Toro Reelmaster 5210, 5410, 5510, 5610 Series Service Repair Manual

$34.00

Manual Included:

- Service Repair Manual: 348 Pages

Specifications:

- Brand: Toro

- Model: Reelmaster 5210, 5410, 5510, 5610 Series

- Type: Large Reel Mowers

- Manuals: Service Repair Manual

- Publication Numbers: 06148SL

- Language: English

- Format: PDF

- Description

- Reviews (0)

Description

Table of Content – Reelmaster 5210, 5410, 5510, 5610 Series

- Title Page

- Revision History

- Reader Comments

- Preface

- Table Of Contents

- 1 – Safety

- Safety Instructions

- Before Operating

- While Operating

- Maintenance and Service

- Jacking Instructions

- Safety and Instruction Decals

- 2 – Product Records and Maintenance

- Product Records

- Maintenance

- Equivalents and Conversions

- Torque Specifications

- 3 – Kubota Diesel Engine

- General Information

- Traction Unit Operator’s Manual

- Stopping the Engine (Reelmaster 5610)

- Specifications: Reelmaster 5210

- Specifications: Reelmaster 5410 and 5510

- Specifications: Reelmaster 5610

- Adjustments

- Adjust Throttle Control

- Service and Repairs

- Fuel System

- Air Cleaner

- Exhaust System

- Radiator

- Engine

- Kubota 05 E2B Series Workshop Manual (S.N below 280000000)

- Kubota 05-E3B Series Workshop Manual (S.N 280000001 and up)

- 4 – Hydraulic System

- Specifications

- General Information

- Traction Unit Operator’s Manual

- Check Hydraulic Fluid

- Towing Traction Unit

- Hydraulic Hoses

- Hydraulic Fitting Installation

- Relieving Hydraulic System Pressure

- Traction Circuit Component Failure

- Hydraulic Schematics

- Hydraulic Flow Diagrams

- Traction Circuit

- Mow Circuit

- Lift Circuit – Raise Cutting Units

- Lift Circuit – Lower Cutting Units

- Steering Circuit

- Special Tools

- Troubleshooting

- General Hydraulic System Problems

- Traction Circuit Problems

- Mow Circuit Problems

- Lift Circuit Problems

- Steering Circuit Problems

- Testing

- Before Performing Hydraulic Tests

- Precautions for Hydraulic Testing

- Which Hydraulic Tests Are Necessary?

- Traction Circuit Relief Valve (R3) and (R4) Pressure Test

- Traction Circuit Charge Pressure Test

- Gear Pump (P3) Flow Test

- Front Wheel Motor Efficiency Test

- Piston (Traction) Pump Flow Test

- Relief Valve (R1) and (R2) Pressure Test

- Gear Pump (P1) and (P2) Flow Test

- Reel Drive Motor Efficiency Test

- Reel Drive Motor Cross–Over Relief Pressure Test

- Lift Relief Valve (SVRV) Pressure Test

- Gear Pump (P4) Flow Test

- Lift Cylinder Internal Leakage Test

- Steering Relief Valve (R10) Pressure Test

- Steering Cylinder Internal Leakage Test

- Service and Repairs

- General Precautions for Removing and Installing Hydraulic System Components

- Check Hydraulic Lines and Hoses

- Flush Hydraulic System

- Filtering Closed-Loop Traction Circuit

- Hydraulic System Start–up

- Hydraulic Reservoir

- Hydraulic Pump Drive Shaft

- Hydraulic Pump Assembly

- Piston (Traction) Pump Service

- Gear Pump Service

- Front Wheel Motor

- Wheel Motor Service (Parker)

- Front Wheel Motor Service (Eaton)

- Mow Control Manifold

- Mow Control Manifold Service

- Lift Control Manifold

- Lift Control Manifold Service

- CrossTrax AWD (Optional Kit) Manifold

- CrossTrax AWD (Optional Kit) Manifold Service

- Cutting Reel Motor

- Cutting Reel Motor Service (Bosch and Sauer-Danfoss)

- Cutting Reel Motor Service (Casappa)

- Lift Cylinder

- Lift Cylinder Service

- Steering Control Valve

- Steering Control Valve Service

- Steering Cylinder

- Steering Cylinder Service

- Oil Cooler

- Danfoss LPV Pump Repair Manual

- Danfoss LPV Pump Service Repair Manual

- Parker Torqmotor Service Procedure

- Eaton Delta Motor Service Procedure

- Danfoss OSPM Steering Unit Service Repair Manual

- 5 – Electrical System

- General Information

- Electrical Diagrams

- Special Tools

- Troubleshooting

- Diagnostic Light

- Diagnostic Display

- Electronic Control Module Logic Chart

- Starting Problems

- General Run and Transport Problems

- Cutting Unit Operating Problems

- TurfDefender Leak Detector (Optional)

- Electrical System Quick Checks

- Battery Test (Open Circuit Test)

- Charging System Test

- Glow Plug System Test

- Check Operation of Interlock Switches

- Adjustments

- Traction Neutral Switch

- Parking Brake Switch

- Up Limit Switch

- Component Testing

- Ignition Switch

- Indicator Lights

- Hour Meter

- Temperature Gauge

- PTO Switch

- Traction Neutral Switch

- Seat Switch

- Headlight Switch

- Parking Brake Switch

- Up Limit Switch

- Joystick Raise and Lower Switches

- Mowith Transport Switch

- Backlap Switches

- Start Relay

- Main Power and Glow Relays

- Electronic Control Module (ECM)

- CAN-bus Termination Resistors (Machine With Serial Number Above 280000000)

- Diode Assembly

- Fusible Link Harness

- Fuses

- Hydraulic Solenoid Valve Coil

- Temperature Sender

- High Temperature Shutdown Switch

- Oil Pressure Switch

- Fuel Stop Solenoid

- Fuel Pump

- Service and Repairs

- Battery Storage

- Battery Care

- Battery Service

- Control Arm

- Hydraulic Solenoid Valve Coil

- Backlap Switches

- TurfDefender Leak Detector (Optional)

- 6 – Chassis

- Specifications

- General Information

- Traction Unit Operator’s Manual

- Service and Repairs

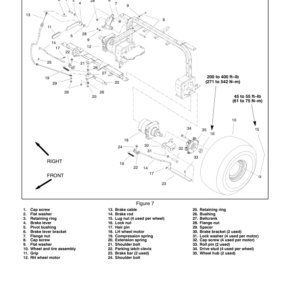

- Wheels

- Steering Column

- Brake Service

- Rear Wheel Bearings (2 Wheel Drive)

- Rear Axle

- Rear Axle Service

- Operator Seat

- Mechanical Seat Suspension

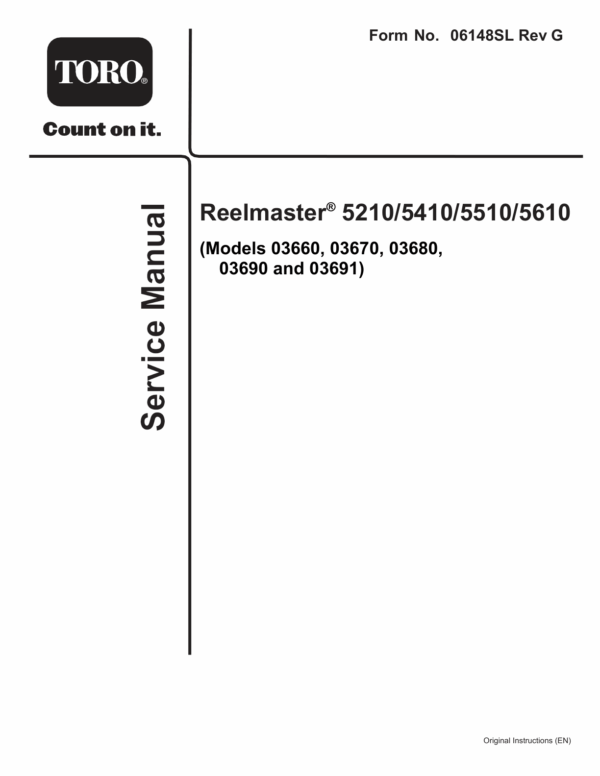

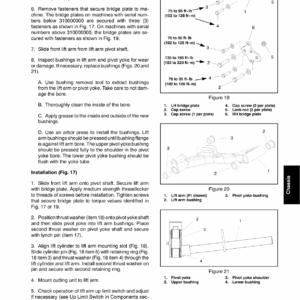

- Front Lift Arms

- Rear Lift Arms

- 7 – DPA Cutting Units

- Table of Contents

- Specifications

- General Information

- Cutting Unit Operator's Manual

- Special Tools

- Gauge Bar Assembly

- Bedknife Screw Tool

- Handle Assembly

- Plastic Plug

- Cutting Unit Kickstand

- Spline Insert Tool

- Rear Roller Bearing and Seal Installation Tools

- Turf Evaluator Tool

- Diameter, Circumference Measuring Tape

- Reel Bearing Installation Tool (cutting units with painted side plates)

- Cutting Reel Shim

- Cutting Performance Paper

- Pulley Alignment Tool

- Bedknife Top Angle Indicator and Mount

- Factors That Can Affect Cutting Performance

- Set Up and Adjustments

- Characteristics

- Reel Bearing Adjustment (cutting units with painted side plates)

- Leveling Rear Roller

- Service and Repairs

- Hydraulic Reel Motor

- Backlapping

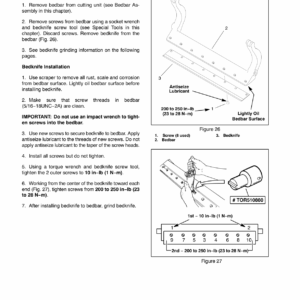

- Bedbar Assembly

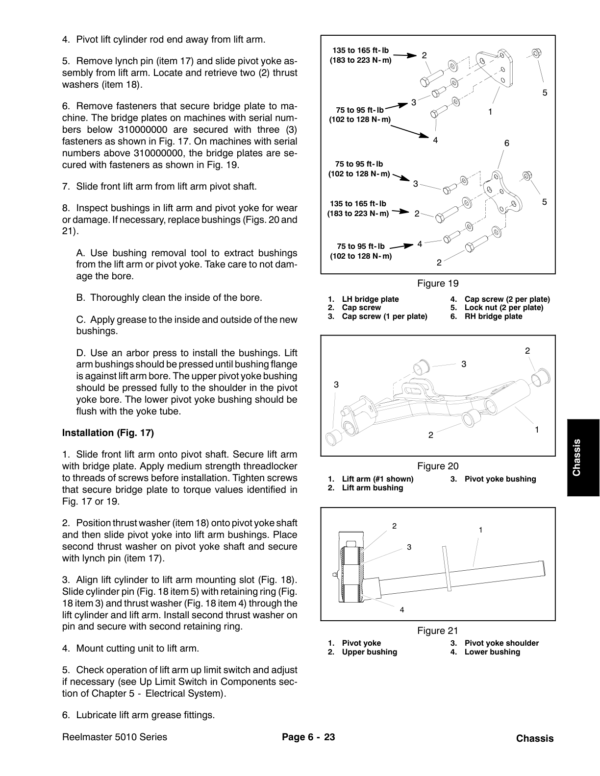

- Bedknife Replacement and Grinding

- Bedbar Adjuster Service

- Reel Assembly (cutting units with painted side plates)

- Reel Assembly Service (cutting units with painted side plates)

- Reel Assembly (cutting units with aluminum side plates)

- Reel Assembly Service (cutting units with aluminum side plates)

- Preparing Reel for Grinding

- Front Roller

- Rear Roller

- Roller Service (greasable bearings with retaining ring)

- Roller Service (greasable bearings with bearing nut)

- Rear Roller Brush – Optional (cutting units with painted side plates)

- Rear Roller Brush – Optional (cutting units with aluminum side plates)

- 8 – Belt Driven Groomer (Optional)

- Grooming Performance

- Troubleshooting

- Adjustments

- Groomer Height, Depth Adjustment

- Service and Repairs

- Groomer Drive Belt Replacement

- Groomer Plate Assembly

- Groomer Reel

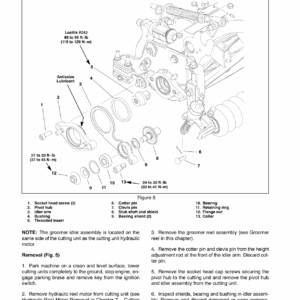

- Groomer Reel Service

- Groomer Pivot Hub

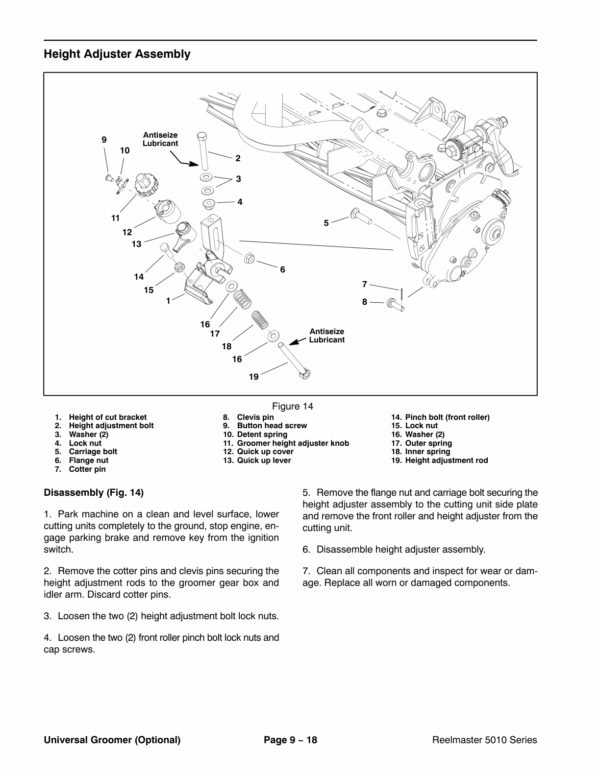

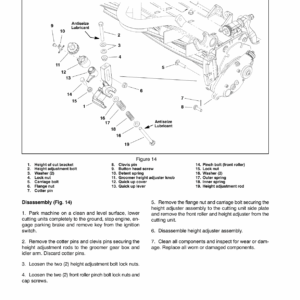

- Height Adjuster Assembly

- 9 – Universal Groomer (Optional)

- Table of Contents

- Grooming Performance

- Troubleshooting

- Groomer Reel Mechanical Problems

- Service and Repairs

- Gear Box Assembly

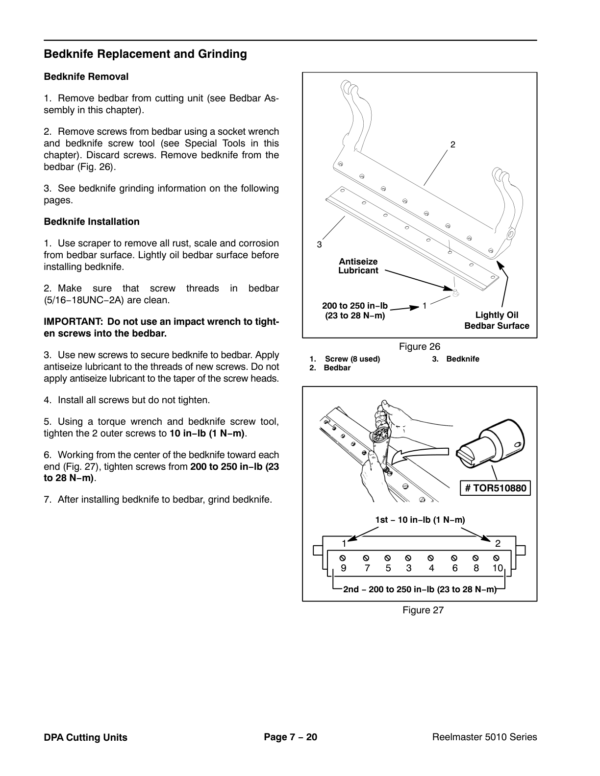

- Idler Assembly

- Groomer Reel

- Groomer Reel Service

- Grooming Brush (Optional) Service

- Height Adjuster Assembly

- 10 – Foldout Drawings

- Electrical Drawing Designations

- Hydraulic Schematic – 5210, 5410

- Hydraulic Schematic – 5510, 5610

- Electrical Schematic (Serial Number Below 310000000)

- Electrical Schematic (Serial Number Above 310000000)

- Glow Plug Circuits

- Crank Circuits

- Run (Transport) Circuits

- Run (Mow) Circuits

- Main Wire Harness Drawing (SN Below 310000000)

- Main Wire Harness Diagram (SN Below 310000000)

- Main Wire Harness Drawing (SN Above 310000000)

- Main Wire Harness Diagram (SN Above 310000000)

- Seat Wire Harness Drawing (SN Below 310000000)

- Seat Wire Harness Diagram (SN Below 310000000)

- Seat Wire Harness Drawing (SN Above 310000000)

- Seat Wire Harness Diagram (SN Above 310000000)

- Engine Wire Harness Drawing

- Engine Wire Harness Diagram

- Turf Defender Schematic

Be the first to review “Toro Reelmaster 5210, 5410, 5510, 5610 Series Service Repair Manual”

You must be logged in to post a review.

Reviews

There are no reviews yet.