Toro Greensmaster 3120 (Model 04355) Service Repair Manual

$34.00

Manual Included:

- Service Repair Manual: 341 Pages

Specifications:

- Brand: Toro

- Model: Greensmaster 3120 (Model 04355)

- Type: Greens Reel Mowers

- Manuals: Service Repair Manual

- Publication Numbers: 17230SL

- Language: English

- Format: PDF

- Description

- Reviews (0)

Description

Table of Content – Greensmaster 3120 (Model 04355)

- Title Page

- Revision History

- Reader Comments

- Preface

- Overall Dimensions

- Service Procedure Icons

- Chapter 1 : Safety

- Safety Instructions

- Supervisor’s Responsibilities

- Before Operating the Machine

- While Operating the Machine

- Maintenance and Service

- Jacking Instructions

- Raising the Machine

- Safety and Instructional Decals

- Chapter 2 : Specifications and Maintenance

- Specifications

- Decimal and Millimeter Equivalents

- U.S. to Metric Conversions

- Torque Specifications

- Calculating the Torque Values When Using a Drive-Adapter Wrench

- Identifying the Fastener

- Standard Torque for Dry, Zinc Plated, and Steel Fasteners (Metric)

- Standard Torque for Dry, Zinc Plated, and Steel Fasteners (Inch)

- Other Torque Specifications

- Conversion Factors

- Shop Supplies

- Special Tools

- Chapter 3 : Engine

- 1 Specifications

- Engine

- General Information

- Traction Unit Operator’s Manual

- Briggs & Stratton Repair Manual

- Service and Repairs

- Fuel Tank

- Engine

- Evaporative Control System

- Disassembly

- Assembly

- Briggs & Stratton Vanguard V-Twin OHV Repair Manual

- Chapter 4 : Hydraulic System

- 1 Specifications

- Hydraulic System

- General Information

- Traction Unit Operator’s Manual

- Relieving Pressure from the Hydraulic System

- Towing the Traction Unit

- Traction Circuit (Closed Loop) Component Failure

- Hydraulic Hoses

- Installing Hydraulic Hoses and Tubes (O-Ring Face Seal)

- Installing the Hydraulic Fittings (SAE Straight Thread O-Ring Fittings)

- Hydraulic Schematics

- Hydraulic Flow Diagrams

- Traction Circuit

- Lift Circuit

- Mow Circuit

- Steering Circuit

- Special Tools

- Hydraulic Pressure Testing Kit

- Hydraulic Tester Kit

- Hydraulic Test Fitting Kit

- O-Ring Kit

- Hydraulic Hose Kit

- Measuring Container

- High Flow Hydraulic Filter Kit

- Troubleshooting

- General Hydraulic System Problems

- Traction Circuit Problems

- Mow Circuit Problems

- Lift, Lower Circuit Problems

- Steering Circuit Problems

- Testing the Hydraulic System

- Hydraulic Test Selection

- Traction Circuit Testing – Charge Pressure Test

- Traction Circuit Testing – Wheel Motor Efficiency Test

- Traction Circuit Testing – Traction Pump (P1) Flow and Relief Pressure Test

- Cutting Unit Circuit Testing – Cutting Unit Motor Efficiency, Case Drain Test

- Cutting Unit Circuit Testing – Relief Valve Test

- Cutting Unit Circuit Testing – Gear Pump (P2) Flow Test

- Steering, Lift Circuit Testing – Gear Pump (P3) Flow and Circuit Relief Valve Test

- Steering, Lift Circuit Testing – Lowering Cutting Units Relief Valve Test

- Steering, Lift Circuit Testing – Steering Control Valve and Steering Cylinder Test

- Adjustments

- Adjusting Relief Valves

- Service and Repairs

- General Precautions for Removing and Installing the Hydraulic System Components

- Checking the Hydraulic Lines and Hoses

- Flushing the Hydraulic System

- Filtering the Closed-Loop Traction Circuit

- Priming the Hydraulic Pumps

- Charging the Hydraulic System

- Gear Pump

- Servicing the Gear Pump

- Traction Pump

- Servicing the Traction Pump

- Wheel Motors

- Servicing the Wheel Motor

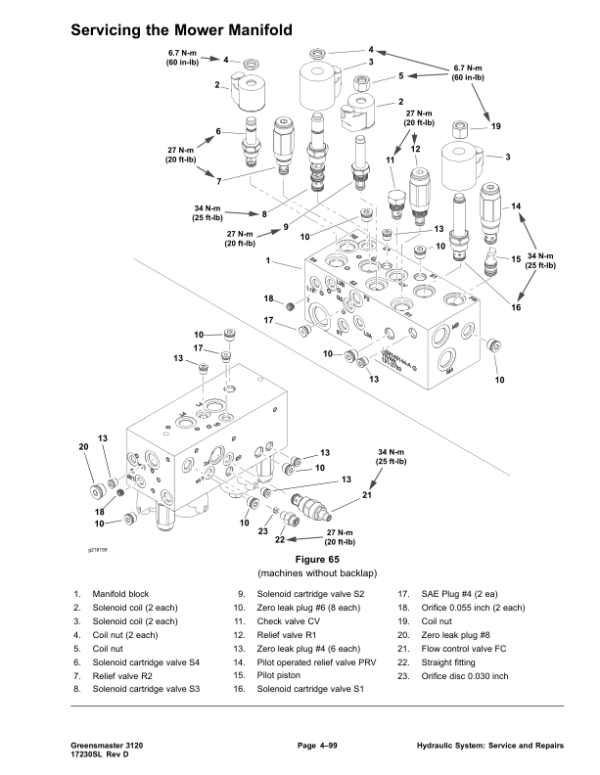

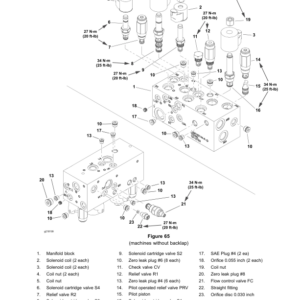

- Mower Manifold

- Servicing the Mower Manifold

- Reel Motors

- Servicing the Reel Motor

- Front Lift Cylinders

- Servicing the Front Lift Cylinders

- Rear Lift Cylinder

- Servicing the Rear Lift Cylinder

- Steering Control Valve

- Servicing the Steering Control Valve

- Steering Cylinder

- Servicing the Steering Cylinder

- Hydraulic Tank

- Hydro-Gear P Series Hydrostatic Pumps Service and Repair Manual

- Parker Torqmotor™ Service Procedure (TF, TG, TH and TL Series)

- Danfoss Steering Unit Type OSPM Service Repair Manual

- Chapter 5 : Electrical System

- General Information

- Electrical Schematics and Diagrams

- Special Tools

- Multimeter

- Battery Terminal Protector

- Battery Hydrometer

- Dielectric Gel

- Troubleshooting

- Electrical System Quick Checks

- Testing the Battery (Open Circuit Test)

- Testing the Charging System

- Checking the Interlock System Operation

- Testing the Electrical Components

- Fusible Links

- Fuses

- Key Switch

- Starter Solenoid

- Hour Meter

- Seat Switch

- Neutral and Mow Switches

- Parking Brake Switch

- Cutting Unit Raise and Lower Joystick Switches

- Backlap Switch (machines with backlap)

- Relays

- Delay Timer (Lower Cutting Units)

- Hydraulic Solenoid Valve Coils

- Diodes

- Service and Repairs

- Caring for the Battery

- Storing the Battery

- Servicing the Battery

- Chapter 6 : Chassis

- 1 Specifications

- Chassis

- General Information

- Service and Repairs

- Front Wheels and Brakes

- Rear Wheel

- Caster Fork

- Cutting Unit Pull Frame Rollers, Pivot Hinges and Lift Arms

- Chapter 7 : DPA Cutting Units

- 1 Specifications

- DPA Cutting Units

- General Information

- Cutting Unit Operator's Manual

- Supporting the Cutting Unit when Servicing

- Aftercut Appearance

- Adjustments

- DPA Cutting Unit Characteristics

- Leveling the Rear Roller

- Service and Repairs

- Bedbar Assembly

- Bedknife

- Reel Assembly

- Roller Assemblies

- Rear Roller Brushes (Optional)

- Chapter 8 : Belt Driven Groomer (Optional)

- 1 Specifications

- Belt Driven Groomer (Optional)

- General Information

- Installation Instructions

- Grooming Performance

- Troubleshooting

- Service and Repairs

- Replacing the Groomer Drive Belt

- The Groomer Plate Assemblies

- The Groomer Reel

- The Groomer Arm Assemblies

- The Grooming Brushes (Optional)

- Chapter 9 : Universal Groomer (Optional)

- 1 Specifications

- Universal Groomer

- General Information

- Installation Instructions

- Grooming Performance

- Troubleshooting

- Service and Repairs

- The Gear Box Assembly

- The Idler Assembly

- The Groomer Reel

- The Height Adjuster Assembly

- The Grooming Brush (Optional)

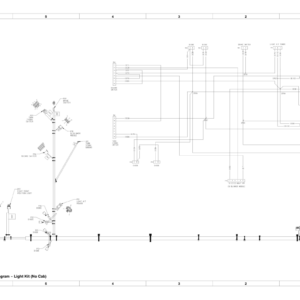

- Appendix A: Foldout Drawings

- Electrical Drawing Designations

- Hydraulic Schematic (machines without backlap)

- Hydraulic Schematic (machines with backlap)

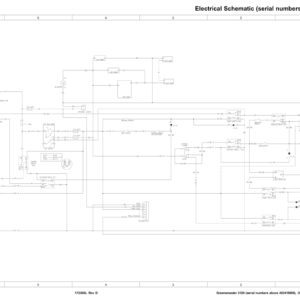

- Electrical Schematic (serial numbers below 403410000)

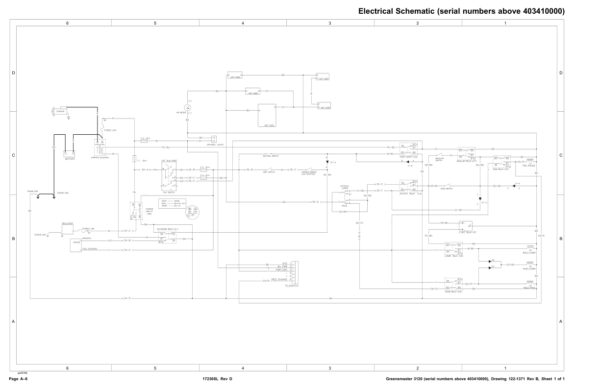

- Electrical Schematic (serial numbers above 403410000)

- Wire Harness Drawing – Main (serial numbers below 403410000)

- Wire Harness Diagram – Main (serial numbers below 403410000)

- Wire Harness Drawing – Main (serial numbers above 403410000)

- Wire Harness Diagram – Main (serial numbers above 403410000)

- Wire Harness – Seat

- Wire Harness – Engine

Be the first to review “Toro Greensmaster 3120 (Model 04355) Service Repair Manual”

You must be logged in to post a review.

Reviews

There are no reviews yet.