Toro Groundsmaster 5900, 5910 (Models 31598, 31599) Service Repair Manual

$34.00

Manual Included:

- Service Repair Manual: 561 Pages

Specifications:

- Brand: Toro

- Model: Groundsmaster 5900, 5910 (Models 31598, 31599)

- Type: Rotary Mowers

- Manuals: Service Repair Manual

- Publication Numbers: 08159SL

- Language: English

- Format: PDF

- Description

- Reviews (0)

Description

Table of Content – Groundsmaster 5900, 5910 (Models 31598, 31599)

- Title Page

- Revision History

- Reader Comments

- Notes:

- Preface

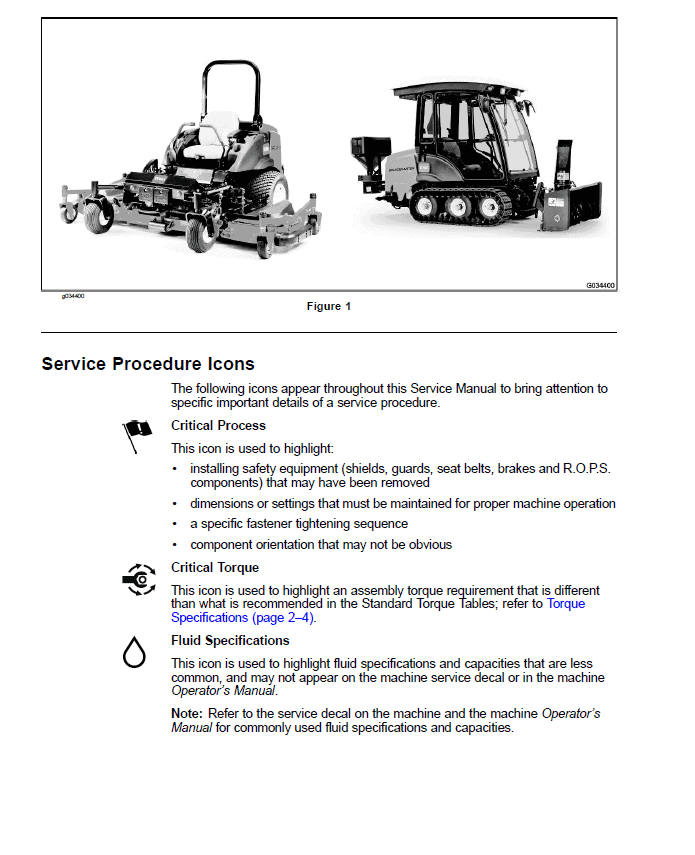

- Service Procedure Icons

- Table of Contents

- Chapter 1 : Safety

- Safety Instructions

- Before Operating the Machine

- While Operating the Machine

- Maintenance and Service

- Jacking Instructions

- Raising the Front of the Machine

- Raising the Rear of the Machine

- Safety and Instructional Decals

- Chapter 2 : Specifications and Maintenance

- Specifications

- Decimal and Millimeter Equivalents

- U.S. to Metric Conversions

- Torque Specifications

- Identifying the Fastener

- Calculating the Torque Values When Using a Drive-Adapter Wrench

- Standard Torque for Dry, Zinc Plated, and Steel Fasteners (Inch Series)

- Standard Torque for Dry, Zinc Plated, and Steel Fasteners (Metric Series)

- Other Torque Specifications

- Conversion Factors

- Shop Supplies

- Special Tools

- Chapter 3 : Diesel Engine

- 1 Specifications

- Diesel Engine

- General Information

- Operator’s Manual

- Engine Identification

- Engine Electronic Control Module (ECM)

- Shutting Off the Engine

- Fuel-Injection System

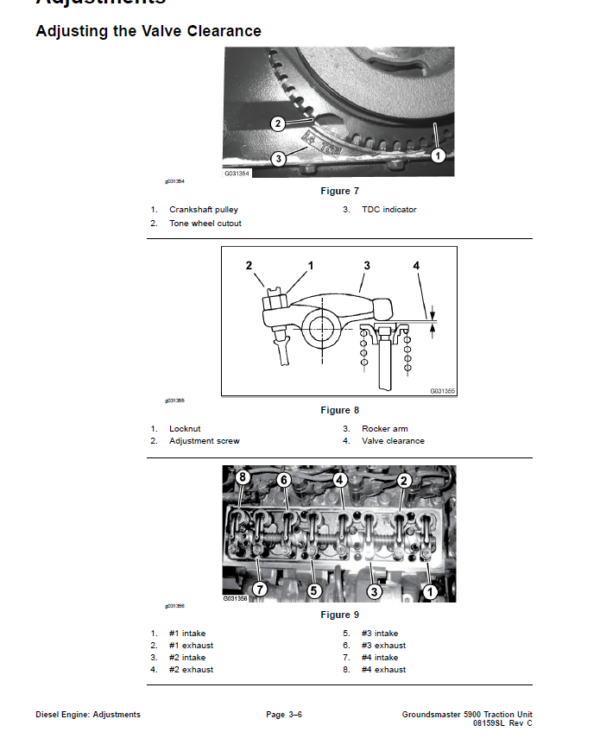

- Adjustments

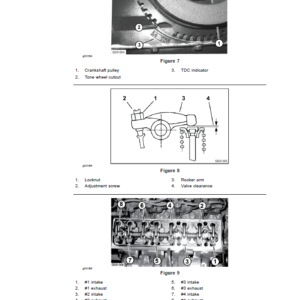

- Adjusting the Valve Clearance

- Service and Repairs

- Air Filter System

- Exhaust System

- Turbocharger

- Fuel Tank

- Radiator

- Alternator

- Starter Motor

- Valve Cover

- Engine Breather System

- Thermostat

- Water Pump

- Front Cover

- Oil Pan

- Engine

- Flywheel Coupling Assembly

- Chapter 4 : Hydraulic System

- 1 Specifications

- Hydraulic System

- General Information

- Checking the Hydraulic Fluid

- Releasing Pressure from the Hydraulic System

- Towing the Traction Unit

- Traction Circuit Component Failure

- Hydraulic Hoses

- Installing the Hydraulic Hose and Tube (O-Ring Face Seal Fitting)

- Installing the Hydraulic Fittings (SAE Straight Thread O-Ring Fitting into the Component Port)

- Hydraulic Schematic

- Hydraulic Flow Diagrams

- Traction Circuit: Low Speed

- Traction Circuit: High Speed

- Traction Circuit: Traction Control

- Raising the Cutting Deck

- Lowering the Cutting Deck

- PTO Mow Circuit

- Steering Circuit

- Engine Cooling Fan Circuit

- Special Tools

- Hydraulic Pressure Testing Kit

- 15 GPM Hydraulic Tester (Pressure and Flow)

- 40 GPM Hydraulic Tester (Pressure and Flow)

- Hydraulic Hose Kit

- High Flow Hydraulic Filter Kit

- O-Ring Kit

- Hydraulic Test Fitting Kit

- Measuring Container

- Rear Wheel Hub Puller

- Troubleshooting

- General Hydraulic System Problems

- Traction Problems

- PTO Problems

- Steering Circuit Problems

- Lift, Lower Problem

- Testing the Hydraulic System

- Determining which Hydraulic Tests to Perform

- Testing the Traction Circuit Charge Pressure (Using Pressure Gauge)

- Testing the Traction Circuit Relief Pressure (Using Pressure Gauge)

- Testing the Rear Traction Circuit (RV) Relief Pressure (Using Pressure Gauge)

- Testing the Traction Circuit Reducing Valve (PR) Pressure (Using Pressure Gauge)

- Testing the Counterbalance Pressure (Using Pressure Gauge)

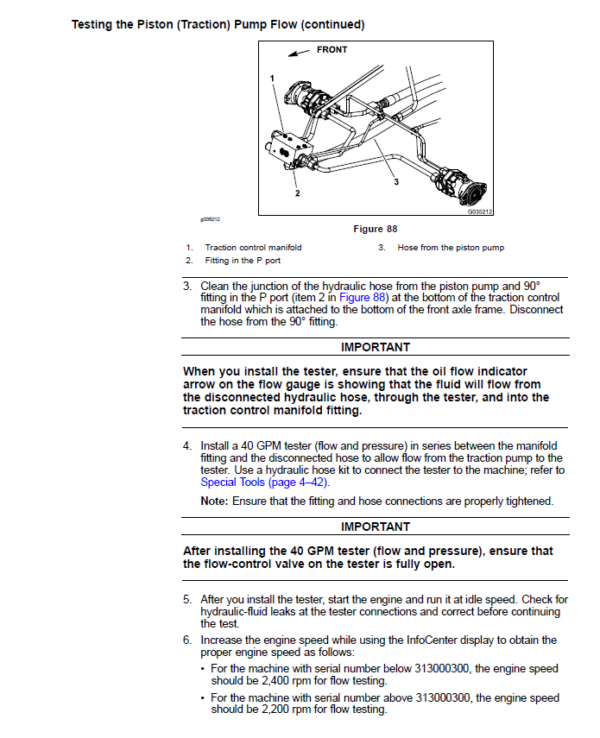

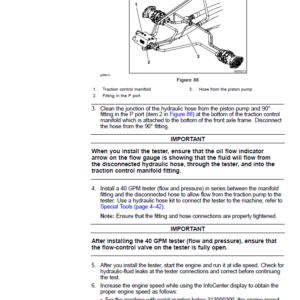

- Testing the Piston (Traction) Pump Flow (Using Tester with Pressure Gauge and 40 GPM Flow Meter)

- Testing the Cutting Deck Circuit Pressure (Using Pressure Gauge)

- Testing the Cutting Deck Circuit Relief Pressure (Using Tester with Pressure Gauge and 40 GPM Flow Meter)

- Testing the Cutting Deck Motor for Case Drain Leakage (Using Tester with Pressure Gauge and 40 GPM Flow Meter)

- Testing the Lift, Lower Circuit Relief Pressure (Using Pressure Gauge)

- Testing the Steering Circuit Relief Pressure (Using Pressure Gauge)

- Testing the Steering Cylinder for Internal Leakage

- Testing the Gear Pump (P3) (PTO, Steering, Cooling Fan, Lift, Lower, and Traction Charge Circuits) Flow (Using Tester with Pressure Gauges and Flow Meter)

- Adjustments

- Adjusting the Pressure Valve

- Service and Repairs

- General Precautions for Removing and Installing the Hydraulic System Components

- Checking the Hydraulic Lines and Hoses

- Flushing the Hydraulic System

- Charging the Hydraulic System

- Filtering the Closed-Loop Traction Circuit

- Hydraulic Reservoir

- Gear Pump

- Servicing the Gear Pump

- Traction Circuit

- Piston (Traction) Pump

- Servicing the Piston (Traction) Pump (Rexroth)

- Servicing the Piston (Traction) Pump (Sauer-Danfoss)

- Front Wheel Motors

- Servicing the Front Wheel Motor

- Rear Wheel Motors

- Servicing the Rear Wheel Motor

- Traction Control Manifold

- Servicing the Traction Control Manifold

- 4-Wheel Drive Control Manifold

- Servicing the 4-Wheel Drive Control Manifold

- Traction Flush Manifold

- PTO Circuit

- Cutting Deck Motor

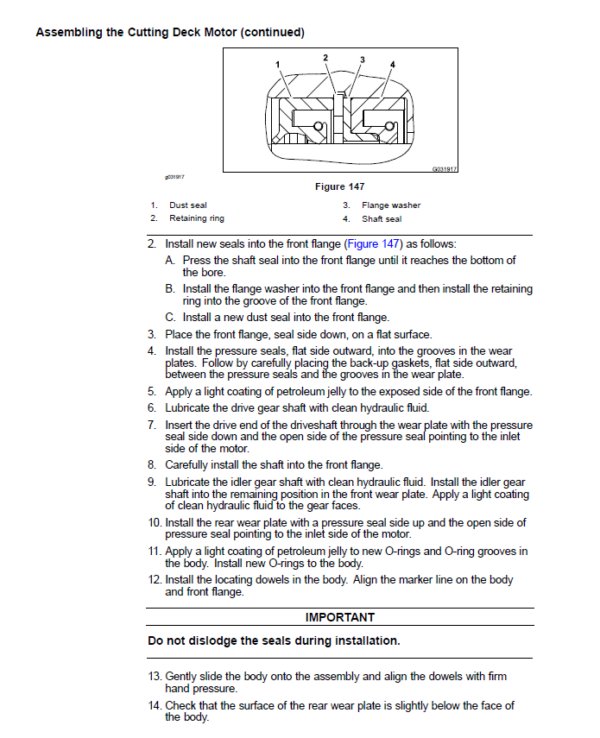

- Servicing the Cutting Deck Motor

- PTO Control Manifolds

- Servicing the PTO Control Manifold

- Filter Manifold

- Hydraulic Oil Cooler

- Cutting Deck Raise, Lower Circuit

- Front Deck Lift Cylinder

- Servicing the Front Deck Lift Cylinder

- Wing Deck Lift Cylinder

- Servicing the Wing Deck Lift Cylinder

- Lift Control Manifold

- Servicing the Lift Control Manifold

- Steering and Engine Cooling Fan Circuit

- Steering Control Valve

- Servicing the Steering Control Valve

- Steering Cylinders

- Servicing the Steering Cylinder

- Engine Cooling Fan Motor

- Servicing the Engine Cooling Fan Motor

- Steering, Engine Cooling Fan Control Manifold

- Servicing the Steering, Engine Cooling Fan Control Manifold

- DANFOSS D SERIES GEAR PUMP SEAL KIT SERVICE INSTRUCTION BULLETIN

- REXROTH VARIABLE PUMP A10VG REPAIR INSTRUCTIONS

- REXROTH VARIABLE PUMP A10VG REPAIR MANUAL

- DANFOSS H1 CLOSED CIRCUIT AXIAL PISTON PUMPS Service Repair Manual

- DANFOSS H1 CLOSED CIRCUIT AXIAL PISTON PUMPS REPAIR INSTRUCTIONS

- EATON REPAIR INFORMATION: MODEL 74318 and 74348 PISTON MOTORS

- PARKER TORQMOTORTM SERVICE PROCEDURE (TC, TB, TE, TJ, TF, TG, TH AND TL SERIES)

- EATON PARTS AND REPAIR INFORMATION: 5 SERIES STEERING CONTROL UNITS

- Chapter 5 : Electrical System

- General Information

- Toro Electronic Controllers (TEC)

- Cummins Engine Electronic Control Module (ECM)

- CAN-Bus Communications

- Electrical Drawings

- Special Tools

- Multimeter

- Dielectric Gel

- Battery Terminal Protector

- Battery Hydrometer

- Troubleshooting

- Starting Problems

- General Run and Transport Problems

- Cutting Deck (PTO) Operating Problems

- Cutting Deck Lift, Lower Problems

- InfoCenter Display

- Operator Information

- Operator Advisories

- Engine Faults

- Diagnostics

- Administration Settings

- Administration Service

- Administration About

- Electrical System Quick Checks

- Testing the Battery (Open Circuit Test)

- Testing the Charging System

- Checking the Operation of the Interlock Switches

- Testing the Component

- Key Switch

- Fuses

- Maxi Fuses

- Mega Fuses

- Cab Fuses (Groundsmaster 5910 Machine Only)

- PTO Switch

- Cutting Deck Lift Switches

- Traction Assist Switch

- Cruise Control Switch

- Throttle Control Switch

- Increment, Decrement Switch

- High-Low Speed Switch

- Headlight Switch

- Turn Signal Switch

- Windshield Wiper, Washer Switch (Groundsmaster 5910 Machine Only)

- Air Conditioning Switch (Groundsmaster 5910 Machine Only)

- Intake Air Heater Contactor

- Seat Switch

- Parking Brake Switch

- Service Brake Switches

- Main Power, Controller, Start, and Cab (Groundsmaster 5910 Machine Only) Relays

- Air Conditioning Relay (Groundsmaster 5910 Machine Only)

- Toro Electronic Controller (TEC)

- Hydraulic Valve Solenoid Coils

- Fuel Sender

- Hydraulic Fluid Temperature Sender

- Diode Assembly

- Audible Alarm

- Traction Pedal Potentiometer

- Air Filter Sensor (Machines with Serial Number Above 313000300)

- Up Limit Switches

- Adjustments

- Calibrating the Traction Pedal

- Traction Pedal Teach

- Service and Repairs

- Battery Storage

- Battery Care

- Servicing the Battery

- Hydraulic Valve Solenoid Coil

- Chapter 6 : Axles, Planetaries, and Brakes

- 1 Specifications

- Axles, Planetaries, and Brakes

- General Information

- Adjustments

- Planetary Drive Assembly Endplay (OPH-2 series planetary drives)

- Service and Repairs

- Wheels

- Brake Assembly

- Servicing the Brake

- Planetary Drive Assembly

- Servicing the OPH-2 Series Planetary Drive

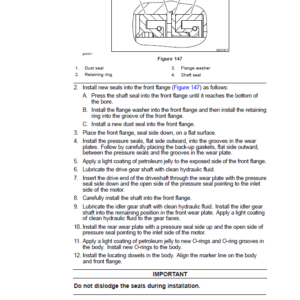

- Servicing the VA02 Series Planetary Drive

- Rear Axle

- Servicing the Rear Axle

- Chapter 7 : Chassis

- General Information

- Service and Repairs

- Steering Tower

- Wing Deck Rear Impact Arm Assembly

- Lift Arm Joint Yoke

- Front Deck Lift Arms

- Wing Deck Lift Arms

- Console Arm

- Traction Pedal

- Operator Seat

- Servicing the Operator Seat

- Operator Seat Suspension (Machine with Serial Number Below 315000200)

- Operator Seat Suspension (Machine with Serial Number Above 315000200)

- Hood

- Chapter 8 : Cutting Decks

- 1 Specifications

- Cutting Decks

- General Information

- Operator’s Manual

- Castor Wheel Tire Pressure

- Blade Stopping Time

- Troubleshooting

- Factors that can Affect Quality of Cut

- Service and Repairs

- Front Cutting Deck

- Wing Cutting Deck

- Idler Assembly

- Front Deck Winglets

- Blade Spindle

- Servicing the Blade Spindle

- Castor Forks and Wheels

- Deck Skids and Rollers

- Chapter 9 : Operator Cab

- General Information

- Operator’s Manual

- Electrical Components and Schematic

- Air Conditioning System

- Cab Heater System

- Air Conditioning System Performance

- Service and Repairs

- General Precautions for Removing and Installing the Air Conditioning System Components

- Air Conditioning Compressor

- Servicing the Air Conditioning Compressor

- Roof Assembly

- Air Conditioning Condenser Assembly

- Heater and Evaporator Assembly

- ICE COMPRESSOR Service Repair Manual

- Appendix A: Foldout Drawings

- Electrical Drawing Designations

- Hydraulic Schematic (Serial Number Below 313000300)

- Hydraulic Schematic (Serial Number Above 313000300)

- Electrical Schematic Sheet 1 of 5 (Serial Number Below 313000300)

- Electrical Schematic Sheet 2 of 5 (Serial Number Below 313000300)

- Electrical Schematic Sheet 3 of 5 (Serial Number Below 313000300)

- Electrical Schematic Sheet 4 of 5 (Serial Number Below 313000300)

- Electrical Schematic Sheet 5 of 5 (Serial Number Below 313000300)

- Electrical Schematic Sheet 1 of 5 Serial Number From 313000301 to 313999999)

- Electrical Schematic Sheet 2 of 5 (Serial Number From 313000301 to 313999999)

- Electrical Schematic Sheet 3 of 5 (Serial Number From 313000301 to 313999999)

- Electrical Schematic Sheet 4 of 5 (Serial Number From 313000301 to 313999999)

- Electrical Schematic Sheet 5 of 5 (Serial Number From 313000301 to 313999999)

- Electrical Schematic Sheet 1 of 5 (Serial Number Above 314000000)

- Electrical Schematic Sheet 2 of 5 (Serial Number Above 314000000)

- Electrical Schematic Sheet 3 of 5 (Serial Number Above 314000000)

- Electrical Schematic Sheet 4 of 5 (Serial Number Above 314000000)

- Electrical Schematic Sheet 5 of 5 (Serial Number Above 314000000)

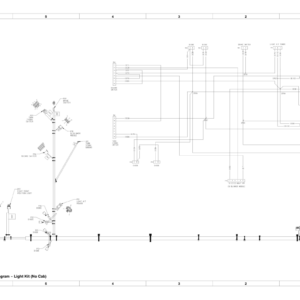

- Electrical Schematic Operator Cab (Serial Number Below 313000300)

- Electrical Schematic Operator Cab (Serial Number From 313000301 to 313999999)

- Electrical Schematic Operator Cab (Serial Number Above 314000000)

- Platform Wire Harness Drawing (Serial Number Below 310000000)

- Platform Wire Harness Diagram Sheet 1 of 2 (Serial Number Below 310000000)

- Platform Wire Harness Diagram Sheet 2 of 2 (Serial Number Below 310000000)

- Platform Wire Harness Drawing (Serial Number From 310000001 to 313000300)

- Platform Wire Harness Diagram Sheet 1 of 2 (Serial Number From 310000001 to 313000300)

- Platform Wire Harness Diagram Sheet 2 of 2 (Serial Number From 310000001 to 313000300)

- Platform Wire Harness Drawing (Serial Number From 313000301 to 313999999)

- Platform Wire Harness Diagram Sheet 1 of 2 (Serial Number From 313000301 to 313999999)

- Platform Wire Harness Diagram Sheet 2 of 2 (Serial Number From 313000301 to 313999999)

- Platform Wire Harness Drawing (Serial Number Above 314000000)

- Platform Wire Harness Diagram Sheet 1 of 2 (Serial Number Above 314000000)

- Platform Wire Harness Diagram Sheet 2 of 2 (Serial Number Above 314000000)

- Rear Wire Harness Drawing (Serial Number Below 313000300)

- Rear Wire Harness Diagram (Serial Number Below 313000300)

- Rear Wire Harness Drawing (Serial Number From 313000301 to 313999999)

- Rear Wire Harness Diagram (Serial Number From 313000301 to 313999999)

- Rear Wire Harness Drawing (Serial Number Above 314000000)

- Rear Wire Harness Diagram (Serial Number Above 314000000)

- Cab Wire Harness Drawing (Serial Number Below 314999999)

- Cab Wire Harness Diagram (Serial Number Below 314999999)

- Cab Wire Harness Drawing (Serial Number Above 315000000)

- Cab Wire Harness Diagram (Serial Number Above 315000000)

Be the first to review “Toro Groundsmaster 5900, 5910 (Models 31598, 31599) Service Repair Manual”

You must be logged in to post a review.

Reviews

There are no reviews yet.