Sumitomo SH80-3B Hydraulic Excavator Repair Service Manual

$36.00

Sumitomo Excavator SH80-3B

Format: PDF

Manual Identification: WLSM0803-00W, WLST0803B-00W, WDL0830-0T , WCL0830-0T

English

- Sumitomo SH80-3B Hydraulic Excavator Repair Service Manual – 179 Pages & 91 Pages

- Operators Manual – 194 Pages

- Parts Catalog – 456 Pages

- Description

- Reviews (0)

Description

Sumitomo SH80-3B Hydraulic Excavator Repair Service Manual

Sumitomo Excavator SH80-3B

Format: PDF

Manual Identification: WLSM0803-00W, WLST0803B-00W, WDL0830-0T , WCL0830-0T

English

- Sumitomo SH80-3B Hydraulic Excavator Repair Service Manual – 179 Pages & 91 Pages

- Operators Manual – 194 Pages

- Parts Catalog – 456 Pages

Sumitomo SH80-3B Manual TABLE OF CONTENTS

Specifications ………………………………………………………………………………………… 1

Overall …………………………………………………………………………………………………………1

1. Main Data ……………………………………………………………………………………………1

2. Performance ………………………………………………………………………………………..1

3. Main Body Dimensions………………………………………………………………………….1

4. Engine ………………………………………………………………………………………………..2

5. Cooling System ……………………………………………………………………………………2

6. Upper Side Work System ………………………………………………………………………3

7. Operating Device………………………………………………………………………………….4

8. Swing Units …………………………………………………………………………………………5

9. Travel Lower Body ………………………………………………………………………………..5

10. Dozer Blade…………………………………………………………………………………………5

Hydraulic Equipment………………………………………………………………………………………6

1. Hydraulic Device…………………………………………………………………………………..6

2. Control Valve, Cylinder ………………………………………………………………………….6

Capacities, Filters ………………………………………………………………………………………….7

1. Coolant and Oil Capacities …………………………………………………………………….7

2. Hydraulic Oil Filters ………………………………………………………………………………7

3. Fuel Filter ……………………………………………………………………………………………7

Overall View ………………………………………………………………………………………….. 8

Overall View (SH80-3B)………………………………………………………………………………….8

1. Standard Arm (1.71 m)………………………………………………………………………….8

2. Long Arm (2.12 m) ……………………………………………………………………………….8

Work Range Diagram……………………………………………………………………………… 9

Work Range Diagram (SH80-3B) …………………………………………………………………….9

1. Standard Arm (1.71 m)………………………………………………………………………….9

2. Long Arm (2.12 m) ……………………………………………………………………………..10

Optional Components …………………………………………………………………………… 11

List of Optional Components …………………………………………………………………………11

Major Equipment ………………………………………………………………………………….. 12

Equipment Configuration ………………………………………………………………………………12

Overall……………………………………………………………………………………………………12

Operator’s Cab………………………………………………………………………………………..13

Lower Mechanism………………………………………………………………………………………..14

Assembly Diagrams (with blade)………………………………………………………………..14

Lower Component ……………………………………………………………………………………….15

1. Travel Unit………………………………………………………………………………………….15

2. Take-up Roller ……………………………………………………………………………………15

3. Upper-roller ……………………………………………………………………………………….15

4. Lower-roller………………………………………………………………………………………..15

5. Recoil Spring……………………………………………………………………………………..16

6. Shoes ……………………………………………………………………………………………….16

Upper Component ……………………………………………………………………………………….17

1. Swing Unit …………………………………………………………………………………………17

Engine-related …………………………………………………………………………………………….18

1. Engine ………………………………………………………………………………………………18

2. Muffler ………………………………………………………………………………………………18

3. Air Cleaner (double element)………………………………………………………………..19

4. Radiator…………………………………………………………………………………………….19

Hydraulic Device………………………………………………………………………………………….20

1. Hydraulic pump ………………………………………………………………………………….20

Control-related…………………………………………………………………………………………….21

1. Control Valve ……………………………………………………………………………………..21

2. Solenoid Valve (4 stack) ………………………………………………………………………21

3. Remote Control Valve (left/right, travel operations) ………………………………….22

4. Remote Control Valve Characteristic Diagram………………………………………..24

5. Center Joint ……………………………………………………………………………………….26

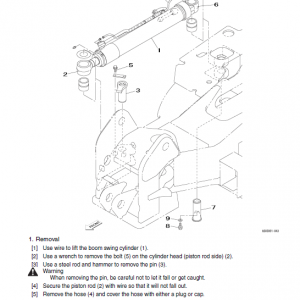

Backhoe Attachment…………………………………………………………………………………….27

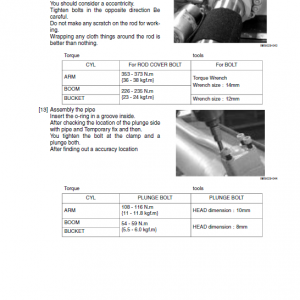

1. Cylinder …………………………………………………………………………………………….27

2. Attachments ………………………………………………………………………………………28

Fuel Tank ……………………………………………………………………………………………………29

Sump Tank………………………………………………………………………………………………….31

Hydraulic Pump Operational Description …………………………………………………… 1

Configuration and Principle of Operation…………………………………………………………..1

Flow Control………………………………………………………………………………………………….3

1. Constant controlling of simultaneous output……………………………………………..3

2. Power-down control by discharge pressure of blade pump (blade shift) ……….4

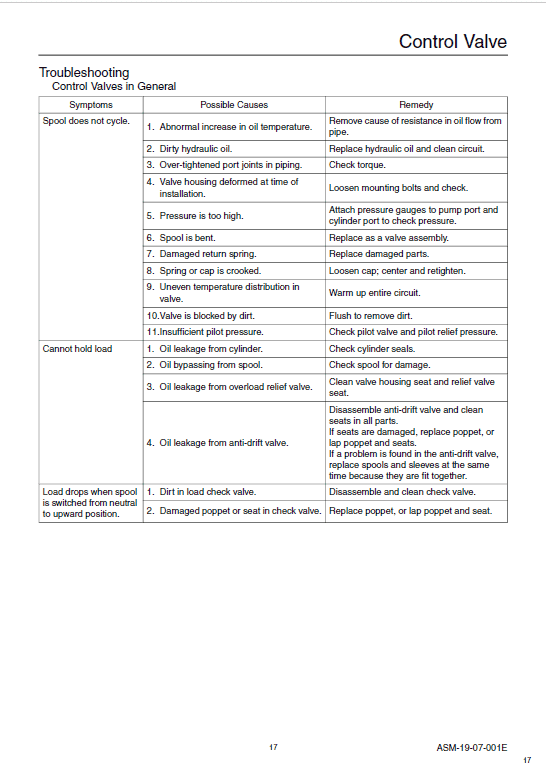

Control Valve Operation ………………………………………………………………………….. 5

Operation with All Spools in Neutral …………………………………………………………………5

1. Main passage ………………………………………………………………………………………5

2. Signal passage…………………………………………………………………………………….5

Independent Operation …………………………………………………………………………………..7

1. Travel spool switch-over (Figure 1) ………………………………………………………….7

2. Backup spool switch-over (Figure 2) ……………………………………………………….7

3. Swing spool switch-over (Figure 3)………………………………………………………….8

4. Bucket spool switch-over (Figure 3) ………………………………………………………..8

5. Boom spool switch-over…………………………………………………………………………9

6. Arm spool switch-over …………………………………………………………………………11

7. Blade spool switch-over (Add-on) (Figure 9) …………………………………………..13

8. Boom Swing spool switch-over (Add-on) (Figure 9A)……………………………….13

9. Relief valve ………………………………………………………………………………………..14

10. Anti-drift valve (Boom section)………………………………………………………………15

Combined Operations…………………………………………………………………………………..17

1. Additional operation with travel (Figure 14) …………………………………………….17

Relief Valve…………………………………………………………………………………………………18

1. Main relief valve………………………………………………………………………………….18

2. Overload relief valve……………………………………………………………………………19

Swing Unit Swing Motor ………………………………………………………………………… 20

Functional and Operational Description ………………………………………………………….20

1. Swash Plate Motor ……………………………………………………………………………..20

2. Parking Brake (for models equipped with parking brakes) ………………………..22

3. Principle of Relief Valve Operation ………………………………………………………..23

4. Makeup Valve …………………………………………………………………………………….26

5. Reduction Gear (2-stage planetary gear)……………………………………………….27

Overview…………………………………………………………………………………………………….28

1. Features ……………………………………………………………………………………………28

2. Operational Description……………………………………………………………………….28

External Dimensional Drawing……………………………………………………………………….32

Basic Structure and Drawings ……………………………………………………………………….33

1. Basic structure of GM motor…………………………………………………………………33

2. Parts list…………………………………………………………………………………………….35

Operational Description ………………………………………………………………………………..36

1. Reduction gear …………………………………………………………………………………..36

2. Hydraulic drive section ………………………………………………………………………..37

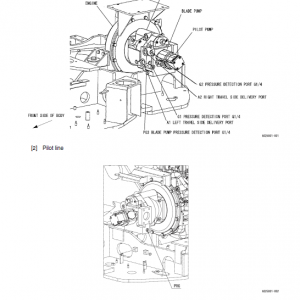

Port Locations ……………………………………………………………………………………….. 1

Hydraulic Pump …………………………………………………………………………………………….1

Control Valve ………………………………………………………………………………………………..2

Control Valve ………………………………………………………………………………………………..3

Pilot Hose Connection Diagrams ……………………………………………………………… 4

Pilot P & T Lines ……………………………………………………………………………………………4

Pilot Control Lines …………………………………………………………………………………………6

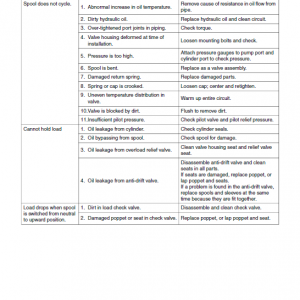

Functional Description…………………………………………………………………………….. 8

List of Functions ……………………………………………………………………………………………8

Control Valve Configuration Table…………………………………………………………………..10

Overview………………………………………………………………………………………………..10

Explanation of Hydraulic Circuit and Operations (standard model)………………. 11

Travel Circuits ……………………………………………………………………………………………..11

High-speed Travel Circuit ………………………………………………………………………….11

Low-speed Travel Circuit …………………………………………………………………………..13

Straight-travel Circuit (Boom-Up and Travel-Forward) …………………………………..15

Swing Circuit……………………………………………………………………………………………….17

Swing Parking Circuit ……………………………………………………………………………….17

Swing Override Throttle Circuit ………………………………………………………………….19

Bucket Circuit………………………………………………………………………………………………21

Bucket-Opening Circuit …………………………………………………………………………….21

Arm CIrcuits………………………………………………………………………………………………..23

Arm-in / Arm-out 2-speed Circuit ……………………………………………………………….23

Boom Circuits ……………………………………………………………………………………………..25

Boom Circuit 1: Boom-up 2-speed Circuit……………………………………………………25

Boom Circuit 2: Boom-down Load Holding Valve Circuit ……………………………….27

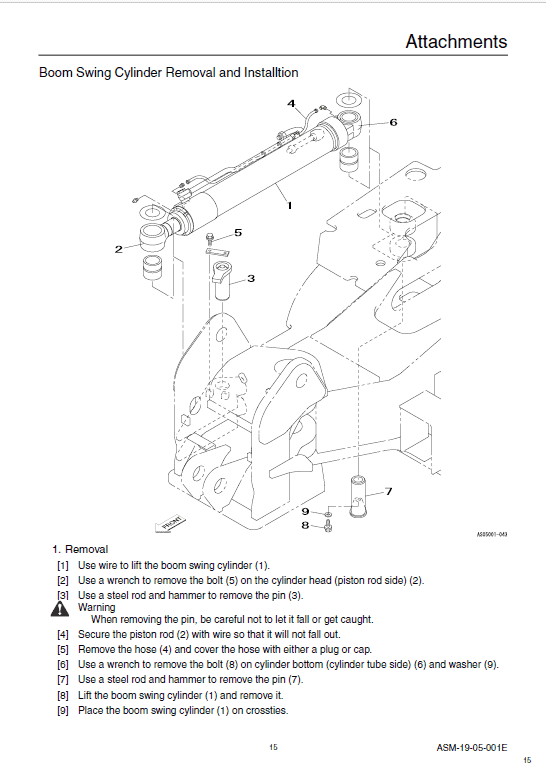

Boom Swing CIrcuit ……………………………………………………………………………………..29

Boom Swing CIrcuit …………………………………………………………………………………29

Blade Circuits ……………………………………………………………………………………………..31

Blade Circuits………………………………………………………………………………………….31

Explanation of Hydraulic Circuit and Operations (option)……………………………. 33

Backup Circuits……………………………………………………………………………………………33

Breaker and Crusher Circuit (2-speed confluence crusher circuit) ………………….33

Breaker and Crusher Circuit (breaker circuit)

Ultra Small Tail Swing Hydraulic Excavator………………………..36

Backup Reciprocating Circuit (ultra small swing hydraulic excavator)………………38

Secondary Backup Reciprocating Circuit

(ultra small tail swing hydraulic excavator) ………………………….40

Operational Description…………………………………………………………………………… 1

Monitor Display ……………………………………………………………………………………………..1

1. Monitor switch panel……………………………………………………………………………..1

2. List of Functions …………………………………………………………………………………..2

Engine Control………………………………………………………………………………………………3

1. Engine start-up control ………………………………………………………………………….3

2. Engine Start-up Circuit ………………………………………………………………………….4

3. Monitor Output Control ………………………………………………………………………..10

4. Monitor Display Control ……………………………………………………………………….17

Electric Circuit Diagrams……………………………………………………………………….. 23

Electric Circuit Diagram 1 ……………………………………………………………………………..23

Electric Circuit Diagram 2 ……………………………………………………………………………..24

Electric Circuit Diagram: Air Conditioner 1 ………………………………………………………25

Electric Circuit Diagram: Air Conditioner 2 ………………………………………………………26

Harness Diagrams ……………………………………………………………………………….. 27

Upper Frame……………………………………………………………………………………………….27

Frame Wiring Main Harness ……………………………………………………………………..27

Inside Cab ………………………………………………………………………………………………….28

Cab Wiring Main Harness…………………………………………………………………………28

Wiring Diagrams…………………………………………………………………………………… 29

Electrical Components and Wiring for Upper Frame (frame)………………………………29

Electrical Components and Wiring for Cab………………………………………………………30

Electrical Components and Wiring for Upper Frame (engine) …………………………….31

Electrical Components and Wiring for Upper Frame (battery)…………………………….32

Heater………………………………………………………………………………………………………..33

Air Conditioner…………………………………………………………………………………………….34

Inside Frame …………………………………………………………………………………………..34

Inside Caiob ……………………………………………………………………………………………35

Measuring / Adjusting Pressure ……………………………………………………………….. 1

Measuring Pressure ………………………………………………………………………………………1

1. Basic conditions …………………………………………………………………………………..1

2. Pressure settings………………………………………………………………………………….1

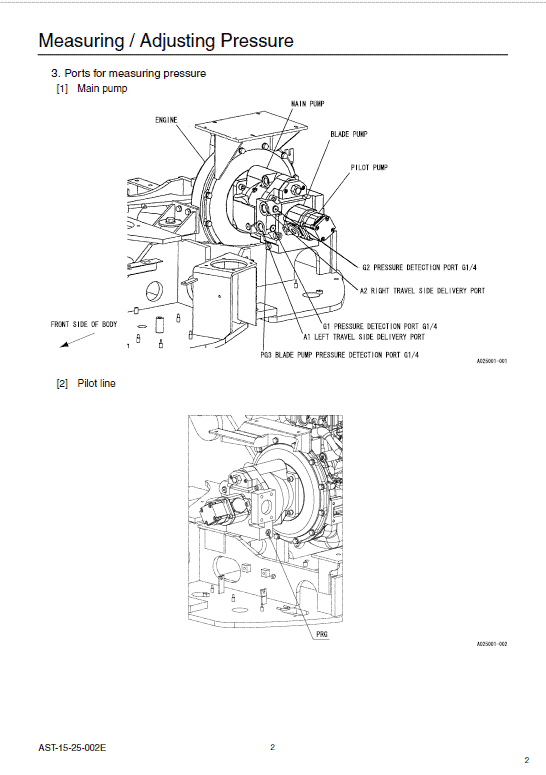

3. Ports for measuring pressure …………………………………………………………………2

4. Preparation for Measuring Pressure………………………………………………………..3

5. Measuring Pressure ……………………………………………………………………………..4

Pressure adjustment………………………………………………………………………………………7

1. Pressure adjusting points ………………………………………………………………………7

Bleeding Air ………………………………………………………………………………………………….9

Attachments Dimensions ………………………………………………………………………. 10

Attachment Installation Methods ……………………………………………………………………10

Appendix …………………………………………………………………………………………….. 11

Unit Conversion Table…………………………………………………………………………………..11

New Hydraulic Oil ………………………………………………………………………………………..12

Long-life hydraulic oil (IDEMITSU Daphne Super Hydro 46SX) ……………………..12

Compatibility………………………………………………………………………………………… 13

List of Common Features and Compatibility of Major Parts ……………………………….13

When parts have to be replaced in either the SH80-3B Hydraulic Excavator , it is essential that only genuine Sumitomo parts should be used. Special attention should be paid to the following points concerning repairs and the fitting of replacement parts and accessories.

Indexing

For convenience the manual is divided into section and parts, each page bearing a section and part number. The sections are subdivided into numbered operation. This simplifies cross referencing and enable the subject to be found easily.

Be the first to review “Sumitomo SH80-3B Hydraulic Excavator Repair Service Manual”

You must be logged in to post a review.

Reviews

There are no reviews yet.