Hino Truck FD2J, FE2J, FF2J, SG1J, SG2J Year 2002 Repair Manual (FD, FE, FF, SG)

$36.00

This is the Repair and Service Manual for Hino Truck 2002

Series: FD, FE, FF, SG

Format: PDF

Language: English

- Hino 2002 Truck FD, FE, FF, SG Series Manual – 1528 Pages

- Hino J05D-TA Engine Manual – 324 Pages

- Hino J08E-TA & J08E-TB Engine Manual – 351 Pages

- Description

- Reviews (0)

Description

Hino Truck FD2J, FE2J, FF2J, SG1J, SG2J Year 2002 Repair Manual (FD, FE, FF, SG)

This is the Repair and Service Manual for Hino Truck 2002

Series: FD, FE, FF, SG

Format: PDF

Language: English

- Hino 2002 Truck FD, FE, FF, SG Series Manual – 1528 Pages

- Hino J05D-TA Engine Manual – 324 Pages

- Hino J08E-TA & J08E-TB Engine Manual – 351 Pages

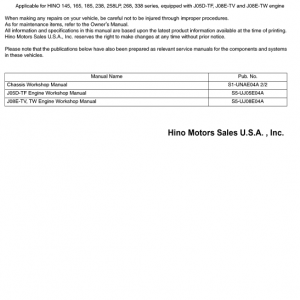

This workshop manual has been prepared to provide information covering repairs on FD, FE, FF, SG series Hino 2002 trucks.

To use Hino 2002 trucks for years, smoothly, safely, and economically without trouble, it is important to perform inspections.

Maintenance required to be performed is the responsibility of the owner. Some recommended repairs of your truck are mentioned. When making any repair of your truck, be careful not to be injured through improper procedures.

As for maintenance items, refer to the Owners and Drivers Manual. All information and specifications in this manual are based upon the latest product information available at the time of printing.

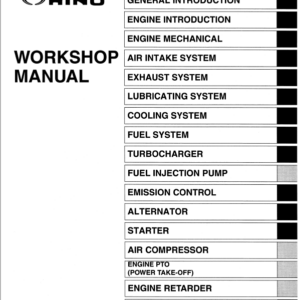

Table of Content For Hino 2002 Truck Manual:

General Introduction

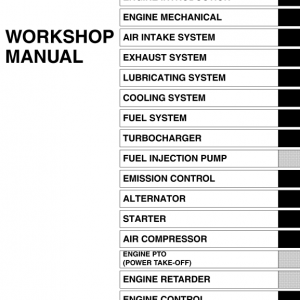

Engine

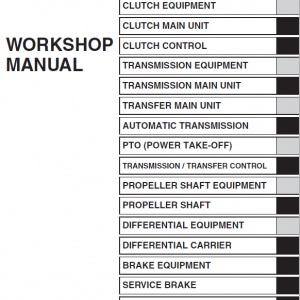

Clutch

Clutch Control

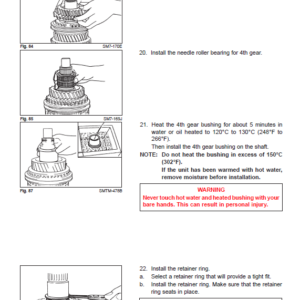

Transmission

Transmission Control

Propeller Shaft

Rear Axle

Front Axle

Steering

Service Brake

Parking Brake

Exhaust Brake

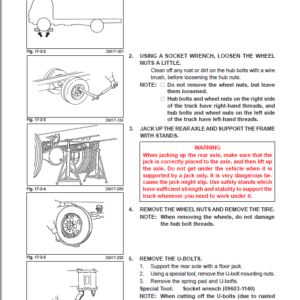

Wheels & Tires

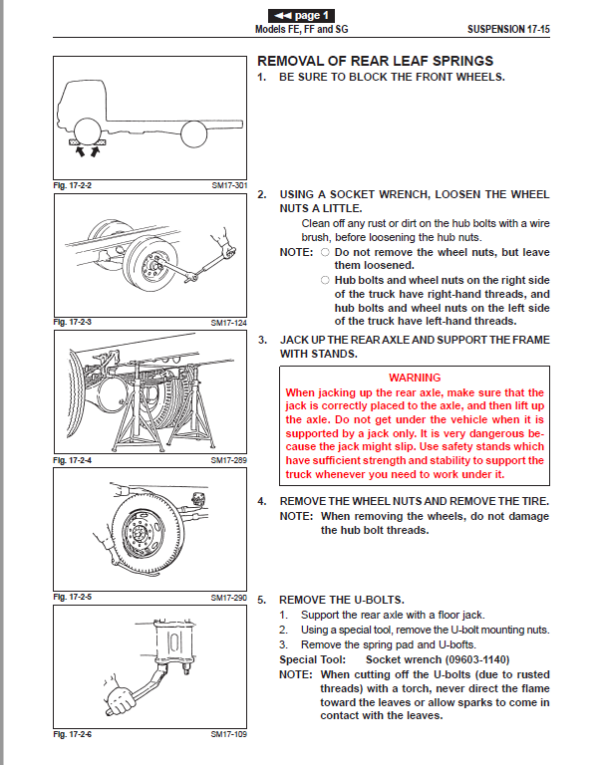

Suspension

Chassis Frame

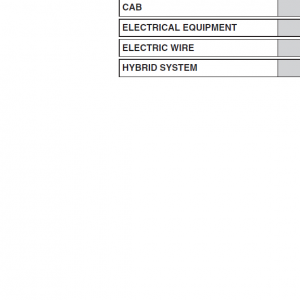

Cab

Electrical Equipment

Alternator

Starter

Compressor

Turbocharger

Spring Brake

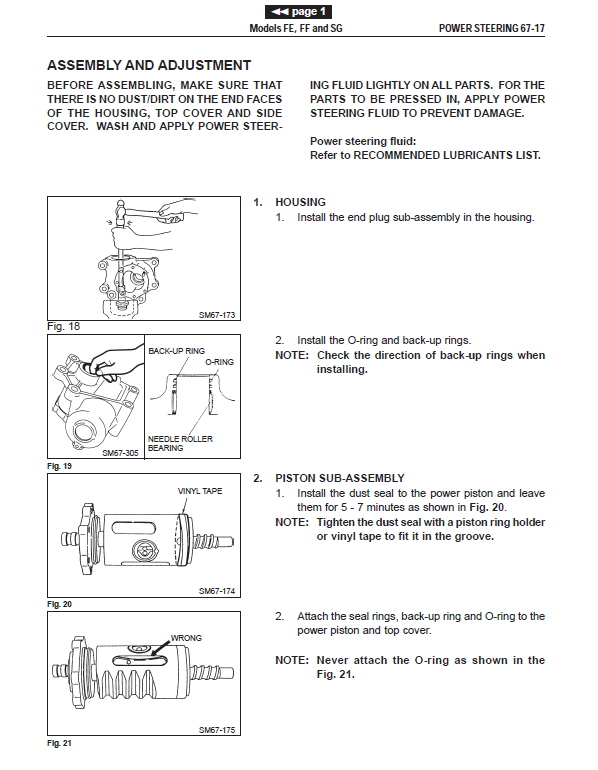

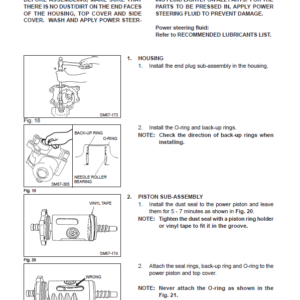

Power Steering

Automatic Transmission

Antilock Brake System

Total Electronics System

Service Specification

Electrical Wiring Diagrams

Hino Truck 2002 Manual Instruction Extract:

If it out of the standard range, adjust the valve clearance using the following.

1. Before checking, make sure that the tightening bolts of the cylinder head, rocker support, nozzle clamp, cam housing and cam bearing cap are tightened to the specified torque.

2. Make sure that there are no foreign particles or dust between the cross head and the valve stem.

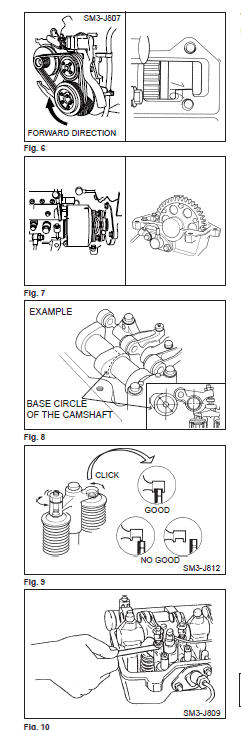

3. Turn the crankshaft in the forward direction to align the No. 1 piston to the top dead center of the compression stroke.

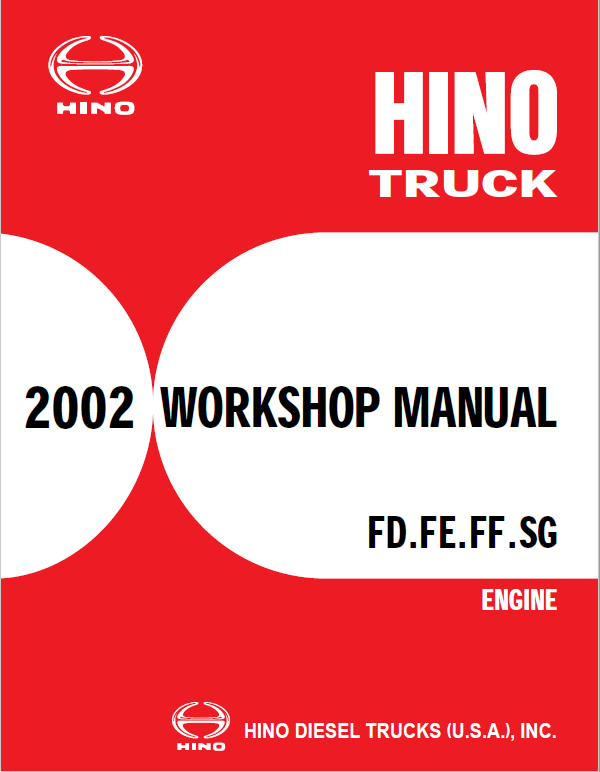

NOTE: Make sure that the roller is on the base circle of the camshaft.

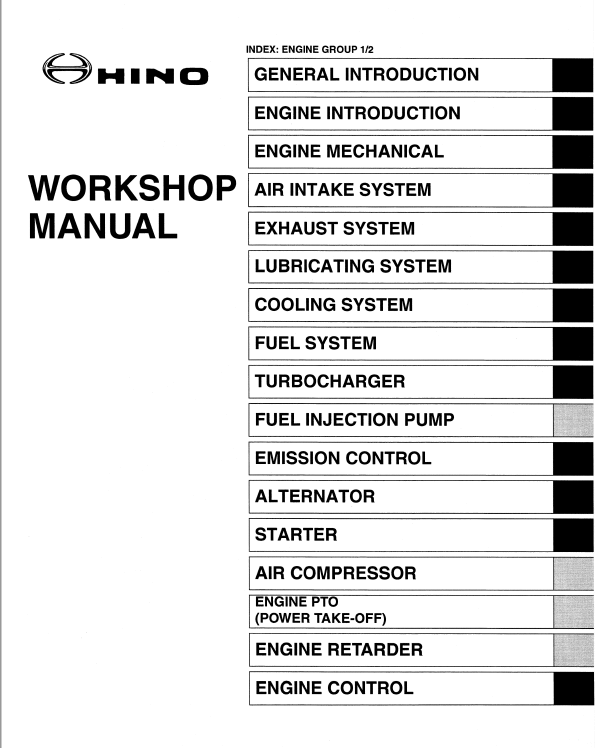

In order to avoid that the cross head runs on the valve stem or that it comes off from the valve stem, turn the cross head to the right and left to ensure that the cross head correctly covers the valve stem by listening for the clicking sound.

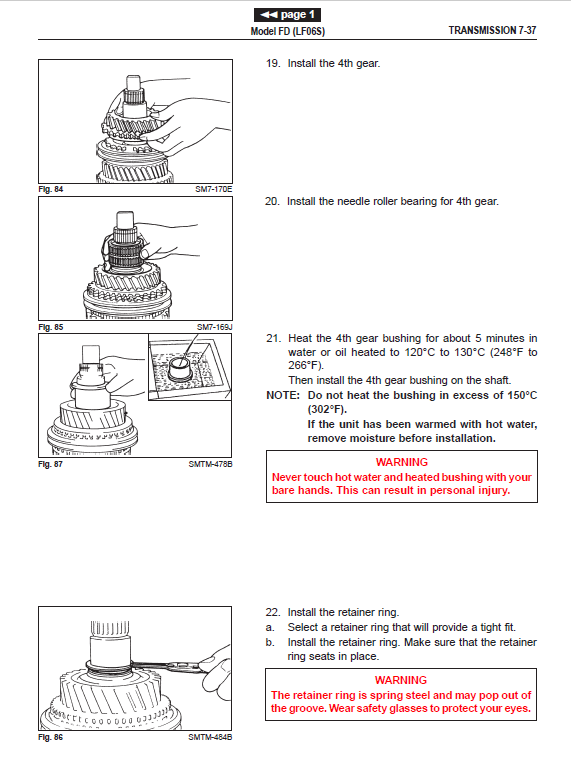

4. Insert the feeler gauge between the rocker arm and the cross head and check that the valve clearance is within the standard range.

Valve clearace (when cold).

Intake valve : 0.30mm (0.0118 in.)

Exhaust valve : 0.45mm (0.0177 in.)

5. Loosen the adjusting screw nut of the cross head completely.

NOTE: The adjusting screw must protrude 10 mm (0.3937 in.) or more from the cross head upper face. Unless the adjusting screw is completely loose to the valve stem, the following adjustments may be adversely affected.

6. Insert a feeler gauge between the rocker arm and cross head. Adjust clearance with the adjusting screw of the rocker arm. Tighten the lock nut with the following torque.

7. With the feeler gauge inserted, loosen the adjusting screw of the cross head. Make sure that the feeler gauge does not feel loose.

NOTE: If it is loose, repeat these steps from 5.

8. Tighten the adjusting screw of the cross head until the feeler gauge does not move.

9. While loosening the adjusting screw of the cross head gradually, adjust the valve clearance. Tighten the lock nut of the cross head when the feeler gauge feels correct.

NOTE: The feeling of the feeler gauge during clearance adjustment is same as before.

Do not overloosen the adjusting screw.

Overloosening of the adjusting screw will cause the same condition as in 5 again. The feeler gauge may feel correct, but there may be excessive clearance between the adjusting screw of the cross head and the valve.

This does not allow for correct adjustment

Be the first to review “Hino Truck FD2J, FE2J, FF2J, SG1J, SG2J Year 2002 Repair Manual (FD, FE, FF, SG)”

You must be logged in to post a review.

Reviews

There are no reviews yet.