Toro Groundsmaster 4100-D, 4110-D (Model 30602, 30604, 30606, 30608, 30643, 30644) Service Repair Manual

$34.00

Manual Included:

- Service Repair Manual: 586 Pages

Specifications:

- Brand: Toro

- Model: Groundsmaster 4100-D, 4110-D (Model 30602, 30604, 30606, 30608, 30643, 30644)

- Type: Rotary Mowers

- Manuals: Service Repair Manual

- Publication Numbers: 13203SL

- Language: English

- Format: PDF

- Description

- Reviews (0)

Description

Table of Content – Groundsmaster 4100-D, 4110-D (Model 30602, 30604, 30606, 30608, 30643, 30644)

- Title Page

- Revision History

- Reader Comments

- NOTES

- Preface

- Service Procedure Icons

- Table of Contents

- Chapter 1 : Safety

- Safety Instructions

- Before Operating the Machine

- While Operating the Machine

- Maintenance and Service

- Jacking Instructions

- Safety and Instructional Decals

- Chapter 2 : Specifications and Maintenance

- Specifications

- Overall Dimensions

- Engine (Models 30602, 30604 and 30643)

- Engine (Models 30606, 30608 and 30644)

- Hydraulic System

- Axles, Planetaries and Brakes

- Cutting Decks

- Torque Specifications

- Calculating the Torque Values When Using a Drive-Adapter Wrench

- Identifying the Fastener

- Standard Torque for Dry, Zinc Plated, and Steel Fasteners (Inch Series)

- Standard Torque for Dry, Zinc Plated, and Steel Fasteners (Metric Fasteners)

- Other Torque Specifications

- Conversion Factors

- Shop Supplies

- Special Tools

- Chapter 3 : Troubleshooting

- GEARS – The Systematic Approach to Defining, Diagnosing and Solving Problems

- General Hydraulic System Problems

- Traction Circuit Problems

- Mow Circuit Problems

- Lift Circuit Problems

- Steering Circuit Problems

- Engine Cooling Fan Circuit Problems

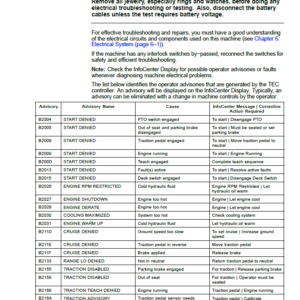

- Operator Advisories

- Fault Codes

- Starting Problems

- General Run and Transport Problems

- Cutting Deck Operating Problems

- Cutting Deck Lift, Lower Problems

- Aftercut Appearance

- Chapter 4 : Yanmar Diesel Engine

- General Information

- Operator’s Manual

- Yanmar Service and Troubleshooting Manuals

- Stopping the Engine

- Engine Electronic Control Unit (ECU)

- Yanmar Engine: Models 30602, 30604 and 30643

- Yanmar Engine: Models 30606, 30608 and 30644

- Diesel Particulate Filter

- Service and Repairs

- Air Cleaner System

- Fuel System

- Radiator and Oil Cooler Assembly

- Engine

- Spring Coupler

- Exhaust System (Models 30606, 30608 and 30644)

- Yanmar TNV (Tier 4i) Series Service Repair Manual

- Yanmar TNV (Tier 4i) Series Troubleshooting Manual

- Yanmar TNV (Tier 4) Series Service Repair Manual

- Yanmar TNV (Tier 4) Series Troubleshooting Manual

- Chapter 5 : Hydraulic System

- General Information

- Operator’s Manual

- Check Hydraulic Fluid

- Relieving Hydraulic System Pressure

- Towing Traction Unit

- Traction Circuit Component Failure

- Hydraulic Hoses

- Installing Hydraulic Hoses and Tubes (O-Ring Face Seal)

- Installing the Hydraulic Fittings (SAE Straight Thread O-Ring Fittings)

- Hydraulic Schematic

- Hydraulic Flow Diagrams

- Traction Circuit: LOW Speed (Mow)

- Traction Circuit: HI Speed (Transport)

- Lower Cutting Deck

- Raise Cutting Deck

- Mow Circuit

- Mow Circuit Cutting Deck Blade Braking

- Steering Circuit

- Engine Cooling Fan Circuit

- Testing

- Precautions for Hydraulic Testing

- Which Hydraulic Tests Are Necessary?

- Traction Circuit Charge Pressure (Using Pressure Gauge)

- Traction Circuit Relief Pressure (Using Pressure Gauge)

- Counterbalance Pressure (Using Pressure Gauge)

- Reverse Traction Circuit Reducing Valve (PR) Pressure (Using Pressure Gauge)

- Rear Traction Circuit Relief Valve (RV) Pressure (Using Pressure Gauge)

- Piston (Traction) Pump Flow Test (Using Tester with Pressure Gauge and Flow Meter)

- Cutting Deck Circuit Pressure (Using Pressure Gauge)

- PTO Relief Pressure (Using Tester with Pressure Gauge and Flow Meter)

- Cutting Deck Motor Case Drain Leakage (Using Tester with Pressure Gauge and Flow Meter)

- Lift, Lower Circuit Relief Pressure (Using Pressure Gauge)

- Steering Circuit Relief Pressure (Using Pressure Gauge)

- Steering Cylinder Internal Leakage

- Engine Cooling Fan Circuit (Using Pressure Gauge and Phototac)

- Engine Cooling Fan Motor Case Drain Leakage Test

- Gear Pump Flow (Using Tester with Pressure Gauge and Flow Meter)

- Adjustments

- Adjust Control Manifold Relief Valves

- Service and Repairs

- General Precautions for Removing and Installing Hydraulic System Components

- Check Hydraulic Lines and Hoses

- Priming Hydraulic Pumps

- Flush Hydraulic System

- Filtering Closed−Loop Traction Circuit

- Charge Hydraulic System

- Hydraulic Reservoir

- Radiator and Oil Cooler Assembly

- Gear Pump

- Gear Pump Service

- Piston (Traction) Pump

- Piston (Traction) Pump Service (For machines serial number below: 400000000)

- Piston (Traction) Pump Service (For machines serial number above: 400000000)

- Rear Axle Motor

- Front Wheel Motors

- Rear Axle and Front Wheel Motor Service

- Rear Traction Manifold

- Rear Traction Manifold Service

- Combination Manifold

- Combination Manifold Service

- Steering Control Valve (For machines serial number below: 400000000)

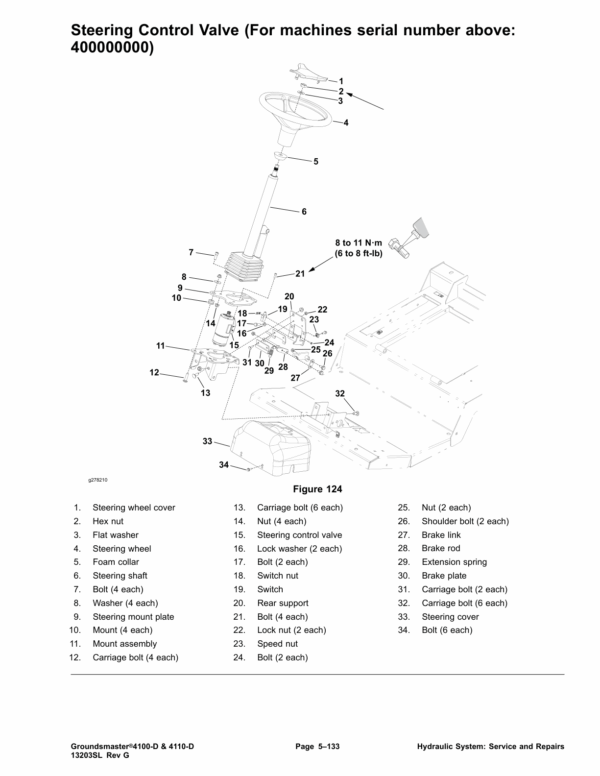

- Steering Control Valve (For machines serial number above: 400000000)

- Steering Control Valve Service (For machines serial number below: 400000000)

- Steering Control Valve Service (For machines serial number above: 400000000)

- Steering Cylinder

- Steering Cylinder Service

- Engine Cooling Fan Motor

- Engine Cooling Fan Motor Service

- Cutting Deck Motors

- Cutting Deck Motor Service (Sauer−Danfoss)

- Cutting Deck Motor Service (Casappa)

- PTO Manifold

- PTO Manifold Service

- Center Deck Lift Cylinders

- Wing Deck Lift Cylinders

- Lift Cylinder Service

- Danfoss H1 Closed Circuit Axial Piston Pumps Service Repair Manual

- Danfoss H1 Closed Circuit Axial Pistonpumps Repair Instructions

- Danfoss K And L Frame Variable Motors Service Repair Manual

- Danfoss Steering Unit Type OSPM Service Repair Manual

- Danfoss MP1 Closed Circuit Axial Piston Pumps Service Repair Manual

- Eaton Parts And Repair Information: 5 Series Steering Control Units

- Chapter 6 : Electrical System

- General Information

- Operator's Manual

- Toro Electronic Controllers (TEC)

- Yanmar Engine Electronic Control Unit (ECU)

- Yanmar Engine Electrical Components

- CAN−bus Communications

- Electrical Drawings

- InfoCenter Display

- Adjustments

- Wing Deck Position Switch Adjustment

- Traction Pedal Adjustment

- Traction Pedal Position Sensor Calibration

- Electrical System Quick Checks

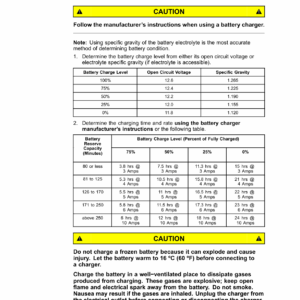

- Battery Test (Open Circuit)

- Charging System Test

- Check Operation of Interlock Switches

- Component Testing

- Key Switch

- Fuses

- Operator Cab Fuses (Groundsmaster 4110−D)

- Fusible Link Harness

- PTO Switch

- HI, LOW Speed, Engine Speed and Cutting Deck Lift Switches

- Cruise Control Switch

- Seat Switch

- Parking Brake Switch

- Service Brake Switches

- Headlight Switch (Groundsmaster 4110-D)

- Windshield Wiper, Washer Switch (Groundsmaster 4110-D)

- Air Conditioning Switch (Groundsmaster 4110-D)

- Turn Signal Switch (Groundsmaster 4110−D)

- Flasher Switch (Groundsmaster 4110−D)

- Traction Pedal Position Sensor

- Relays with Four (4) Terminals

- Relays with Five (5) Terminals

- Toro Electronic Controllers (TEC)

- Hydraulic Solenoid Valve Coils

- Piston (Traction) Pump Control Solenoid Coils

- CAN−bus Termination Resistor

- Diode Assemblies

- Resistor Assembly

- Fuel Sender

- Fuel Pump (Models 30602, 30604 and 30643)

- Fuel Pump (Models 30606, 30608 and 30644)

- Wing Deck Position Switches

- Hydraulic Oil Temperature Sender

- Fan Speed Switch (Machines with Two−Post ROPS Extension Operator Fan Kit)

- Resistor Module (Machines with Two−Post ROPS Extension Operator Fan Kit)

- Audio Alarm

- Service and Repairs

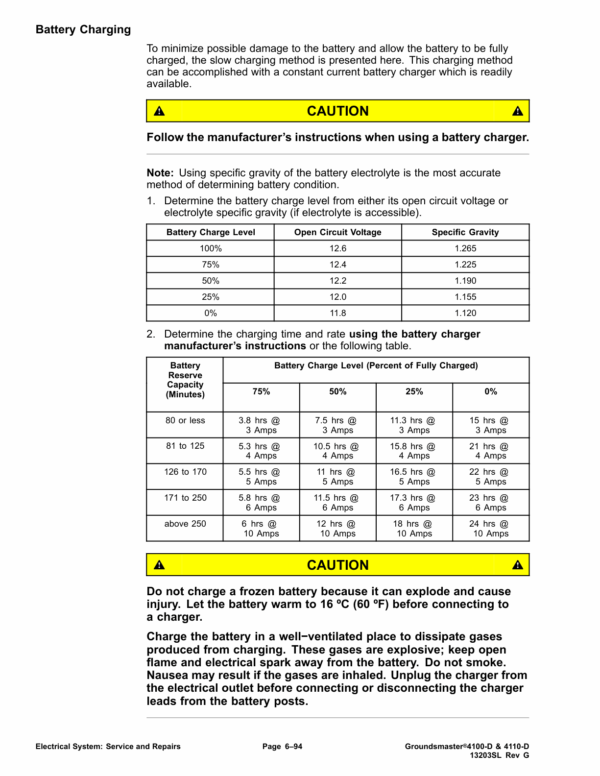

- Battery Care

- Battery Storage

- Battery Service

- Chapter 7 : Axles, Planetaries and Brakes

- General Information

- Operator’s Manual

- Adjustments

- Planetary Drive Assembly Endplay (OPH−2 series planetary drives)

- Service and Repairs

- Brake Assembly

- Brake Inspection and Repair

- Planetary Drive Assembly

- OPH−2 Series Planetary Drive Service

- VA02 Series Planetary Drive Service

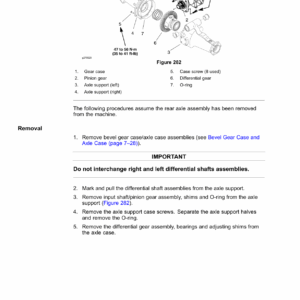

- Rear Axle Assembly

- Rear Axle Service

- Bevel Gear Case and Axle Case

- Differential Shafts

- Axle Shafts

- Input Shaft, Pinion Gear

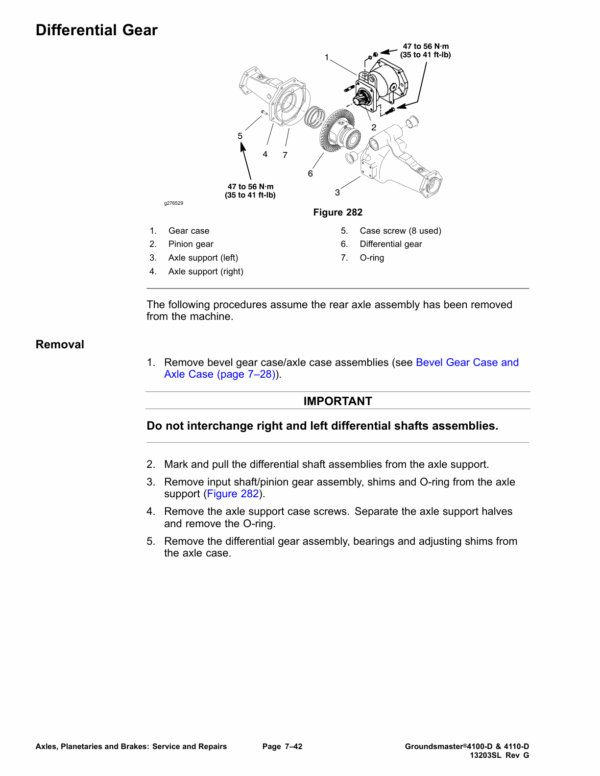

- Differential Gear

- Pinion Gear to Ring Gear Engagement

- Gear Pattern Movement Summary

- Chapter 8 : Chassis

- General Information

- Operator’s Manual

- Service and Repairs

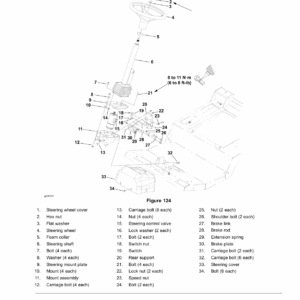

- Steering Tower (For machines serial number below: 400000000)

- Steering Tower (For machines serial number above: 400000000)

- Center Deck Lift Arms

- Control Arm

- Traction Pedal

- Operator Platform

- Operator Seat

- Operator Seat Service

- Operator Seat Suspension

- Hood

- Chapter 9 : Cutting Decks

- General Information

- Operator’s Manual

- Castor Wheel Tire Pressure

- Blade Stopping Time

- Service and Repairs

- Center Cutting Deck

- Wing Deck Service

- Cutting Deck Link Service

- Wing Deck Latch

- Blade Spindle

- Blade Spindle Service

- Idler Assembly

- Castor Forks and Wheels

- Deck Rollers and Skids

- Chapter 10 : Operator Cab (For models 30602 and 30606)

- General Information

- Operator’s Manual

- Electrical Components and Schematic

- Air Conditioning System

- Cab Heater System

- Service and Repairs

- General Precautions for Removing and Installing the Air Conditioning System Components

- Air Conditioning Compressor

- Roof Assembly

- Air Conditioning Condenser Assembly

- Heater, Evaporator Assembly

- Windshield Wiper

- Sanden SD Compressor Service Guide

- Chapter 11 : Operator Cab (For models 30643 and 30644)

- General Information

- Traction Unit Operator’s Manual

- Electrical Components and Schematic

- Air Conditioning System

- Cab Heater System

- Air Conditioning System Performance

- Service and Repairs

- General Precautions for Removing and Installing the Air Conditioning System Components

- Air Conditioning Compressor

- Roof Assembly

- Heating and Air Conditioning Components

- Air Conditioning Condenser Fan Assembly

- Air Conditioning Condenser Assembly

- Mixing Box Assembly

- Heater and Air Conditioning Evaporator Cores

- Blower Fan

- Windshield Wiper Assembly

- Badger Compressor Service Repair Manual

- Appendix A: Foldout Drawings

- Electrical Drawing Designations

- Hydraulic Schematic

- Electrical Schematic for Models 30604 and 30602, 30643 (For machines serial number below 400000000)

- Electrical Schematic for Models 30604 and 30602, 30643 (For machines serial number below 400000000)

- Electrical Schematic for Models 30604 and 30602, 30643 (For machines serial number 400000001 to 403450000)

- Electrical Schematic for Models 30604 and 30602, 30643 (For machines serial number 400000001 to 403450000)

- Electrical Schematic for Models 30604 and 30602, 30643 (For machines serial number 403450001 to 408000000)

- Electrical Schematic for Models 30604 and 30602, 30643 (For machines serial number 403450001 to 408000000)

- Electrical Schematic for Models 30604 and 30602, 30643 (For machines serial number above 408000000)

- Electrical Schematic for Models 30604 and 30602, 30643 (For machines serial number above 408000000)

- Electrical Schematic for Models 30608 and 30606, 30644 (For machines serial number below 400000000)

- Electrical Schematic for Models 30608 and 30606, 30644 (For machines serial number below 400000000)

- Electrical Schematic for Models 30608 and 30606, 30644 (For machines serial numbers 400000001 to 403450000)

- Electrical Schematic for Models 30608 and 30606, 30644 (For machines serial numbers 400000001 to 403450000)

- Electrical Schematic for Models 30608 and 30606, 30644 (For machines serial numbers 403450001 to 408000000)

- Electrical Schematic for Models 30608 and 30606, 30644 (For machines serial numbers 403450001 to 408000000)

- Electrical Schematic for Models 30608 and 30606, 30644 (For machines serial numbers above 408000000)

- Electrical Schematic for Models 30608 and 30606, 30644 (For machines serial numbers above 408000000)

- Electrical Schematic – Operator Cab (shown with lights for US model)

- Electrical Schematic – International Light Kits

- Platform Wire Harness Diagram (For machines serial number below 400000000)

- Platform Wire Harness Diagram (For machines serial number below 400000000)

- Platform Wire Harness Diagram (For machines serial number below 400000000)

- Platform Wire Harness Diagram (For machines serial numbers 400000001 to 403450000)

- Platform Wire Harness Diagram (For machines serial numbers 400000001 to 403450000)

- Platform Wire Harness Diagram (For machines serial numbers 400000001 to 403450000)

- Platform Wire Harness Diagram (For machines serial number 403450001 to 408000000)

- Platform Wire Harness Diagram (For machines serial number 403450001 to 408000000)

- Platform Wire Harness Diagram (For machines serial number 403450001 to 408000000)

- Platform Wire Harness Diagram (For machines serial number above 408000000)

- Platform Wire Harness Diagram (For machines serial number above 408000000)

- Platform Wire Harness Diagram (For machines serial number above 408000000)

- Rear Wire Harness Diagram (For machines serial number below 400000000)

- Rear Wire Harness Diagram (For machines serial number below 400000000)

- Rear Wire Harness Diagram (For machines serial number 400000000 to 408000000)

- Rear Wire Harness Diagram (For machines serial number 400000000 to 408000000)

- Rear Wire Harness Diagram (For machines serial numbers above 408000000)

- Rear Wire Harness Diagram (For machines serial numbers above 408000000)

- Engine Wire Harness Drawing for Models 30606, 30608, 30644 (For machines serial number below 400000000)

- Engine Wire Harness Diagram for Models 30606, 30608, 30644 (For machines serial number below 400000000)

- Engine Wire Harness Diagram for Models 30606, 30608, 30644 (For machines serial numbers 400000001 to 403450000)

- Engine Wire Harness Diagram for Models 30606, 30608, 30644 (For machines serial numbers 400000001 to 403450000)

- Engine Wire Harness Diagram for Models 30606, 30608, 30644 (For machines serial number 403450001 to 408000000)

- Engine Wire Harness Diagram for Models 30606, 30608, 30644 (For machines serial number 403450001 to 408000000)

- Engine Wire Harness Diagram for Models 30606, 30608, 30644 (For machines serial number above 408000000)

- Engine Wire Harness Diagram for Models 30606, 30608, 30644 (For machines serial number above 408000000)

- Engine DPF Wire Harness Diagram for Models 30606, 30608, 30644 (For machines serial number above 408000000)

- NO TITLE

- Engine Wire Harness Drawing for Models 30602, 30604, 30643

- Engine Wire Harness Drawing for Models 30602, 30604, 30643

- Operator Cab Wire Harness Diagram (For machines serial number below 400000000)

- Operator Cab Wire Harness Diagram (For machines serial number below 400000000)

- Operator Cab Wire Harness Diagram (For machines serial number above 400000000)

- Operator Cab Wire Harness Diagram (For machines serial number above 400000000)

- Operator Cab Interconnect Wire Harness

- Wire Harness Diagram − Two−Post ROPS Extension (Models 30604 and 30608)

- Wire Harness Diagram − Two−Post ROPS Extension (Models 30604 and 30608)

- Light Kit Wire Harness

- RH Rear Lights Wire Harness

- LH Rear Lights Wire Harness

Be the first to review “Toro Groundsmaster 4100-D, 4110-D (Model 30602, 30604, 30606, 30608, 30643, 30644) Service Repair Manual”

You must be logged in to post a review.

Reviews

There are no reviews yet.