Toro Groundsmaster 4500-D, 4700-D (Model 30856, 30868) Service Repair Manual

$30.00

Manual Included:

- Service Repair Manual: 278 Pages

Specifications:

- Brand: Toro

- Model: Groundsmaster 4500-D, 4700-D (Model 30856, 30868)

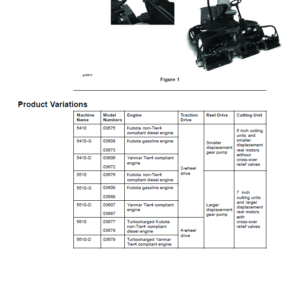

- Type: Rotary Mowers

- Manuals: Service Repair Manual

- Publication Numbers: 02104SL

- Language: English

- Format: PDF

- Description

- Reviews (0)

Description

Table of Content – Groundsmaster 4500-D, 4700-D (Model 30856, 30868)

- Title Page

- Revision History

- Reader Comments

- Preface

- Table Of Contents

- 1 – Safety

- General Safety Instructions

- Before Operating

- While Operating

- Maintenance and Service

- Jacking Instructions

- Safety and Instruction Decals

- 2 – Product Records and Maintenance

- Product Records

- Equivalents and Conversions

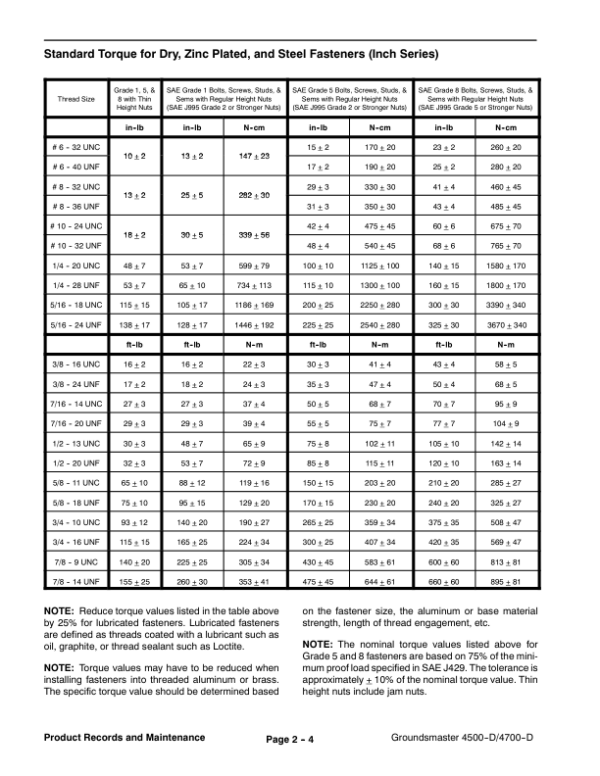

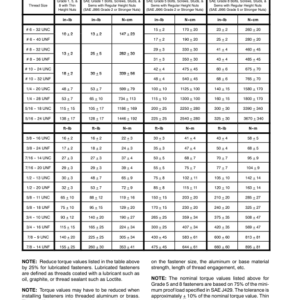

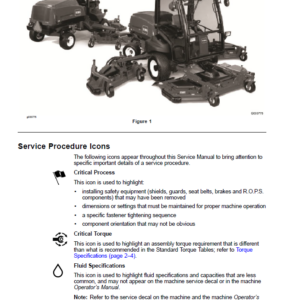

- Torque Specifications

- Maintenance

- 3 – Kubota Diesel Engine

- General Information

- Specifications

- Adjustments

- Engine Run Solenoid

- Service and Repairs

- Air Filter System

- Exhaust System

- Fuel System

- Radiator

- Engine

- Pump Adapter Plate

- Kubota V2003-T Workshop Manual

- 4 – Hydraulic System

- Specifications

- General Information

- Hydraulic Hoses

- Hydraulic Fitting Installation

- Towing Traction Unit

- Check Hydraulic Fluid

- Hydraulic Schematics

- GM 4500-D Hydraulic Schematic

- GM 4700-D Hydraulic Schematic

- Hydraulic Flow Diagrams

- Traction Circuit

- Lower Cutting Units

- Raise Cutting Units

- Mow Circuit

- Cutting Deck Blade Braking

- Steering Circuit

- Special Tools

- Troubleshooting

- Testing

- TEST NO. 1: Traction Circuit Charge Pressure

- Before Performing Hydraulic Tests

- TEST NO. 2: Traction Circuit Relief Pressure

- TEST NO. 3: Cutting Deck Circuit Pressure

- TEST NO. 4: Cutting Deck Gear Pump Flow

- TEST NO. 5: Cutting Deck Manifold Relief Pressure

- TEST NO. 6: Cutting Deck Motor Case Drain Leakage

- TEST NO. 7: Steering Circuit Relief Pressure

- TEST NO. 8: Lift, Lower Circuit Relief Pressure

- TEST NO. 9: Steering and Lift, Lower Gear Pump Flow

- TEST NO. 10: Counterbalance (RV1) Pressure

- TEST NO. 11: Rear Traction Circuit (RV5) Relief Pressure

- TEST NO. 12: Traction Circuit Reducing Valve (PR1) Pressure

- TEST NO. 13: Traction Assist (RV2) Pressure

- Service and Repairs

- General Precautions for Removing and Installing Hydraulic System Components

- Check Hydraulic Lines and Hoses

- Flush Hydraulic System

- Charge Hydraulic System

- Gear Pump

- Gear Pump Service

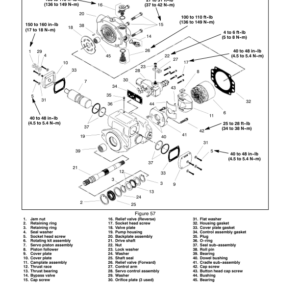

- Piston (Traction) Pump

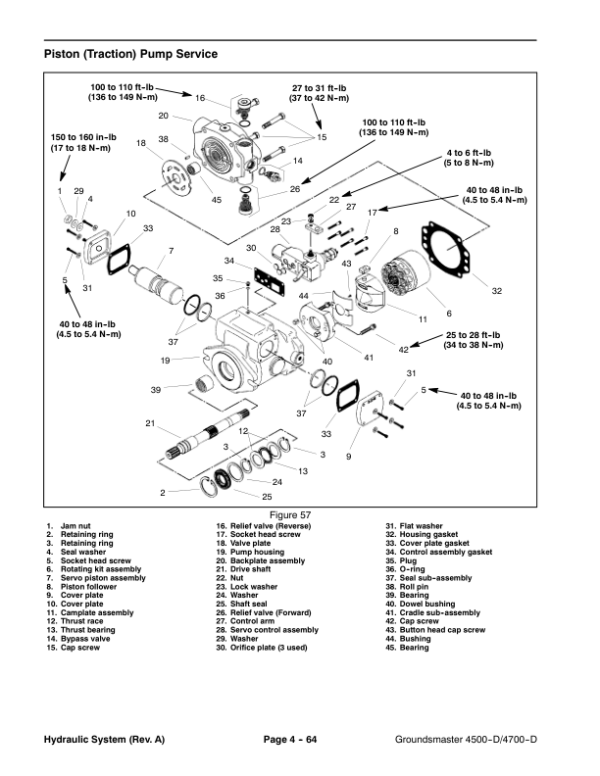

- Piston (Traction) Pump Service

- Piston Pump Manual Servo Control Assembly

- Hydraulic Control Manifolds: 2 Wheel, 4 Wheel Drive, Filtration and Charge, Power Down and Traction Assist

- Hydraulic Control Manifold Service: 2 Wheel, 4 Wheel Drive Control

- Hydraulic Control Manifold Service: Filtration and Charge Control

- Hydraulic Control Manifold Service: Power Down and Traction Assist (GM 4500–D)

- Hydraulic Control Manifold Service: Power Down and Traction Assist (GM 4700–D)

- Hydraulic Control Manifold: Deck Drive (GM 4500–D)

- Hydraulic Control Manifold Service: Deck Drive (GM 4500–D)

- Hydraulic Control Manifold: Deck Drive (GM 4700-D)

- Hydraulic Control Manifold Service: Deck Drive (GM 4700–D)

- Rear Axle Motor

- Front Wheel Motors

- Rear Axle, Front Wheel Motor Service

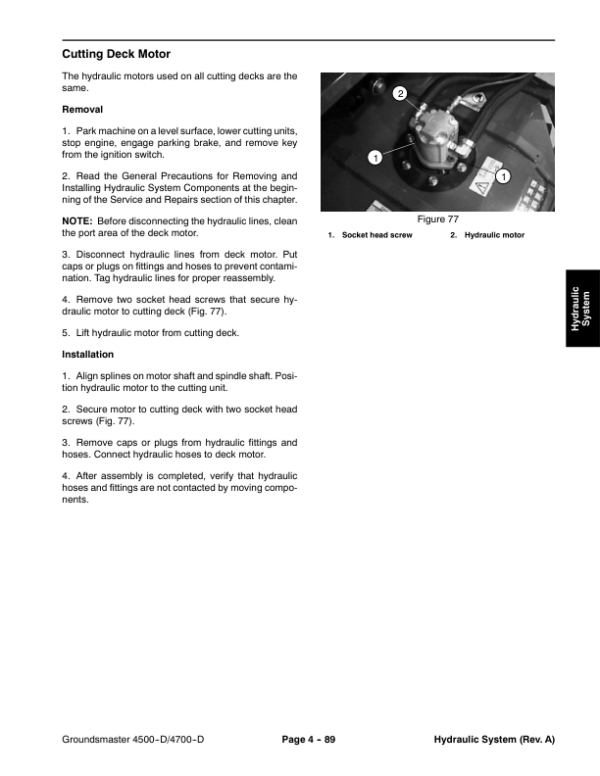

- Cutting Deck Motor

- Cutting Deck Motor Service

- Lift, Lower Control Valve (GM 4500–D)

- Lift, Lower Control Valve Service (GM 4500–D)

- Lift, Lower Control Valve (GM 4700–D)

- Lift, Lower Control Valve Service (G 4700–D)

- Steering Valve

- Steering Valve Service

- Lift Cylinders: Decks #1, #4, and #5

- Lift Cylinders: Decks #2 and #3

- Lift Cylinders: Decks #6 and #7 (GM 4700–D)

- Lift Cylinder Service

- Steering Cylinder

- Steering Cylinder Service

- Hydraulic Reservoir

- Hydraulic Oil Cooler

- 5 – Electrical System

- Electrical Schematic and Electrical Harness and Connectors Drawings

- Special Tools

- Troubleshooting

- Starting Problems

- General Run and Transport Problems

- Cutting Unit Operating Problems

- Electrical System Quick Checks

- Battery Test (Open Circuit Test)

- Check Operation of Interlock Switches

- Component Testing

- Ignition Switch

- Fuses

- Indicator Lights

- PTO and Hi–Lo Speed Control Switches

- Seat Switch

- Parking Brake Switch

- Cutting Deck Position Switch

- Cutting Deck Lift, Lower Switch

- Ramp–up Module

- Hour Meter

- Glow Relay

- Start, Neutral, Seat, Cutting Deck, Parking Brake, and High Temperature Relays

- Hydraulic Valve Solenoids

- Engine Run Solenoid

- Fuel Pump

- Glow Controller

- Temperature Sender

- Temperature Gauge

- High Temperature Shutdown Switch

- Traction Neutral Switch

- Diode Assemblies

- Diode Circuit Board

- Standard Control Module (S.N 230000001 and up)

- Service and Repairs

- Battery Storage

- Battery Care

- Battery Service

- 6 – Axles, Planetaries, and Brakes

- Specifications

- Adjustments

- Service and Repairs

- Brake Assembly

- Brake Inspection and Repair

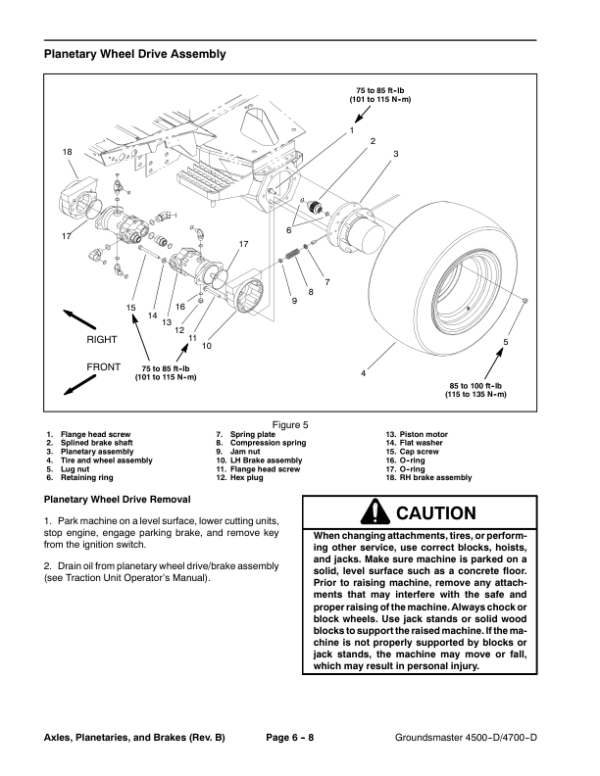

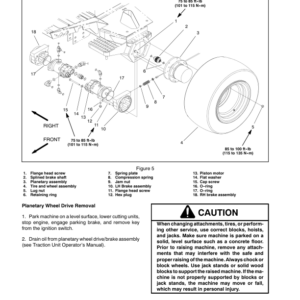

- Planetary Wheel Drive Assembly

- Planetary Wheel Drive Service

- Rear Axle Assembly

- Bevel Gear Case and Axle Case

- Differential Shafts

- Axle Shafts

- Input Shaft, Pinion Gear

- Differential Gear

- Pinion Gear to Ring Gear Engagement

- 7 – Chassis

- General Information

- Cutting Deck Identification

- Service and Repairs

- Steering Tower

- Lift Arms for Cutting Decks #1, #4, and #5

- Lift Arms for Cutting Decks #2 and #3

- Lift Arms for Cutting Decks #6 and #7 (Groundsmaster 4700–D only)

- Hood

- 8 – Cutting Units

- Specifications

- Troubleshooting

- Special Tools

- Adjustments

- Blade Stopping Time

- Blade Plane Inspection and Adjustment

- Service and Repairs

- Blade Spindle Assembly

- Blade Spindle Service

- Rear Roller

- Rear Roller Service (Non-Greasable Bearings)

- Rear Roller Service (Greasable Bearings with Retaining Ring)

- Rear Roller Service (Greasable Bearings with Bearing Nut)

- Front Roller Service

- Cutting Deck Carrier Frame

- 9 – Electrical Diagrams

- Schematic GM4500-D (S.N below 220999999)

- Schematic GM4500-D (S.N 230000001 to 260000600)

- Schematic GM4500-D (S.N 260000601 and up)

- Schematic GM4700-D (S.N below 220999999)

- Schematic GM4700-D (S.N 230000001 to 260000600)

- Schematic GM4700-D (S.N 260000601 and up)

- Glow Plug Circuit

- Crank Circuit

- Run (Transport) Circuit

- Run (Mow) Circuit

- Main Harness Diagram (S.N below 220999999)

- Main Wire Harness (S.N below 220999999)

- Main Harness Diagram (S.N 230000001 to 260000600)

- Main Wire Harness (S.N 230000001 to 260000600)

- Main Harness Diagram (S.N 260000601 and up)

- Main Wire Harness (S.N 230000601 and up)

- Console Harness Diagram (S.N below 220999999)

- Console Wire Harness (S.N below 220999999)

- Console Harness Diagram (S.N 230000001 to 260000600)

- Console Wire Harness (S.N 230000001 to 260000600)

- Console Harness Diagram (S.N 260000601 and up)

- Console Wire Harness (S.N 260000601 and up)

- Engine Harness Diagram (S.N below 220999999)

- Engine Wire Harness (S.N below 220999999)

- Engine Harness Diagram (S.N 230000001 and up)

- Engine Wire Harness (S.N 230000001 and up)

- Deck 6 and 7 Harness Diagram GM4700-D

Be the first to review “Toro Groundsmaster 4500-D, 4700-D (Model 30856, 30868) Service Repair Manual”

You must be logged in to post a review.

Reviews

There are no reviews yet.