Hitachi ZW100 and ZW120 Wheel Loader Service Repair Manual

$34.00

Service Repair Manual (Troubleshooting) : Vol. No.T4FJ-E-00 (442 Pages)

Workshop Manual : Vol. No.W4FJ-E-00 (350 Pages)

- Description

- Reviews (0)

Description

Hitachi ZW100 and ZW120 Wheel Loader Service Manual

The manual is applicable for the Hitachi ZW100 and ZW120 Wheel Loader Model

Format: PDF

Language: English

Service Manual consists of the following:

For Model ZW100 and ZW120 as mentioned above:

Service Manual (Troubleshooting) : Vol. No.T4FJ-E-00 (442 Pages)

Workshop Manual : Vol. No.W4FJ-E-00 (350 Pages)

Table of Content of the Workshop Manual

SECTION 1 GENERAL INFORMATION

Group 1 Precautions for disassembling

and Assembling

Group 2 Tightening Torque

Group 3 Painting

Group 4 Bleeding Air from Hydraulic

Circuit

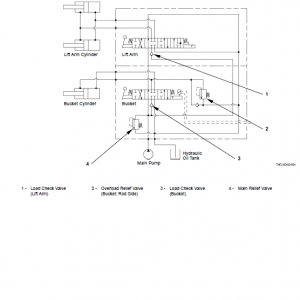

Group 5 Hydraulic Circuit Pressure

Release Procedure

Group 6 Preparation

SECTION 2 BODY

Group 1 Cab

Group 2 Counterweight

Group 3 Center Hinge

Group 4 Hydraulic Oil Tank

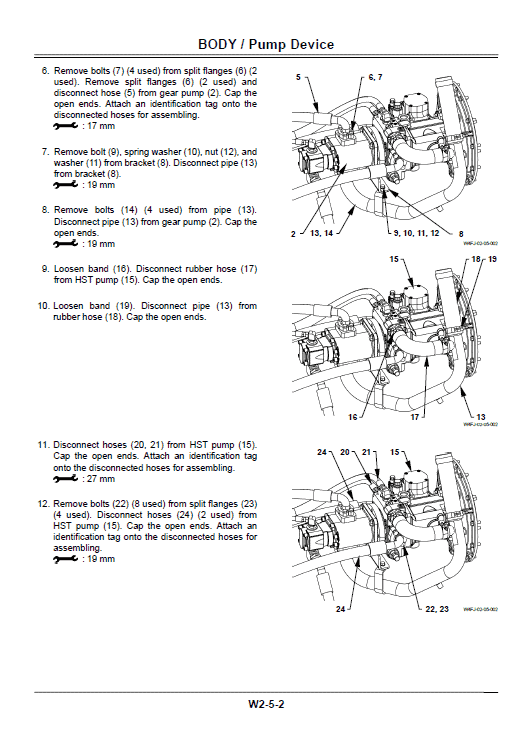

Group 5 Pump Device

Group 6 Control Valve

Group 7 Steering Valve

Group 8 Brake Valve

Group 9 Priority Valve

Group 10 Inching Valve

SECTION 3 TRAVEL SYSTEM

Group 1 Steering Cylinder

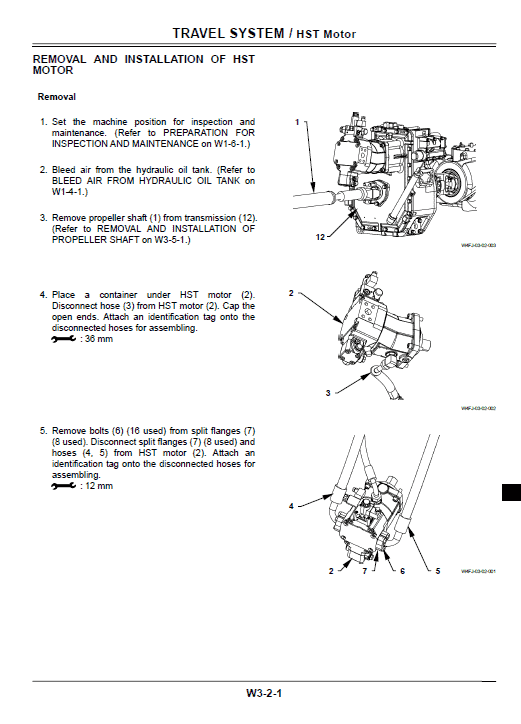

Group 2 HST Motor

Group 3 Transmission

Group 4 Axle

Group 5 Propeller Shaft

Group 6 Tire

SECTION 4 ATTACHMENT

Group 1 Front Attachment

Group 2 Cylinder

Table of Content of the Technical Manual

SECTION 4 OPERATIONAL PERFORMANCE

TEST

Group 1 Introduction

Group 2 Standard

Group 3 Engine Test

Group 4 Wheel Loader Test

Group 5 Component Test

SECTION 5 TROUBLESHOOTING

Group 1 Diagnosing Procedure

Group 2 Dr. ZX

Group 3 e-Wheel

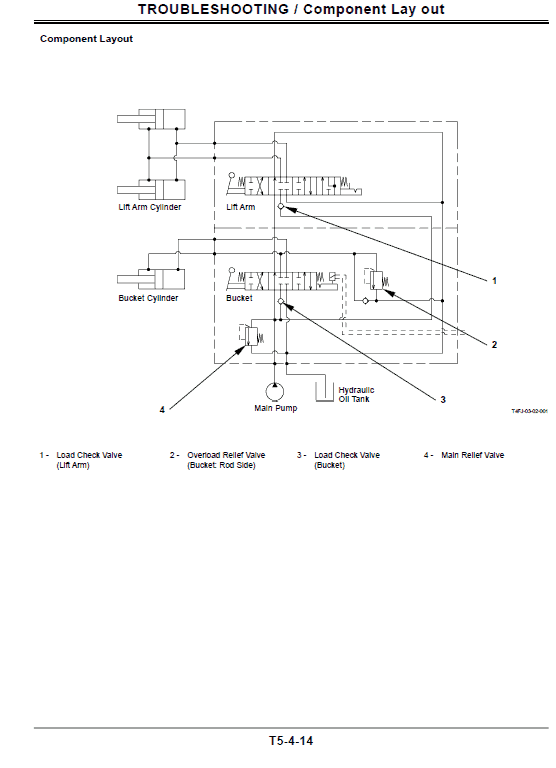

Group 4 Component Layout

Group 5 Troubleshooting A

Group 6 Troubleshooting B

Group 7 Troubleshooting C

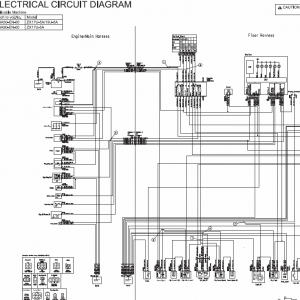

Group 8 Electrical System Inspection

Manual guide composition

Hitachi ZAXIS ZW100 and ZW120 service manual consists of the Troubleshooting and the Workshop Manual.

- Information included in the Service Manual: Technical information needed for redelivery and delivery, operation and activation of all devices and systems, operational performance tests, and troubleshooting procedures.

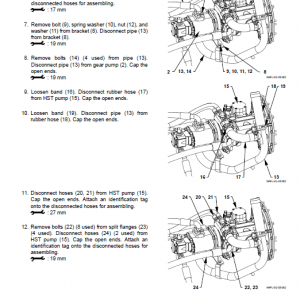

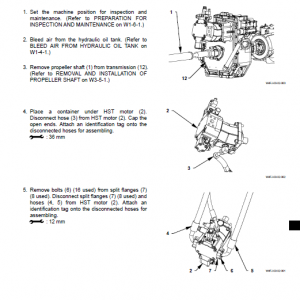

- Information included in the Workshop Manual: Technical information needed for maintenance and repair of the machine, tools and devices needed for maintenance and repair, maintenance standards, and removal / installation and assemble / disassemble procedures.

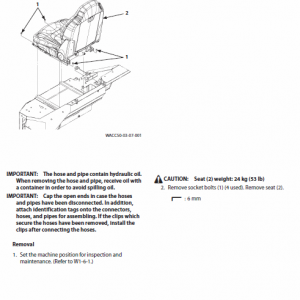

If the refrigerant container becomes empty during the charging work, replace it with a new refrigerant container as follows:

• Close the high pressure and low pressure valves on the manifold gauge.

• Replace the empty container with a new one.

• Tighten, then slightly loosen the refrigerant container joint.

• Slightly open the low pressure valve on the manifold gauge.

• When the refrigerant container joint starts to leak, immediately tighten the refrigerant container joint and close the low pressure valve on the manifold gauge.

Be the first to review “Hitachi ZW100 and ZW120 Wheel Loader Service Repair Manual”

You must be logged in to post a review.

Reviews

There are no reviews yet.