John Deere 5085M, 5100M, 5100MH, 5100ML, 5115M, 5115ML (FT4) Tractors Repair Manual

$60.00

Manual Included:

- Repair Technical Manual: 1209 Pages (TM134219)

- Diagnostic Manual: 1356 Pages (TM134319)

- Operators Manual: 362 Pages (OMSU43612)

Specifications:

- Brand: John Deere

- Model: 5085M, 5100M, 5100MH, 5100ML, 5115M, 5115ML with Final Tier 4 Engine (FT4)

- Type: Tractor

- Manuals: Repair Technical Manual, Diagnostic Manual, Operators Manual

- Publication Numbers: TM134219, TM134319 and OMSU43612

- Language: English

- Format: PDF

- Description

- Reviews (0)

Description

Table of Content

Foreword

General Information

Safety

General References

Technical Specific References

Diagnostic Trouble Codes

Observable Symptoms and System Diagnostics

General References

Engine Diagnostics

Fuel, Air Intake, Exhaust, and Cooling Diagnostics

Electrical Diagnostics

Electronic Control Unit Diagnostics

Drive Systems and Transmission Diagnostics

Steering and Brakes Diagnostics

Hydraulic Diagnostics

Cab/Open Operator`s Station Diagnostics

Engine

General References

Engine Component and Connector Information

Engine Tests and Adjustments

Fuel, Air Intake, Exhaust, and Cooling

General References

Fuel, Air Intake, Exhaust, and Cooling Theory of Operation

Electrical General and Theory of Operation

General References

Turn Signal Switch and Warning Lights

Wipers (Two Speed)

Rear Wipers

Instrument Cluster Control (ICC)

Electrohydraulic Control Unit (EHC)

Hitch Control Unit (HCU)

Power Train Reverser (PTR)

Chassis Control Unit (CCU) (PR Transmission)

Chassis Control Unit (CCU) (SS Transmission)

Engine Control Unit (ECU)

Controller Area Network

Electrical Schematics

General References

Key Switch, Starter, and Alternator (SE01)

Neutral Start (SS Transmission) (SE02A)

Neutral Start (PR Transmission) (SE02B)

Accessory Power (SE03)

Horn (SE04)

Light Switch and Headlights (SE05A)

Turn and Brake Lights (SE05B)

Cab Work Lighting (SE05C)

Open Operator Station Work Lighting (SE05D)

Warning Lights (SE06)

Junction Block Power (SE09)

Implement Connector (SE10)

Loader Lights (SE12)

Back-Up Alarm (SE13A)

Beacon Light (SE13B)

Mid-Mount SCV (SE14)

Power Outlets (SE15)

Heating (SE16)

Air Conditioning (SE17)

Front Wiper (Two Speed) (SE19)

Rear Wiper (SE21)

Dome Light, Door Switch, and Radio (SE22)

Air Seat (SE23)

Instrument Cluster Control (ICC) (SE24)

Seat Switch, Rear PTO Switch, and Wheel Speed Sensor (SE25)

ELX Relay and Fuses (SE26)

Mechanical Front-Wheel Drive (MFWD) (SE27)

Brake Switch (SE28)

Chassis Control Unit (CCU) (PR Transmission) (SE29A)

Electrohydraulic Control Unit (EHC) (SE29B)

Hitch Control Unit (HCU) (SE29C)

Chassis Control Unit (CCU) (SS Transmission) (SE29D)

Engine Control Unit (ECU) (SE30)

Controller Area Network (SE32)

AutoTrac Universal (ATU) (SE33)

JDLink (SE34)

Electrical Components and Connectors

General References

Key Switch, Starter, and Alternator (SE01)

Neutral Start (SS Transmission) (SE02A)

Neutral Start (PR Transmission) (SE02B)

Accessory Power (SE03)

Horn (SE04)

Light Switch and Headlights (SE05A)

Turn and Brake Lights (SE05B)

Cab Work Lighting (SE05C)

Open Operator Station Work Lighting (SE05D)

Warning Lights (SE06)

Junction Block Power (SE09)

Implement Connector (SE10)

Loader Lights (SE12)

Back-Up Alarm (SE13A)

Beacon Light (SE13B)

Mid-Mount SCV (SE14)

Power Outlets (SE15)

Heating (SE16)

Air Conditioning (SE17)

Front Wiper (Two Speed) (SE19)

Rear Wiper (SE21)

Dome Light, Door Switch and Radio (SE22)

Air Seat (SE23)

Instrument Control Cluster (ICC) (SE24)

Seat Switch, Rear PTO Switch, and Wheel Speed Sensor (SE25)

ELX Relay and Fuses (SE26)

Mechanical Front-Wheel Drive (MFWD) (SE27)

Brake Switch (SE28)

Chassis Control Unit (CCU) (PR Transmission) (SE29A)

Electrohydraulic Control Unit (EHC) (SE29B)

Hitch Control Unit (HCU) (SE29C)

Chassis Control Unit (CCU) (SS Transmission) (SE29D)

Engine Control Unit (ECU) (SE30)

Controller Area Network (SE32)

AutoTrac Universal (ATU) (SE33)

JDLink (SE34)

Fuses and Relays

Ground Points

Interconnects

Wiring Harnesses

Electrical Tests and Adjustments

General References

Tests and Adjustments

Electronic Control Units

General References

Calibrations, Preliminary Checks and Operational Checks

Theory of Operation

Schematics

Component and Connector Information

Tests and Adjustments

Chassis Control Unit (CCU)

Engine Control Unit (ECU)

Engine Interface Control Unit (EIC)

Hitch Control Unit (HCU)

Instrument Cluster Control Unit (ICC)

Power Train Reverser (PTR)

Drive Systems and Transmissions

General References

Calibrations, Preliminary Checks and Operational Checks

Creeper Theory of Operation

Differential Theory of Operation

Differential Lock Theory of Operation

Final Drive Theory of Operation

Rear PTO Theory of Operation

High Crop Axle Theory of Operation

MFWD Theory of Operation

PR Transmission Theory of Operation

PR Plus Transmission Theory of Operation

SS Transmission Theory of Operation

Drive Systems Schematics

Transmission Schematics

Drive Systems Component and Connector Information

Transmission Component and Connector Information

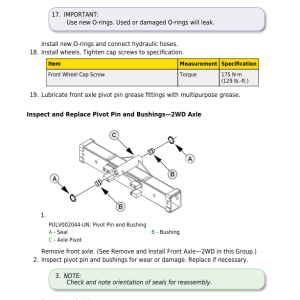

Drive Systems Tests and Adjustments

Transmission Tests and Adjustments

Steering and Brakes

General References

Brake Calibrations, Preliminary Checks and Operational Checks

Steering Calibrations, Preliminary Checks and Operational Checks

Brake Theory of Operation

Steering Theory of Operation

Brake Schematics

Steering Schematics

Brake Component and Connector Information

Steering Component and Connector Information

Brake Tests and Adjustments

Steering Tests and Adjustments

Hydraulics

General References

Hydraulic Calibrations, Preliminary and Operational Checks

General Hydraulics Theory of Operation

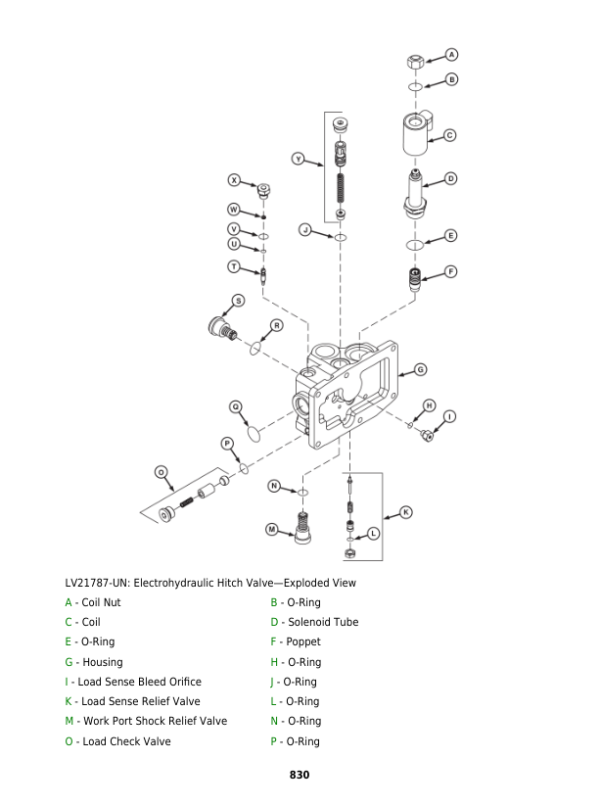

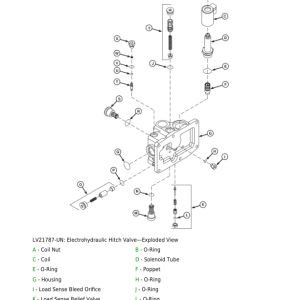

Electrohydraulic Hitch Theory of Operation

Mechanical Hitch Theory of Operation

Front Hitch Theory of Operation

Hydraulic Filter Theory of Operation

Hydraulic Pump Theory of Operation

Dual Mid-Mount SCV Theory of Operation

Power Beyond Theory of Operation

Quick Disconnect Coupler Theory of Operation

Dual Rear SCV Theory of Operation

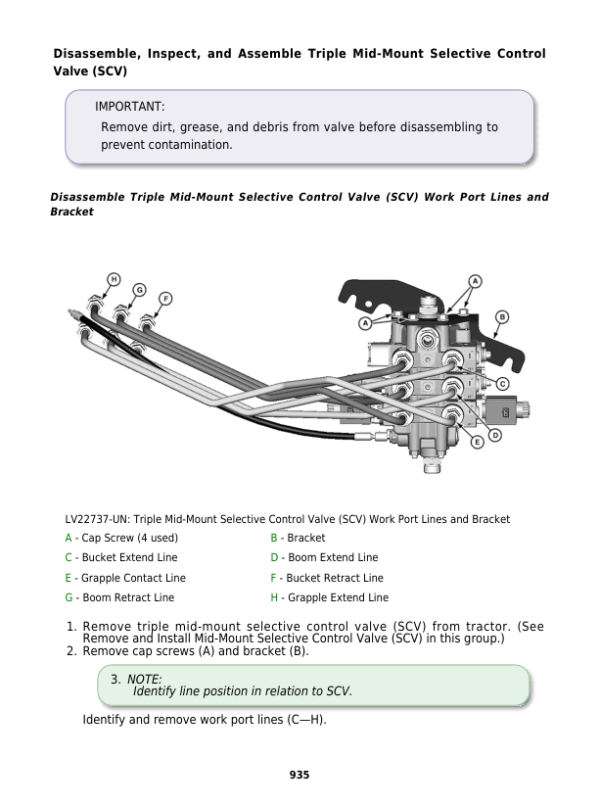

Triple Mid-Mount SCV Theory of Operation

Triple Rear SCV Theory of Operation

Schematics

Component and Connector Information

Tests and Adjustments

Cab/Open Operator`s Station

General References

Calibrations, Preliminary Checks and Operational Checks

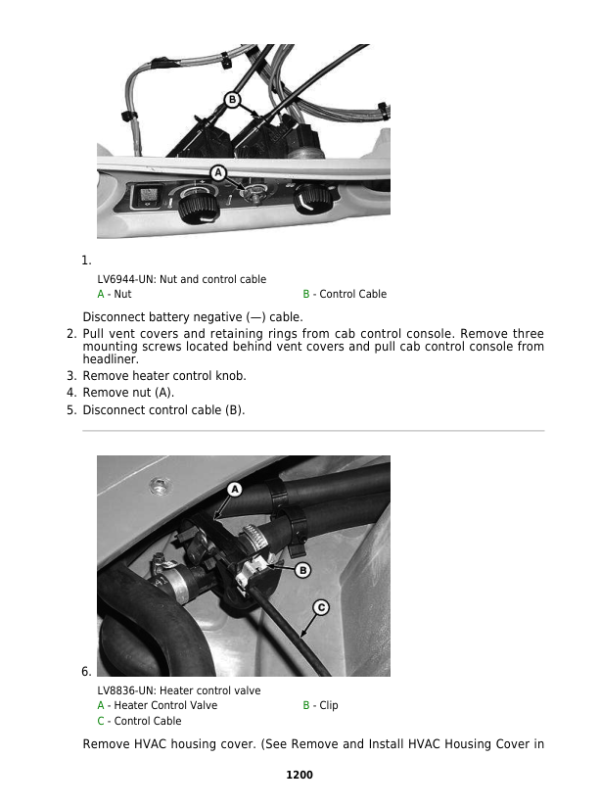

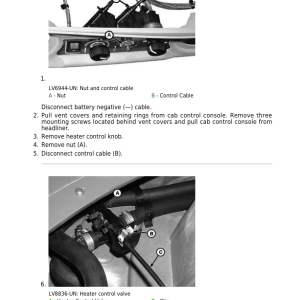

HVAC Theory of Operation

Seat Theory of Operation

Schematics

Component and Connector Information

Tests and Adjustments

Special Tools

General References

Dealer Fabricated and Service Tools

Technical Manuals are concise guides for specific machines. They are on-the-job guides containing only the vital information needed for diagnosis, analysis, testing, and repair.

Fundamental service information is available from other sources covering basic theory of operation, fundamentals of troubleshooting, general maintenance, and basic type of failures and their causes.

Be the first to review “John Deere 5085M, 5100M, 5100MH, 5100ML, 5115M, 5115ML (FT4) Tractors Repair Manual”

You must be logged in to post a review.

Reviews

There are no reviews yet.