Toro Reelmaster 5010-H Service Repair Manual

$34.00

Manual Included:

- Service Repair Manual: 364 Pages

Specifications:

- Brand: Toro

- Model: Reelmaster 5010-H

- Type: Large Reel Mowers

- Manuals: Service Repair Manual

- Publication Numbers: 15212SL

- Language: English

- Format: PDF

- Description

- Reviews (0)

Description

Table of Content – Reelmaster 5010-H

- Title Page

- Revision History

- Reader Comments

- Preface

- Table Of Contents

- Table Of Contents (Continued)

- 1 – Safety

- Table of Contents

- Safety Instructions

- Before Operating

- While Operating

- Maintenance and Service

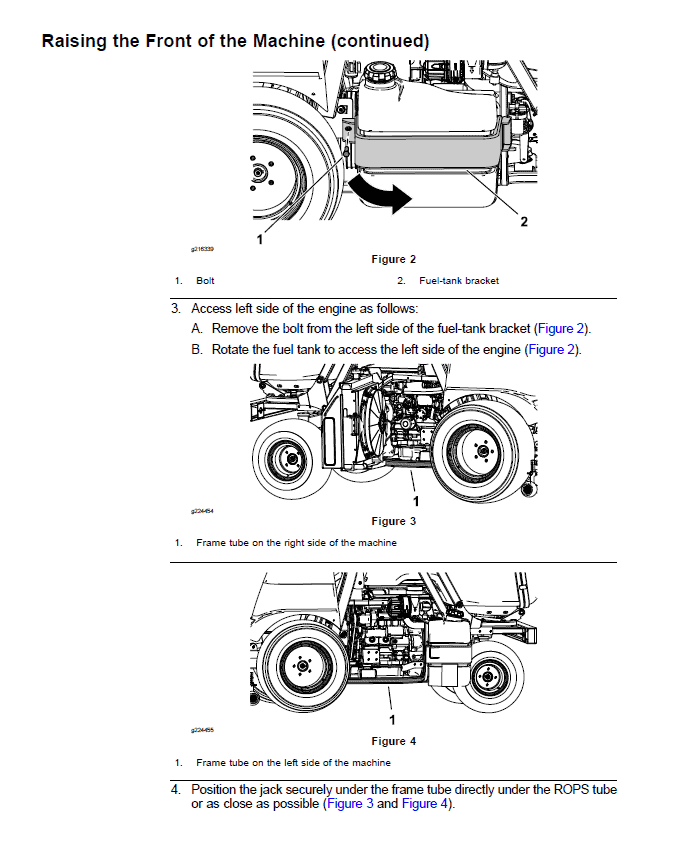

- Jacking Instructions

- Safety and Instruction Decals

- 2 – Product Records and Maintenance

- Table of Contents

- Product Records

- Maintenance

- Equivalents and Conversions

- Torque Specifications

- Fastener Identification

- Using a Torque Wrench with an Offset Wrench

- Standard Torque for Dry, Zinc Plated and Steel Fasteners (Inch Series)

- Standard Torque for Dry, Zinc Plated and Steel Fasteners (Metric Series)

- Other Torque Specifications

- Conversion Factors

- 3 – Kubota Diesel Engine

- Table of Contents

- Specifications

- General Information

- Traction Unit Operator’s Manual

- Kubota Workshop Manual

- 48 VDC Battery Disconnect

- Service and Repairs

- Air Cleaner Assembly

- Exhaust System

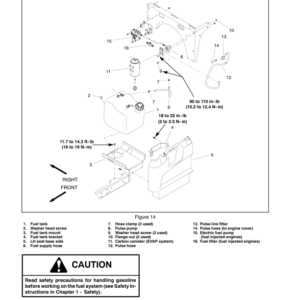

- Fuel System

- Radiator Assembly

- Engine

- Engine Removal

- Engine Installation

- Engine Bellhousing Assembly

- Kubota Workshop Manual, 05-E4B Series

- 4 – Hydraulic System

- Table of Contents

- Specifications

- General Information

- Traction Unit Operator’s Manual

- 48 VDC Battery Disconnect

- Check Hydraulic Fluid

- Towing Traction Unit

- Hydraulic Hoses

- Hydraulic Hose and Tube Installation

- Hydraulic Fitting Installation

- Relieving Hydraulic System Pressure

- Traction Circuit Component Failure

- Hydraulic Schematic

- Hydraulic Flow Diagrams

- Traction Circuit

- Lift Circuit: Raise Cutting Units

- Lift Circuit: Lower Cutting Units

- Steering Circuit

- Special Tools

- Troubleshooting

- General Hydraulic System Problems

- Traction Circuit Problems

- Lift Circuit Problems

- Steering Circuit Problems

- Testing

- Traction Circuit Relief Valve (R3) and (R4) Pressure Test

- Traction Circuit Charge Pressure Test

- Gear Pump (P2) Flow Test

- Front Wheel Motor Efficiency Test

- Piston (Traction) Pump Flow Test

- Lift Relief Valve (SVRV) Pressure Test

- Gear Pump (P1) Flow Test

- Lift Cylinder Internal Leakage Test

- Steering Relief Valve (R10) Pressure Test

- Steering Cylinder Internal Leakage Test

- Service and Repairs

- General Precautions for Removing and Installing Hydraulic System Components

- Check Hydraulic Lines and Hoses

- Flush Hydraulic System

- Filtering Closed- Loop Traction Circuit

- Hydraulic System Start- up

- Hydraulic Reservoir

- Piston (Traction) Pump Control Assembly

- Hydraulic Pump Assembly

- Piston (Traction) Pump Service

- Gear Pump Service

- Hydraulic Pump Drive Shaft

- Hydraulic Pump Drive Shaft Cross and Bearing Service

- Front Wheel Motors

- Front Wheel Motor Service

- Rear Wheel Motors (Machines with Optional CrossTrax Kit)

- Rear Wheel Motor Service (Machines with Optional CrossTrax Kit)

- Control Manifold Cartridge Valve Service

- Lift Control Manifold

- Lift Control Manifold Service

- CrossTrax AWD Manifold

- CrossTrax AWD Manifold Service

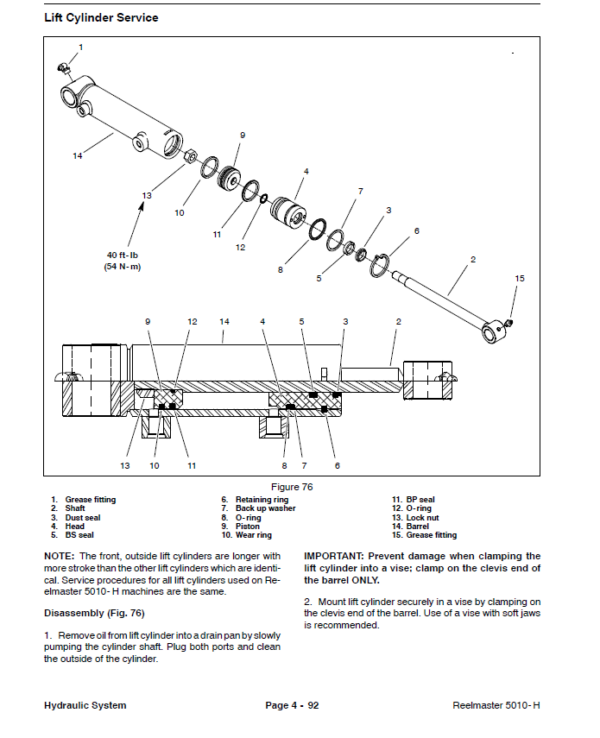

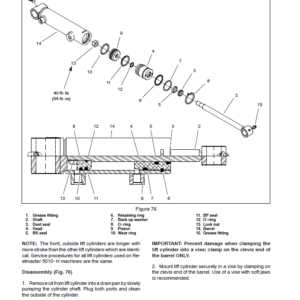

- Lift Cylinders

- Lift Cylinder Service

- Steering Control Valve

- Steering Control Valve Service

- Steering Cylinder

- Steering Cylinder Service

- Hydraulic Oil Cooler

- Danfoss LPV Closed Circuit Axial Piston Pumps Repair Manual

- Danfoss LPV Closed Circuit Axial Piston Pumps Service Instructions

- Eaton Delta Motors Parts and Repair Manual

- Parker Torqmotor Service Procedure (TC, TB, TE, TJ, TF, TG, TH, and TL Series)

- Danfoss Steering Unit Type OSPM Service Repair Manual

- 5 – Electrical System

- Table of Contents

- General Information

- Operator’s Manual

- Electrical Drawings

- 48 VDC Battery Disconnect

- Toro Electronic Controller

- CAN-bus Communications

- Electrical System Operation

- 12 VDC System Operation

- 48 VDC System Operation

- Special Tools

- InfoCenter Display

- Splash Screen

- Main Information Screens

- Access Protected Display Screens

- Main Menu Screen

- Faults Screen

- Service Screen

- Diagnostics Screen

- Settings Screen

- About Screen

- Troubleshooting

- Operator Advisories

- Fault Codes

- Starting Problems

- General Run and Transport Problems

- Cutting Unit Operating Problems

- Electrical System Quick Checks

- 12 VDC Battery Test (Open Circuit Test)

- Engine Charging System Test

- Glow Plug System Test

- Check Operation of Interlock Switches

- Adjustments

- Traction Neutral Switch

- Parking Brake Switch

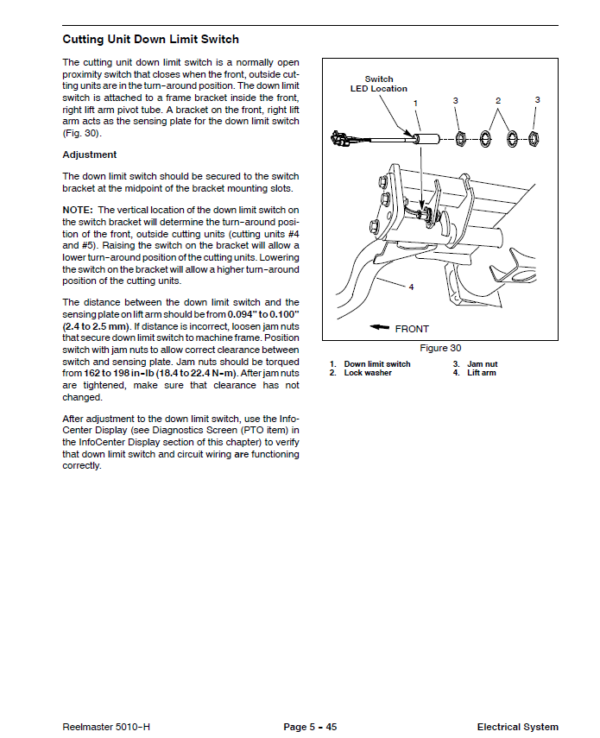

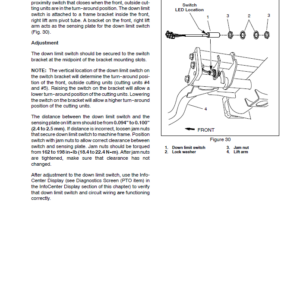

- Cutting Unit Down Limit Switch

- Mowith Transport Switch

- Component Testing

- Ignition Switch

- 12 VDC System Fuses

- 48 VDC System Fuses

- Engine Speed Switch

- Reel Engage, Disengage Switch

- Headlight Switch

- Seat Switch

- Parking Brake Switch

- Traction Neutral Switch

- Cutting Unit Down Limit Switch

- Joystick Raise and Lower Switches

- Mowith Transport Switch

- Main Power, Glow and 48 VDC Logic Relays

- Start Relay

- Main Contactor

- Toro Electronic Controller (TEC)

- Isolation Module

- Fusible Link Harness

- Diode Assembly

- 48 VDC System Protection Diode

- Location ID Module

- Cutting Reel Motor

- CAN-bus Termination Resistors

- Hydraulic Solenoid Valve Coil

- Temperature Sender

- Oil Pressure Switch

- Fuel Actuator

- Fuel Sender

- Fuel Pump

- Service and Repairs

- Hydraulic Solenoid Valve Coils

- 12 VDC Battery Service

- 48 VDC Battery Pack Service

- 48 VDC Electrical Power Connections

- Cutting Reel Motor

- Cutting Reel Motor Service

- Motor, Generator Assembly

- Motor, Generator Assembly Service

- 6 – Chassis

- Table of Contents

- Specifications

- General Information

- Traction Unit Operator’s Manual

- 48 VDC Battery Disconnect

- Special Tools

- Service and Repairs

- Wheels

- Steering Column

- Brake Service

- Rear Wheel Bearings (2 Wheel Drive)

- Rear Axle

- Rear Axle Service

- Control Arm

- Operator Seat

- Mechanical Seat Suspension

- Front Lift Arms

- Rear Lift Arms

- Hood

- 7 – Cutting Units

- Table of Contents

- Specifications

- General Information

- Cutting Unit Operator’s Manual

- 48 VDC Battery Disconnect

- Special Tools

- Factors That Can Affect Cutting Performance

- Set Up and Adjustments

- Characteristics

- Leveling Rear Roller

- Service and Repairs

- Cutting Reel Motor

- Backlapping

- Bedbar Assembly

- Bedknife Replacement and Grinding

- Bedbar Adjuster Service

- Cutting Reel Assembly Removal and Installation

- Cutting Reel Assembly Service

- Preparing Reel for Grinding

- Front Roller

- Rear Roller

- Roller Service

- Rear Roller Brush (Optional)

- Rear Roller Brush Drive System (Optional)

- 8 – Belt Driven Groomer (Optional)

- Table of Contents

- General Information

- Groomer Kit Installation Instructions

- 48 VDC Battery Disconnect

- Special Tools

- Grooming Performance

- Troubleshooting

- Groomer Reel Mechanical Problems

- Adjustments

- Groomer Height, Depth Adjustment

- Service and Repairs

- Groomer Drive Belt Replacement

- Groomer Drive Assembly

- Groomer Reel and Groomer Plate Assembly

- Groomer Reel Service

- Height Adjuster Assembly

- 9 – Universal Groomer (Optional)

- Table of Contents

- Grooming Performance

- Troubleshooting

- Groomer Reel Mechanical Problems

- Service and Repairs

- Gear Box Assembly

- Idler Assembly

- Groomer Reel

- Groomer Reel Service

- Grooming Brush (Optional) Service

- Height Adjuster Assembly

- 10 – Foldout Drawings

- Table of Contents

- Electrical Drawing Designations

- Hydraulic Schematic

- Electrical Schematic (Serial number below 403430000)

- Electrical Schematic(Serial numbers above 403430001)

- Main Wire Harness Drawing (Serial number below 403430000)

- Main Wire Harness Diagram (Serial number below 403430000)

- Main Wire Harness Drawing(Serial numbers 403430001 to 406599999)

- Main Wire Harness Drawing(Serial numbers 403430001 to 406599999)

- Main Wire Harness Drawing(Serial numbers above 406600000)

- Main Wire Harness Drawing(Serial numbers above 406600000)

- Seat Wire Harness Drawing

- Seat Wire Harness Diagram

Be the first to review “Toro Reelmaster 5010-H Service Repair Manual”

You must be logged in to post a review.

Reviews

There are no reviews yet.