Toro Reelmaster 7000 (Models 03780, 03781) Service Repair Manual

$34.00

Manual Included:

- Service Repair Manual: 468 Pages

Specifications:

- Brand: Toro

- Model: Reelmaster 7000 (Models 03780, 03781)

- Type: Large Reel Mowers

- Manuals: Service Repair Manual

- Publication Numbers: 15214SL

- Language: English

- Format: PDF

- Description

- Reviews (0)

Description

Table of Content – Reelmaster 7000 (Models 03780, 03781)

- Title Page

- Revision History

- Reader Comments

- Preface

- Table of Contents

- 1 – Safety

- General Safety Instructions

- Before Operating

- While Operating

- Maintenance and Service

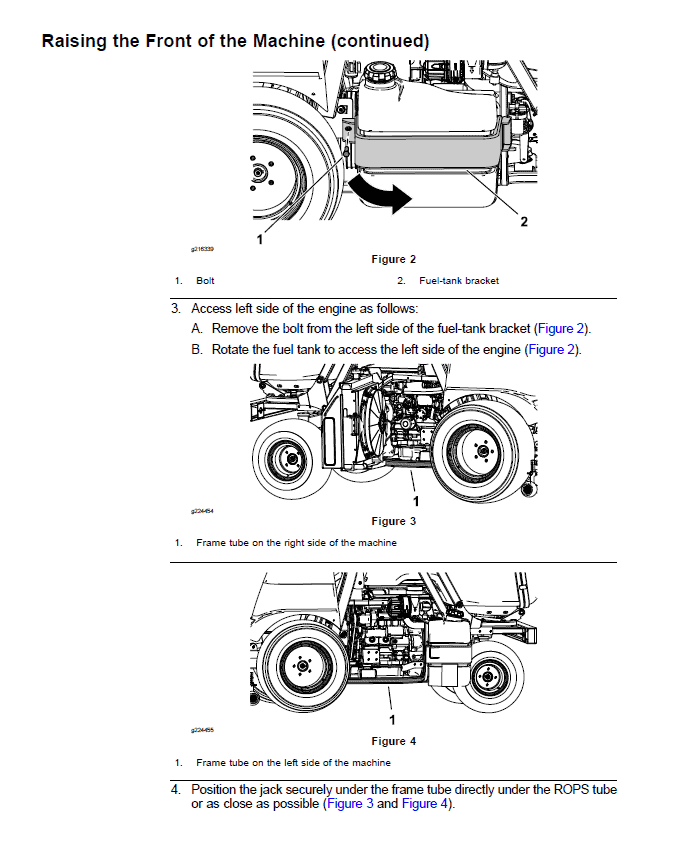

- Jacking Instructions

- Safety and Instruction Decals

- 2 – Product Records and Maintenance

- Product Records

- Maintenance

- Equivalents and Conversions

- Torque Specifications

- Fastener Identification

- Using a Torque Wrench with an Offset Wrench

- Standard Torque for Dry, Zinc Plated and Steel Fasteners (Inch Series)

- Standard Torque for Dry, Zinc Plated and Steel Fasteners (Metric Series)

- Conversion Factors

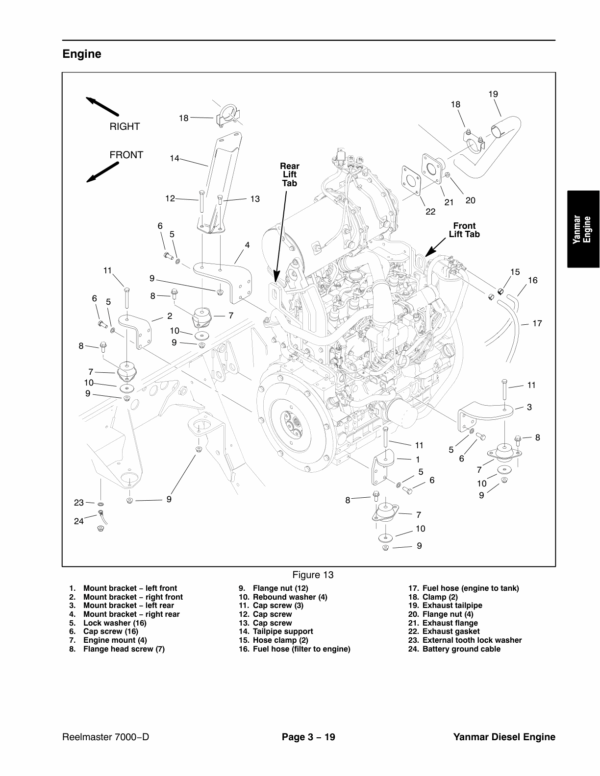

- 3 – Yanmar Diesel Engine

- Specifications

- General Information

- Operator's Manuals

- Yanmar Service and Troubleshooting Manuals

- Stopping the Engine

- Engine Electronic Control Unit (ECU)

- Yanmar Engine

- Service and Repairs

- Air Cleaner System

- Exhaust System

- Fuel System

- Radiator, Hydraulic Oil Cooler

- Engine

- Pump Adapter Plate

- YANMAR TNV (Tier 4) SERIES Service Repair Manual

- YANMAR TNV (Tier 4) SERIES TROUBLESHOOTING MANUAL

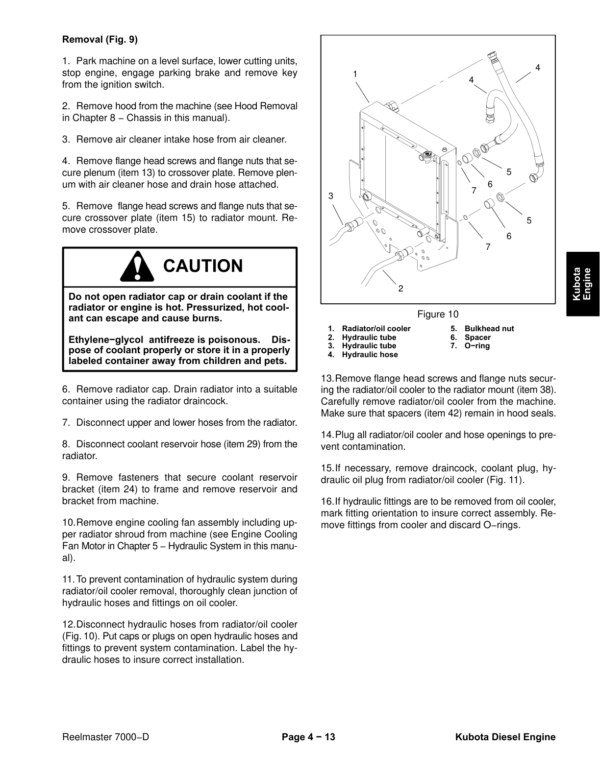

- 4 – Kubota Diesel Engine

- Specifications

- General Information

- Operator's Manual

- Service and Repairs

- Air Filter System

- Exhaust System

- Fuel System

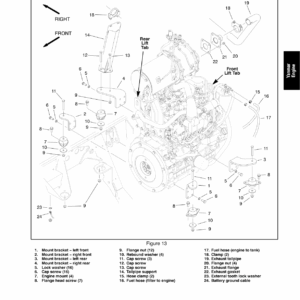

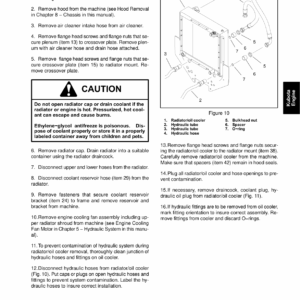

- Radiator, Hydraulic Oil Cooler

- Engine

- Pump Adapter Plate

- KUBOTA WORKSHOP MANUAL DIESEL ENGINE 03−M−DI−E3B SERIES

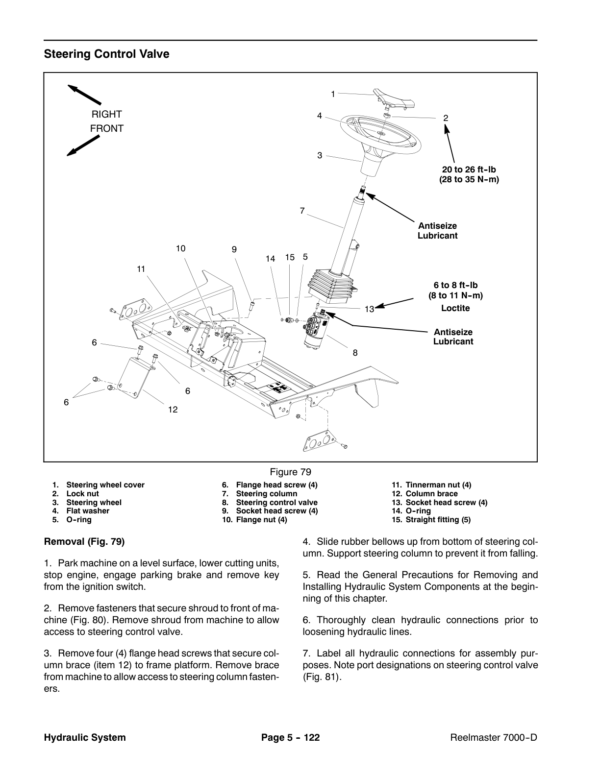

- 5 – Hydraulic System

- Specifications

- General Information

- Operator's Manual

- Hydraulic Component Locations

- Relieving Hydraulic System Pressure

- Traction Circuit Component Failure

- Towing Traction Unit

- Hydraulic Hoses

- Hydraulic Hose and Tube Installation (O-Ring Face Seal Fitting)

- Hydraulic Fitting Installation (SAE Straight Thread O-Ring Fitting into Component Port)

- Hydraulic Schematic

- Hydraulic Flow Diagrams

- Traction Circuit: LOW Speed (Mow)

- Traction Circuit: HI Speed (Transport)

- Mow Circuit

- Steering Circuit

- Lower Cutting Units

- Raise Cutting Units

- Engine Cooling Fan Circuit

- Special Tools

- Hydraulic Pressure Test Kit

- Hydraulic Tester (Pressure and Flow)

- 40 GPM Hydraulic Tester (Pressure and Flow)

- Hydraulic Hose Kit

- High Flow Hydraulic Filter Kit

- Hydraulic Test Fitting Kit

- Measuring Container

- O-ring Kit

- Remote Starter Switch

- Troubleshooting

- General Hydraulic System Problems

- Traction Circuit Problems

- Mow Circuit Problems

- Steering Circuit Problems

- Lift, Lower Circuit Problems

- Engine Cooling Fan Circuit Problems

- Testing

- Traction Circuit – Charge Pressure Test

- Traction Circuit – Relief Pressure Test

- Traction Circuit – Piston (traction) Pump Flow Test

- Traction Circuit – Front Wheel Motor Case Drain Leakage Test

- Traction Circuit – Reverse Reducing Valve (PR) Pressure Test

- Traction Circuit – Rear Relief Valve (RV) Pressure Test

- Cutting Unit Circuit – Pressure Test

- Cutting Unit Circuit – Relief Pressure Test

- Cutting Unit Circuit – Cutting Unit Motor Case Drain Leakage Test

- Steering, Lift Circuit – Steering Relief Pressure Test

- Steering, Lift Circuit – Steering Cylinder Test

- Steering, Lift Circuit – Lift Relief Pressure Test

- Cooling Fan Circuit – Pressure Test

- Cooling Fan Circuit – Fan Motor Case Drain Leakage Test

- Gear Pump Flow Test (pump sections P2 thru P5)

- Adjustments

- Control Manifold Relief Valve Adjustment

- Service and Repairs

- General Precautions for Removing and Installing Hydraulic System Components

- Check Hydraulic Lines and Hoses

- Priming Hydraulic Pumps

- Flush Hydraulic System

- Filtering Closed-Loop Traction Circuit

- Charge Hydraulic System

- Gear Pump

- Gear Pump Service

- Piston (Traction) Pump

- Piston (traction) Pump Service

- Rear Traction Manifold

- Rear Traction Manifold Service

- HI, LOW Range Manifold

- Front Wheel Motors

- Rear Axle Motor

- Front Wheel Motor and Rear Axle Motor Service

- Cutting Unit Motor

- Cutting Unit Motor Service

- Mow Control Manifold

- Mow Control Manifold Service

- Steering Control Valve

- Steering Control Valve Service

- Steering Cylinder

- Steering Cylinder Service

- Engine Cooling Fan Motor

- Engine Cooling Fan Motor Service

- Fan Control Manifold

- Fan Control Manifold Service

- Lift Manifold

- Lift Manifold Service

- Control Manifold Cartridge Valve Service

- Lift Junction Manifold

- Front Lift Cylinders

- Rear Lift Cylinders

- Lift Cylinder Service

- Hydraulic Reservoir

- Hydraulic Oil Cooler

- EATON MODEL 72400 SERVO CONTROLLED PISTON PUMP REPAIR INFORMATION

- DANFOSS K and L FRAME VARIABLE MOTORS Service Repair Manual

- DANFOSS STEERING UNIT TYPE OSPM Service Repair Manual

- 6 – Electrical System

- General Information

- Operator's Manual

- Toro Electronic Controller (TEC)

- Engine Electrical Components

- Engine Electronic Control Unit (ECU) (Yanmar Diesel Engines Only)

- CAN-bus Communications

- Electrical Drawings

- Special Tools

- Multimeter

- Dielectric Gel

- Battery Hydrometer

- Terminal Protector

- InfoCenter Display

- InfoCenter Display Screens

- Splash Screen

- Main Information Screen

- Operator Advisory Screen

- Main Menu Screen

- Faults Screen

- Service Screen

- Diagnostics Screen

- Settings Screen

- About Screen

- Troubleshooting

- Operator Advisories

- Using the InfoCenter Display for Troubleshooting

- Fault Codes

- Starting Problems

- General Run and Transport Problems

- Cutting Unit Operating Problems

- Cutting Unit Lift, Lower Problems

- Electrical System Quick Checks

- Battery Test (Open Circuit Test)

- Charging System Test

- Glow Plug System Test

- Check Operation of Interlock Switches

- Adjustments

- HI, LOW (transport, mow) Switch

- Cutting Unit Position Switch

- Component Testing

- Fusible Link Harness

- Fuses

- Toro Electronic Controllers (TEC)

- Ignition Switch

- Reel Enable, Disable Switch

- Engine Speed Switch (Yanmar Diesel Engine Only)

- Lower, Raise Joystick Switches

- Seat Switch

- Traction Neutral Switch

- Parking Brake Switch

- HI, LOW (Transport, Mow) Switch

- Cutting Unit Position Switch

- Backlap Switches

- Hydraulic Oil Temperature Sender

- Engine Temperature Sender (Kubota Diesel Engine Only)

- Relays with Four (4) Terminals

- Relays with Five (5) Terminals

- Hydraulic Solenoid Valve Coils

- Fuel Pump (Yanmar Diesel Engine Only)

- Fuel Pump (Kubota Diesel Engine Only)

- Fuel Stop Solenoid (Kubota Diesel Engines Only)

- CAN-bus Termination Resistor

- Diode Assembly

- Resistor Assembly

- Worklight Switch

- Service and Repairs

- Battery Storage

- Battery Care

- Battery Service

- Hydraulic Solenoid Valve Coils

- Worklight Bulb Replacement

- 7 – Axles, Planetaries and Brakes

- Table of Contents

- Specifications

- General Information

- Operator's Manual

- Adjustments

- Planetary Drive End Play (OPH-2 series planetary drives)

- Service and Repairs

- Brake Assembly

- Brake Inspection and Repair

- Planetary Drive Assembly

- OPH-2 Planetary Drive Service

- VA02 Series Planetary Drive Service

- Rear Axle Assembly

- Rear Axle Service

- Bevel Gear Case and Axle Case

- Differential Shafts

- Axle Shafts

- Input Shaft, Pinion Gear

- Differential Gear

- Pinion Gear to Ring Gear Engagement

- 8 – Chassis

- General Information

- Operator's Manual

- Cutting Unit Identification

- Service and Repairs

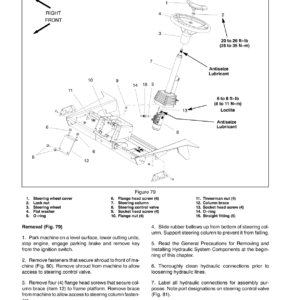

- Steering Column

- Console Arm

- Lift Arms for Front Cutting Units (#1, #4 and #5)

- Lift Arms for Rear Cutting Units (#2 and #3)

- Operator Seat

- Operator Seat Service

- Operator Seat Suspension

- Hood

- 9 – DPA Cutting Units

- Table of Contents

- Specifications

- General Information

- Cutting Unit Operator's Manual

- Special Tools

- Gauge Bar Assembly

- Bedknife Screw Tool

- Handle Assembly

- Plastic Plug

- Cutting Unit Kickstand

- Spline Insert Tool

- Diameter, Circumference Measuring Tape

- Roller Rebuild Kit

- Turf Evaluator Tool

- Reel Bearing Installation Tool (cutting units with painted side plates)

- Cutting Reel Shim

- Cutting Performance Paper

- Pulley Alignment Tool

- Bedknife Top Angle Indicator and Mount

- Factors That Can Affect Cutting Performance

- Adjustments

- Characteristics

- Reel Bearing Adjustment (cutting units with painted side plates)

- Leveling Rear Roller

- Service and Repairs

- Hydraulic Reel Motor

- Backlapping

- Bedbar Assembly

- Bedknife Replacement and Grinding

- Bedbar Adjuster Service

- Reel Assembly (cutting units with painted side plates)

- Reel Assembly Service (cutting units with painted side plates)

- Reel Assembly (cutting units with aluminum side plates)

- Reel Assembly Service (cutting units with aluminum side plates)

- Preparing Reel for Grinding

- Front Roller

- Rear Roller

- Roller Service

- Rear Roller Brush – Optional (cutting units with painted side plates)

- Rear Roller Brush – Optional (cutting units with aluminum side plates)

- 10 – Belt Driven Groomer (Optional)

- Table of Contents

- Grooming Performance

- Troubleshooting

- Groomer Reel Mechanical Problems

- Adjustments

- Groomer Height, Depth Adjustment

- Service and Repairs

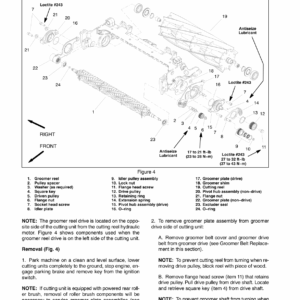

- Groomer Drive Belt Replacement

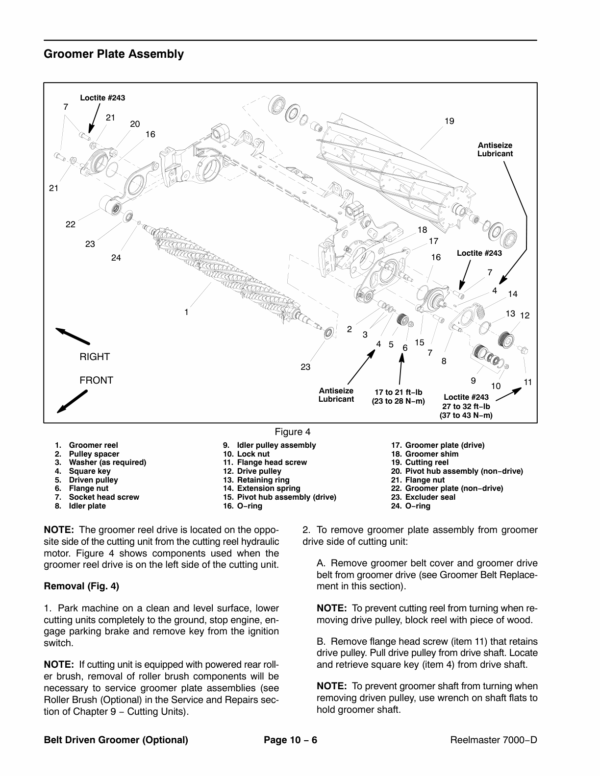

- Groomer Plate Assembly

- Groomer Reel

- Groomer Reel Service

- Groomer Pivot Hub

- Height Adjuster Assembly

- 11 – Universal Groomer (Optional)

- Table of Contents

- Grooming Performance

- Troubleshooting

- Groomer Reel Mechanical Problems

- Service and Repairs

- Gear Box Assembly

- Idler Assembly

- Groomer Reel

- Groomer Reel Service

- Grooming Brush (Optional) Service

- Height Adjuster Assembly

- 12 – Foldout Drawings

- Electrical Drawing Designations

- Hydraulic Schematic

- Electrical Schematic – Traction Unit Model 03780 – Yanmar Engine (Serial numbers below 316000000)

- Electrical Schematic — Traction UnitModel 03780 — Yanmar Engine(Serial numbers 316000001 to 403350000)

- Electrical Schematic — Traction UnitModel 03780 — Yanmar Engine(Serial numbers above 403350001)

- Electrical Schematic – Traction Unit Model 03781 – Kubota Engine (Serial numbers below 316000000)

- Electrical Schematic — Traction UnitModel 03781 — Kubota Engine(Serial numbers 316000001 to 403350000)

- Electrical Schematic — Traction UnitModel 03781 — Kubota Engine(Serial numbers above 403350001)

- Electrical Schematic – Cab

- Main Wire Harness Drawing (Serial numbers below 316000000)

- Main Wire Harness Diagram (Serial numbers below 316000000)

- Main Wire Harness DrawingModel 03780 & 03781(Serial numbers 316000001 to 403350000)

- Main Wire Harness DiagramModel 03780 & 03781(Serial numbers 316000001 to 403350000)

- Main Wire Harness DrawingModel 03780 & 03781(Serial numbers 403350001 to 405699999)

- Main Wire Harness DiagramModel 03780 & 03781(Serial numbers 403350001 to 405699999)

- Main Wire Harness DrawingModel 03780 & 03781(Serial numbers above 405700000)

- Main Wire Harness DiagramModel 03780 & 03781(Serial numbers above 405700000)

- Engine Wire Harness Drawing – Yanmar

- Engine Wire Harness Diagram – Yanmar

- Engine Wire Harness Drawing – Kubota

- Engine Wire Harness Diagram – Kubota

- Seat and Console Wire Harness Drawing

- Seat and Wire Harness Diagram

- Power Center Wire Harness Drawing (Serial numbers below 403350000)

- Power Center Wire Harness Diagram (Serial numbers below 403350000)

- Power Center Wire Harness DrawingModel 03780 & 03781(Serial numbers above 403350001)

- Power Center Wire Harness DiagramModel 03780 & 03781(Serial numbers above 403350001)

Be the first to review “Toro Reelmaster 7000 (Models 03780, 03781) Service Repair Manual”

You must be logged in to post a review.

Reviews

There are no reviews yet.