Sumitomo SH145X-6 Hydraulic Excavator Repair Service Manual

$42.00

Sumitomo Excavator SH145X-6

Format: PDF

Manual Identification: WLSM1456-00T, WCL145X6-0T, WDL1356-1T

English

- Sumitomo SH145X-6 Hydraulic Excavator Repair Service Manual – 1358 Pages

- Operators Manual – 272 Pages

- Parts Catalog – 666 Pages

- Description

- Reviews (0)

Description

Sumitomo SH145X-6 Hydraulic Excavator Repair Service Manual

Sumitomo Excavator SH145X-6

Format: PDF

Manual Identification: WLSM1456-00T, WCL145X6-0T, WDL1356-1T

English

- Sumitomo SH145X-6 Hydraulic Excavator Repair Service Manual – 1358 Pages

- Operators Manual – 272 Pages

- Parts Catalog – 666 Pages

Sumitomo SH145X-6 Manual TABLE OF CONTENTS

Safety, general information and standard torque data…………………………………………… 4

General Information…………………………………………………………………………………………. 5

Standard Torque Data For Cap Screws And Nuts………………………………………………. 14

Specifications And Special Torque Settings………………………………………………………. 15

Abbreviation………………………………………………………………………………………………….. 16

Specifications………………………………………………………………………………………………… 24

Main Equipment Table……………………………………………………………………………………. 33

Overall View………………………………………………………………………………………………….. 51

Main Unit Weight…………………………………………………………………………………………… 57

FLUIDS AND LUBRICANTS……………………………………………………………………………. 75

Circuits and Operation explanation…………………………………………………………………… 79

Main Equipment Structure and Operation Explanation………………………………………… 82

Hydraulic Pump…………………………………………………………………………………………….. 83

Travel Motor………………………………………………………………………………………………… 100

Swing Motor………………………………………………………………………………………………… 113

Control Valve………………………………………………………………………………………………. 121

4 Stack Solenoid Valve Operation Explanation………………………………………………… 160

Upper Pilot Valve (remote control valve)…………………………………………………………. 162

Travel Pilot Valve (remote control valve)…………………………………………………………. 168

Blade Pilot Valve (remote control valve)………………………………………………………….. 173

Cushion Valve …………………………………………………………………………………………….. 175

Engine Summary…………………………………………………………………………………………. 180

Hydraulic Equipment Layout………………………………………………………………………….. 232

Overall View………………………………………………………………………………………………… 233

Port Diagram……………………………………………………………………………………………….. 239

Hydraulic Device………………………………………………………………………………………….. 264

Electrical and Engine Functions and Service Support……………………………………….. 265

Basic Functions…………………………………………………………………………………………… 266

Service Support…………………………………………………………………………………………… 339

Maintenance precautions………………………………………………………………………………. 384

Electrical Equipment Layout Diagram……………………………………………………………… 399

Connection Connector Pin Layout………………………………………………………………….. 429

Sequence Circuit Diagram…………………………………………………………………………….. 432

Removal / Installation and Assembly / Disassembly………………………………………… 449

Removal and Installation of Track………………………………………………………………….. 456

Removal and Installation of Shoe Assembly……………………………………………………. 457

Removal and Installation of Shoe Plate…………………………………………………………… 460

Removal and Installation of Roller………………………………………………………………….. 461

Removal and Installation of Upper Roller………………………………………………………… 462

Assembly and Disassembly of Upper Roller…………………………………………………….. 464

Removal and Installation of Lower Roller………………………………………………………… 470

Assembly and Disassembly of Lower Roller…………………………………………………….. 472

Removal and Installation of Drive Sprocket……………………………………………………… 478

Removal and Installation of Take-up Roller……………………………………………………… 480

Assembly and Disassembly of Take-up Roller…………………………………………………. 482

Removal and Installation of Grease Cylinder…………………………………………………… 490

Assembly and Disassembly of Tension Shock Absorber…………………………………… 492

Removal and Installation of Center Joint…………………………………………………………. 495

Assembly and Disassembly of Center Joint…………………………………………………….. 499

Removal and Installation of Travel Motor………………………………………………………… 506

Assembly and Disassembly of Travel Motor…………………………………………………….. 511

Removal and Installation of Swing Unit…………………………………………………………… 549

Assembly and Disassembly of Swing Motor…………………………………………………….. 553

Assembly and Disassembly of Swing Unit……………………………………………………….. 566

Removal and Installation of Hydraulic Pump……………………………………………………. 570

Removal and Installation of Pump Coupling…………………………………………………….. 574

Procedures for Assembly and Disassembly of Hydraulic Pump Main Unit……………. 577

Pump Main Unit Maintenance Standards………………………………………………………… 583

Removal and Installation of Control Valve……………………………………………………….. 607

Procedures for Assembly and Disassembly of Control Valve……………………………… 612

Removal and Installation of Engine Assembly………………………………………………….. 653

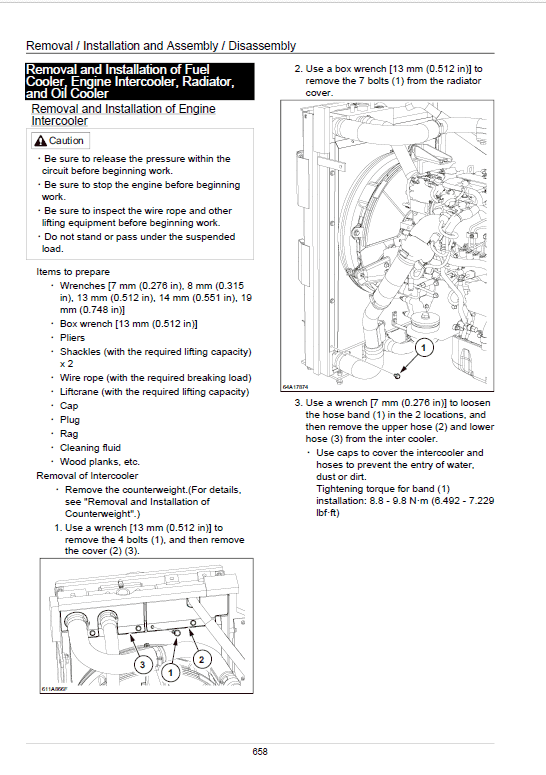

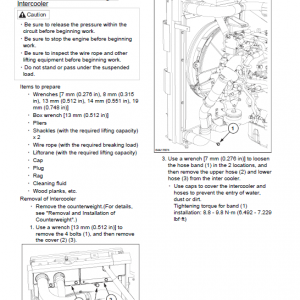

Removal and Installation of Fuel Cooler, Engine Intercooler, Radiator, and Oil

Cooler………………………………………………………………………………………………………… 658

Removal and Installation of Turbo Charger……………………………………………………… 667

Removal and Installation of EGR Valve…………………………………………………………… 670

Removal and Installation of EGR Cooler…………………………………………………………. 671

Removal and Installation of EGR Valve…………………………………………………………… 673

Removal and Installation of Top Cover……………………………………………………………. 674

Removal and Installation of Muffler………………………………………………………………… 675

Removal and Installation of Cylinder Head Cover…………………………………………….. 677

Removal and Installation of Cylinder Block……………………………………………………… 716

Lubrication System………………………………………………………………………………………. 767

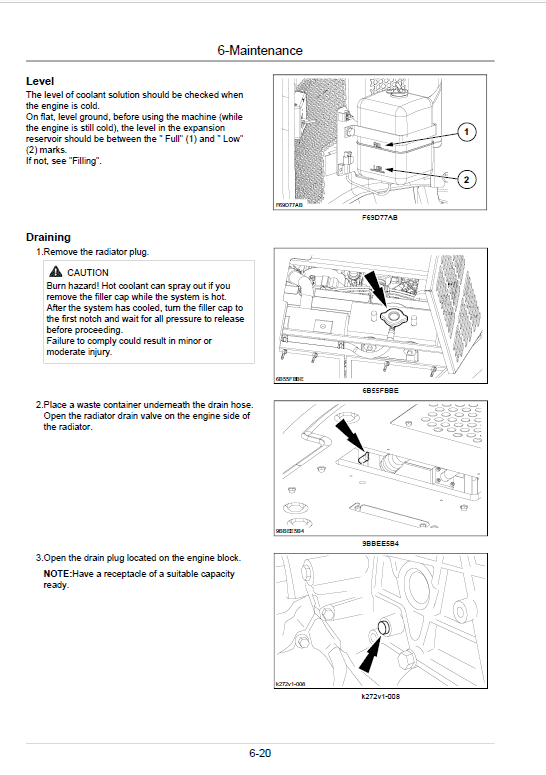

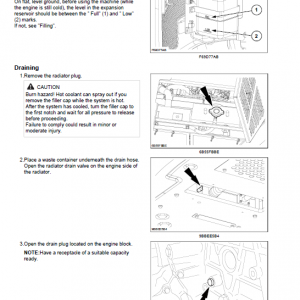

Cooling System……………………………………………………………………………………………. 818

Removal and Installation of Exhaust Manifold………………………………………………….. 824

Disassembly, Removal and Installation of DPD Assembly…………………………………. 829

Removal and Installation of Fuel Supply Pump………………………………………………… 834

Removal and Installation of Common Rail Assembly………………………………………… 848

Removal and Installation of Injector………………………………………………………………… 851

Removal and Installation of Starter Motor……………………………………………………….. 856

Removal and Installation of Alternator…………………………………………………………….. 857

Preheating System………………………………………………………………………………………. 858

Removal and Installation of Fuel Tank……………………………………………………………. 870

Removal and Installation of Hydraulic Oil Tank………………………………………………… 873

Removal and Installation of Pilot Blocs……………………………………………………………. 877

Removal and Installation of Travel Remote Control Valve…………………………………. 878

Procedures for Assembly and Disassembly of Travel Remote Control Valve……….. 881

Removal and Installation of Operation Remote Control Valve……………………………. 894

Procedures for Assembly and Disassembly of Operation Remote Control Valve….. 902

Removal and Installation of Blade Remote Control Valve………………………………….. 913

Assembly and Disassembly Procedures…………………………………………………………. 916

Removal and Installation of 4 Stack Solenoid………………………………………………….. 924

Removal and Installation of Cushion Valve……………………………………………………… 927

Assembly and Disassembly of Cushion Valve………………………………………………….. 931

Removal and Installation of Operator’s Seat……………………………………………………. 935

Removal and Installation of Cab Assembly……………………………………………………… 936

Removal and Installation of Wiper………………………………………………………………….. 940

Removal and Installation of Wiper Controller…………………………………………………… 941

Removal and Installation of Wiper Motor…………………………………………………………. 942

Removal and Installation of ECM…………………………………………………………………… 944

Removal and Installation of Computer A…………………………………………………………. 945

Removal and Installation of Computer B…………………………………………………………. 946

Removal and Installation of Monitor……………………………………………………………….. 947

Removal and Installation of Cab Front Glass…………………………………………………… 948

Window Lock Adjustment Procedures…………………………………………………………….. 950

Tightening torque…………………………………………………………………………………………. 952

Removal and Installation of Counterweight……………………………………………………… 953

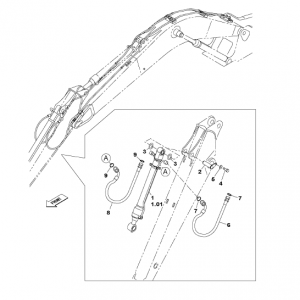

Removal and Installation of Bucket………………………………………………………………… 957

Removal and Installation of Bucket Link………………………………………………………….. 959

Removal and Installation of Arm…………………………………………………………………….. 961

Removal and Installation of Boom………………………………………………………………….. 963

Removal and Installation of Blade………………………………………………………………….. 969

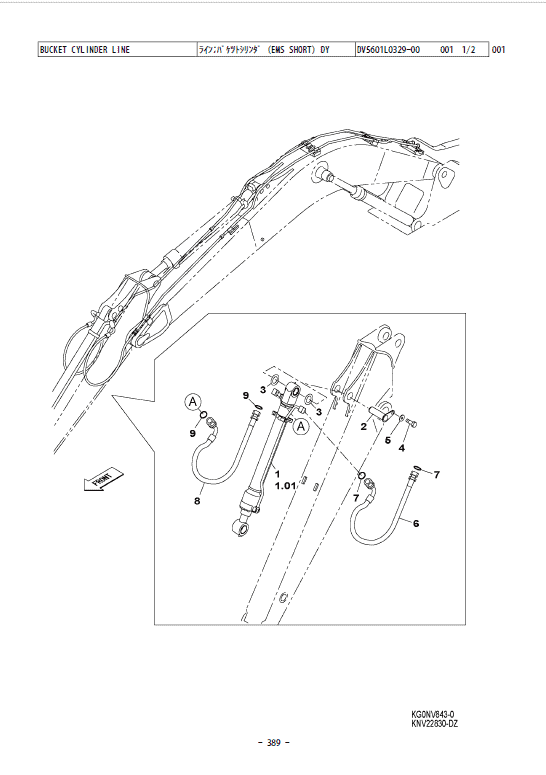

Removal and Installation of Bucket Cylinder……………………………………………………. 971

Removal and Installation of Arm Cylinder………………………………………………………… 974

Removal and Installation of Boom Cylinder……………………………………………………… 979

Removal and Installation of Blade Cylinder……………………………………………………… 984

Procedures for Operation/Assembly and Disassembly of Hydraulic Cylinder

(made by KYB)……………………………………………………………………………………………. 988

Removal and Installation of HBCV……………………………………………………………….. 1028

List of special tools…………………………………………………………………………………….. 1031

Maintenance standards and Measurement procedures………………………………….. 1053

Pressure Measurement and Adjustment Procedures………………………………………. 1054

Hydraulic Pump Flow Measurement Procedures……………………………………………. 1069

Drain Volume Measurement Procedures……………………………………………………….. 1073

Air Bleed Procedure……………………………………………………………………………………. 1076

Maintenance Standards………………………………………………………………………………. 1079

Bolt Size and Torque Table…………………………………………………………………………. 1094

Air Conditioning…………………………………………………………………………………………… 1101

Air Conditioner Overall Diagram…………………………………………………………………… 1102

Assembly and Disassembly of Unit………………………………………………………………. 1144

Removal and Installation of Compressor……………………………………………………….. 1149

Removal and Installation of Condenser…………………………………………………………. 1150

Removal and Installation of Receiver Dryer…………………………………………………… 1152

Work Precautions………………………………………………………………………………………. 1153

Troubleshooting…………………………………………………………………………………………… 1163

Engine-side Diagnostic Trouble Code List……………………………………………………… 1166

Main Unit-side Diagnostic Trouble Code List………………………………………………….. 1168

Engine-side Trouble……………………………………………………………………………………. 1170

Main Unit-side Trouble………………………………………………………………………………… 1238

Symptom…………………………………………………………………………………………………… 1335

Data Reference Values……………………………………………………………………………….. 1348

The Sumitomo Manual Preface

The purpose of this Sumitomo Excavator manual is to assist dealers and repair serviceman in efficient repair and maintenance of their machinery. Carrying out the procedures as detailed, together with the use of any special tools needed.

Using the Sumitomo SH145X-6 Manual

To make information easier to find, there is an index at the beginning of each section listing the various parts in that section. At the beginning of each part there is a table of contents which should also be used as a guide to locate information.

To assist with locating information, each section of the manual is preceded by a contents page listing the repair operations, Each instruction within an operating has a sequence number. To complete the operation in the minimum time is possible follow the manual guideline and repair instructions.

When parts have to be replaced in either the SH145X-6 Hydraulic Excavator , it is essential that only genuine Sumitomo parts should be used. Special attention should be paid to the following points concerning repairs and the fitting of replacement parts and accessories.

Indexing

For convenience the manual is divided into section and parts, each page bearing a section and part number. The sections are subdivided into numbered operation. This simplifies cross referencing and enable the subject to be found easily.

Be the first to review “Sumitomo SH145X-6 Hydraulic Excavator Repair Service Manual”

You must be logged in to post a review.

Reviews

There are no reviews yet.