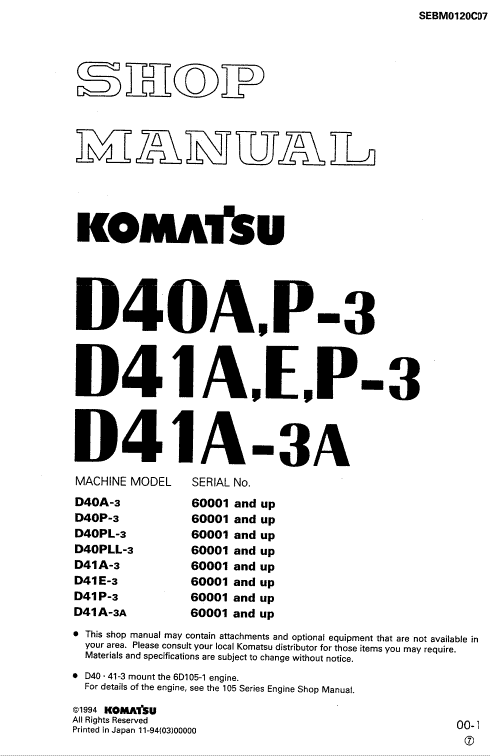

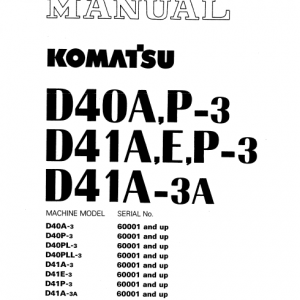

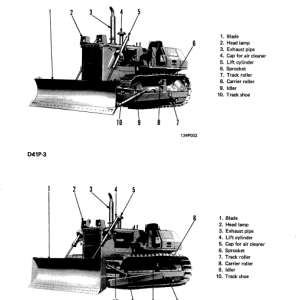

Komatsu D40A-3, D40P-3, D40PL-3, D40PLL-3 Dozer Service Manual

$33.00

Manual Included:

- Shop Manual: 556 pages

Specifications:

- Brand: Komatsu

- Model: D40A-3, D40P-3, D40PL-3, D40PLL-3

- Type: Dozer

- Serial Number: 60001 and up

- Manuals: Shop Manual

- Publication Numbers: SEBM0120C07

- Language: English

- Format: PDF

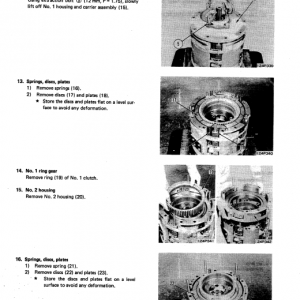

- Description

- Reviews (0)

Description

Table of Contents

10 ENGINE

11 STRUCTURE AND FUNCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-1

12 TESTING AND ADJUSTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 2-1

13 DISASSEMBLY AND ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-1

20 POWER TRAIN

21 STRUCTURE AND FUNCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21 -1

22 TESTING AND ADJUSTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22-1

23 DISASSEMBLY AND ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23-1

24 MAINTENANCE STANDARD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24-1

30 UNDERCARRIAGE

31 STRUCTURE AND FUNCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31 -1

33 DISASSEMBLY AND ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33-1

34 MAINTENANCE STANDARD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34-1

60 HYDRAULIC SYSTEM

61 STRUCTURE AND FUNCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61-1

62 TESTING AND ADJUSTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62-1

63 DISASSEMBLY AND ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63-1

64 MAINTENANCE ST AND ARD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64-1

70 WORK EQUIPMENT

71 STRUCTURE AND FUNCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71-1

73 DISASSEMBLY AND ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73-1

7 4 MAINTENANCE STANDARD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 4-1

90 ELECTRIC AND ELECTRONIC SYSTEM

90 ELECTRONIC SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90-1

This shop manual has been prepared as an aid to improve the quality of repairs by giving the serviceman an accurate understanding of the product and by showing him the correct way to perform repairs and make judgements. Make sure you understand the contents of this manual and use it to full effect at every opportunity.

This shop manual mainly contains the necessary technical information for operations performed in a service workshop. For ease of understanding, the manual is divided into the following chapters; these chapters are further divided into the each main group of components.

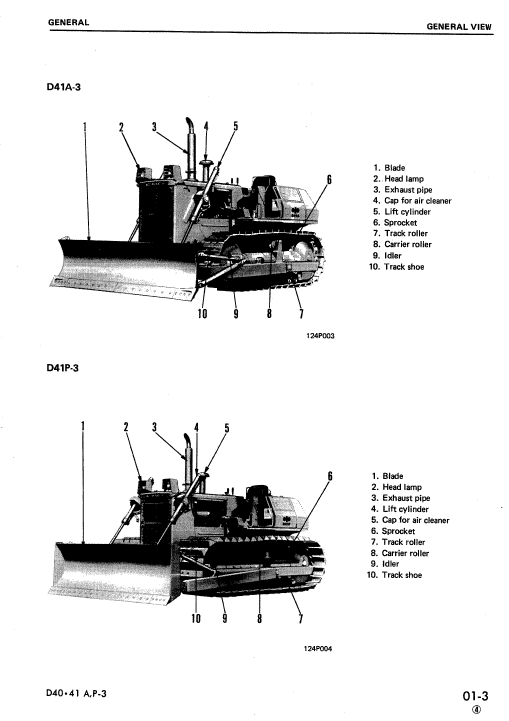

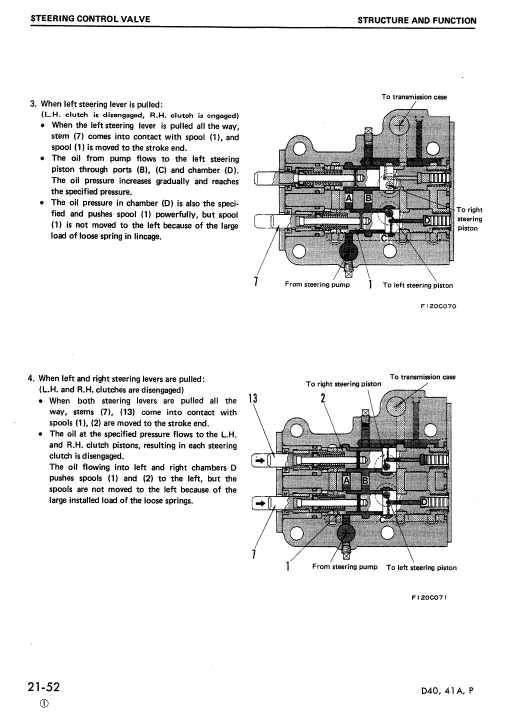

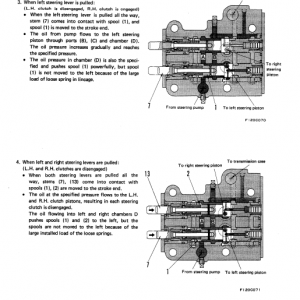

STRUCTURE AND FUNCTION

This section explains the structure and function of each component. It serves not only to give

an understanding of the structure, but also serves as reference material for troubleshooting.

TESTING AND ADJUSTING

This section explains checks to be made before and after performing repairs, as well as adjustments to be made at completion of the checks and repairs. Troubleshooting charts correlating “Problems” to “Causes” are also included in this section.

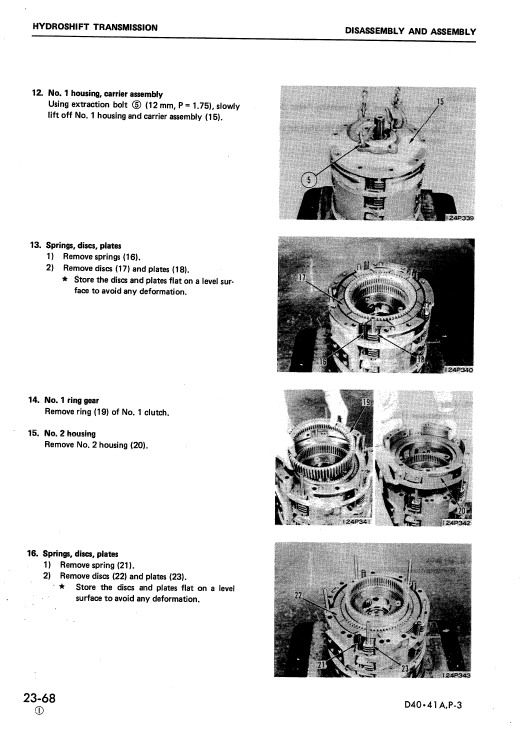

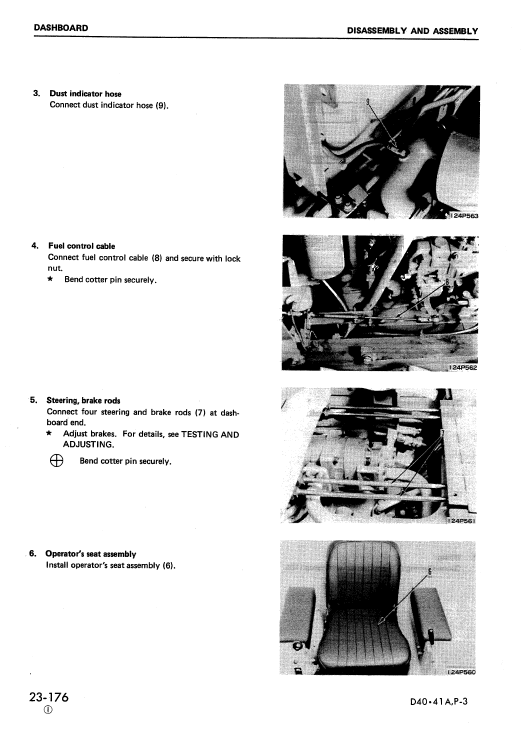

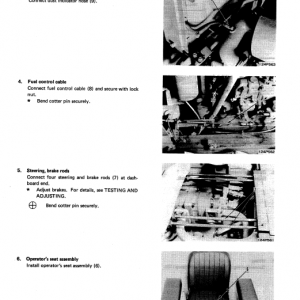

DISASSEMBLY AND ASSEMBLY

This section explains the order to be followed when removing, installing, disassembling or assembling each component, as well as precautions to be taken for these operations.

MAINTENANCE STANDARD

This section gives the judgement standards when inspecting disassembled parts.

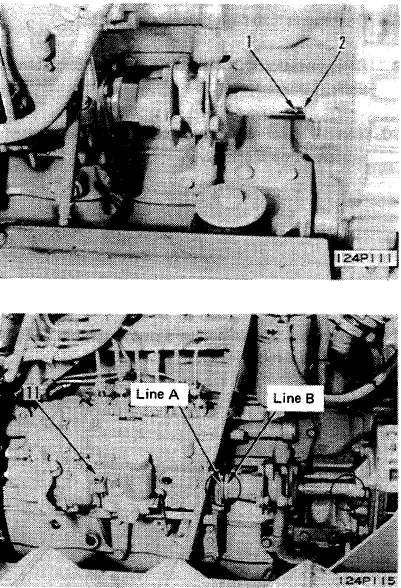

3. Adjust fuel injection timing as follows.

1) Rotate crankshaft in normal direction and align pointer (2) with line on drive shaft (1 ). * When doing this, if the line on the coupling is not at the front, rotate one more turn.

2) Move injection pump to inside or outside, and align line A on pump side with line B on coupling side.

3) Hold injection pump in this position and tighten four mounting bolts (11) uniformly and in turn.

When repairing or replacing the fuel injection pump, or when there are no lines

marked, adjust the injection timing by the delivery method.

For details of adjustment, see TESTING AND ADJUSTING FUEL INJECTION TIMING.

Be the first to review “Komatsu D40A-3, D40P-3, D40PL-3, D40PLL-3 Dozer Service Manual”

You must be logged in to post a review.

Reviews

There are no reviews yet.