Fendt 309, 310, 311, 312 Vario COM III Tractors Repair Workshop Manual

$49.00

- Fendt 309, 310, 311, 312 Vario COM III Tractors Workshop Repair Manual – 1185 Pages

- Fendt 300 Vario COM III Wiring Diagram and Schematics – 107 Pages & 63 Pages

- Fendt Tractor 300 Vario Series Repair Time Schedules – 110 Pages

- DEUTZ Engine Manual TCD 2012 4V – 377 Pages

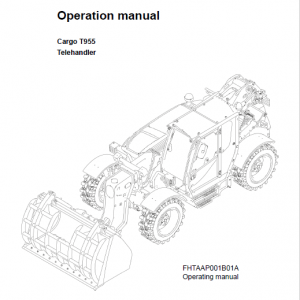

- Operators Manual – 160 Pages

- Maintenance Manual – 166 Pages

- Technical Data – 120 Pages

See description below for applicable models

- Description

- Reviews (0)

Description

Fendt 309, 310, 311, 312 Vario COM III Tractors Repair Workshop Manual

Applicable Models:

| Model | Chassis Number | Serial |

| FENDT 309 Vario COM III | 336 | 01001 – |

| FENDT 310 Vario COM III | 337 | 01001 – |

| FENDT 311 Vario COM III | 338 | 01001 – |

| FENDT 312 Vario COM III | 339 | 01001 – |

- Fendt 309, 310, 311, 312 Vario COM III Tractors Workshop Repair Manual – 1185 Pages

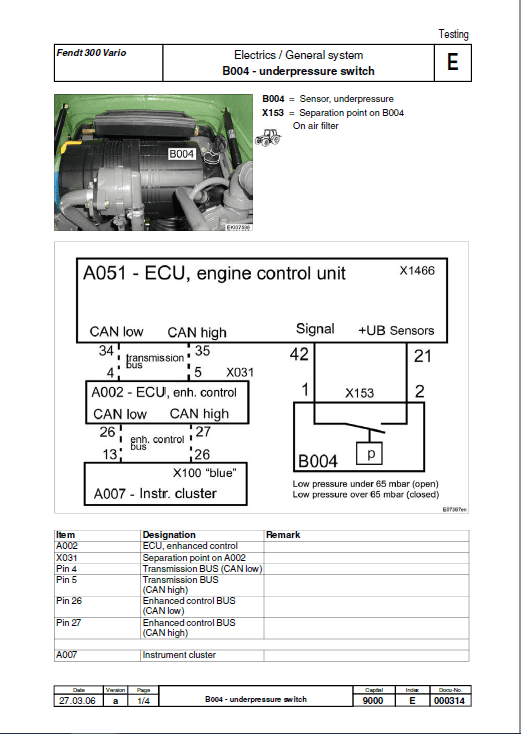

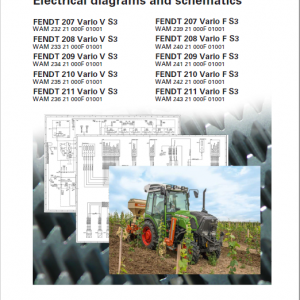

- Fendt 300 Vario COM III Wiring Diagram and Schematics – 107 Pages & 63 Pages

- Fendt Tractor 300 Vario Series Repair Time Schedules – 110 Pages

- DEUTZ Engine Manual TCD 2012 4V – 377 Pages

- Operators Manual – 160 Pages

- Maintenance Manual – 166 Pages

- Technical Data – 120 Pages

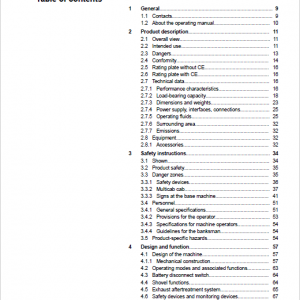

Workshop Manual TABLE OF CONTENTS

- 0000 Tractor / General system

- 1000 Transmission

1005 Transmission control unit

1010 Differential

1015 Axle drive

1030 Handbrake

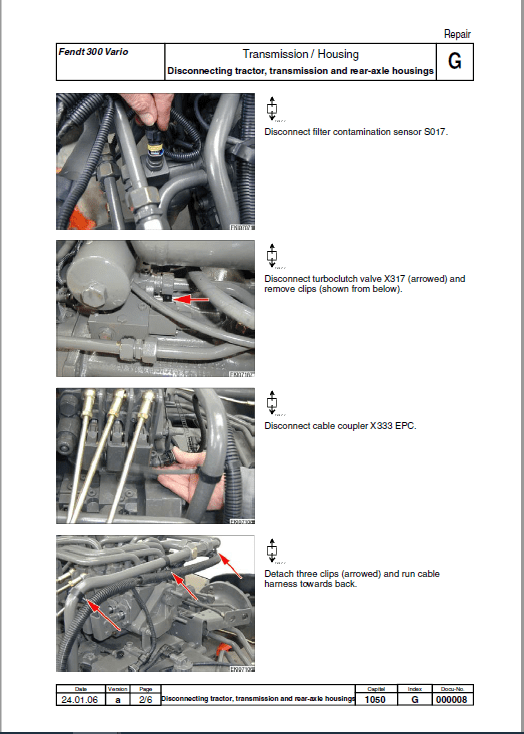

1050 Housing

1070 Brake system

1080 Vario transmission unit

1090 Emergency control

1100 Clutch actuation system

1150 Cardan brake

1170 ML range control

1200 Front PTO

1220 Live PTO

1320 Front-wheel drive

1430 Hydrodamp

1432 Hydraulic pump

1470 Transmission lubrication system

1490 Pump drive

1530 ML adjustment

1600 Enhanced control system valves

1620 Enhanced control system pipes - 2000 Engine

2010 Cylinder head

2020 Speed adjustment

2050 Cooling system

2060 Fuel system

2170 Engine brake

2180 Cold-start system

2190 Intercooler

2210 Crankcase

2250 Engine preheater

2312 Lubrication

2710 Injection pump

2712 Injectors

2714 Governor - 3000 Front axle

3010 Front axle support

3020 Axle housing

3050 Suspension

3060 Suspension valve fitting

3070 Suspension pipe

3100 Track rod

3120 Steering cylinder

3170 Frame

3180 Cardan shaft

3190 Diff. lock actuation system - 4000 Steering

4070 Steering wheel

4090 Hydraulic steering assembly - 5000 Vehicle body

5010 Design

5030 Driver seat

5050 Trailer hitch

5161 Trailer hitch coupling

5200 Cab mount, suspension - 5500 Air conditioning system

5520 Compressor drive

5530 Coolant lines

5550 Evaporator

5560 Condenser

5570 Electrical cables - 8100 Cab

8113 Heater

8114 Ventilation

8117 Windscreen wipers

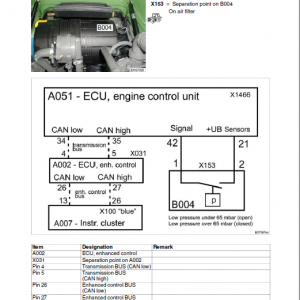

8121 Cable loom - 8600 Power lift

8610 Electrohydraulic EPC control

8618 External control

8631 Control lifting gear - 8700 Three-point hitch

8730 Lift arms

8740 Support - 8800 Compressed air system

8810 Compressor

8820 Brake fittings

8830 Lines

8850 Electrical actuation system

8890 Air tank - 8900 Front loader

8910 Mounting frame

8915 Hydraulic implement actuation system

8955 3. hydraulic circuit

8958 Multi-coupling

8970 Pipes

8990 Lift cylinder - 9000 Electrics

9010 Alternator

9015 Starter lockout

9040 Fuses

9050 Battery system

9060 Starter motor system - 9200 Front power lift

9210 Lift gear

9211 External control

9220 Cylinder

9230 Pipes

9260 Enhanced control power lift

9280 Frame - 9400 Hydraulic pump assembly

9410 LS pump

9420 Transmission pump

9430 Steering pump - 9500 Hydraulic pipes

9510 Base circle

9516 Power lift

9525 with oil cooler

9530 Hydraulic trailer brake

9531 Steering

9534 Reversing system

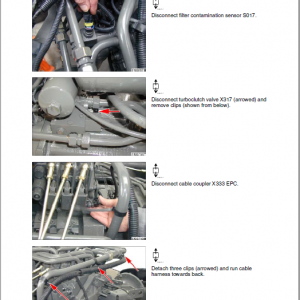

Manual Extract

This workshop manual provides notes for trained technicians to maintain our tractors. Read and observe the information in this documentation. This will help you prevent accidents.

Intended use includes maintaining operating the service and maintenance conditions as specified by the manufacturer. Operation, maintenance and repair of the tractor may only be carried out by people who are familiar with this equipment and aware of the associated dangers. Ensure that this documentation is available to and understood by everyone involved in operation, maintenance and repair. Not observing this documentation

can lead to faults, damage and personal injury.

The prerequisite for the Fendt 309, 310, 311, 312 Vario COM III tractor being correctly serviced and maintained is the perfect condition and availability of all necessary equipment, standard tools and general workshop equipment as well as special tools. Special tools must only be used where absolutely necessary. The tools are displayed where they need to be used in each case.

The machine must be maintained according to its proper use. Always replace parts with genuine FENDT spare parts! When ordering parts, please provide the chassis number as per the most up-to-date spare parts documentation.

Workshops should also refer to documentation on maintenance work and technical data. Once maintenance is complete, take a test drive to ensure the vehicle’s correct operation and road safety.

Be the first to review “Fendt 309, 310, 311, 312 Vario COM III Tractors Repair Workshop Manual”

You must be logged in to post a review.

Reviews

There are no reviews yet.