Sumitomo SH75X-3B Hydraulic Excavator Repair Service Manual

$40.00

Sumitomo Excavator SH75X-3B

Format: PDF

Manual Identification: WLSM0753B-00W, WDL0754-0T and WLST0753B-00W

English

- Sumitomo SH75X-3B Hydraulic Excavator Repair Service Manual – 448 Pages & 216 Pages

- Operators Manual – 190 Pages

- Description

- Reviews (0)

Description

Sumitomo SH75X-3B Hydraulic Excavator Repair Service Manual

Sumitomo Excavator SH75X-3B

Format: PDF

Manual Identification: WLSM0753B-00W, WDL0754-0T and WLST0753B-00W

English

- Sumitomo SH75X-3B Hydraulic Excavator Repair Service Manual – 448 Pages & 216 Pages

- Operators Manual – 190 Pages

Sumitomo SH75X-3B Manual TABLE OF CONTENTS

Introduction

Using Technical Information

Precautions for Use

Tightening Torque

Specifications

Performances

Hydraulic Pump

Assembly and Disassembly Procedures …………………………………………………………..1

1. Tools and Jigs………………………………………………………………………………………1

2. Cautions ……………………………………………………………………………………………..1

3. Disassembly Procedures……………………………………………………………………….2

4. Assembly Procedures……………………………………………………………………………8

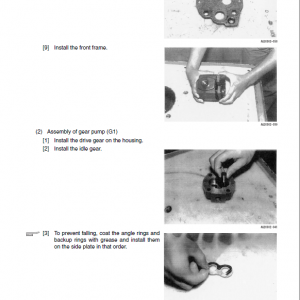

5. Disassembly of Gear Pump………………………………………………………………….14

6. Assembly of Gear Pump………………………………………………………………………17

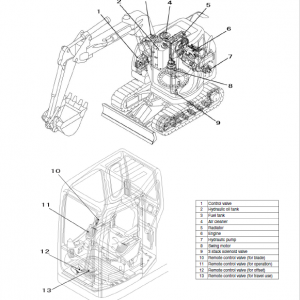

Internal structure diagram……………………………………………………………………………..23

Travel Unit

Maintenance Procedures………………………………………………………………………………28

1. Tools …………………………………………………………………………………………………28

2. Tightening Torque……………………………………………………………………………….32

3. Weight Table………………………………………………………………………………………32

Disassembly ……………………………………………………………………………………………….33

1. Preparations ………………………………………………………………………………………33

2. General Work Precautions …………………………………………………………………..33

3. Disassembly Procedure……………………………………………………………………….34

Maintenance Standards………………………………………………………………………………..52

1. Seals ………………………………………………………………………………………………..52

2. Maintenance Standards for Worn Parts …………………………………………………52

Assembly ……………………………………………………………………………………………………54

1. Preparations ………………………………………………………………………………………54

2. General Work Precautions …………………………………………………………………..54

3. Assembly Procedures………………………………………………………………………….54

Performance Confirmation Test ……………………………………………………………………..72

3-Dimensional Disassembly Diagram of Reduction Gear Section……………………….73

3-Dimensional Disassembly Diagram of Hydraulic Motor Section……………………….74

Travel Motor ………………………………………………………………………………………………..75

Swing Unit

Maintenance Procedures………………………………………………………………………………77

1. Trouble and Countermeasures ……………………………………………………………..77

2. Tool …………………………………………………………………………………………………..84

3. Disassembly Procedures……………………………………………………………………..87

4. Assembly Procedures………………………………………………………………………….97

5. Quality Check after Assembly …………………………………………………………….108

6. Maintenance Standards …………………………………………………………………….109

7. Development Diagram……………………………………………………………………….112

8. Configuration Diagram……………………………………………………………………….114

Reverse Prevention Valve……………………………………………………………………………117

1. Trouble and Countermeasures ……………………………………………………………117

2. Tools for Assembly and Disassembly …………………………………………………..118

Reverse Prevention Valve Breakdown Diagram ……………………………………………..122

Control Valve

Disassembly ……………………………………………………………………………………………..123

1. Cautions for Disassembly…………………………………………………………………..123

2. Disassembly Procedures……………………………………………………………………123

Cleaning …………………………………………………………………………………………………..127

Inspection …………………………………………………………………………………………………127

Assembly ………………………………………………………………………………………………….128

1. Sub Assembly…………………………………………………………………………………..128

2. Assembly of Control Valve Main Unit …………………………………………………..129

Relief Valve……………………………………………………………………………………………….133

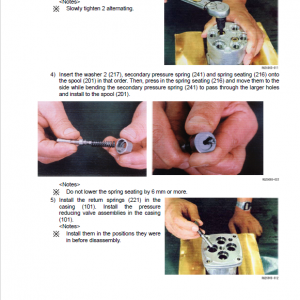

1. Procedures for Assembly and Disassembly of Main Relief Valve …………….133

2. Procedures for Assembly and Disassembly of Overload Relief Valve……….134

3. Relief Valve Adjustment……………………………………………………………………..135

Installation ………………………………………………………………………………………………..136

Operation………………………………………………………………………………………………….136

Control Valve Specifications List…………………………………………………………………..136

Troubles and Countermeasures …………………………………………………………………..137

Control Valves Overall…………………………………………………………………………….137

Relief Valve …………………………………………………………………………………………..138

Hydraulic System Overall………………………………………………………………………..138

Part List ……………………………………………………………………………………………………139

Reference Diagram…………………………………………………………………………………….140

Cylinder

Structural Diagram……………………………………………………………………………………..152

1. Boom Cylinder (mono-boom machine)…………………………………………………152

2. Boom Cylinder (offset-boom machine)…………………………………………………153

3. Arm Cylinder (mono-boom machine) …………………………………………………..154

4. Arm Cylinder (offset-boom machine)……………………………………………………155

5. Bucket Cylinder (mono-boom machine) ……………………………………………….156

6. Bucket Cylinder (offset-boom machine) ……………………………………………….157

7. Offset Cylinder (offset-boom machine)…………………………………………………158

8. Blade Cylinder (mono-boom/offset-boom machine)……………………………….159

Maintenance Procedures…………………………………………………………………………….160

1. Explanation of Functions ……………………………………………………………………160

2. Maintenance inspection and service ……………………………………………………163

3. Trouble diagnostics……………………………………………………………………………164

4. Storage standards …………………………………………………………………………….169

5. Assembly and disassembly procedures ……………………………………………….170

Specialty Tool and Jig for Repair ………………………………………………………………….186

1. Tool Dimensions ……………………………………………………………………………….186

2. Handling of Specialty Jigs for Cylinder Repair ………………………………………187

Remote Control Valve

Safety Items………………………………………………………………………………………………208

1. Cautions Concerning Operator’s Manual ……………………………………………..208

2. Safety Cautions ………………………………………………………………………………..208

3. Disclaimer………………………………………………………………………………………..209

For Operation…………………………………………………………………………………………….210

1. Summary …………………………………………………………………………………………210

2. Specifications …………………………………………………………………………………..210

3. Structure………………………………………………………………………………………….210

4. Function…………………………………………………………………………………………..210

5. Operation…………………………………………………………………………………………211

6. Maintenance Procedures …………………………………………………………………..213

7. Causes of Trouble and Countermeasures…………………………………………….224

8. Remote Control Valve Assembly Cross-Section Diagram……………………….225

9. Special Jig Assembly Cross-Section Diagram and Detailed Diagram……….226

For Travel Use……………………………………………………………………………………………227

1. Structure………………………………………………………………………………………….227

2. Operation Explanation……………………………………………………………………….228

3. Assembly and Disassembly………………………………………………………………..231

4. Troubles and Countermeasures ………………………………………………………….234

For Offset and Blade…………………………………………………………………………………..235

1. Operation Explanation……………………………………………………………………….235

2. Parts Maintenance and Replacement ………………………………………………….235

3. Causes of Trouble and Solutions…………………………………………………………236

4. Assembly and Disassembly Procedures ………………………………………………236

5. Structural Diagram…………………………………………………………………………….238

Solenoid Valve (3 stack)

Assembly Diagram……………………………………………………………………………………..239

Operation Principle …………………………………………………………………………………….239

Maintenance ……………………………………………………………………………………………..240

1. Assembly and Disassembly Precautions………………………………………………240

2. Assembly and Disassembly of Electromagnetic Switchover Valve……………240

3. Maintenance Standards …………………………………………………………………….241

4. Troubleshooting ………………………………………………………………………………..241

Cautions for Safety…………………………………………………………………………………242

Cushion Valve

Structure …………………………………………………………………………………………………..244

Operation Explanation ………………………………………………………………………………..245

Assembly and Disassembly…………………………………………………………………………247

General Precautions ………………………………………………………………………………247

Disassembly Procedure ………………………………………………………………………….247

Troubles and countermeasures ……………………………………………………………………248

The Sumitomo Manual Preface

The purpose of this Sumitomo Excavator manual is to assist dealers and repair serviceman in efficient repair and maintenance of their machinery. Carrying out the procedures as detailed, together with the use of any special tools needed.

Using the Sumitomo SH75X-3B Manual

To make information easier to find, there is an index at the beginning of each section listing the various parts in that section. At the beginning of each part there is a table of contents which should also be used as a guide to locate information.

To assist with locating information, each section of the manual is preceded by a contents page listing the repair operations, Each instruction within an operating has a sequence number. To complete the operation in the minimum time is possible follow the manual guideline and repair instructions.

When parts have to be replaced in either the SH75X-3B Hydraulic Excavator , it is essential that only genuine Sumitomo parts should be used. Special attention should be paid to the following points concerning repairs and the fitting of replacement parts and accessories.

Indexing

For convenience the manual is divided into section and parts, each page bearing a section and part number. The sections are subdivided into numbered operation. This simplifies cross referencing and enable the subject to be found easily.

Be the first to review “Sumitomo SH75X-3B Hydraulic Excavator Repair Service Manual”

You must be logged in to post a review.

Reviews

There are no reviews yet.