Gehl GE 283Z Compact Excavator Repair Service Manual

$36.00

Language: English

Format: PDF

Applicable for the Gehl Excavator Model GE 283Z

- Gehl GE 283Z Excavator Repair Service Manual – 154 Pages

- Gehl GE 283Z Excavator Operators Manual – 108 Pages

- Gehl GE 283Z Excavator Repair Parts Manual – 124 Pages

- Description

- Reviews (0)

Description

Gehl GE 283Z Compact Excavator Repair Service Manual

Language: English

Format: PDF

Applicable for the Gehl Excavator Model GE 283Z

- Gehl GE 283Z Excavator Repair Service Manual – 154 Pages

- Gehl GE 283Z Excavator Operators Manual – 108 Pages

- Gehl GE 283Z Excavator Repair Parts Manual – 124 Pages

Table of Content of the Gehl GE 283Z Excavator Manual:

Introduction

General Information ……………………………………………………………………………………. 1-1

Serial number locations, type decals and component numbers ………………………… 1-2

Designated uses and exemption from liability ………………………………………………… 1-4

Abbreviations/symbols ………………………………………………………………………………… 1-4

Identification of warnings and dangers ………………………………………………………….. 1-5

Machine overview ………………………………………………………………………………………. 1-6

Cab overview …………………………………………………………………………………………….. 1-7

Cab legend ……………………………………………………………………………………………….. 1-8

Instrument panel overview …………………………………………………………………………… 1-9

Instrument panel legend ……………………………………………………………………………. 1-10

Engine compartment overview …………………………………………………………………… 1-11

Chassis overview ……………………………………………………………………………………… 1-12

Valve compartment …………………………………………………………………………………… 1-13

Overview of open engine and valve compartment …………………………………………. 1-14

Specifications

Chassis …………………………………………………………………………………………………….. 2-1

Engine ………………………………………………………………………………………………………. 2-1

Fuel injection pump ………………………………………………………………………………. 2-2

Engine capacities …………………………………………………………………………………. 2-2

Engine tightening torques ………………………………………………………………………. 2-2

Hydraulic system ……………………………………………………………………………………….. 2-2

Work hydraulics ……………………………………………………………………………………. 2-2

Auxiliary hydraulics oil flow …………………………………………………………………….. 2-3

Undercarriage and swivel unit ……………………………………………………………………… 2-3

Dozer blade ………………………………………………………………………………………………. 2-3

Electric system …………………………………………………………………………………………… 2-3

Fuse box ……………………………………………………………………………………………… 2-4

Noise levels ………………………………………………………………………………………………. 2-5

Vibration …………………………………………………………………………………………………… 2-5

Coolant compound table ……………………………………………………………………………… 2-5

Model-specific tightening torques …………………………………………………………………. 2-6

General tightening torques ………………………………………………………………………….. 2-6

Tightening torques for hydraulic screw connections (dry assembly) …………….. 2-6

Tightening torques for high-resistance screw connections ………………………….. 2-8

Dimensions ……………………………………………………………………………………………….. 2-9

Lift capacity table ……………………………………………………………………………………… 2-10

Lift capacity table with optional counterweight ………………………………………………. 2-11

Bucket geometry ………………………………………………………………………………………. 2-12

Maintenance

Fluids and lubricants …………………………………………………………………………………… 3-1

Additional oil change and filter replacement (hydraulics) ……………………………. 3-2

Maintenance label ………………………………………………………………………………………. 3-3

Explanation of symbols on the maintenance label ……………………………………… 3-3

Maintenance schedule ………………………………………………………………………………… 3-5

Check, clean or inspect …………………………………………………………………………. 3-5

Fluid and filter changes ………………………………………………………………………….. 3-6

Functional check …………………………………………………………………………………… 3-6

Leakage check ……………………………………………………………………………………… 3-6

Daily lubrication ……………………………………………………………………………………. 3-7

Service package ………………………………………………………………………………………… 3-8

Introduction ……………………………………………………………………………………………….. 3-8

Fuel system ……………………………………………………………………………………………….. 3-9

Specific safety instructions …………………………………………………………………….. 3-9

Refueling ……………………………………………………………………………………………… 3-9

Stationary fuel pumps ………………………………………………………………………….. 3-10

Bleeding the fuel system ………………………………………………………………………. 3-10

Emptying the fuel tank …………………………………………………………………………. 3-11

Diesel fuel specification ……………………………………………………………………….. 3-11

Fuel shut-off valve and water separator …………………………………………………. 3-11

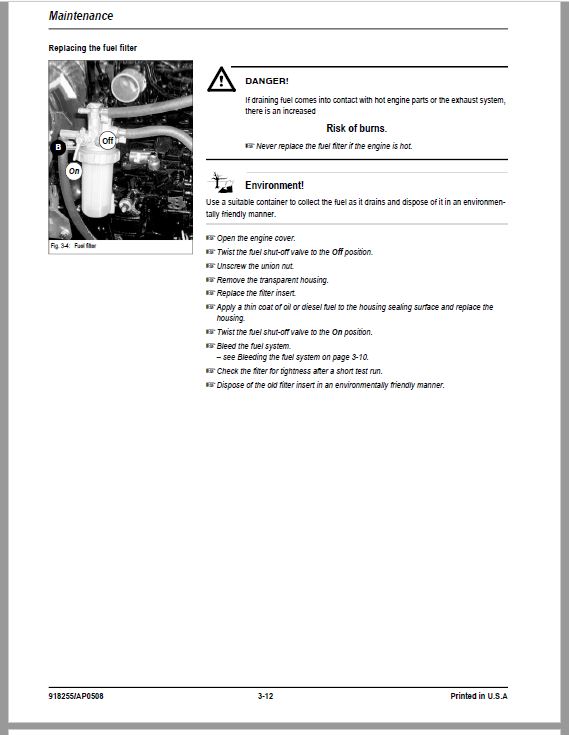

Replacing the fuel filter ………………………………………………………………………… 3-12

Engine lubrication system ………………………………………………………………………….. 3-13

Checking the oil level …………………………………………………………………………… 3-13

Adding engine oil ………………………………………………………………………………… 3-14

Changing engine oil and filter ……………………………………………………………….. 3-15

Cooling system ………………………………………………………………………………………… 3-16

Specific safety instructions …………………………………………………………………… 3-16

Checking/adding coolant ……………………………………………………………………… 3-17

Draining coolant ………………………………………………………………………………….. 3-18

Air filter ……………………………………………………………………………………………………. 3-19

Replacing the filter ………………………………………………………………………………. 3-20

Functional check of the dust valve once a week ……………………………………… 3-21

V-belt ………………………………………………………………………………………………………. 3-22

Checking V-belt tension ……………………………………………………………………….. 3-22

Tightening the V-belt ……………………………………………………………………………. 3-23

Pressure checks ………………………………………………………………………………………. 3-24

General ……………………………………………………………………………………………… 3-24

Pilot control pressure check ………………………………………………………………….. 3-24

Variable-displacement pump P1 pressure check …………………………………….. 3-25

Variable-displacement pump P2 pressure check …………………………………….. 3-26

Gear pump P3 pressure check ……………………………………………………………… 3-27

Gear motor secondary pressure limiting valve pressure check ………………….. 3-28

Test ports overview ……………………………………………………………………………… 3-28

Primary pressure limiting valves ……………………………………………………………. 3-29

Test report ……………………………………………………………………………………………….. 3-31

Hydraulic system ………………………………………………………………………………………. 3-33

Specific safety instructions …………………………………………………………………… 3-33

Checking the hydraulic oil level …………………………………………………………….. 3-34

Adding hydraulic oil ……………………………………………………………………………… 3-35

Changing hydraulic oil …………………………………………………………………………. 3-35

Monitoring the hydraulic oil return filter …………………………………………………… 3-36

Checking hydraulic pressure lines …………………………………………………………. 3-37

Travel drive ……………………………………………………………………………………………… 3-38

Checking the oil level and adding oil ……………………………………………………… 3-38

Draining oil …………………………………………………………………………………………. 3-38

Tracks …………………………………………………………………………………………………….. 3-39

Checking track tension ………………………………………………………………………… 3-39

Track tension ……………………………………………………………………………………… 3-39

Lubrication ………………………………………………………………………………………………. 3-41

Dozer blade ……………………………………………………………………………………….. 3-41

Lubrication points on the swivel console ………………………………………………… 3-41

Boom lubrication points ……………………………………………………………………….. 3-42

Lubrication points on the dipper arm ……………………………………………………… 3-42

Lubrication strip ………………………………………………………………………………….. 3-43

Maintenance of attachments ………………………………………………………………… 3-43

Electrical system ………………………………………………………………………………………. 3-44

Specific safety instructions …………………………………………………………………… 3-44

Regular service/maintenance ……………………………………………………………….. 3-45

Specific component instructions ……………………………………………………………. 3-45

Alternator …………………………………………………………………………………………… 3-45

Battery ………………………………………………………………………………………………. 3-46

Jump-starting the engine ……………………………………………………………………… 3-47

Cab ………………………………………………………………………………………………………… 3-48

Replacing the cab filter ………………………………………………………………………… 3-48

General maintenance ……………………………………………………………………………….. 3-49

Cleaning ……………………………………………………………………………………………. 3-49

General instructions for all areas …………………………………………………………… 3-49

Inside the cab …………………………………………………………………………………….. 3-50

Seat belt ……………………………………………………………………………………………. 3-50

Exterior of the machine ………………………………………………………………………… 3-50

Engine compartment …………………………………………………………………………… 3-50

Screw connections and attachments ……………………………………………………… 3-50

Pivots and hinges ……………………………………………………………………………….. 3-50

Engine

3TNV76-NNS engine overview …………………………………………………………………….. 4-1

Fuel system ………………………………………………………………………………………………. 4-3

Checking and adjusting valve tip clearance ……………………………………………………. 4-4

Tightening order for cylinder head bolts ………………………………………………………… 4-4

Checking the injection nozzles …………………………………………………………………….. 4-5

Pressure check …………………………………………………………………………………….. 4-5

Checking the nozzle jet ……………………………………………………………………………….. 4-5

Injection time ……………………………………………………………………………………………… 4-6

Checking and adjusting injection time ……………………………………………………… 4-6

Fuel injection pump replacement …………………………………………………………….. 4-7

Adjusting engine rpm ………………………………………………………………………………….. 4-8

Compression ……………………………………………………………………………………………… 4-8

Checking the coolant thermostat ………………………………………………………………….. 4-8

Checking the thermal switch ………………………………………………………………………… 4-9

Oil pressure switch …………………………………………………………………………………….. 4-9

Checking the coolant circuit ……………………………………………………………………….. 4-10

Engine troubleshooting …………………………………………………………………………….. 4-10

Hydraulic system

Hydraulic pump PVD-0B-23BP-8G3-5083A …………………………………………………… 5-1

Pump unit: exploded view ………………………………………………………………………. 5-3

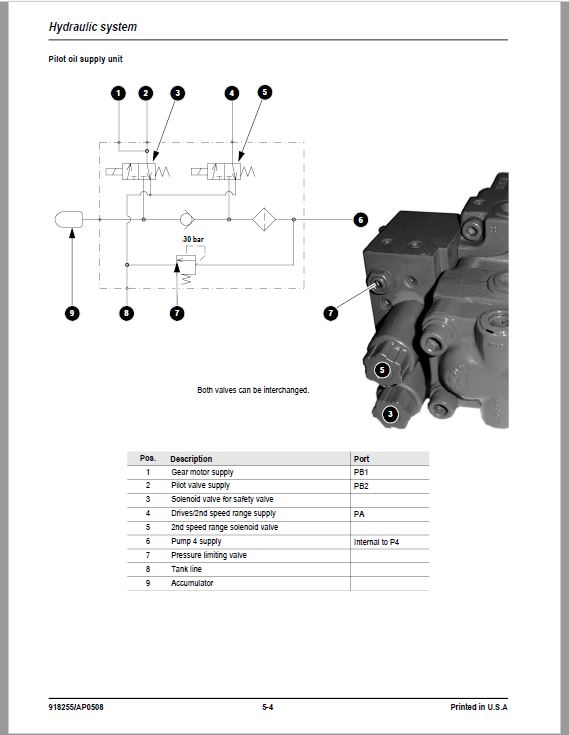

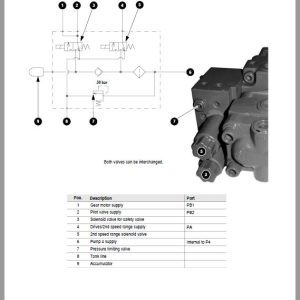

Pilot oil supply unit ………………………………………………………………………………… 5-4

Main valve block ………………………………………………………………………………………… 5-5

Ports …………………………………………………………………………………………………… 5-5

Legend ………………………………………………………………………………………………… 5-6

Main valve block diagram ………………………………………………………………………. 5-7

Pressure limiting valves …………………………………………………………………………. 5-8

Pump assignment …………………………………………………………………………………. 5-9

Drive counterbalancing system …………………………………………………………………… 5-10

Pump assignment for drive counterbalancing ………………………………………….. 5-10

Regeneration – dipper arm section ……………………………………………………………… 5-11

Bucket pre-tension ……………………………………………………………………………………. 5-11

Flow rate adjustment of auxiliary hydraulics …………………………………………………. 5-12

Pilot valves ………………………………………………………………………………………………. 5-13

Joystick ……………………………………………………………………………………………… 5-13

Pilot valve (driving) ……………………………………………………………………………… 5-14

Pilot valve for auxiliary hydraulics ………………………………………………………….. 5-16

Changeover valve for SAE/ISO controls (option) …………………………………………… 5-17

Proportional valve (option) …………………………………………………………………………. 5-17

Travel drive ……………………………………………………………………………………………… 5-18

Function …………………………………………………………………………………………….. 5-19

Swivel unit ……………………………………………………………………………………………….. 5-21

Swivel unit brake …………………………………………………………………………………. 5-22

Swivel joint ………………………………………………………………………………………………. 5-25

Sealing ………………………………………………………………………………………………. 5-25

Breather filter …………………………………………………………………………………………… 5-26

Troubleshooting the hydraulic system …………………………………………………………. 5-27

Hydraulics diagram: legend ……………………………………………………………………….. 5-28

Hydraulics diagram …………………………………………………………………………………… 5-29

Hydraulics diagram for options …………………………………………………………………… 5-30

Main valve block diagram ………………………………………………………………………….. 5-31

Electric system

Ohm’s Law (current, voltage, resistance); power …………………………………………….. 6-1

Measuring equipment, measuring methods ……………………………………………………. 6-1

Cable color coding ……………………………………………………………………………………… 6-3

Relays ………………………………………………………………………………………………………. 6-3

Use, mode of function ……………………………………………………………………………. 6-3

Socket ………………………………………………………………………………………………………. 6-3

Electric units ………………………………………………………………………………………………. 6-4

Fuse box …………………………………………………………………………………………………… 6-4

Switches: overview …………………………………………………………………………………….. 6-5

Instrument panel legend ………………………………………………………………………… 6-5

Alternator ………………………………………………………………………………………………….. 6-6

Starter ………………………………………………………………………………………………………. 6-6

Wiring diagram legend ………………………………………………………………………………… 6-7

Wiring diagram …………………………………………………………………………………………… 6-8

Engine wiring harness legend ………………………………………………………………………. 6-9

Engine wiring harness diagram …………………………………………………………………… 6-10

Cab wiring harness …………………………………………………………………………………… 6-11

Proportional controls (option) ……………………………………………………………………… 6-12

Options

Counterweight ……………………………………………………………………………………………. 7-1

Specifications ………………………………………………………………………………………. 7-1

Connecting auxiliary hydraulics ……………………………………………………………………. 7-1

Attachments …………………………………………………………………………………………. 7-2

Auxiliary hydraulics connections …………………………………………………………………… 7-2

Proportional controls …………………………………………………………………………………… 7-3

Function ………………………………………………………………………………………………. 7-3

Ports …………………………………………………………………………………………………… 7-4

Measures to be taken in case of malfunctions ………………………………………….. 7-4

Joystick ……………………………………………………………………………………………….. 7-4

Boom swivel controls …………………………………………………………………………….. 7-5

Auxiliary hydraulics ……………………………………………………………………………….. 7-5

Hammer operation ………………………………………………………………………………… 7-5

Adjusting control response …………………………………………………………………….. 7-6

Characteristic curves – status display ……………………………………………………… 7-6

Wiring harness ……………………………………………………………………………………… 7-7

Control valve plug assignment ……………………………………………………………….. 7-8

Safety features …………………………………………………………………………………….. 7-9

Measures to be taken in case of malfunctions ………………………………………….. 7-9

Diagnostic display …………………………………………………………………………………. 7-9

This Service Manual is intended for Gehl GE 283Z Excavator so as to give the owner/operator assistance in preparing, adjusting, maintaining and servicing the machine. More importantly, this manual provides an operating plan for safe and proper use of the machine. Major points of safe operation are

detailed in Chapter 2 – Safety. Read and understand the contents of this manual completely and become familiar with the machine before

attempting to operate it..

Throughout this manual, information is introduced by the word NOTE or IMPORTANT. Be sure to read the message carefully and comply with the message. Following this information will improve operating and maintenance efficiency, help to avoid breakdown and damage and extend the service life of the machine.

Be the first to review “Gehl GE 283Z Compact Excavator Repair Service Manual”

You must be logged in to post a review.

Reviews

There are no reviews yet.