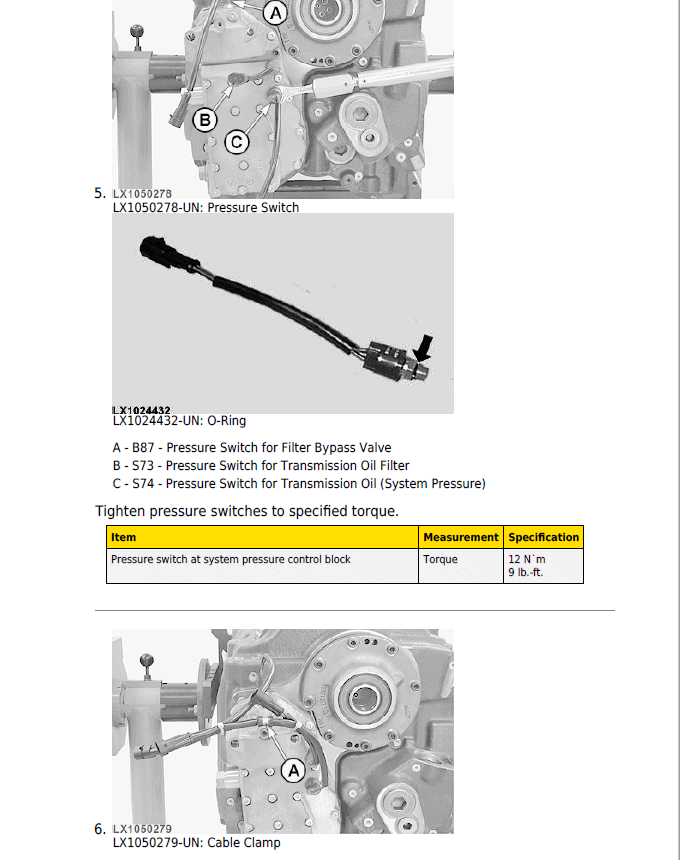

Oil Filter, Charge Pump and Hydraulic Pump

Hitch

Selective control valves (SCVs)

Independent Control Valves (ICVs)

Hydraulic block

Miscellaneous

Functional Tests

Tests and Settings

Operation

Operator`s Cab

Functional Tests

Tests and Settings

Ventilation/Heating

Air-conditioning system

ClimaTrak

Cab Suspension

Special Tools

Special Tools (Dealer-Fabricated)

Special Tools (Available as Spare Parts)

READ THIS MANUAL carefully to learn how to operate and service your Tractors correctly.

Technical manual is divided into two parts: maintenance manual as well as operational principle and test manual. Maintenance manual introduces how to repair machine parts. Operational principle and test manual helps you quickly handle common faults.

The John Deere 7430, 7530 Premium Technical manuals are divided in two parts: repair and operation and tests. Repair sections tell how to repair the components. Operation and tests sections help you identify the majority of routine failures quickly.

Information is organized in groups for the various components requiring service instruction. At the beginning of each group are summary listings of all applicable essential tools, service equipment and tools, other materials needed to do the job, service parts kits, specifications, wear tolerances, and torque values.

Technical Manuals are concise guides for specific machines. They are on-the-job guides containing only the vital information needed for diagnosis, analysis, testing, and repair.

Fundamental service information is available from other sources covering basic theory of operation, fundamentals of troubleshooting, general maintenance, and basic type of failures and their causes.

Additional information

| Built in | Europe. TM8042 & TM8060, North America. TM400319 & TM400019 |

|---|

Be the first to review “John Deere 7430, 7430 E, 7530, 7530 E (Premium) Tractors Repair Manual”

You must be logged in to post a review.

Reviews

There are no reviews yet.