Toro Groundsmaster 5900, 5910 (Model 31698, 31600 – Tier 4) Service Repair Manual

$34.00

Manual Included:

- Service Repair Manual: 577 Pages

Specifications:

- Brand: Toro

- Model: Groundsmaster 5900, 5910 (Model 31698, 31600 – Tier 4)

- Type: Rotary Mowers

- Manuals: Service Repair Manual

- Publication Numbers: 16227SL

- Language: English

- Format: PDF

- Description

- Reviews (0)

Description

Table of Content – Groundsmaster 5900, 5910 (Model 31698, 31600 – Tier 4)

- Title Page

- Revision History

- Reader Comments

- NOTES

- Preface

- Service Procedure Icons

- Table of Contents

- Chapter 1 : Safety

- Safety Instructions

- Before Operating the Machine

- While Operating the Machine

- Maintenance and Service

- Battery-Disconnect Switch

- Jacking Instructions

- Safety and Instructional Decals

- Chapter 2 : Specifications and Maintenance

- Specifications

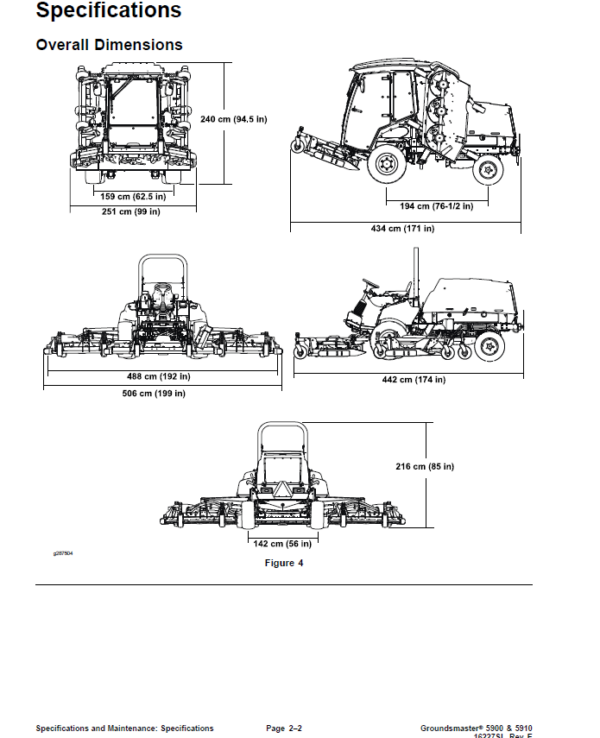

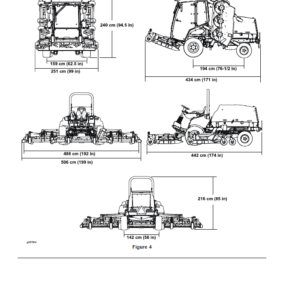

- Overall Dimensions

- Engine

- Hydraulic System

- Chassis

- Cutting Decks

- Torque Specifications

- Calculating the Torque Values When Using a Drive-Adapter Wrench

- Identifying the Fastener

- Standard Torque for Dry, Zinc Plated, and Steel Fasteners (Inch Series)

- Standard Torque for Dry, Zinc Plated, and Steel Fasteners (Metric Fasteners)

- Other Torque Specifications

- Conversion Factors

- Shop Supplies

- Special Tools

- Chapter 3 : Troubleshooting

- GEARS – The Systematic Approach to Defining, Diagnosing and Solving Problems

- Gather Information

- Evaluate Potential Causes

- Assess Performance

- Repair

- Solution Confirmation

- General Hydraulic System Problems

- Traction Circuit Problems

- PTO Problems

- Lift, Lower Circuit Problems

- Steering Circuit Problems

- Starting Problems

- General Run and Transport Problems

- Cutting Deck (PTO) Operating Problems

- Cutting Deck Lift, Lower Problems

- Operator Advisories

- TO START

- TO ENGAGE PTO

- TO SET CRUISE CONTROL

- TO LOWER DECK

- TO FLOAT DECK

- TO SET HIGH RANGE

- TO SET LOW RANGE

- FOR TRACTION

- ENGINE

- FUEL LEVEL

- TRACTION PEDAL

- TO RAISE DECK

- Using the InfoCenter Display for Troubleshooting

- Machine Faults

- Engine Faults

- Factors That Can Affect Quality of Cut and Clipping Dispersion

- Chapter 4 : Yanmar Diesel Engine

- General Information

- Operator’s Manuals

- Yanmar Service and Troubleshooting Manuals

- Stopping the Engine

- Engine Electronic Control Unit (ECU)

- Yanmar Engine

- Diesel Particulate Filter

- Service and Repairs

- Air Filter

- Exhaust System

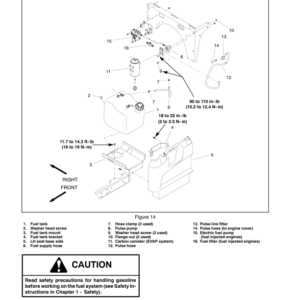

- Fuel System

- Radiator

- Engine

- Pump Adapter Plate (Coupler)

- Yanmar TNV (Tier 4) Series Service Repair Manual

- Yanmar TNV (Tier 4) Series Troubleshooting Manual

- Chapter 5 : Hydraulic System

- General Information

- Operator’s Manual

- Relieving Hydraulic System Pressure

- Towing Traction Unit

- Traction Circuit Component Failure

- Hydraulic Hoses

- Installing Hydraulic Hoses and Tubes (O-Ring Face Seal)

- Installing the Hydraulic Fittings (SAE Straight Thread O-Ring Fittings)

- Hydraulic Schematic

- Hydraulic Flow Diagrams

- Traction Circuit Operation

- Traction Circuit: Low Range Traction Speed (Mow)

- Traction Circuit: High Range Traction Speed (Transport)

- Raise Cutting Deck

- Lower Cutting Deck

- PTO Mow Circuit

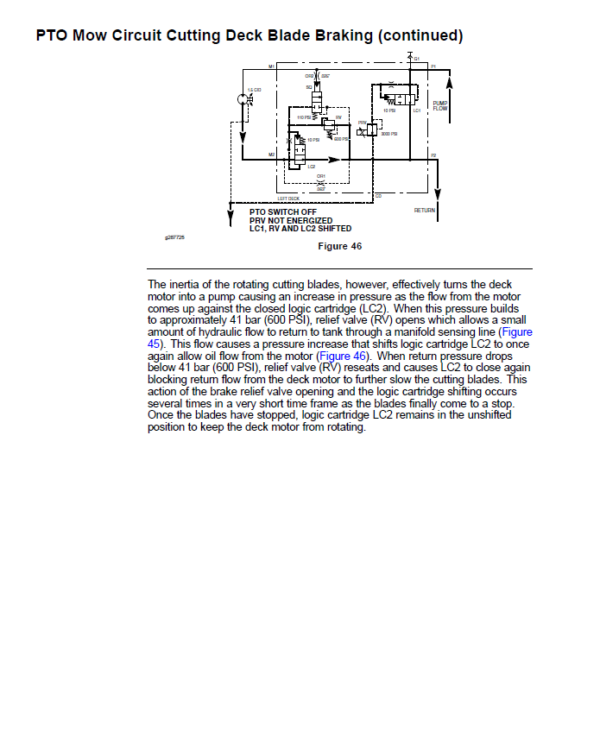

- PTO Mow Circuit Cutting Deck Blade Braking

- Steering Circuit

- Testing

- Before Performing Hydraulic Tests

- Precautions for Hydraulic Testing

- Which Hydraulic Tests Are Necessary?

- Traction Circuit Charge Pressure Test (Using Pressure Gauge)

- Traction Circuit Relief Pressure Test (Using Pressure Gauge)

- Counterbalance Pressure Test (Using Pressure Gauge)

- Piston (Traction) Pump Flow Test (Using Tester with Pressure Gauge & 40 GPM Flow Meter)

- Cutting Deck Circuit Pressure Test (Using Pressure Gauge)

- Cutting Deck Circuit Relief Pressure Test (Using Tester with Pressure Gauge and 40 GPM Flow Meter)

- Cutting Deck Motor Case Drain Leakage Test (Using Tester with Pressure Gauge & 40 GPM Flow Meter)

- Lift, Lower Circuit Relief Pressure Test (Using Pressure Gauge)

- Steering Circuit Relief Pressure Test (Using Pressure Gauge)

- Steering Cylinder Internal Leakage Test

- Gear Pump (PTO, Steering, Deck Lift, Lower and Traction Charge Circuits) Flow Test (Using Tester with Pressure Gauges and Flow Meter)

- Adjustments

- Adjust Manifold Relief Valves

- Service and Repairs

- General Precautions for Removing and Installing Hydraulic System Components

- Check Hydraulic Lines and Hoses

- Priming Hydraulic Pumps

- Flush Hydraulic System

- Charge Hydraulic System

- Filtering Closed−Loop Traction Circuit

- Hydraulic Reservoir

- Gear Pump

- Gear Pump Service

- Traction Circuit

- Piston (Traction) Pump

- Piston (Traction) Pump Service

- Front Wheel Motors

- Rear Wheel Motors

- Wheel Motor Service

- Traction Control Manifold

- Traction Control Manifold Service

- Brake Release Manifold

- Brake Release Manifold Service

- Cutting Deck Circuit

- Cutting Deck Motor

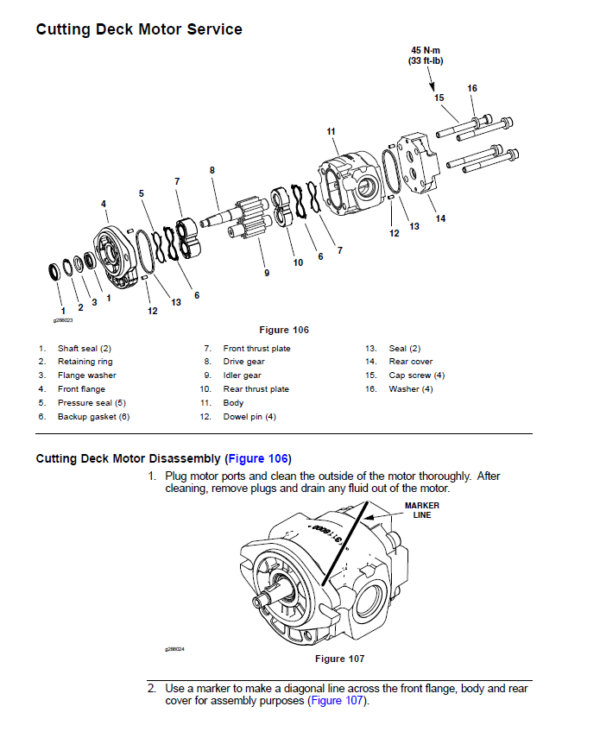

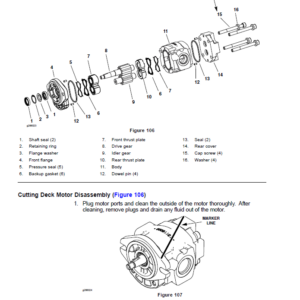

- Cutting Deck Motor Service

- Cutting Deck Control Manifolds

- Cutting Deck Control Manifold Service

- Steering and Cutting Deck Lift Circuits

- Steering Control Valve (For machines serial number below 403450000)

- Steering Control Valve (For machines serial number above 403450001)

- Steering Control Valve Service (For machines serial number below 40345000)

- Steering Control Valve Service (For machines serial number above 403450001)

- Steering Cylinders

- Steering Cylinder Service

- Front Cutting Deck Lift Cylinders

- Front Cutting Deck Lift Cylinder Service

- Wing Cutting Deck Lift Cylinders

- Wing Cutting Deck Lift Cylinder Service

- Steering, Deck Lift Control Manifold

- Steering, Deck Lift Control Manifold Service

- Cartridge Valve Service

- Hydraulic Oil Cooler

- Danfoss H1 Closed Circuit Axial Piston Pumps Service Repair Manual

- Danfoss H1 Closed Circuit Axial Piston pumps Repair Instructions

- Danfoss Steering Unit Type OSPM Service Repair Manual

- Eaton Parts And Repair Information: 5 Series Steering Control Units

- Chapter 6 : Electrical System

- General Information

- Operator’s Manual

- Operator Cab Components

- Toro Electronic Controllers (TEC)

- Engine Electronic Control Unit (ECU)

- Yanmar Engine Electrical Components

- Battery−Disconnect Switch

- Electrical System Operation

- 12 Volt System

- 24 Volt System

- CAN−bus Communications

- Electrical Drawings

- InfoCenter Display

- Operator Information Screen

- MAIN MENU

- SERVICE

- HOURS

- TRACTION PEDAL

- FAN OVERRIDE

- FAN DEMO

- REGENERATION

- DIAGNOSTICS SCREENS

- Electrical System Quick Checks

- Adjustments

- Cutting Deck Position Switch Adjustment

- Component Testing

- Fusible Link Harness

- Mega Fuses

- Fuses

- Battery−Disconnect Switch

- Toro Electronic Controllers (TECs)

- Key Switch

- PTO Switch

- Cutting Deck Raise, Lower Switches

- Throttle Switch

- High, Low Range Traction Speed Switch

- Cruise Control Switch

- Headlight Switch

- Turn Signal Switch

- Hazard Switch

- Parking Brake Switch

- Horn Button

- Contactors

- Seat Switch

- Windshield Wiper, Washer Switch (Groundsmaster 5910)

- Air Conditioning Switch (Groundsmaster 5910)

- Fan Speed Switch (Groundsmaster 5910)

- Work Light and Beacon Switches (Groundsmaster 5910 − Optional)

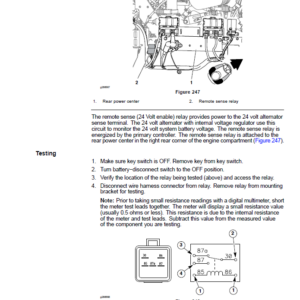

- Relays with Four (4) Terminals

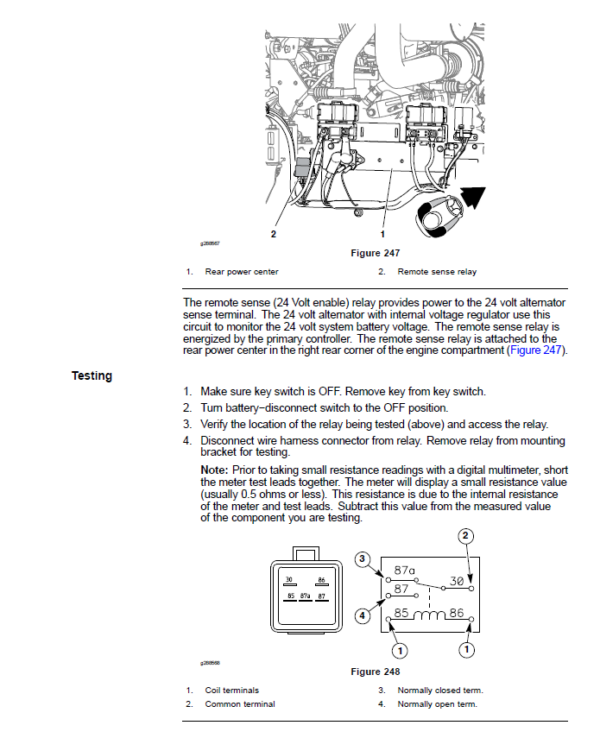

- Relays with Five (5) Terminals

- Hydraulic Solenoid Valves

- Air Filter Service Indicator

- Fuel Sender

- Fuel Pump

- Hydraulic Oil Temperature Sender

- CAN−bus Terminator Resistor

- Resistor Assemblies

- Diode Assemblies

- Audible Alarm

- Traction Pedal Position Sensor

- Piston (Traction) Pump Control Solenoid Coils

- Cutting Deck Position Switches

- 24 Volt Cooling Fans

- 24 Volt Alternator

- 24 Volt Voltage Divider

- Fan Speed Switch (Machines with Two−Post ROPS Extension Operator Fan Kit)

- Resistor Module (Machines with Two−Post ROPS Extension Operator Fan Kit)

- Service and Repairs

- Batteries

- Hydraulic Solenoid Valve Coils

- 24 Volt Alternator, Air Conditioning Compressor Drive Belt

- 24 Volt Alternator

- Chapter 7 : Chassis

- General Information

- Operator’s Manual

- Service and Repairs

- Wheels

- Steering Column (For machines serial number below 403450000)

- Steering Column (For machines serial number above 403450001)

- Rear Axle

- Rear Axle Service

- Front Deck Lift Arms

- Wing Deck Lift Arms

- Wing Deck Lift Arm Joint Yoke

- Wing Deck Impact Arm Assembly

- Console Arm

- Traction Pedal

- Operator Seat

- Operator Seat Service

- Operator Seat Suspension

- Hood and Lower Shrouds

- Chapter 8 : Cutting Decks

- General Information

- Operator’s Manual

- Blade Stopping Time

- Service and Repairs

- Front Cutting Deck

- Front Cutting Deck Winglets

- Wing Cutting Decks

- Drive Belt Idler Assemblies

- Blade Spindles

- Blade Spindle Service

- Castor Forks and Wheels

- Deck Skids and Front Deck Roller ( and )

- Chapter 9 : Operator Cab

- General Information

- Operator’s Manual

- Electrical Components, Schematics and Wire Harness Drawings

- Air Conditioning System

- Cab Heater System

- Air Conditioning System Performance

- Service and Repairs

- General Precautions for Removing and Installing Air Conditioning System Components

- Air Conditioning Compressor

- Roof Assembly

- Heating and Air Conditioning Components

- A, C Condenser Fan Assembly

- A, C Condenser Assembly

- Mixing Box Assembly

- Heater and A, C Evaporator Cores

- Blower Fan

- Windshield Wiper Assembly

- Sanden SD Compressor Service Guide

- Appendix A: Foldout Drawings

- Electrical Drawing Designations

- Hydraulic Schematic

- Electrical Schematic (machine serial numbers below 316000200)

- Electrical Schematic (machine serial numbers below 316000200)

- Electrical Schematic (machine serial numbers 316000201 to 399999999)

- Electrical Schematic (machine serial numbers 316000201 to 399999999)

- Electrical Schematic (machine serial numbers 400000000 to 403450000)

- Electrical Schematic (machine serial numbers 400000000 to 403450000)

- Electrical Schematic (machine serial numbers 403450001 to 405600000)

- Electrical Schematic (machine serial numbers 403450001 to 405600000)

- Electrical Schematic (machine serial numbers 405600001 to 408000000)

- Electrical Schematic (machine serial numbers 405600001 to 408000000)

- Electrical Schematic (machine serial numbers above 408000000)

- Electrical Schematic (machine serial numbers above 408000000)

- Operator Platform Wire Harness Drawing (machine serial numbers below 316000200)

- Operator Platform Wire Harness Diagram (machine serial numbers below 316000200)

- Operator Platform Wire Harness Diagram (machine serial numbers below 316000200)

- Operator Platform Wire Harness Drawing (machine serial numbers 316000201 to 316999999)

- Operator Platform Wire Harness Diagram (machine serial numbers 316000201 to 316999999)

- Operator Platform Wire Harness Diagram (machine serial numbers 316000201 to 316999999)

- Operator Platform Wire Harness Diagram (machine serial numbers 400000000 to 403450000)

- Operator Platform Wire Harness Diagram (machine serial numbers 400000000 to 403450000)

- Operator Platform Wire Harness Diagram (machine serial numbers 400000000 to 403450000)

- Operator Platform Wire Harness Diagram (machine serial numbers 403450001 to 405600000)

- Operator Platform Wire Harness Diagram (machine serial numbers 403450001 to 405600000)

- Operator Platform Wire Harness Diagram (machine serial numbers 403450001 to 405600000)

- Operator Platform Wire Harness Drawing (machine serial numbers 405600001 to 408000000)

- Operator Platform Wire Harness Diagram (machine serial numbers 405600001 to 408000000)

- Operator Platform Wire Harness Drawing (machine serial numbers above 408000000)

- Operator Platform Wire Harness Diagram (machine serial numbers above 408000000)

- Rear Wire Harness Drawing (machine serial numbers below 316000200)

- Rear Wire Harness Diagram (machine serial numbers below 316000200)

- Rear Wire Harness Drawing (machine serial numbers 316000201 to 403450000)

- Rear Wire Harness Drawing (machine serial numbers 316000201 to 403450000)

- Rear Wire Harness Drawing (machine serial numbers 403450001 to 405600000)

- Rear Wire Harness Drawing (machine serial numbers 403450001 to 405600000)

- Rear Wire Harness Drawing (machine serial numbers 405600001 to 408000000)

- Rear Wire Harness Diagram (machine serial numbers 405600001 to 408000000)

- Rear Wire Harness Drawing (machine serial numbers above 408000000)

- Rear Wire Harness Diagram (machine serial numbers above 408000000)

- Engine Wire Harness Drawing (machine serial numbers 316000001 to 316999999)

- Engine Wire Harness Drawing (machine serial numbers 316000001 to 316999999)

- Engine Wire Harness Drawing (machine serial numbers 400000000 to 403450000)

- Engine Wire Harness Drawing (machine serial numbers 400000000 to 403450000)

- Engine Wire Harness Drawing (machine serial numbers above 403450001)

- Engine Wire Harness Drawing (machine serial numbers above 403450001)

- Engine DPF Wire Harness Drawing (machine serial numbers above 408000000)

- NO TITLE

- Cab Power Supply Wire Harness (Machine serial numbers below 316000200)

- Cab Headliner Wire Harness Drawing (Machine serial numbers below 308000000)

- Cab Headliner Wire Harness Diagram (Machine serial numbers below 308000000)

- Cab Headliner Wire Harness Drawing (Machine serial numbers above 308000000)

- Cab Headliner Wire Harness Diagram (Machine serial numbers above 308000000)

- Wire Harness Diagram − Two−Post ROPS Extension

- Wire Harness Diagram − Two−Post ROPS Extension

Be the first to review “Toro Groundsmaster 5900, 5910 (Model 31698, 31600 – Tier 4) Service Repair Manual”

You must be logged in to post a review.

Reviews

There are no reviews yet.