Toro ProLine H800 (Model 31050, 31050TE, 31051) Service Repair Manual

$34.00

Manual Included:

- Service Repair Manual: 348 Pages

Specifications:

- Brand: Toro

- Model: ProLine H800 (Model 31050, 31050TE, 31051)

- Type: Rotary Mowers

- Manuals: Service Repair Manual

- Publication Numbers: 19241SL

- Language: English

- Format: PDF

- Description

- Reviews (0)

Description

Table of Content – ProLine H800 (Model 31050, 31050TE, 31051)

- Title Page

- Revision History

- Reader Comments

- Preface

- Service Procedure Icons

- Table of Contents

- Chapter 1 : Safety

- Safety Instructions

- Supervisor’s Responsibilities

- Before Operating the Machine

- While Operating the Machine

- Maintenance and Service

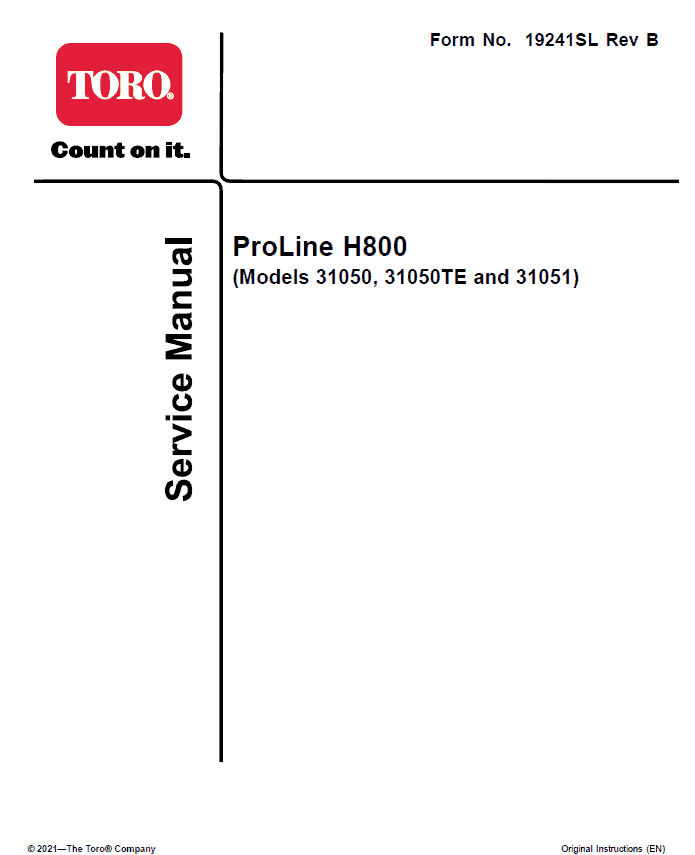

- Jacking Instructions

- Raising the Front of the Machine

- Raising the Rear of the Machine

- Safety and Instructional Decals

- Chapter 2 : Specifications and Maintenance

- Specifications

- Overall Dimensions

- Engine – ProLine H800 (for Model 31050)

- Engine – ProLine H800 (for Model 31050TE and 31051)

- Hydraulic System

- Chassis

- Torque Specifications

- Identifying the Fastener

- Calculating the Torque Values When Using a Drive-Adapter Wrench

- Standard Torque for Dry, Zinc Plated, and Steel Fasteners (Inch)

- Standard Torque for Dry, Zinc Plated, and Steel Fasteners (Metric Fasteners)

- Other Torque Specifications

- Conversion Factors

- Shop Supplies

- Special Tools

- Chapter 3 : Troubleshooting

- GEARS – The Systematic Approach to Defining, Diagnosing and Solving Problems

- General Hydraulic System Problems

- Steering Circuit Problems

- The Height Of Cut Circuit Problems

- The Cutting Deck Lift Circuit Problems

- The Hopper Lift Circuit

- The Hopper Tilt Circuit

- Chapter 4 : Engine

- General Information

- Traction Unit Operator’s Manual

- Yanmar Service Repair Manuals

- Service and Repairs

- Air Cleaner Assembly

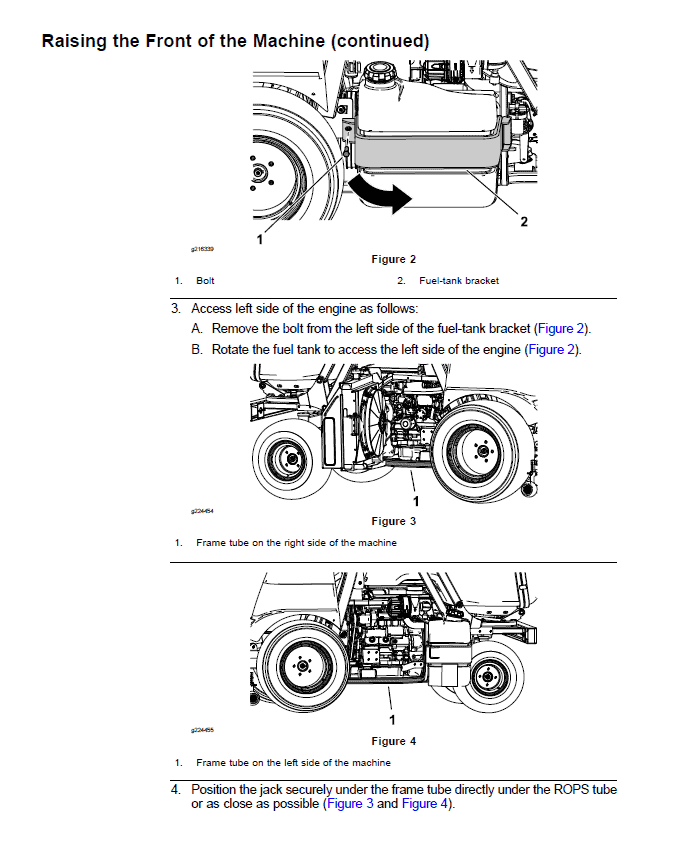

- Exhaust System

- Radiator

- Fuel System

- Engine

- Yanmar 3TNV76 Service Repair Manual

- Yanmar 3TNV80F Service Repair Manual

- Chapter 5 : Hydraulic System

- General Information

- Checking the Hydraulic Fluid

- Pushing or Towing the Traction Unit

- Releasing Pressure from the Hydraulic System

- Traction Circuit Component Failure

- Hydraulic Hoses

- Installing the Hydraulic Hoses and Tubes

- Installing the Hydraulic Fittings

- Hydraulic Schematic

- Hydraulic Flow Diagrams

- Traction Circuit

- Steering Circuit

- Height Of Cut Circuit

- Auxiliary Control Circuit

- Testing the Hydraulic System

- Testing the Traction Circuit – Charge Pressure

- Testing the Wheel Motors Efficiency

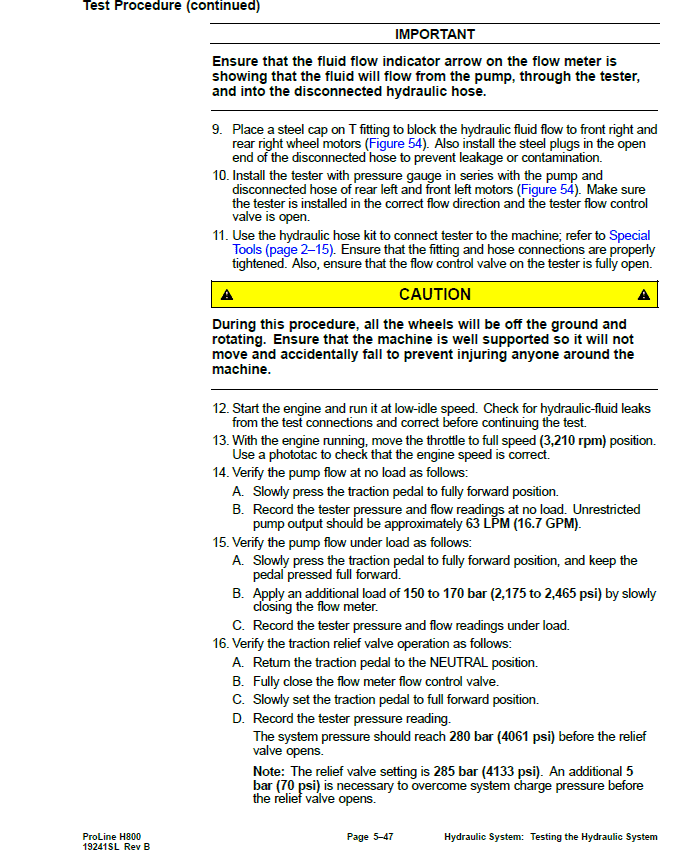

- Testing the Traction Circuit – Hydraulic Pump Flow and Relief Pressure

- Testing the Steering Circuit – Steering Control Valve, Relief Valve Pressure and Steering Cylinder

- Testing the Steering Circuit – Charge Pump Flow

- Testing the Auxiliary Control Circuit – Cutting Deck Lift Cylinder Internal Leakage

- Testing the Auxiliary Control Circuit – Hopper Lift Cylinder Internal Leakage

- Testing the Auxiliary Control Circuit – Hopper Tilt Cylinder Internal Leakage

- Testing the Height Of Cut Cylinder Internal Leakage

- Service and Repairs

- General Precautions for Removing and Installing the Hydraulic System Components

- Checking the Hydraulic Lines and Hoses

- Flushing the Hydraulic System

- Filtering the Closed-Loop Traction Circuit

- Priming the Hydraulic Pump

- Charging the Hydraulic System

- Hydraulic Tank

- Auxiliary Control Valve

- Traction Neutral Arm Assembly

- Hydraulic Pump Assembly

- Servicing the Hydraulic Piston Pump

- Servicing the Gear Pump

- Front Wheel Motors

- Rear Wheel Motors

- Servicing the Hydraulic Wheel Motor

- Differential Valve

- Height Of Cut Valve

- Lift Cylinder

- Steering Control Valve

- Steering Cylinder

- Hopper Lift Cylinder

- Hopper Tilt Cylinder

- Height Of Cut Cylinder

- Chute Cleaning Cylinder

- Oil Cooler

- Danfoss DDC20 Axial Piston Pump Service Repair Manual

- Parker Torqmotor Service Procedure (TF, TG, TH, and TL Series)

- Chapter 6 : Electrical System

- General Information

- Electrical Schematics and Wire Harness Drawings, Diagrams

- Electronic Control Unit (ECU)

- Electrical System Quick Checks

- Testing the Battery (Open Circuit Test)

- Testing the Charging System

- Testing the Glow Plug System

- Checking the Operation of the Interlock Switches

- Testing the Electrical Components

- Fuses

- Key Switch

- PTO Switch

- Hazard Light Switch

- Differential Lock Switch

- Radiator Fan Reversal Switch

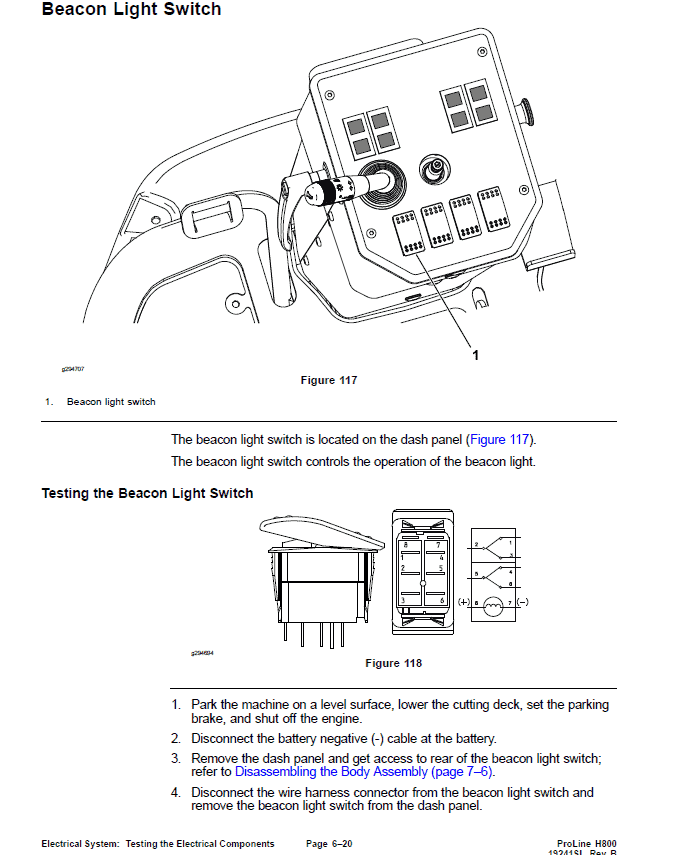

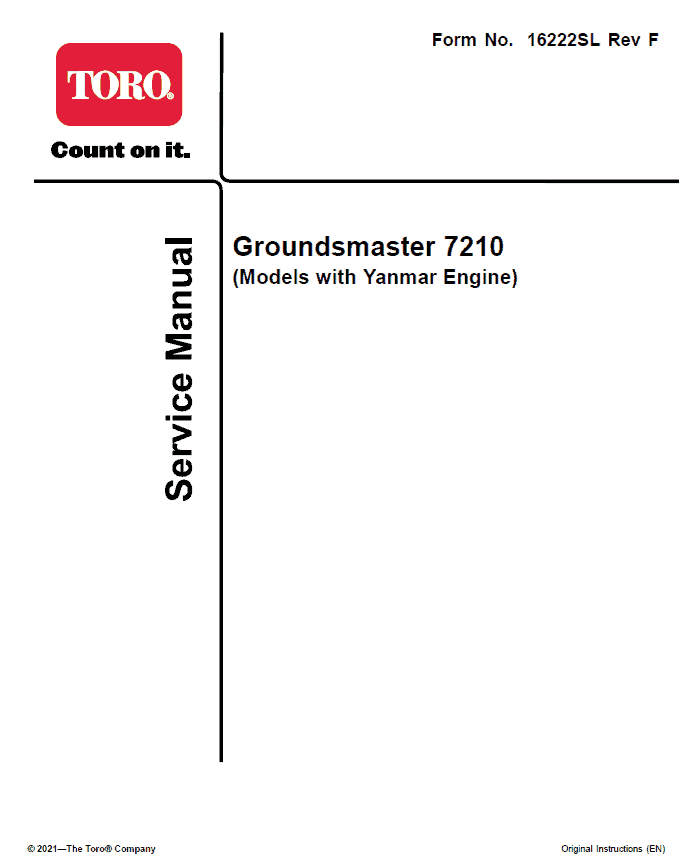

- Beacon Light Switch

- Indicator Lights

- Height Of Cut Switch

- Seat Switch

- Hour Meter

- Traction Neutral Switch

- Traction Reverse Switch

- Parking Brake Switch

- Oil Pressure Switch

- PTO Electric Clutch

- Fuel Stop Solenoid

- Relays

- Diode Assembly

- Slope Sensor (Optional)

- Service and Repairs

- Battery Storage

- Battery Care

- Servicing the Battery

- Chapter 7 : Chassis

- General Information

- Service and Repairs

- Wheels

- Body Assembly

- Steering Column

- Lift Arms

- Traction Pedal

- Brake Pedal

- Operator Seat

- Servicing the Operator Seat

- Frame Assembly

- Grammer Seats Repair Manual

- Chapter 8 : Axle and PTO

- General Information

- Service and Repairs

- Servicing the Brake

- Rear Axle assembly

- Servicing the Rear Axle

- Steering Spindle

- PTO Drive Belt

- Electric Clutch

- PTO Driveshaft

- Servicing the Driveshaft

- PTO Shaft Assembly

- Servicing the PTO Shaft Assembly

- Servicing the Gearbox Assembly

- Chapter 9 : Hopper Assembly

- General Information

- Service and Repairs

- Hopper Assembly

- Hopper Frame Assembly

- Hopper

- Hopper Lift Frame Assembly

- Chute Assembly

- Chapter 10 : Cutting Unit

- General Information

- Service and Repairs

- Idler Assembly

- Blade Spindle

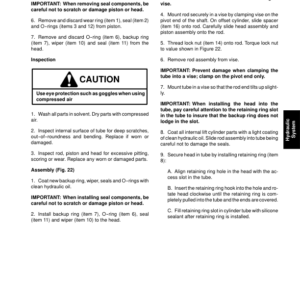

- Servicing the Blade Spindle

- Caster Wheel and Flat Frame Assembly

- Cutting Deck Rollers and Skids

- Height Of Cut Linkage

- Cutting Deck Covers

- Appendix A: Foldout Drawings

- Electrical Drawing Designations

- Hydraulic Schematic

- Electrical Schematic – Main

- Electrical Schematic – Lights

- Wire Harness Diagram – Main

- Wire Harness Diagram – Lights

- Wire Harness – Slope Sensor (Optional)

Be the first to review “Toro ProLine H800 (Model 31050, 31050TE, 31051) Service Repair Manual”

You must be logged in to post a review.

Reviews

There are no reviews yet.