Gehl Z35 Gen 2, Mustang 350Z Nxt 2 Compact Excavator Repair Service Manual

$40.00

Language: English

Format: PDF

Applicable for the Gehl Excavator Model Gehl Z35 Gen 2, Mustang 350Z Nxt 2

- Gehl Z35 Gen 2, Mustang 350Z Nxt 2 Excavator Repair Service Manual – 730 Pages

- Gehl Z35 Gen 2, Mustang 350Z Nxt 2 Excavator Operators Manual – 318 Pages

- Gehl Z35 Gen 2, Mustang 350Z Nxt 2 Excavator Parts Manual – 424 Pages

- Description

- Reviews (0)

Description

Key Chapters and Highlights

- General Cautions for Maintenance Work:

- Safety guidelines for maintenance tasks, disassembly, reassembly, and handling of hydraulic components.

- Best practices for hydraulic hose installation, seal handling, and air release procedures.

- Technical Data:

- Detailed specifications, working area dimensions, and weight lists of main parts.

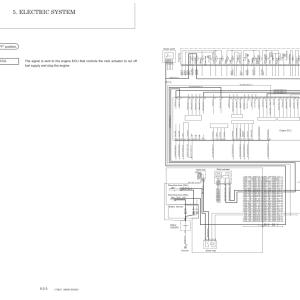

- Hydraulic and electrical schematics, wiring diagrams, and recommended fuel, lubricants, and grease.

- Lifting capacity and periodic inspection schedules.

- Service Standards:

- Performance standards for the machine, engine, undercarriage, and hydraulic equipment.

- Tightening torque values for various components and pressure adjustment settings for hydraulic valves.

- Specifications for rubber crawlers, blade moving devices, and bucket teeth.

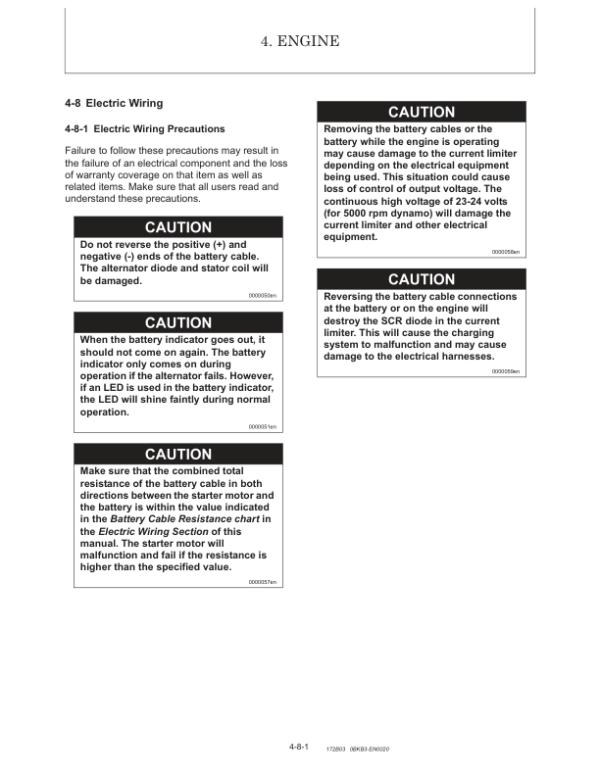

- Engine:

- Comprehensive servicing instructions for the engine, including valve clearance adjustments and EGR system maintenance.

- Detailed procedures for fuel system components, cooling systems, lubrication systems, starter motors, alternators, and the electronic control system.

- Wiring diagrams and troubleshooting methods for engine-related components.

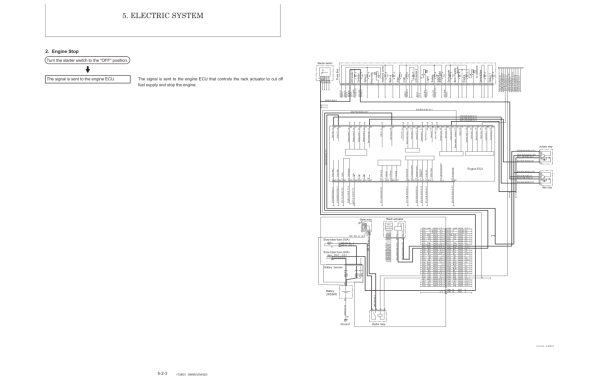

- Electric System:

- Overview of the electrical equipment, LCD monitor, and alarm systems.

- Description of electronic control systems for start/stop, auto deceleration, Eco mode, and engine speed/output control.

- Error codes and diagnostic tools for troubleshooting.

- Hydraulic System:

- Detailed explanations of hydraulic circuit operations, including boom, arm, bucket, swing, and blade systems.

- Instructions for handling simultaneous operations, quick couplers, and hydraulic P.T.O. (Power Take-Off).

- Maintenance and repair procedures for hydraulic pumps, control valves, pilot valves, swing motors, and travel motors.

- Adjustment and Repair:

- Instructions for the removal, reinstallation, and servicing of key components such as the engine, undercarriage, controls, swing bearings, and cabin.

- Hydraulic system repairs, including disassembly and reassembly of hydraulic cylinders, swivel joints, and oil tanks.

- Work implement adjustments, including quick coupler and air conditioner servicing.

- Troubleshooting:

- Diagnostic guides for non-breakdown issues, such as bucket release, arm movement irregularities, and thermal shocks.

- Quick reference tables for troubleshooting common problems, including hydraulic system oil fluctuations and travel speed delays.

Be the first to review “Gehl Z35 Gen 2, Mustang 350Z Nxt 2 Compact Excavator Repair Service Manual”

You must be logged in to post a review.

Reviews

There are no reviews yet.