Toro Groundsmaster 4500-D, 4700-D (Models 30873, 30874, 30881, 30882) Service Repair Manual

$34.00

Manual Included:

- Service Repair Manual: 390 Pages

Specifications:

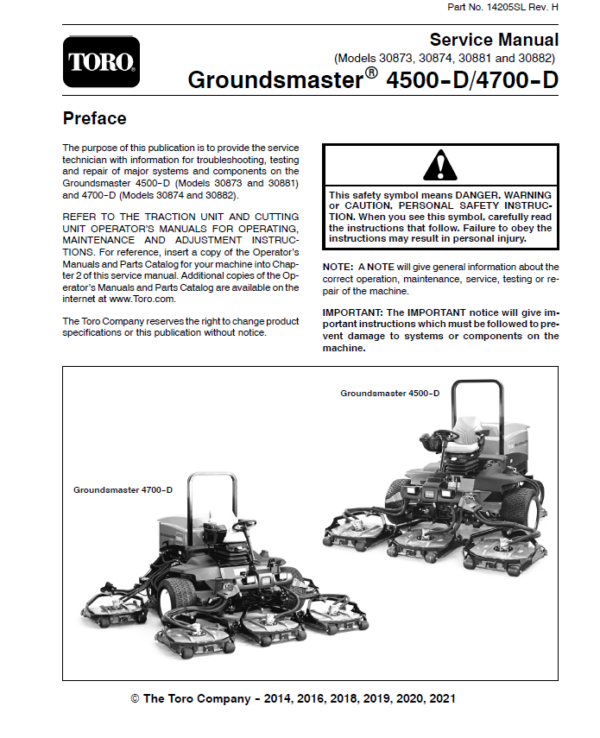

- Brand: Toro

- Model: Groundsmaster 4500-D, 4700-D (Models 30873, 30874, 30881, 30882) REVISED

- Type: Rotary Mowers

- Manuals: Service Repair Manual

- Publication Numbers: 14205SL

- Language: English

- Format: PDF

- Description

- Reviews (0)

Description

Table of Content – Groundsmaster 4500-D, 4700-D (Models 30873, 30874, 30881, 30882) REVISED

- Title Page

- Revision History

- Reader Comments

- Preface

- Table Of Contents

- 1 – Safety

- Table of Contents

- General Safety Instructions

- Before Operating

- While Operating

- Maintenance and Service

- Jacking Instructions

- Safety and Instruction Decals

- 2 – Product Records and Maintenance

- Table of Contents

- Product Records

- Maintenance

- Equivalents and Conversions

- Decimal and Millimeter Equivalents

- U.S. to Metric Conversions

- Torque Specifications

- Fastener Identification

- Using a Torque Wrench with an Offset Wrench

- Standard Torque for Dry, Zinc Plated and Steel Fasteners (Inch Series)

- Standard Torque for Dry, Zinc Plated and Steel Fasteners (Metric Series)

- Other Torque Specifications

- Conversion Factors

- 3 – Yanmar Diesel Engine

- Table of Contents

- Specifications (Models 30873 and 30874)

- Specifications (Models 30881 and 30882)

- General Information

- Operator’s Manuals

- Yanmar Service and Troubleshooting Manuals

- Stopping the Engine

- Engine Electronic Control Unit (ECU)

- Yanmar Engine: Models 30873 and 30874

- Yanmar Engine: Models 30881 and 30882

- Diesel Particulate Filter (DPF)

- Service and Repairs

- Air Cleaner System

- Fuel System

- Radiator and Oil Cooler Assembly

- Engine

- Pump Adapter Plate

- Exhaust System (Models 30881 and 30882)

- YANMAR TNV (Tier 4i) SERIES Service Repair Manual

- YANMAR TNV (Tier 4i) SERIES TROUBLESHOOTING

MANUAL - YANMAR TNV (Tier 4) SERIES Service Repair Manual

- YANMAR TNV (Tier 4) SERIES TROUBLESHOOTING

MANUAL - 4 – Hydraulic System

- Table of Contents

- Specifications

- General Information

- Operator’s Manual

- Check Hydraulic Fluid

- Towing Traction Unit

- Relieving Hydraulic System Pressure

- Traction Circuit Component Failure

- Hydraulic Hoses

- Hydraulic Hose and Tube Installation (O-Ring Face Seal Fitting)

- Hydraulic Fitting Installation (SAE Straight Thread O-Ring Fitting into Component Port)

- Hydraulic Schematics

- Groundsmaster 4500-D

- Grondsmaster 4700-D

- Hydraulic Flow Diagrams

- Traction Circuit: LOW Speed

- Traction Circuit: HI Speed

- Lower Cutting Decks (GM4500-D)

- Lower Cutting Decks (GM4700-D)

- Raise Cutting Decks (GM4500-D)

- Raise Cutting Decks (GM4700-D)

- Mow Circuit

- Cutting Deck Blade Braking

- Steering Circuit

- Engine Cooling Fan Circuit

- Special Tools

- Troubleshooting

- General Hydraulic System Problems

- Traction Circuit Problems

- Mow Circuit Problems

- Steering Circuit Problems

- Lift, Lower Circuit Problems

- Engine Cooling Fan Circuit Problems

- Testing

- Traction Circuit Charge Pressure

- Traction Circuit Relief Pressure

- Reverse Traction Circuit Reducing Valve (PR) Pressure

- Rear Traction Circuit Relief (RV) Pressure

- Piston (Traction) Pump Flow

- Cutting Deck Circuit Pressure

- Cutting Deck Circuit Relief Pressure

- Deck Motor Case Drain Leakage

- Steering Circuit Relief Pressure

- Steering Cylinder Internal Leakage

- Lift, Lower Circuit Relief Pressure

- Engine Cooling Fan Circuit

- Gear Pump Flow

- Adjustments

- Adjust Control Manifold Relief Valves

- Service and Repairs

- General Precautions for Removing and Installing Hydraulic System Components

- Check Hydraulic Lines and Hoses

- Priming Hydraulic Pumps

- Flush Hydraulic System

- Filtering Closed-Loop Traction Circuit

- Charge Hydraulic System

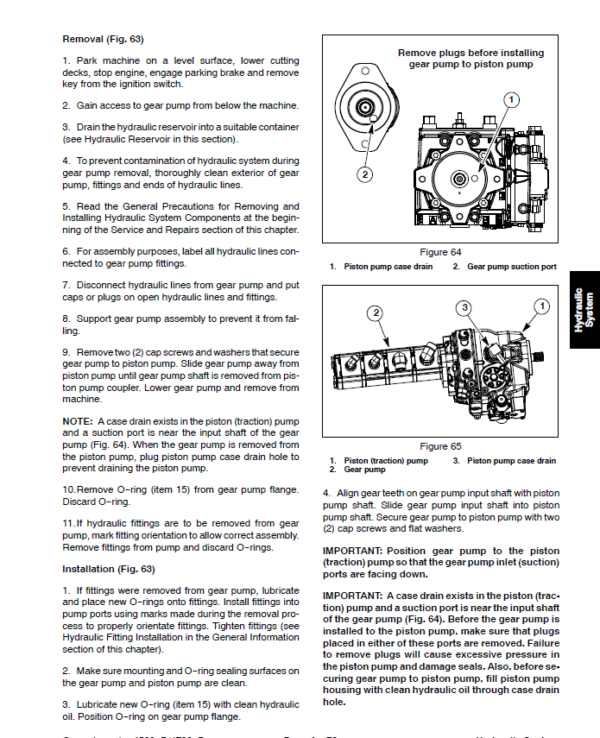

- Gear Pump

- Gear Pump Service

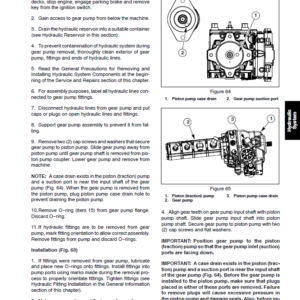

- Piston (Traction) Pump

- Piston (Traction) Pump Service

- Rear Traction Control Manifold

- Rear Traction Control Manifold Service

- Control Manifold Cartridge Valve Service

- HI, LOW Range Control Manifold

- Rear Axle Motor

- Front Wheel Motors

- Rear Axle and Front Wheel Motor Service

- Cutting Deck Motor

- Cutting Deck Motor Service

- Deck Control Manifold

- Deck Control Manifold Service (GM 4500-D)

- Deck Control Manifold Service (GM 4700-D)

- Steering Control Valve

- Steering Control Valve Service

- Steering Cylinder

- Steering Cylinder Service

- Engine Cooling Fan Motor

- Engine Cooling Fan Motor Service

- Fan Control Manifold

- Fan Control Manifold Service

- Lift Control Manifold

- Lift Control Manifold Service (GM 4500-D)

- Lift Control Manifold Service (GM 4700-D)

- Lift Circuit Junction Manifold

- Lift Cylinders: Decks #1, #4 and #5

- Lift Cylinders: Decks #2 and #3

- Lift Cylinders: Decks #6 and #7 (GM 4700-D)

- Lift Cylinder Service

- Hydraulic Reservoir

- Radiator and Oil Cooler Assembly

- DANFOSS H1 AXIAL PISTON PUMPS Service Repair Manual

- DANFOSS H1 AXIAL PISTON PUMPS REPAIR INSTRUCTIONS

- DANFOSS MP1 CLOSED CIRCUIT AXIAL PISTON PUMPS Service Repair Manual

- DANFOSS K and L MOTORS Service Repair Manual

- DANFOSS STEERING UNIT OSPM Service Repair Manual

- 5 – Electrical System

- Table of Contents

- General Information

- Operator’s Manual

- Electrical Drawings

- Toro Electronic Controllers (TEC)

- Yanmar Engine Electronic Control Unit (ECU)

- Yanmar Engine Electrical Components

- CAN-bus Communications

- Special Tools

- InfoCenter Display

- Splash Screens

- Main Information Screens

- Main Menu Screen

- Faults Screen

- Service Screen

- Diagnostics Screen

- Settings Screen

- About Screen

- Troubleshooting

- Operator Advisories

- Fault Codes

- Starting Problems

- General Run and Transport Problems

- Cutting Deck Operating Problems

- Cutting Deck Lift, Lower Problems

- Electrical System Quick Checks

- Battery Test (Open Circuit Test)

- Charging System Test

- Check Operation of Interlock Switches

- Adjustments

- Traction Pedal Adjustment

- Traction Pedal Position Sensor Calibration

- Component Testing

- Ignition Switch

- Fuses

- Fusible Link Harness

- PTO Switch

- Hi, Low Speed, Engine Speed Request and Cutting Deck Lift Switches

- Headlight Switch

- Seat Switch

- Parking Brake Switch

- Cutting Deck Position Switches

- Relays with Four (4) Terminals

- Relays with Five (5) Terminals

- Traction Pedal Position Sensor

- Toro Electronic Controllers (TEC)

- Hydraulic Solenoid Valve Coils

- Piston (Traction) Pump Control Solenoid Coils

- Hydraulic Oil Temperature Sender

- Fuel Pump (Models 30873 and 30874)

- Fuel Pump (Models 30881 and 30882)

- CAN-bus Termination Resistor

- Diode Assemblies

- Resistor Assemblies

- Fan Speed Switch (Machines with Two−Post ROPS Extension Operator Fan Kit)

- Resistor Module (Machines with Two−Post ROPS Extension Operator Fan Kit)

- Service and Repairs

- Battery Care

- Battery Storage

- Battery Service

- Battery Removal and Installation

- Battery Inspection and Maintenance

- Battery Testing

- Battery Charging

- 6 – Axles, Planetaries and Brakes

- Table of Contents

- Specifications

- General Information

- Operator's Manual

- Adjustments

- Planetary Drive Endplay (OPH-2 series planetary drives)

- Service and Repairs

- Brake Assembly

- Brake Inspection and Repair

- Planetary Drive Assembly

- OPH-2 Series Planetary Drive Service

- VA02 Series Planetary Drive Service

- Rear Axle Assembly

- Rear Axle Service

- Bevel Gear Case and Axle Case

- Differential Shafts

- Axle Shafts

- Input Shaft, Pinion Gear

- Differential Gear

- Pinion Gear to Ring Gear Engagement

- 7 – Chassis

- Table of Contents

- General Information

- Operator’s Manual

- Cutting Deck Identification

- Service and Repairs

- Steering Column

- Traction Pedal

- Console Arm

- Lift Arms for Cutting Decks #1, #4 and #5

- Lift Arms for Cutting Decks #2 and #3

- Lift Arms for Cutting Decks #6 and #7 (GM 4700-D)

- Operator Seat

- Operator Seat Service

- Operator Seat Suspension

- Hood

- 8 – Cutting Decks

- Table of Contents

- Specifications

- General Information

- Operator’s Manual

- Troubleshooting

- Factors That Can Affect Quality of Cut

- Special Tools

- Adjustments

- Blade Stopping Time

- Service and Repairs

- Blade Spindle Assembly

- Blade Spindle Service

- Rear Roller

- Rear Roller Service

- Front Roller Service

- Cutting Deck Carrier Frame

- 9 – Foldout Drawings

- Electrical Drawing Designations

- Groundsmaster 4500–D Hydraulic Schematic

- Groundsmaster 4500–D With Optional Flow Divider Kit Hydraulic Schematic

- Groundsmaster 4700–D Hydraulic Schematic

- Groundsmaster 4700–D With Optional Flow Divider Kit Hydraulic Schematic

- Electrical Schematic

Groundsmaster 4500–D, 4700–D

Models 30881 and 30882

(Serial numbers below 315000300) - Electrical Schematic Groundsmaster 4500–D, 4700–DModels 30873 and 30874(Serial numbers below 315000300)

- Groundsmaster 4500–D, 4700–D

Electrical Schematic

Models 30881 and 30882

(Serial Numbers 315000301 to 399999999) - Groundsmaster 4500–D, 4700–D Electrical Schematic Models 30873 and 30874 (Serial Numbers 315000301 to 399999999)

- Groundsmaster 4500–D, 4700–D Electrical Schematic Models 30881 and 30882(Serial Numbers 400000000 to 403450000)

- Groundsmaster 4500–D, 4700–D Electrical Schematic Models 30873 and 30874(Serial Numbers 400000000 to 403450000)

- Groundsmaster 4500–D, 4700–D Electrical Schematic (Serial Numbers Serial Numbers 403450001 to 408000000)Models 30881 and 30882

- Groundsmaster 4500–D, 4700–DElectrical Schematic(Serial Numbers Above 408000000)

- Groundsmaster 4500–D, 4700–D Electrical Schematic (Serial Numbers Above 403450001) Models 30873 and 30874

- Electrical Schematic Groundsmaster 4500–D, 4700–D Optional Operator Cab (Serial number below 399999999)

- Groundsmaster 4500–D, 4700–D Electrical Schematic Optional Operator Cab (Serial Numbers Above 400000000)

- Groundsmaster 4500–D, 4700–D Main Wire Harness (Serial number below 315000300)

- Groundsmaster 4500–D, 4700–D Main Wire Harness (Serial Numbers 315000301 to 399999999)

- Groundsmaster 4500–D, 4700–D Main Wire Harness (Serial Numbers 400000000 to 403450000)

- Groundsmaster 4500–D, 4700–D Main Wire Harness (Serial Numbers Above 403450001)

- Groundsmaster 4500–D, 4700–D Seat and Console Wire Harness (Serial number below 399999999)

- Groundsmaster 4500–D, 4700–D Seat and Console Wire Harness (Serial Numbers 400000000 to 403450000)

- Groundsmaster 4500–D, 4700–D Seat and Console Wire Harness (Serial Numbers Above 403450001)

- Groundsmaster 4500–D, 4700–D Power Center Wire Harness(Serial number below 403450000)

- Groundsmaster 4500–D, 4700–D Power Center Wire Harness(Serial Numbers Above 403450001)

- Deck 6 and 7 Wire Harness Groundsmaster 4700–D

- (Models 30881 and 30882) Engine Wire Harness Drawing Groundsmaster 4500–D, 4700–D (Serial number below 315000000)

- Groundsmaster 4500–D, 4700–D (Models 30881 and 30882) Engine Wire Harness Drawing(Serial Numbers 315000001 to 408000000)

- Groundsmaster 4500–D, 4700–D(Models 30881 and 30882)Engine Wire Harness Drawing(Serial Numbers Above 408000000)

- Groundsmaster 4500–D, 4700–D(Models 30881 and 30882)Engine DPF Sub–Wire Harness Drawing(Serial Numbers Above 408000000)

- (Models 30873 and 30874) Engine Wire Harness Drawing Groundsmaster 4500–D, 4700–D

- Groundsmaster 4500–D, 4700–D Wire Harness Diagram — Two–Post ROPS Extension

- Groundsmaster 4500–D, 4700–DPower Harness Kit — Wiring Diagram

Be the first to review “Toro Groundsmaster 4500-D, 4700-D (Models 30873, 30874, 30881, 30882) Service Repair Manual”

You must be logged in to post a review.

Reviews

There are no reviews yet.