Sumitomo SH210LC-5 Hydraulic Excavator Repair Service Manual

$44.00

Sumitomo Excavator SH210LC-5

Format: PDF

Manual Identification: WDL2005-2T, WLSM2105-00W, WLST2005TS-00W, WLST2105-01T, WCL2005-0F_T02

English

- Sumitomo SH210LC-5 Hydraulic Excavator Repair Service Manual – 1701 Pages

- Operators Manual – 246 Pages

- Parts Catalog – 604 Pages

- Description

- Reviews (0)

Description

Sumitomo SH210LC-5 Hydraulic Excavator Repair Service Manual

Sumitomo Excavator SH210LC-5

Format: PDF

Manual Identification: WDL2005-2T, WLSM2105-00W, WLST2005TS-00W, WLST2105-01T, WCL2005-0F_T02

English

- Sumitomo SH210LC-5 Hydraulic Excavator Repair Service Manual – 1701 Pages

- Operators Manual – 246 Pages

- Parts Catalog – 604 Pages

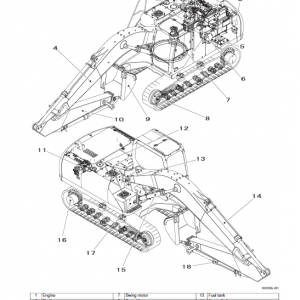

Sumitomo SH210LC-5 Manual TABLE OF CONTENTS

Procedures for Replacing Consumable Parts

Engine Oil …………………………………………………………………………………………………….1

Removal and Installation of Engine Oil Filter Element…………………………………………4

Fuel Filter……………………………………………………………………………………………………..5

Charge Fuel Pump Filter ………………………………………………………………………………..9

Removal and Installation of Fan Belt ……………………………………………………………..11

Removal and Installation of Air Conditioner Belt ………………………………………………13

Assembly and Disassembly

Removal and Installation of Engine Hood………………………………………………………..15

Removal and Installation of Engine Assembly………………………………………………….17

Removal and Installation of Starter Motor ……………………………………………………….29

Removal and Installation of Alternator…………………………………………………………….31

Removal and Installation of Supply Pump ……………………………………………………….33

Removal and Installation of Common Rail……………………………………………………….47

Removal and Installation of Injector………………………………………………………………..50

Removal and Installation of Muffler ………………………………………………………………..62

Removal and Installation of Turbo Charger ……………………………………………………..64

Removal and Installation of EGR Cooler and EGR Valve…………………………………..69

Removal and Installation of Engine Sensors ……………………………………………………73

Removal and Installation of Fuel Cooler………………………………………………………….74

Removal and Installation of Engine Inter Cooler ………………………………………………75

Air Conditioner

Assembly and Disassembly

Removal and Installation of Compressor…………………………………………………………..1

Removal and Installation of Condenser…………………………………………………………….3

Removal and Installation of Receiver Dryer ………………………………………………………5

Assembly and Disassembly of Unit ………………………………………………………………….7

Procedures for Gas Filling

Work Precautions ………………………………………………………………………………………..13

Work Procedures…………………………………………………………………………………………14

Procedures for Filling……………………………………………………………………………………16

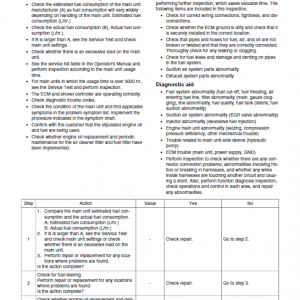

Maintenance

Procedure for Electrical Equipment Judgment

Procedure for Electricity Measurement …………………………………………………………….1

Maintenance Standards

Check Sheet …………………………………………………………………………………………………3

Assembly and Disassembly

Track Shoe

Removal and Installation of Shoe Assembly ……………………………………………………..1

Removal and Installation of Shoe Plate…………………………………………………………….6

Travel Unit

Removal and Installation of Travel Motor…………………………………………………………..7

Assembly and Disassembly of Travel Motor …………………………………………………….15

Travel Motor Internal Structure Diagram………………………………………………………….81

Travel Motor Part Table …………………………………………………………………………………82

Take-up Roller

Removal and Installation of Take-up Roller ……………………………………………………..83

Assembly and Disassembly of Take-up Roller …………………………………………………86

Upper Roller

Removal and Installation of Upper Roller ………………………………………………………..98

Assembly and Disassembly of Upper Roller…………………………………………………..101

Lower Roller

Removal and Installation of Lower Roller ………………………………………………………112

Assembly and Disassembly of Lower Roller…………………………………………………..115

Swing Unit

SH210-5 Removal and Installation of Swing Unit ……………………………………………125

SH210-5 Assembly and Disassembly of Swing Unit ……………………………………….131

SH210-5 Assembly and Disassembly of Swing Motor……………………………………..136

SH210-5 Assembly and Disassembly of Swing Reduction Gear……………………….160

Center Joint

Removal and Installation of Center Joint ……………………………………………………….217

Counterweight

Removal and Installation of Counterweight ……………………………………………………222

Hydraulic Pump

Removal and Installation of Pump ………………………………………………………………..225

Procedures for Assembly and Disassembly of Hydraulic Pump Main Unit………….231

Pump Main Unit Maintenance Standards ………………………………………………………239

Explanation of Regulator Operation………………………………………………………………242

Procedures for Assembly and Disassembly of Regulator…………………………………248

Remote Control Valve

Removal and Installation of Operation Remote Control Valve ………………………….257

Procedures for Assembly and Disassembly of Operation Remote Control Valve…266

Removal and Installation of Travel Remote Control Valve ………………………………..279

Procedures for Assembly and Disassembly of Travel Remote Control Valve ………283

Control Valve

Removal and Installation of Control Valve ……………………………………………………..302

Procedures for Assembly and Disassembly of Control Valve ……………………………312

Other Valves

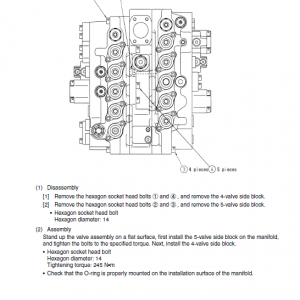

Removal and Installation of 5 Stack Solenoid ………………………………………………..335

Removal and Installation of Cushion Valve…………………………………………………….339

Assembly and Disassembly of Cushion Valve………………………………………………..343

Radiator and Oil Cooler

Removal and Installation of Radiator…………………………………………………………….351

Removal and Installation of Oil Cooler ………………………………………………………….361

Tank

Removal and Installation of Hydraulic Oil Tank……………………………………………….365

Removal and Installation of Fuel Tank…………………………………………………………..375

Attachments

Removal and Installation of Bucket……………………………………………………………….381

Removal and Installation of Bucket Link………………………………………………………..383

Removal and Installation of Bucket Cylinder ………………………………………………….386

Removal and Installation of Arm Cylinder………………………………………………………390

Removal and Installation of Arm…………………………………………………………………..395

Removal and Installation of Boom Cylinder……………………………………………………397

Removal and Installation of Boom ………………………………………………………………..402

Removal and Installation of Arm HBCV…………………………………………………………408

Removal and Installation of Boom HBCV………………………………………………………410

Procedures for Operation / Assembly and Disassembly of Hydraulic Cylinder ……413

Lights

Removal and Installation of Boom Light ………………………………………………………..442

Removal and Installation of Tool Box Light …………………………………………………….443

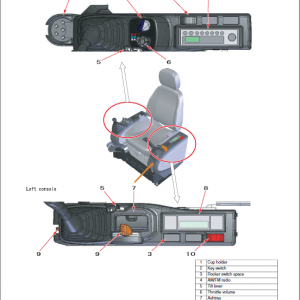

Procedures for Removal and Installation of Cab Inner and Outer Parts

Removal and Installation of Cab Assembly ……………………………………………………444

Removal and Installation of Operator’s Seat ………………………………………………….452

Removal and Installation of Wiper ………………………………………………………………..454

Removal and Installation of Wiper Controller …………………………………………………455

Removal and Installation of Wiper Motor……………………………………………………….458

Removal and Installation of Monitor ……………………………………………………………..462

Removal and Installation of Cab Front Glass …………………………………………………463

Procedure for Window Lock Adjustment………………………………………………………..466

Hydraulic Equipment-related Parts

Accumulator………………………………………………………………………………………………468

Suction Filter……………………………………………………………………………………………..469

Return Filter………………………………………………………………………………………………471

Pilot Filter………………………………………………………………………………………………….473

Other

Removal and Installation of Side Door ………………………………………………………….474

Draining Oil from Hydraulic Oil Tank……………………………………………………………..475

The Sumitomo Manual Preface

The purpose of this Sumitomo Excavator manual is to assist dealers and repair serviceman in efficient repair and maintenance of their machinery. Carrying out the procedures as detailed, together with the use of any special tools needed.

Using the Sumitomo SH210LC-5 Manual

To make information easier to find, there is an index at the beginning of each section listing the various parts in that section. At the beginning of each part there is a table of contents which should also be used as a guide to locate information.

To assist with locating information, each section of the manual is preceded by a contents page listing the repair operations, Each instruction within an operating has a sequence number. To complete the operation in the minimum time is possible follow the manual guideline and repair instructions.

When parts have to be replaced in either the SH210LC-5 Hydraulic Excavator , it is essential that only genuine Sumitomo parts should be used. Special attention should be paid to the following points concerning repairs and the fitting of replacement parts and accessories.

Indexing

For convenience the manual is divided into section and parts, each page bearing a section and part number. The sections are subdivided into numbered operation. This simplifies cross referencing and enable the subject to be found easily.

Be the first to review “Sumitomo SH210LC-5 Hydraulic Excavator Repair Service Manual”

You must be logged in to post a review.

Reviews

There are no reviews yet.