Challenger MT555E, MT565E, MT575E, MT585E, MT595E Tractor Workshop Manual

$40.00

Challenger MT555E, MT565E, MT575E, MT585E, MT595E Tractor Workshop Manual : 3455 Pages

Parts Catalog MT500E AutoPower VI, TechStar CVT: 366 Pages & 424 Pages

Technician Service Book MT500E (Schematics and Electronics) : 814Pages

- Description

- Reviews (0)

Description

Challenger MT555E, MT565E, MT575E, MT585E, MT595E Tractor Repair Workshop Manual

Manual for: AGCO Challenger

Format: PDF

February 2015

No. ACT0009250

MT500E AutoPower IV Series

MT500E AutoPower VI Series

MT500E TechStar CVT Series

North America – English

Challenger MT555E, MT565E, MT575E, MT585E, MT595E Tractor Workshop Manual : 3455 Pages

Parts Catalog MT500E AutoPower VI, TechStar CVT: 366 Pages & 424 Pages

Technician Service Book MT500E (Schematics and Electronics) : 814Pages

Challenger MT500E Series Manual TABLE OF CONTENTS

- Introduction

- Separation of assemblies

- Engine

- Clutch

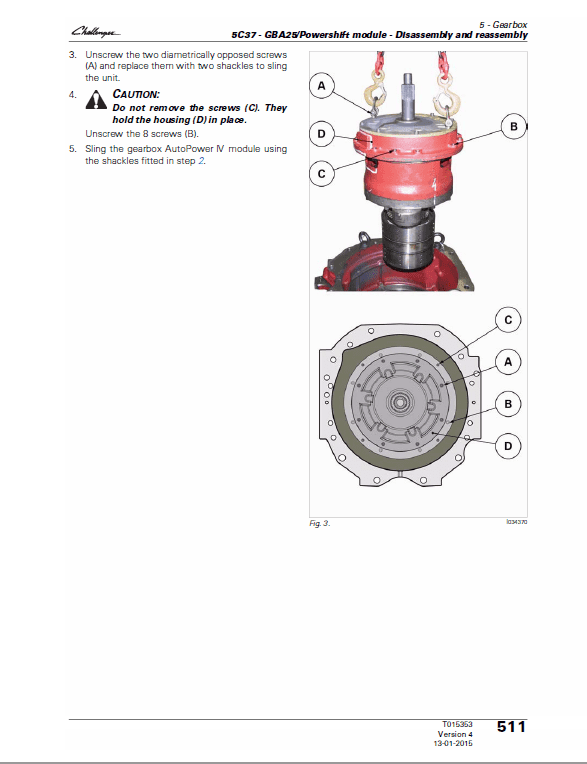

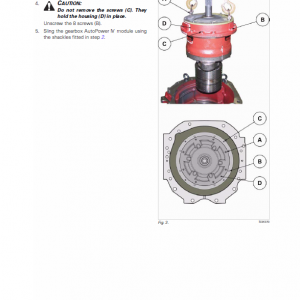

- Gearbox

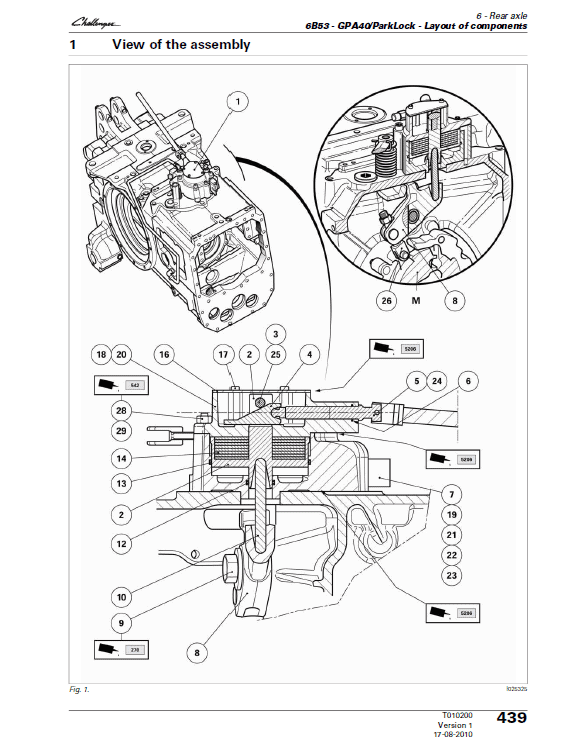

- Rear Axle

- Power Take off

- Front Axle

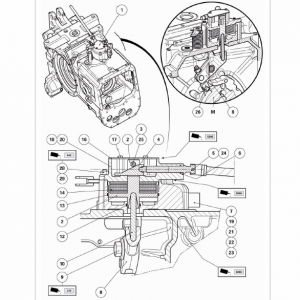

- Hydraulics

- Electricity

- Electronics

- Operator Environment

- Accessories

- Services Tools

MT555E, MT565E, MT575E, MT585E, MT595E Manual Extract

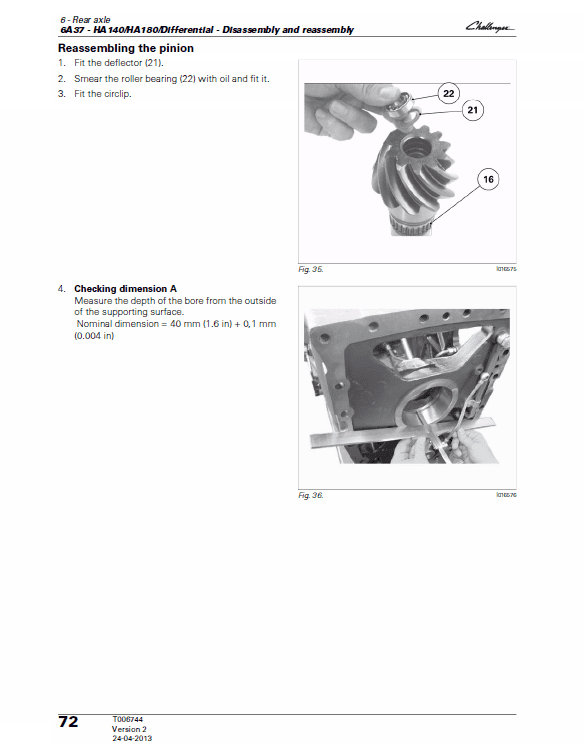

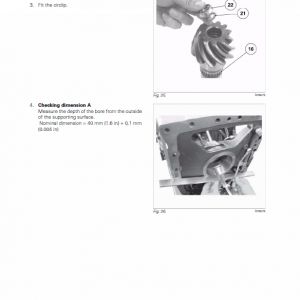

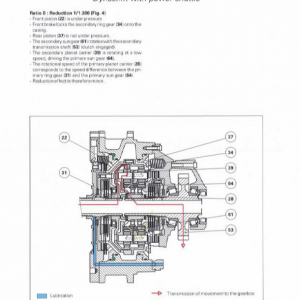

The efficiency and continued operation of mechanical units depend on constant, correct maintenance and also on efficient repair work, should there be a break-down or malfunction. The instructions contained in this manual have been based on a complete overhaul of the unit. However, it is up to the mechanic to decide whether or not it is necessary to assemble only individual components, when partial repair work is needed. The manual provides a quick and sure guide which, with the use of photographs and diagrams illustrating the various phases of the operations, allows accurate work to be performed.All the information needed for correct disassembly, checks and assembly of each individual component is set out below. In order to remove the differential unit from the vehicle, the manuals provided by the vehicle manufacturer should be consulted. In describing the following operations it is presumed that the unit has already been removed from the vehicle.

IMPORTANT: In order to facilitate work and protect both working surfaces and operators, it is advisable to use proper equipment such as: trestles or supporting benches, plastic or copper hammers, appropriate levers, pullers and specific spanners or wrenches. Before going on to disassemble the parts and drain the oil, it is best to thoroughly clean the unit, removing any encrusted or accumulated grease.

INTRODUCTORY REMARKS: All the disassembled mechanical units should be thoroughly cleaned with appropriate products and restored or replaced if damage, wear, cracking or seizing have occurred. In particular, thoroughly check the condition of all moving parts (bearings, gears, crown wheel and pinion, shafts) and sealing parts (o-rings, oil shields) which are subject to major stress and wear. In any case, it is advisable to replace the seals every time a component is overhauled or repaired. During assembly, the sealing rings must be lubricated on the sealing edge.

In the case of the crown wheel and pinion, replacement of one component requires the replacement of the other one. During assembly, the prescribed pre-loading, backlash and torque of parts must be maintained.

Be the first to review “Challenger MT555E, MT565E, MT575E, MT585E, MT595E Tractor Workshop Manual”

You must be logged in to post a review.

Reviews

There are no reviews yet.