Toro Greensmaster 3150 (Model 04358) Service Repair Manual

$30.00

Manual Included:

- Service Repair Manual: 296 Pages

Specifications:

- Brand: Toro

- Model: Greensmaster 3150 (Model 04358)

- Type: Greens Reel Mowers

- Manuals: Service Repair Manual

- Publication Numbers: 12191SL

- Language: English

- Format: PDF

- Description

- Reviews (0)

Description

Table of Content – Greensmaster 3150 (Model 04358)

- Title Page

- Revision History

- Reader Comments

- Preface

- Table Of Contents

- Chapter 1 – Safety

- Safety Instructions

- Before Operating

- While Operating

- Maintenance and Service

- Jacking Instructions

- Safety and Instruction Decals

- Chapter 2 – Product Records and Maintenance

- Product Records

- Maintenance

- Equivalents and Conversions

- Torque Specifications

- Fastener Identification

- Using a Torque Wrench with an Offset Wrench

- Standard Torque for Dry, Zinc Plated and Steel Fasteners (Inch Series)

- Standard Torque for Dry, Zinc Plated and Steel Fasteners (Metric Fasteners)

- Other Torque Specifications

- Conversion Factors

- Chapter 3 – Engine

- General Information

- Operator's Manual

- Specifications

- Service and Repairs

- Fuel Tank

- Engine

- Fuel Evaporative Control System

- Briggs & Stratton Vanguard V−Twin OHV Repair Manual

- Chcpter 4 – Hydraulic System

- Specifications

- General Information

- Operator's Manual

- Check Hydraulic System Fluid

- Towing Traction Unit

- Hydraulic Hoses

- Hydraulic Hose and Tube Installation (O-Ring Face Seal Fitting)

- Hydraulic Fitting Installation (SAE Straight Thread O-Ring Fitting into Component Port)

- Hydraulic Schematic

- Hydraulic Flow Diagrams

- Traction Forward and Reverse

- Raise and Lower Cutting Units

- Mow and Backlap

- Right and Left Turn

- Special Tools

- Hydraulic Pressure Test Kit

- Hydraulic Tester (Pressure and Flow)

- O-ring Kit

- High Flow Hydraulic Filter Kit

- Hydraulic Hose Kit

- Hydraulic Test Fitting Kit

- Measuring Container

- Wheel Hub Puller

- Troubleshooting

- Refer to the Testing section of this Chapter for precautions and specific test procedures.

- General Hydraulic System Problems

- Traction Circuit Problems

- Mow Circuit Problems

- Lift, Lower Circuit Problems

- Steering Circuit Problems

- Testing

- Charge Relief Valve Pressure Test (Using Pressure Gauge)

- Wheel Motor Efficiency Test (Using Tester with Flowmeter and Pressure Gauge)

- Piston (Traction) Pump Flow Test (Using Tester with Flowmeter and Pressure Gauge)

- Gear Pump (Rear Section) Flow Test (Using Tester with Flowmeter and Pressure Gauge)

- Implement Relief Valve Pressure Test (Using Tester with Flowmeter and Pressure Gauge)

- Lower Cutting Units Relief Valve (R2) Pressure Test (Using Tester with Flowmeter and Pressure Gauge)

- Gear Pump (Front Section) Flow Test (Using Tester with Flowmeter and Pressure Gauge)

- Mow Circuit Relief Valve (S1R1) Pressure Test (Using Tester with Flowmeter and Pressure Gauge)

- Reel Motor Case Drain Flow Test (Using Tester with Flowmeter and Pressure Gauge)

- Steering Control Valve Test

- Adjustments

- Adjust Manifold Relief Valve (R2)

- Service and Repairs

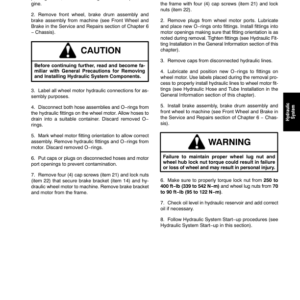

- General Precautions for Removing and Installing Hydraulic System Components

- Flush Hydraulic System

- Filtering Closed-Loop Traction Circuit

- Hydraulic System Start-up

- Gear Pump

- Gear Pump Service

- Piston (Traction) Pump Neutral Assembly

- Piston (Traction) Pump

- Piston (Traction) Pump Service

- Piston Pump Crush Ring Replacement

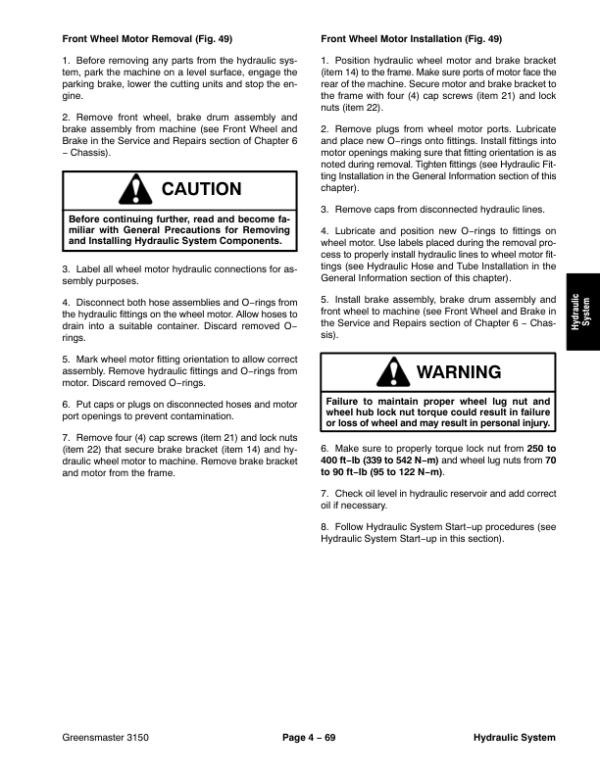

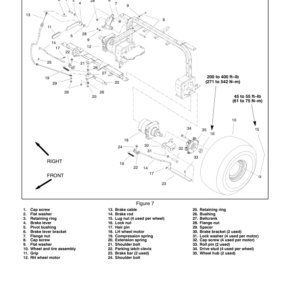

- Front Wheel Motors

- Rear Wheel Motor (Optional 3WD)

- Wheel Motor Service

- Cutting Reel Motors

- Cutting Reel Motor Service

- Front Lift Cylinders

- Center Lift Cylinder

- Lift Cylinder Service

- Hydraulic Manifold

- Hydraulic Manifold Service

- Steering Control Valve

- Steering Control Valve Service

- Steering Cylinder

- Steering Cylinder Service

- Leak Detector

- Hydraulic Reservoir

- Eaton Model 70160 Variable Displacement Piston Pump Repair Information

- Parker Torqmotor Service Procedure TF, TG, TH and TL Series Hydraulic Torqmotors

- Danfoss Steering OSPM Service Repair Manual

- Chapter 5 – Electrical System

- General Information

- Operator's Manual

- Electrical Drawings

- Special Tools

- Multimeter

- Skin-Over Grease

- Battery Terminal Protector

- Dielectric Lubricant, Sealant

- Battery Hydrometer

- Turf Guardian™ Leak Detector System Operation

- Before Start‐Up (Cold Oil)

- Normal Operation (Warm Oil)

- Leak Alert!

- Troubleshooting

- Starting Problems

- General Run and Transport Problems

- Cutting Unit Operating Problems

- Electrical System Quick Checks

- Battery Test

- Charging System Test

- Component Testing

- Ignition Switch

- Fuse Block

- Hour Meter

- Seat Switch

- Safety Relays

- Neutral and Mow Switches

- Parking Brake Sensor

- Joystick Raise and Lower Switches

- Lower Reels Time Delay

- Starter Solenoid

- Solenoid Valve Coils

- Backlap Switch

- Diodes

- Fusible Links

- Leak Detector Test, Light Switch

- Leak Detector Alarm and Delay Timer

- Leak Detector Float Sensor

- Leak Detector Solenoid Valve

- Service and Repairs

- Battery Care

- Battery Storage

- Battery Service

- Chapter 6 – Chassis

- Specifications

- General Information

- Operator's Manual

- Special Tools

- Wheel Hub Puller

- Service and Repairs

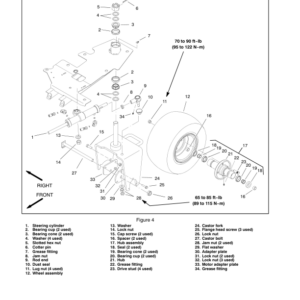

- Front Wheel and Brakes

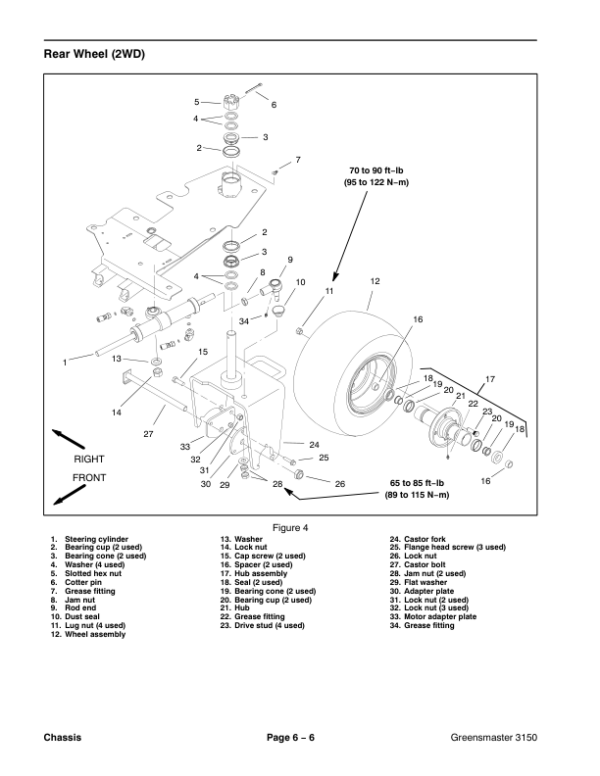

- Rear Wheel (2WD)

- Rear Wheel (Optional 3WD)

- Rear Wheel Hub and Motor Assembly (Optional 3WD)

- Rear Castor Fork

- Cutting Unit Pull Frame

- Chapter 7 – DPA Cutting Units

- Specifications

- General Information

- Cutting Unit Operator's Manual

- Supporting Cutting Unit when Servicing

- Special Tools

- Gauge Bar Assembly

- Bedknife Screw Tool

- Handle Assembly

- Roller Bearing Installation Tools

- Diameter, Circumference Measuring Tape

- Turf Evaluator Tool

- Bedknife Top Angle Indicator and Mount

- Reel Thread Repair Taps

- Factors That Can Affect Cutting Performance

- Set Up and Adjustments

- Characteristics

- Leveling Rear Roller

- Service and Repairs

- Backlapping

- Bedbar Assembly

- Bedknife Replacement and Grinding

- Bedbar Adjuster Service

- Reel Assembly

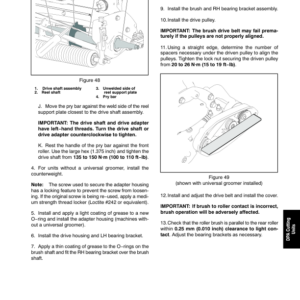

- Reel Assembly Service

- Preparing Reel for Grinding

- Front Roller

- Rear Roller

- Roller Service

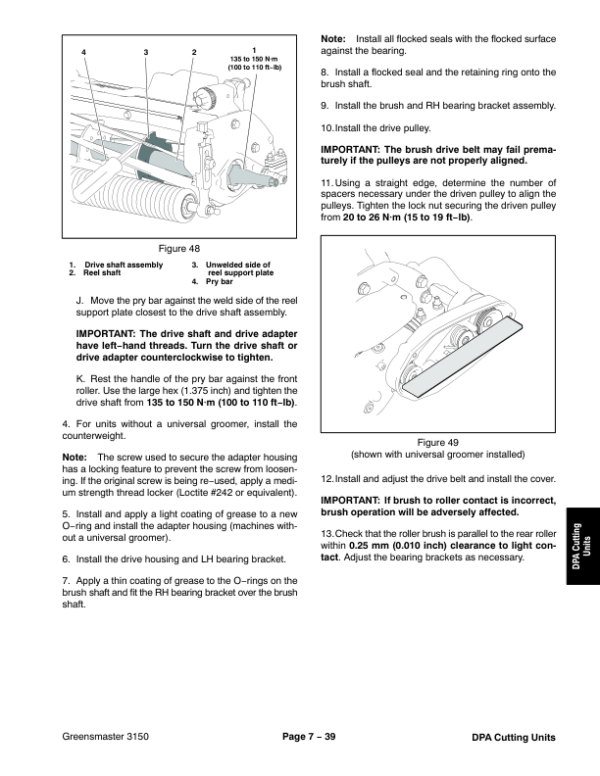

- Rear Roller Brushes (Optional)

- Servicing the Rear Roller Brush (with or without a belt driven groomer)

- Servicing the Rear Roller Brush (with or without a universal groomer)

- Chapter 8 – Belt Driven Groomer (Optional)

- 1 Specifications

- General Information

- Installation Instructions

- Grooming Performance

- Troubleshooting

- Service and Repairs

- Replacing the Groomer Drive Belt

- The Groomer Plate Assemblies

- The Groomer Reel

- The Groomer Arm Assemblies

- The Grooming Brushes (Optional)

- Chapter 9 – Universal Groomer (Optional)

- 1 Specifications

- General Information

- Installation Instructions

- Troubleshooting

- Grooming Performance

- Groomer Reel Mechanical Problems

- Special Tools

- Service and Repairs

- The Gear Box Assembly

- The Idler Assembly

- The Groomer Reel

- The Height Adjuster Assembly

- The Grooming Brush (Optional)

- Appendix A: Foldout Drawings

- Electrical Drawing Designations

- Hydraulic Schematic

- Electrical Circuit Diagrams – Crank Circuits (typical)

- Electrical Circuit Diagrams – Run Circuits (typical)

- Electrical Circuit Diagrams – Raise Cutting Units Circuits (typical)

- Electrical Circuit Diagrams – Lower Cutting Units (6 seconds) Circuits (typical)

- Electrical Circuit Diagrams – Mow Circuits (typical)

- Electrical Circuit Diagrams – Backlap Circuits (typical)

- Electrical Schematic (serial numbers before 315000000)

- Electrical Schematic (serial numbers 315000000 to 403410000)

- Electrical Schematic (serial numbers above 403410000)

- Main Wire Harness Drawing (serial numbers below 315000000)

- Main Wire Harness Diagram (serial numbers below 315000000)

- Main Wire Harness Drawing (serial numbers 315000000 to 403410000)

- Main Wire Harness Diagram (serial numbers 315000000 to 403410000)

- Main Wire Harness Drawing (serial numbers above 403410000)

- Main Wire Harness Diagram (serial numbers above 403410000)

- Engine Wire Harness

Be the first to review “Toro Greensmaster 3150 (Model 04358) Service Repair Manual”

You must be logged in to post a review.

Reviews

There are no reviews yet.