Toro Groundsmaster 4500-D, 4700-D (Models 30885, 30887, 30893, 30893TE, 30899, 30899TE) Service Repair Manual

$34.00

Manual Included:

- Service Repair Manual: 492 Pages

Specifications:

- Brand: Toro

- Model: Groundsmaster 4500-D, 4700-D (Models 30885, 30887, 30893, 30893TE, 30899, 30899TE)

- Type: Rotary Mowers

- Manuals: Service Repair Manual

- Publication Numbers: 19245SL

- Language: English

- Format: PDF

- Description

- Reviews (0)

Description

Table of Content – Groundsmaster 4500-D, 4700-D (Models 30885, 30887, 30893, 30893TE, 30899, 30899TE)

- Title Page

- Revision History

- Reader Comments

- NOTES

- Preface

- Service Procedure Icons

- Table of Contents

- Chapter 1 : Safety

- Safety Instructions

- Before Operating the Machine

- While Operating the Machine

- Maintenance and Service

- Jacking Instructions

- Safety and Instructional Decals

- Chapter 2 : Specifications and Maintenance

- Specifications

- Overall Dimensions

- Engine (Models 30893, 30893TE, 30899 and 30899TE)

- Engine (Models 30885 and 30887)

- Hydraulic System

- Axles, Planetaries and Brakes

- Cutting Decks

- Torque Specifications

- Calculating the Torque Values When Using a Drive-Adapter Wrench

- Identifying the Fastener

- Standard Torque for Dry, Zinc Plated, and Steel Fasteners (Inch Series)

- Standard Torque for Dry, Zinc Plated, and Steel Fasteners (Metric Fasteners)

- Other Torque Specifications

- Conversion Factors

- Shop Supplies

- Special Tools

- Chapter 3 : Troubleshooting

- GEARS – The Systematic Approach to Defining, Diagnosing and Solving Problems

- Gather Information

- Evaluate Potential Causes

- Assess Performance

- Repair

- Solution Confirmation

- General Hydraulic System Problems

- Traction Problems

- Mow Problems

- Steering Problems

- Lift Problems

- Engine Cooling Fan Problems

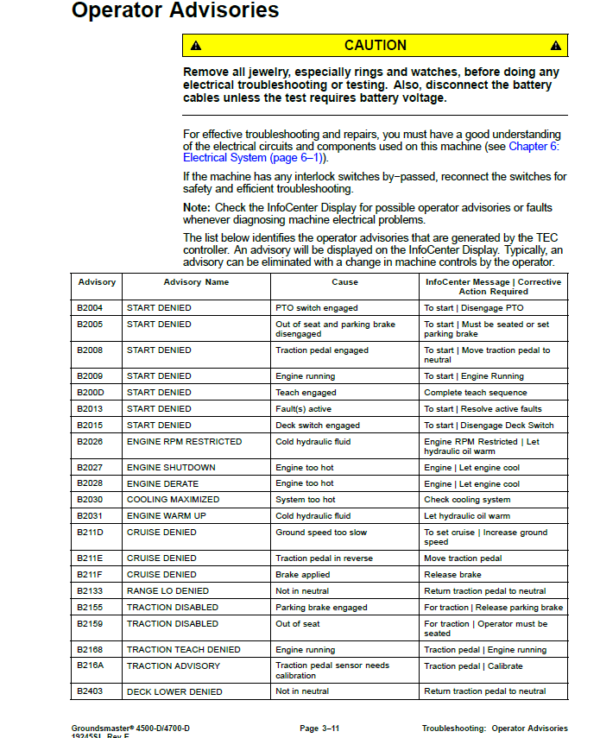

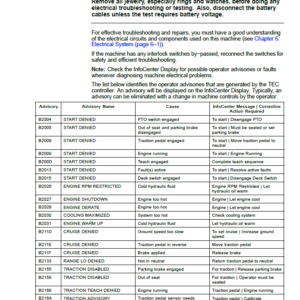

- Operator Advisories

- Machine Fault Codes

- Starting Problems

- General Run and Transport Problems

- Cutting Deck Operating Problems

- Cutting Deck Lift, Lower Problems

- Aftercut Appearance

- Chapter 4 : Yanmar Diesel Engine

- General Information

- Operator’s Manual

- Yanmar Service and Troubleshooting Manuals

- Stopping the Engine

- Engine Electronic Control Unit (ECU)

- Yanmar Engine: Models 30893, 30893TE, 30899 and 30899TE

- Yanmar Engine: Models 30885 and 30887

- Diesel Particulate Filter

- Service and Repairs

- Air Cleaner System

- Fuel System

- Radiator and Oil Cooler Assembly

- Engine

- Pump Adaptor Plate

- Exhaust System (Models 30885 and 30887)

- Yanmar TNV (Tier 4i) Series Service Repair Manual

- Yanmar TNV (Tier 4i) Series Troubleshooting Manual

- Yanmar TNV (Tier 4) Series Service Repair Manual

- Yanmar TNV (Tier 4) Series Troubleshooting Manual

- Chapter 5 : Hydraulic System

- General Information

- Operator’s Manual

- Check Hydraulic Fluid

- Towing Traction Unit

- Relieving Hydraulic System Pressure

- Traction Circuit Component Failure

- Hydraulic Hoses

- Installing Hydraulic Hoses and Tubes (O-Ring Face Seal)

- Installing the Hydraulic Fittings (SAE Straight Thread O-Ring Fittings)

- Hydraulic Schematic

- Hydraulic Flow Diagrams

- Traction Circuit: LOW Speed

- Traction Circuit: HIGH Speed

- Lower Cutting Decks: Groundsmaster 4500-D

- Lower Cutting Decks: Groundsmaster 4700-D

- Raise Cutting Decks: Groundsmaster 4500-D

- Raise Cutting Decks: Groundsmaster 4700-D

- Mow Circuit

- Cutting Deck Blade Braking

- Steering Circuit

- Engine Cooling Fan Circuit

- Testing

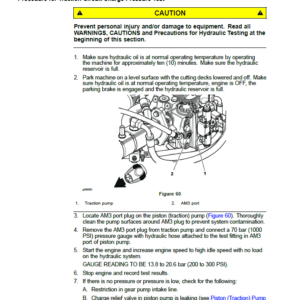

- Precautions for Hydraulic Testing

- Which Hydraulic Tests Are Necessary?

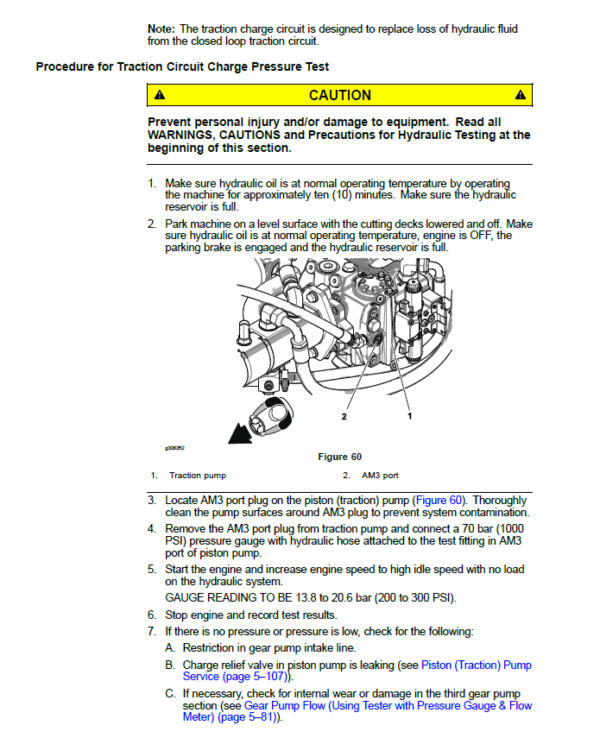

- Traction Circuit Charge Pressure (Using Pressure Gauge)

- Traction Circuit Relief Pressure (Using Pressure Gauge)

- Reverse Traction Circuit Reducing Valve (PR) Pressure (Using Pressure Gauge)

- Rear Traction Circuit Relief (RV) Pressure (Using Pressure Gauge)

- Piston (Traction) Pump Flow (Using Tester with Pressure Gauge & Flow Meter)

- Cutting Deck Circuit Pressure (Using Pressure Gauge)

- Cutting Deck Circuit Relief Pressure (Using Tester with Pressure Gauge & Flow Meter)

- Deck Motor Case Drain Leakage (Using Tester with Pressure Gauge & Flow Meter)

- Steering Circuit Relief Pressure (Using Pressure Gauge)

- Steering Cylinder Internal Leakage

- Lift, Lower Circuit Relief Pressure (Using Pressure Gauge)

- Engine Cooling Fan Circuit (Using Pressure Gauge and Phototac)

- Gear Pump Flow (Using Tester with Pressure Gauge & Flow Meter)

- Procedure for Gear Pump Flow Test

- Adjustments

- Adjust Control Manifold Relief Valves

- Service and Repairs

- General Precautions for Removing and Installing Hydraulic System Components

- Check Hydraulic Lines and Hoses

- Priming Hydraulic Pumps

- Flush Hydraulic System

- Filtering Closed−Loop Traction Circuit

- Charge Hydraulic System

- Gear Pump

- Gear Pump Service

- Piston (Traction) Pump

- Piston (Traction) Pump Service

- Rear Traction Control Manifold

- Rear Traction Manifold Service

- Control Manifold Cartridge Valve Service

- Two Speed Shift Manifold

- Rear Axle Motor

- Front Wheel Motors

- Rear Axle and Front Wheel Motor Service

- Cutting Deck Motor

- Cutting Deck Motor Service

- Deck Control Manifold

- Deck Control Manifold Service (GM4500-D)

- Deck Control Manifold Service (GM4700-D)

- Steering Control Valve

- Steering Control Valve Service

- Steering Cylinder

- Steering Cylinder Service

- Engine Cooling Fan Motor

- Engine Cooling Fan Motor Service

- Fan Control Manifold

- Fan Control Manifold Service

- Lift Control Manifold

- Lift Control Manifold Service (GM4500-D)

- Lift Control Manifold Service (GM4700-D)

- Lift Circuit Junction Manifold

- Lift Cylinders: Decks #1, #4 and #5

- Lift Cylinders: Decks #2 and #3

- Lift Cylinders: Decks #6 and #7 (GM4700-D)

- Lift Cylinder Service

- Hydraulic Reservoir

- Radiator and Oil Cooler Assembly

- Danfoss K And L Frame Variable Motors Service Repair Manual

- Danfoss Steering Unit Type OSPM Service Repair Manual

- Danfoss MP1 Closed Circuit Axial Piston Pumps Service Repair Manual

- Chapter 6 : Electrical System

- General Information

- Operator's Manual

- Electrical Drawings

- Toro Electronic Controllers (TEC)

- Engine Electronic Control Unit (ECU)

- Yanmar Engine Electrical Components

- CAN−bus Communications

- Electrical Drawings

- InfoCenter Display

- Adjustments

- Traction Pedal Adjustment

- Traction Pedal Position Sensor Calibration

- Traction Pump Swashplate Angle Sensor Calibration

- Electrical System Quick Checks

- Battery Test (Open Circuit)

- Charging System Test

- Check Operation of Interlock Switches

- Component Testing

- Ignition Switch

- Fuses

- Fusible Link Harness

- PTO Switch

- High, Low Speed, Engine Speed Request and Cutting Deck Lift Switches

- Headlight Switch

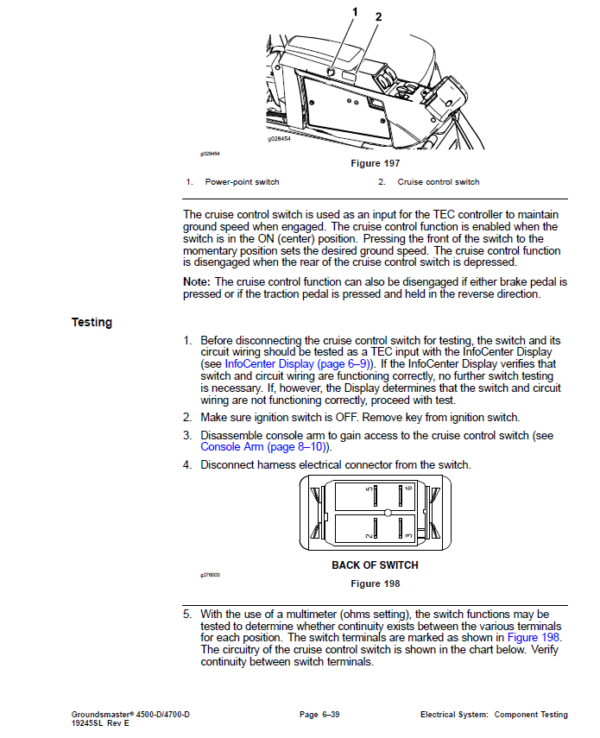

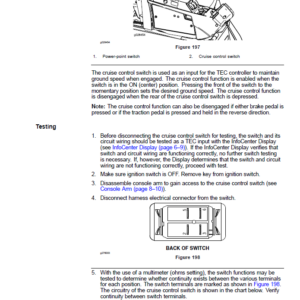

- Cruise Control Switch

- Seat Switch

- Parking Brake Switch

- Service Brake Switches

- Cutting Deck Position Switches

- Relays with Four (4) Terminals

- Relays with Five (5) Terminals

- Traction Pedal Position Sensor

- Swashplate Angle Sensor

- Toro Electronic Controllers (TEC)

- Hydraulic Solenoid Valve Coils

- Piston (Traction) Pump Control Solenoid Coils

- Hydraulic Oil Temperature Sender

- Traction Pressure Sensor

- Fuel Pump (Models 30893, 30893TE, 30899 and 30899TE)

- Fuel Pump (Models 30885 and 30887)

- CAN−bus Termination Resistor

- Diode Assemblies

- Resistor Assembly

- Capacitor Assembly

- Fan Speed Switch (Machines with Two−Post ROPS Extension Operator Fan Kit)

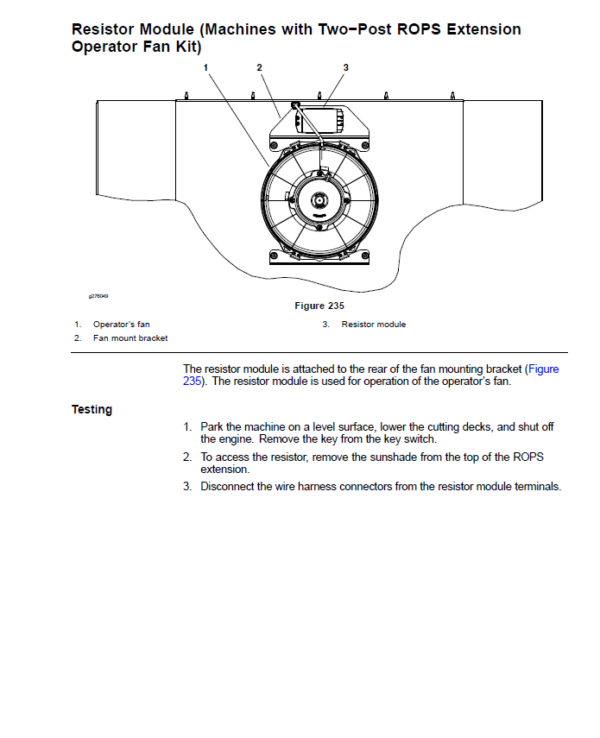

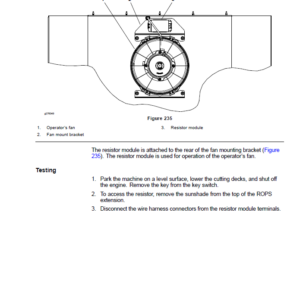

- Resistor Module (Machines with Two−Post ROPS Extension Operator Fan Kit)

- Service and Repairs

- Battery Care

- Battery Storage

- Battery Service

- Chapter 7 : Axles, Planetaries and Brakes

- General Information

- Operator’s Manual

- Adjustments

- Planetary Drive Assembly Endplay

- Service and Repairs

- Brake Assembly

- Brake Inspection and Repair

- Planetary Drive Assembly

- VA02 Series Planetary Drive Service

- Rear Axle Assembly

- Rear Axle Service

- Bevel Gear Case and Axle Case

- Differential Shafts

- Axle Shafts

- Input Shaft, Pinion Gear

- Differential Gear

- Pinion Gear to Ring Gear Engagement

- Gear Pattern Movement Summary

- Chapter 8 : Chassis

- General Information

- Operator’s Manual

- Cutting Deck Identification

- Service and Repairs

- Steering Column

- Traction Pedal

- Console Arm

- Lift Arms for Cutting Decks #1, #4 and #5

- Lift Arms for Cutting Decks #2 and #3

- Lift Arms for Cutting Decks #6 and #7 (Groundsmaster 4700-D)

- Operator Seat

- Operator Seat Service

- Operator Seat Suspension

- Hood

- Chapter 9 : Cutting Decks

- General Information

- Operator’s Manual

- Adjustments

- Blade Stopping Time

- Service and Repairs

- Blade Spindle Assembly

- Blade Spindle Service

- Rear Roller

- Rear Roller Service

- Front Roller Service

- Cutting Deck Carrier Frame

- Appendix A: Foldout Drawings

- Electrical Drawing Designations

- Hydraulic Schematic – Groundsmaster 4500-D

- Hydraulic Schematic – Groundsmaster 4700-D

- Electric Schematic – Groundsmaster 4500-D, 4700-D (Models 30885 and 30887)

- Electric Schematic – Groundsmaster 4500-D, 4700-D (Models 30893, 30893TE, 30899 and 30899TE)

- Optional Operator Cab Electrical Schematic – Groundsmaster 4500-D, 4700-D

- Main Wire Harness – Groundsmaster 4500-D, 4700-D

- Main Wire Harness – Groundsmaster 4500-D, 4700-D

- Seat and Console Wire Harness – Groundsmaster 4500-D, 4700-D

- Seat and Console Wire Harness – Groundsmaster 4500-D, 4700-D

- Power Center Wire Harness – Groundsmaster 4500-D, 4700-D

- Power Center Wire Harness – Groundsmaster 4500-D, 4700-D

- Deck 6 and 7 Wire Harness – Groundsmaster 4700-D

- Deck 6 and 7 Wire Harness – Groundsmaster 4700-D

- Engine Wire Harness Drawing – Groundsmaster 4500−D, 4700−D (Models 30885 and 30887) (Serial Numbers Below 408000000)

- Engine Wire Harness Drawing – Groundsmaster 4500−D, 4700−D (Models 30885 and 30887) (Serial Numbers Below 408000000)

- Engine Wire Harness Drawing – Groundsmaster 4500−D, 4700−D (Models 30885 and 30887) (Serial Numbers Above 408000000)

- Engine Wire Harness Drawing – Groundsmaster 4500−D, 4700−D (Models 30885 and 30887) (Serial Numbers Above 408000000)

- Engine DPF Wire Harness Drawing – Groundsmaster 4500−D, 4700−D (Models 30885 and 30887) (Serial Numbers Above 408000000)

- NO TITLE

- Engine Wire Harness Drawing – Groundsmaster 4500−D, 4700−D (Models 30893, 30893TE, 30899 and 30899TE)

- Engine Wire Harness Drawing – Groundsmaster 4500−D, 4700−D (Models 30893, 30893TE, 30899 and 30899TE)

- Wire Harness Diagram – Two−Post ROPS Extension

- Wire Harness Diagram – Two−Post ROPS Extension

Be the first to review “Toro Groundsmaster 4500-D, 4700-D (Models 30885, 30887, 30893, 30893TE, 30899, 30899TE) Service Repair Manual”

You must be logged in to post a review.

Reviews

There are no reviews yet.