Komatsu D61EXi-23, D61PXi-23 Dozer Service Manual

$35.00

Manual Included:

- Shop Manual: 1939 pages

- Operation and Maintenance Manual: 163 pages

Specifications:

- Brand: Komatsu

- Model: D61EXi-23, D61PXi-23

- Type: Dozer

- Serial Number: 30324 and up

- Manuals: Shop Manual and Operation and Maintenance Manual

- Publication Numbers: SEN06256-01 and TEN00616-04

- Language: English

- Format: PDF

- Description

- Reviews (0)

Description

Table of Contents

- Index and foreword

- Specification

- Structure, function and maintenance standard

- Standard value table

- Testing and adjusting

- Troubleshooting

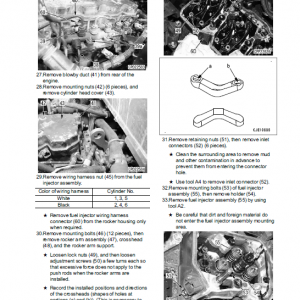

- Disassembly and assembly

- Maintenance Standard

- Appendix

- Diagrams and drawings

- Index

Proper service and repair are extremely important for safe machine operation. The service and repair techniques recommended by Komatsu and described in this manual are both effective and safe. Some of these techniques require the use of tools specially designed by Komatsu for the specific purpose.

Overall disassembly and assembly of track shoe assembly (Standard type track shoe)

This section of the manual describes the lubricated track.

1. Place the track shoe assembly on a flat floor with the shoes facing up. Remove the track shoe bolt from the master link and remove the shoe.

Loosen master link bolts without using an impact wrench.

2. If a half assembly (in mass and length) is too large for disassembly and assembly, divide the track shoe assembly into quarter assemblies.

3. Sling the track shoe assembly, and place the assembly on the floor with the shoes up.

Remove the track shoe from the regular link by using an impact wrench.

When repositioning the track shoe assembly, be careful not to damage the master links.

If the shoe nut needs to be removed by gas cut, keep the temperature in the seal section below 80°C to prevent thermal deterioration of the seals. Take measures to prevent the spatters from entering through the clearances between the links.

4. Draining oil

Before disassembling the link assembly, drain oil from inside the pin to prevent the link press being smeared with oil.

If it is decided that the track should be rebuilt as a dry type track before starting the disassembly, the following work is not necessary to perform.

1) Place the link assembly on a flat floor with the large plug side facing up and chamfer the pin end to remove burrs by using a grinder, etc.

If the track shoe is disassembled with burrs remaining on the pin end faces, the pin press-fitting hole in the link will be damaged and result in oil leaks from the press-fitting portion after the track is rebuilt.

Be the first to review “Komatsu D61EXi-23, D61PXi-23 Dozer Service Manual”

You must be logged in to post a review.

Reviews

There are no reviews yet.