Toro Groundsmaster 4300-D Service Repair Manual

$30.00

Manual Included:

- Service Repair Manual: 267 Pages

Specifications:

- Brand: Toro

- Model: Groundsmaster 4300-D

- Type: Rotary Mowers

- Manuals: Service Repair Manual

- Publication Numbers: 10178SL

- Language: English

- Format: PDF

- Description

- Reviews (0)

Description

Table of Content – Groundsmaster 4300-D

- Title Page

- Revision History

- Reader Comments

- Preface

- Table of Contents

- 1 – Safety

- Safety Instructions

- Before Operating

- While Operating

- Maintenance and Service

- Jacking Instructions

- Safety and Instruction Decals

- 2 – Product Records and Maintenance

- Product Records

- Maintenance

- Equivalents and Conversions

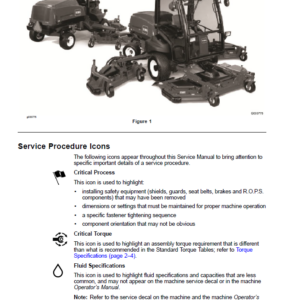

- Torque Specifications

- Fastener Identification

- Using a Torque Wrench with an Offset Wrench

- Standard Torque for Dry, Zinc Plated and Steel Fasteners (Inch Series)

- Standard Torque for Dry, Zinc Plated and Steel Fasteners (Metric Series)

- Other Torque Specifications

- Conversion Factors

- 3 – Kubota Diesel Engine

- General Information

- Operator’s Manual

- Stopping the Engine

- Specifications

- Adjustments

- Adjust Throttle Control

- Service and Repairs

- Fuel System

- Air Cleaner

- Exhaust System

- Radiator

- Engine

- Kubota 05 E3B Series Workshop Manual

- 4 – Hydraulic System

- Specifications

- General Information

- Operator’s Manual

- Check Hydraulic Fluid

- Towing Machine

- Hydraulic Hoses

- Hydraulic Hose and Tube Installation (O–Ring Face Seal Fitting)

- Hydraulic Fitting Installation (SAE Straight Thread O–Ring Fitting into Component Port)

- Relieving Hydraulic System Pressure

- Traction Circuit Component Failure

- Hydraulic Schematic

- Hydraulic Flow Diagrams

- Traction Circuit

- Mow Circuit

- Mow Circuit Cutting Deck Blade Braking

- Lift Circuit: Raise Cutting Decks

- Lift Circuit: Lower Cutting Decks

- Steering Circuit

- Special Tools

- Troubleshooting

- General Hydraulic System Problems

- Traction Circuit Problems

- Mow Circuit Problems

- Lift Circuit Problems

- Steering Circuit Problems

- Testing

- Traction Circuit Relief Valve (R3) and (R4) Pressure Test

- Traction Circuit Charge Pressure Test

- Gear Pump (P3) Flow Test

- Front Wheel Motor Efficiency Test

- Piston (Traction) Pump Flow Test

- Relief Valve (PRV1) and (PRV2) Pressure Test

- Gear Pump (P1) and (P2) Flow Test

- Deck Motor Efficiency Test

- Lift Relief Valve (PRV) Pressure Test

- Gear Pump (P4) Flow Test

- Lift Cylinder Internal Leakage Test

- Steering Relief Valve (R10) Pressure Test

- Steering Cylinder Internal Leakage Test

- Service and Repairs

- General Precautions for Removing and Installing Hydraulic System Components

- Check Hydraulic Lines and Hoses

- Flush Hydraulic System

- Filtering Closed–Loop Traction Circuit

- Hydraulic System Start–up

- Hydraulic Reservoir

- Hydraulic Pump Drive Shaft

- Hydraulic Pump Assembly

- Piston (Traction) Pump Service

- Gear Pump Service

- Front Wheel Motors

- Rear Wheel Motors

- Wheel Motor Service

- CrossTrax AWD Manifold

- CrossTrax AWD Manifold Service

- Deck Control Manifold

- Deck Control Manifold Service

- Cutting Deck Motor

- Cutting Deck Motor Service

- Lift Control Manifold

- Lift Control Manifold Service

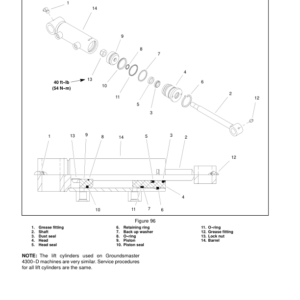

- Lift Cylinder

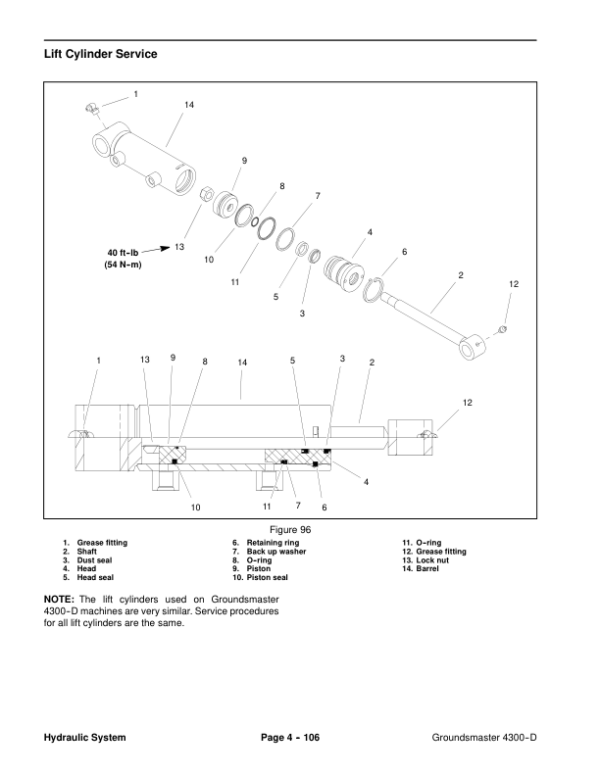

- Lift Cylinder Service

- Steering Control Valve

- Steering Control Valve Service

- Steering Cylinder

- Steering Cylinder Service

- Oil Cooler

- Danfoss LPV Pump Repair Manual

- Danfoss LPV Pump Service Repair Manual

- Parker Torqmotor Service Procedure

- Danfoss OSPM Steering Unit Service Repair Manual

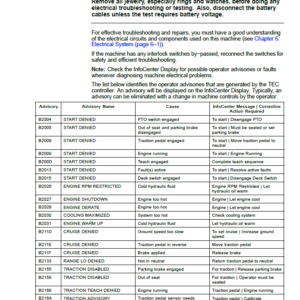

- 5 – Electrical System

- General Information

- Operator’s Manual

- Toro Electronic Controller (TEC)

- CAN–bus Communications

- Electrical Drawings

- Special Tools

- Troubleshooting

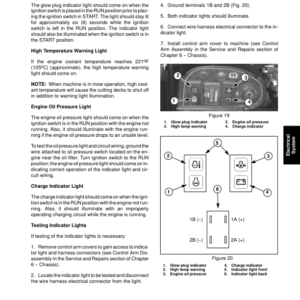

- Diagnostic Light

- Diagnostic Display

- TEC Controller Logic Chart

- Starting Problems

- General Run and Transport Problems

- Cutting Deck Operating Problems

- Electrical System Quick Checks

- Battery Test (Open Circuit Test)

- Charging System Test

- Glow Plug System Test

- Check Operation of Interlock Switches

- Adjustments

- Traction Neutral Switch

- Parking Brake Switch

- Mowith Transport Switch

- Component Testing

- Ignition Switch

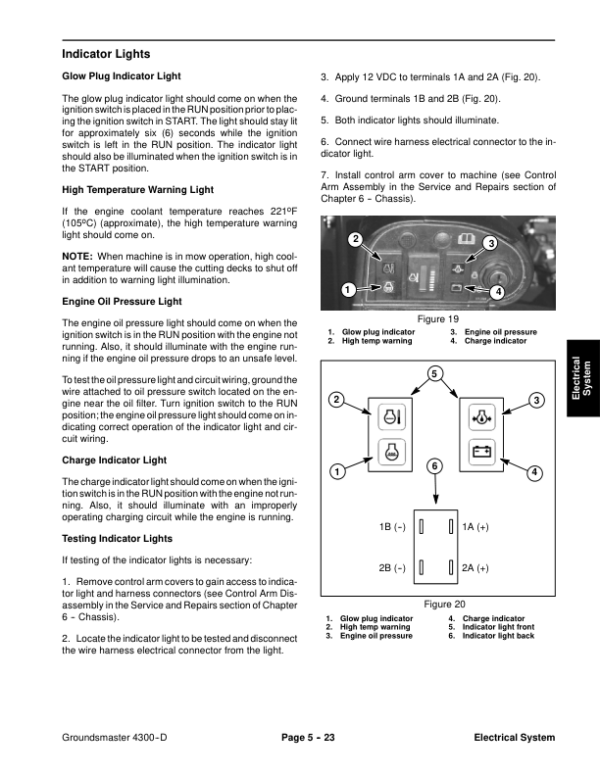

- Indicator Lights

- Hour Meter

- Temperature Gauge

- PTO Switch

- Headlight Switch

- Seat Switch

- Joystick Raise and Lower Switches

- Traction Neutral Switch

- Parking Brake Switch

- Mowith Transport Switch

- Start Relay

- Main Power and Glow Relays

- Toro Electronic Controller (TEC)

- Fuses

- Diode Assembly

- Fusible Link Harness

- Hydraulic Solenoid Valve Coil

- Temperature Sender

- High Temperature Shutdown Switch

- Oil Pressure Switch

- Fuel Stop Solenoid

- Fuel Pump

- Service and Repairs

- Battery Storage

- Battery Care

- Battery Service

- Battery Removal and Installation

- Battery Inspection and Maintenance

- Battery Testing

- Battery Charging

- Hydraulic Solenoid Valve Coil

- 6 – Chassis

- Specifications

- General Information

- Operator’s Manual

- Special Tools

- Service and Repairs

- Wheels

- Steering Column

- Brake Service

- Rear Axle Motor Housings

- Rear Axle

- Control Arm

- Operator Seat

- Mechanical Seat Suspension

- Front Lift Arms

- Rear Lift Arms

- 7 – Cutting Decks

- Specifications

- General Information

- Operator’s Manual

- Troubleshooting

- Factors That Can Affect Quality of Cut

- Special Tools

- Adjustments

- Blade Stopping Time

- Service and Repairs

- Blade Spindle Assembly

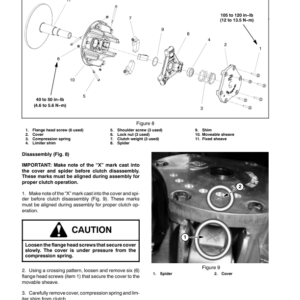

- Blade Spindle Service

- Rear Roller

- Rear Roller Service

- Front Roller Service

- Cutting Deck Carrier Frame

- 8 – Foldout Drawings

- Hydraulic Schematic

- Electrical Schematic Sheet 1 of 2 (Serial numbers below 315000000)

- Electrical Schematic Sheet 2 of 2 (Serial numbers below 315000000)

- Eclectrical Schematic (Serial numbers 315000001 to 403430000)

- Eclectrical Schematic (Serial numbers above 403430001)

- Main Wire Harness Drawing (Serial numbers below 315000000)

- Main Wire Harness Diagram (Serial numbers below 315000000)

- Main Wiring Harness Drawing (Serial numbers 315000001 to 403430000)

- Main Wiring Harness Diagram (Serial numbers 315000001 to 403430000)

- Main Wiring Harness Drawing (Serial numbers 403430001 to 405699999)

- Main Wiring Harness Diagram (Serial numbers 403430001 to 405699999)

- Main Wiring Harness Drawing (Serial numbers above 405700000)

- Main Wiring Harness Diagram (Serial numbers above 405700000)

- Seat Wire Harness Drawing

- Seat Wire Harness Diagram

- Engine Wire Harness Drawing

- Engine Wire Harness Diagram

Be the first to review “Toro Groundsmaster 4300-D Service Repair Manual”

You must be logged in to post a review.

Reviews

There are no reviews yet.