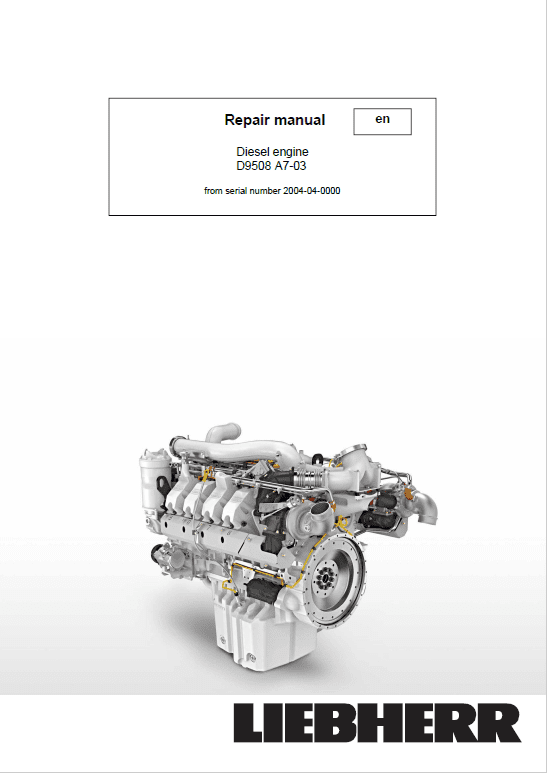

Liebherr D9508 A7-03 Diesel Engine Service Repair Manual

$37.00

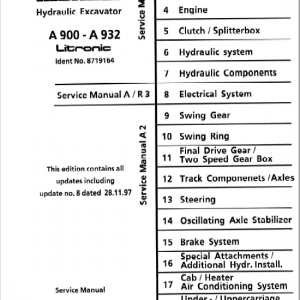

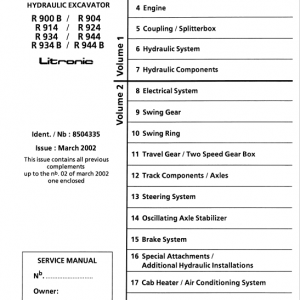

Manual Included:

- Service Repair Manual: 326 Pages

- Operators Manual: 82 Pages & 186 Pages

Specifications:

- Brand: Liebherr

- Model: D9508 A7-03

- Type: Engine

- Manuals: Service Repair Manual & Operators Manual

- Publication Numbers:

- Language: English

- Format: PDF

- Description

- Reviews (0)

Description

Table of Content of the D9508 A7-03 Manual:

1 General information

1.1 Structure of these instructions

1.2 Important notes in these instructions

1.3 Safety instructions

1.4 Safety instructions for working on the fuel and injection system

1.5 Engine diagrams and engine components

1.6 Technical data

1.7 Standard torques

1.8 Special torques, tensioning instructions, instructions for mounting and installation instructions

1.9 Cleaning and locking agents, greases

1.10 Fuel diagram

1.11 Lubricating oil diagram

1.12 Coolant diagram

1.13 Charge air diagram

1.14 Assigning the channels in the crankcase and the cylinder head

1.15 Transport device and fastening parts

1.16 Tools

2 Cylinder head, engine control unit and valves

2.1 Removing and installing the cylinder head cover

2.2 Removing and installing the rocker arm bracket and push rods

2.3 Removing and installing the valve bridge (engines with and without ABS)

2.4 Removing and installing the cylinder head

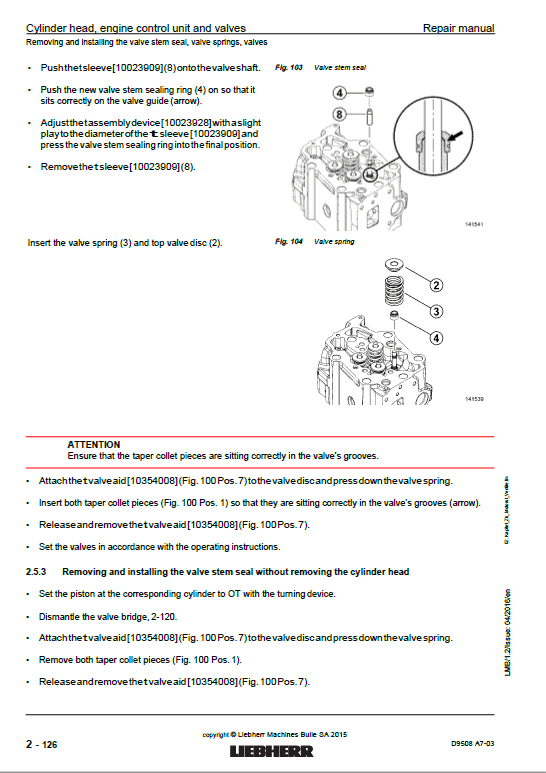

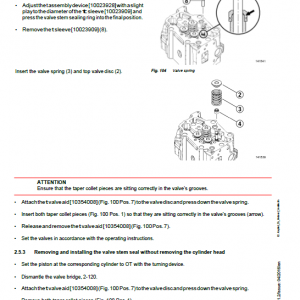

2.5 Removing and installing the valve stem seal, valve springs, valves

2.6 Removing and installing the roller tappet

2.7 Removing and installing the camshaft

2.8 Removing and installing the camshaft bearing

3 Driving gear

3.1 Removing and installing the piston with connecting rod and piston rings

3.2 Removing and installing the cylinder liner

3.3 Removing and installing the crankshaft attachments

3.4 Removing and installing the front crankshaft seal

3.5 Removing and installing the unit carrier

3.6 Removing and installing the intermediate wheel

3.7 Removing and installing the flywheel

3.8 Removing and installing the rear crankshaft seal

3.9 Removing and installing the crankshaft gear wheel

3.10 Removing and installing the flywheel housing

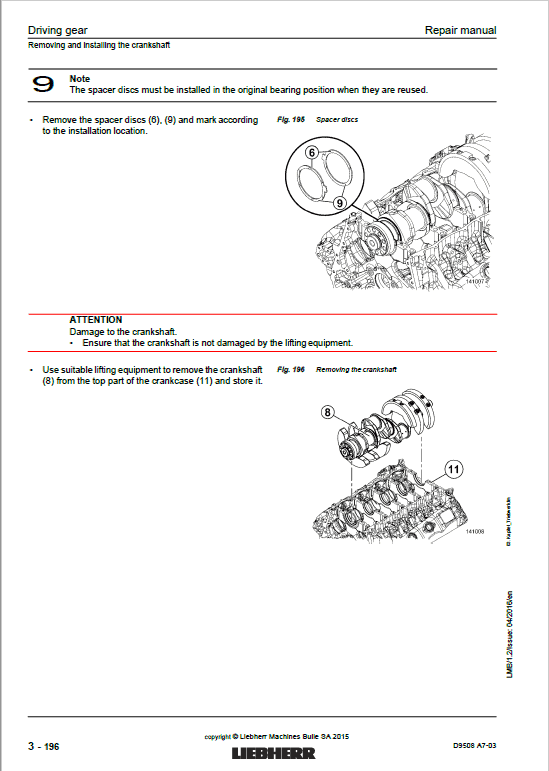

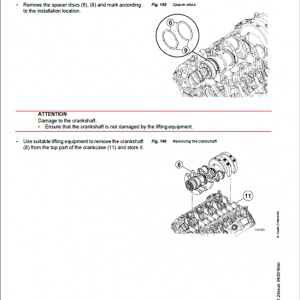

3.11 Removing and installing the crankshaft

4 Fuel and injection system

4.1 Removing and installing the fuel lines

4.2 Removing and installing the injection line

4.3 Removing and installing the rail

4.4 Removing and installing the pressure pipe branch and injector

4.5 Removing and installing the fuel fine filter module

4.6 Removing and installing the high pressure pump

4.7 Removing and installing the high pressure pump drive

5 Belt drive

5.1 Removing and installing the V-ribbed belt tensioning device and deflection rollers

6 Charge air and exhaust system

6.1 Removing and installing the intake branch

6.2 Removing and installing the charge air line

6.3 Removing and installing the air intake

6.4 Removing and installing the connecting line

6.5 Removing and installing the air intake pipe

6.6 Removing and installing the exhaust branch

6.7 Removing and installing the charge air control unit

6.8 Removing and installing the exhaust turbocharger

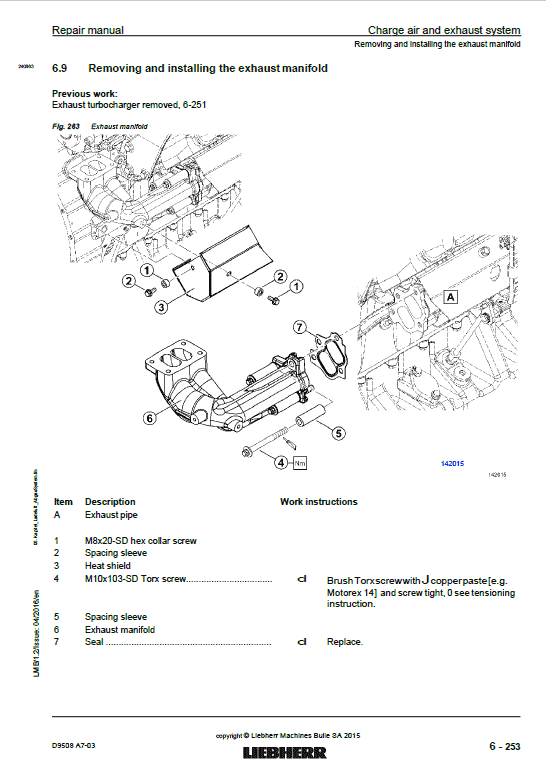

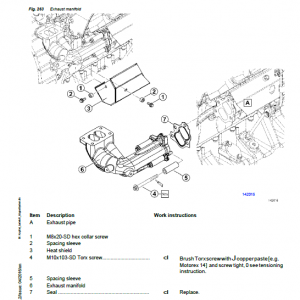

6.9 Removing and installing the exhaust manifold

6.10 Removing and installing the exhaust pipe

6.11 Removing and installing the exhaust gas recycling EXR

7 Electrical system

7.1 Removing and installing the heating flange

7.2 Removing and installing the alternator

7.3 Removing and installing the starter

7.4 Removing and installing the engine control unit

7.5 Removing and installing the engine control unit console

7.6 Removing and installing sensors

7.7 Replacing the cable harness

8 Lubrication system

8.1 Removing and installing the end control valve

8.2 Removing and installing the crankcase ventilation pipeline

8.3 Removing and installing the crankcase ventilation

8.4 Removing and installing the oil module

8.5 Removing and installing the oil cooler

8.6 Removing and installing the oil pan

8.7 Removing and installing the lubricating oil pump

8.8 Removing and installing the piston cooling

9 Cooling system

9.1 Removing and installing the ventilation line

9.2 Removing and installing the coolant manifold

9.3 Removing and installing the coolant pump

9.4 Removing and installing the thermostat housing

9.5 Removing and installing the thermostats

9.6 Check the thermostat

10 Auxiliary output, air conditioning compressor, fan

10.1 Removing and installing auxiliary output 1

10.2 Removing and installing auxiliary output 2

10.3 Removing and installing the locking pieces for the auxiliary outputs

10.4 Removing and installing the air conditioning compressor

10.5 Removing and installing the air compressor

10.6 Removing and installing the fan and fan drive

11 Appendix

11.1 Abbreviations used

This service handbook comprises a summary of the most important maintenance, adjustment and repair tasks, as well as details regarding technical data and tightening specifications for screws for Liebherr diesel engine D9508 A7-03 It is prerequisite that these tasks are performed by trained, specialist personnel.

The repair work is divided into sections and sub-sections. Each sub-section begins with a page, which lists the necessary prerequisites for the work. The prerequisites for the work contain a summary of the essential specification for the represented repair section. The work prerequisites can take the form of a detailed description of the work. In the repair chapters the only torque tightening values quoted are those which differ from the values given in the standard for screw connections.

Important instructions, which relate to technical safety and personal protection, are, as indicated in the following, given special emphasis. During all repair work the general safety instructions must be observed.

Be the first to review “Liebherr D9508 A7-03 Diesel Engine Service Repair Manual”

You must be logged in to post a review.

Reviews

There are no reviews yet.