Toro Groundsmaster 4300-D (Model 30864) (Serial No. 314000101 and Up) Service Repair Manual

$34.00

Manual Included:

- Service Repair Manual: 405 Pages

Specifications:

- Brand: Toro

- Model: Groundsmaster 4300-D (Model 30864) (Serial No. 314000101 and Up)

- Type: Rotary Mowers

- Manuals: Service Repair Manual

- Publication Numbers: 16226SL

- Language: English

- Format: PDF

- Description

- Reviews (0)

Description

Table of Content – Groundsmaster 4300-D (Model 30864) (Serial No. 314000101 and Up)

- Title Page

- Revision History

- Reader Comments

- NOTES:

- Preface

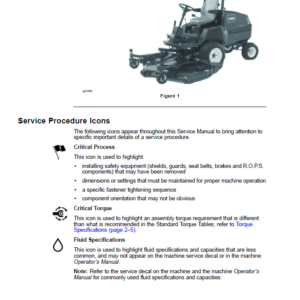

- Service Procedure Icons

- Table of Contents

- Chapter 1 : Safety

- Safety Instructions

- Supervisor’s Responsibilities

- Before Operating the Machine

- While Operating the Machine

- Maintenance and Service

- Jacking Instructions

- Raising the Front of the Machine

- Raising the Rear of the Machine

- Safety and Instructional Decals

- Chapter 2 : Specifications and Maintenance

- Specifications

- Decimal and Millimeter Equivalents

- U.S. to Metric Conversions

- Torque Specifications

- Identifying the Fastener

- Calculating the Torque Values When Using a Drive-Adapter Wrench

- Standard Torque for Dry, Zinc Plated, and Steel Fasteners (Inch Series)

- Standard Torque for Dry, Zinc Plated, and Steel Fasteners (Metric Fasteners)

- Other Torque Specifications

- Conversion Factors

- Shop Supplies

- Special Tools

- Chapter 3 : Diesel Engine

- 1 Specifications

- Engine

- General Information

- Traction Unit Operator’s Manual

- Yanmar Engine Service and Troubleshooting Manuals

- Engine Electronic Control Unit (ECU)

- Yanmar Engine

- Diesel Particulate Filter (DPF)

- Shutting Off the Engine

- Service and Repairs

- Air Cleaner System

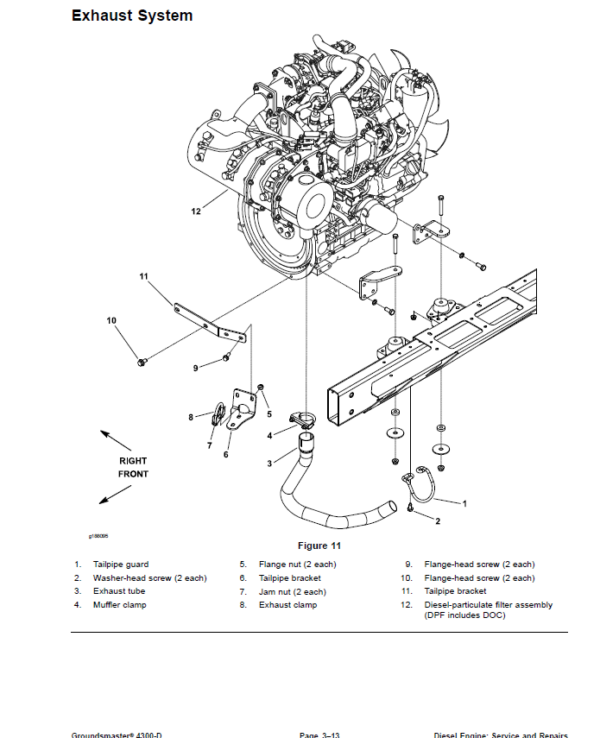

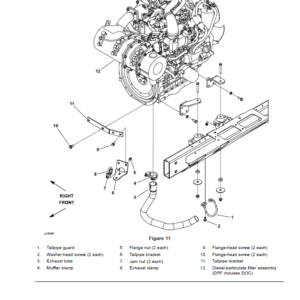

- Exhaust System

- Radiator

- Fuel System

- Engine

- Yanmar TNV (Tier 4) Series Service Repair Manual

- Yanmar TNV (Tier 4) Series Troubleshooting Manual

- Chapter 4 : Hydraulic System

- 1 Specifications

- Hydraulic System

- General Information

- Checking the Hydraulic Fluid

- Pushing or Towing the Traction Unit

- Releasing Pressure from the Hydraulic System

- Traction Circuit Component Failure

- Hydraulic Hoses

- Installing the Hydraulic Hose and Tube (O-Ring Face Seal Fitting)

- Installing the Hydraulic Fittings (SAE Straight Thread O-Ring Fitting into the Component Port)

- Hydraulic Schematics

- Hydraulic Flow Diagrams

- Traction Circuits

- Mow Circuit

- Mow Circuit Cutting Deck Blade Braking

- Lift Cylinder Circuit: Raise the Cutting Decks

- Lift Cylinder Circuit: Lower the Cutting Decks

- Steering Circuit

- Special Tools

- Hydraulic Pressure Testing Kit

- 15 GPM Hydraulic Tester Kit (Pressure and Flow)

- 40 GPM Hydraulic Tester (Pressure and Flow)

- Hydraulic Hose Kit

- O-Ring Kit

- High Flow Hydraulic Filter Kit

- Hydraulic Test Fitting Kit

- Spindle Plug

- Wheel Hub Puller

- Measuring Container

- Remote Starter Switch

- Troubleshooting

- General Hydraulic System Problems

- Traction Circuit Problems

- Mow Circuit Problems

- Lift, Lower Circuit Problems

- Steering Circuit Problems

- Testing the Hydraulic System

- Testing the Traction Circuit–Charge Pressure

- Testing the Traction Circuit–Wheel Motor Efficiency

- Testing the Traction Circuit–Piston Pump, Hydrostat Flow and Relief Pressure

- Testing the Mow Circuit–Circuit Pressure

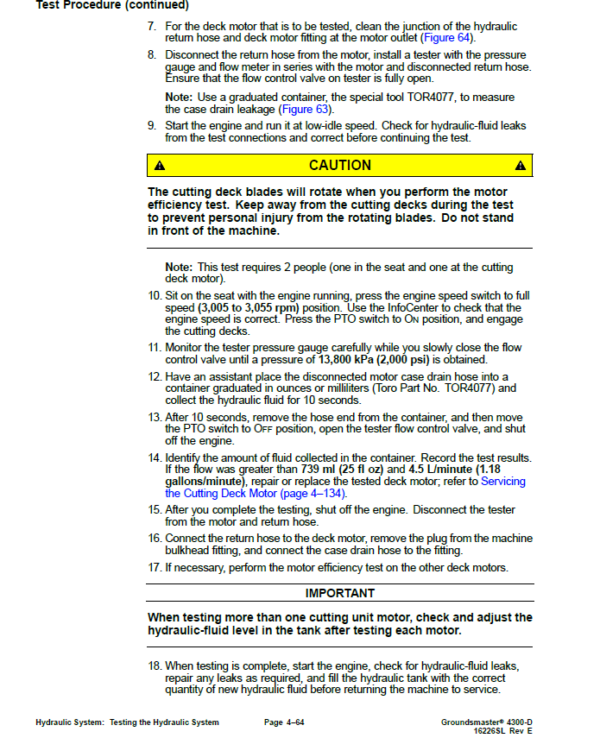

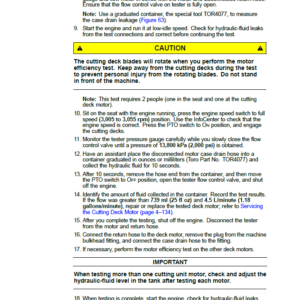

- Testing the Mow Circuit–Deck Motor Efficiency, Case Drain

- Testing the Mow Circuit–Relief Valve (PRV1) and (PRV2) Pressure

- Testing the Mow Circuit–Gear Pump (P1) and (P2) Flow

- Testing the Steering Circuit–Steering Control Valve, Relief Valve (R10) Pressure, and Steering Cylinder

- Testing the Steering Circuit–Gear Pump (P3) Flow

- Testing the lift Circuit–Relief Valve (PRV) Pressure

- Testing the Lift Circuit–Lift Cylinder Internal Leakage

- Testing the Lift Circuit–Gear Pump (P4) Flow

- Service and Repairs

- General Precautions for Removing and Installing the Hydraulic System Components

- Checking the Hydraulic Lines and Hoses

- Priming the Hydraulic Pumps

- Flushing the Hydraulic System

- Filtering the Closed-Loop Traction Circuit

- Charging the Hydraulic System

- Hydraulic Tank

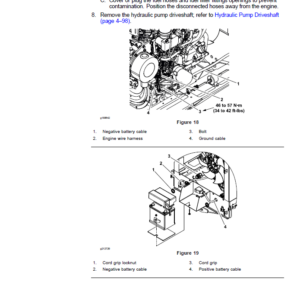

- Hydraulic Pump Driveshaft

- Hydraulic Pump Assembly

- Servicing the Piston (Traction) Pump

- Servicing the Gear Pump

- Front Wheel Motors

- Servicing the Front Wheel Motor

- Rear Wheel Motors

- Servicing the Rear Wheel Motor

- CrossTrax™ AWD Control Manifold Assembly

- Servicing the CrossTrax AWD Control Manifold Assembly

- Deck Control Manifold Assembly

- Servicing the Deck Control Manifold Assembly

- Cutting Deck Motor

- Servicing the Cutting Deck Motor

- Lift Control Manifold

- Servicing the Lift Control Manifold

- Lift Cylinder

- Servicing the Lift Cylinder

- Steering Control Valve

- Servicing the Steering Control Valve

- Steering Cylinder

- Servicing the Steering Cylinder

- Oil Cooler Assembly

- Danfoss LPV Pump Repair Manual

- Danfoss LPV Pump Service Repair Manual

- Eaton Delta Motors Parts and Repair Manual

- Parker Torqmotor Service Procedure (TC, TB, TE, TJ, TF, TG, TH, and TL Series)

- Danfoss OSPM Steering Unit Service Repair Manual

- Chapter 5 : Electrical System

- General Information

- Electrical Schematic and Wire Harness Drawings, Diagrams

- Toro Electronic Controller (TEC)

- CAN-bus Communications

- Yanmar Engine Electronic Control Unit (ECU)

- Yanmar Engine Electrical Components

- Special Tools

- Multimeter

- Terminal Protector

- Battery Hydrometer

- Dielectric Gel

- InfoCenter Display

- Splash Screen

- Main Information Screen

- Operator Advisory Screen

- Main Menu Screen

- Faults Screen

- Service Screen

- Diagnostics Screen

- Settings Screen

- About Screen

- Troubleshooting

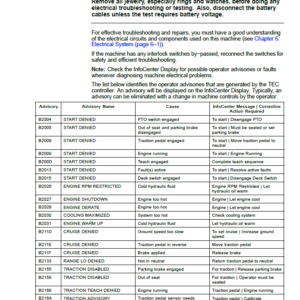

- Operator Advisories

- Using the InfoCenter Display for Troubleshooting

- Machine Faults

- Engine Faults

- Starting Problems

- General Run and Transport Problems

- Cutting Deck Operating Problems

- Cutting Deck Lift, Lower Problems

- Electrical System Quick Checks

- Testing the Battery (Open Circuit Test)

- Testing the Charging System

- Testing the Glow Plug System

- Checking the Operation of the Interlock Switches

- Adjustments

- Traction Neutral Switch

- Parking Brake Switch

- Mowith Transport Switch

- Testing the Electrical Components

- Fusible Link Harness

- Fuses

- Toro Electronic Controller (TEC)

- Key Switch

- PTO Switch

- Engine Speed Switch

- Lower, Raise Joystick Switches

- Headlight Switch

- Seat Switch

- Traction Neutral Switch

- Parking Brake Switch

- Mowith Transport Switch

- Relays with 4 Terminals

- Relays with 5 Terminals

- Hydraulic Solenoid Valve Coils

- Fuel Sender

- Fuel Pump

- CAN-bus Terminator Resistor

- Resistor Assembly

- Diode Assemblies

- Pressure Transducer

- Fan Speed Switch (Machines with Two−Post ROPS Extension Operator Fan Kit)

- Resistor Module (Machines with Two−Post ROPS Extension Operator Fan Kit)

- Service and Repairs

- Hydraulic Solenoid Valve Coils

- Battery Storage

- Battery Care

- Servicing the Battery

- Chapter 6 : Chassis

- 1 Specifications

- Chassis

- General Information

- Special Tools

- Wheel Hub Puller

- Service and Repairs

- Wheels

- Steering Column

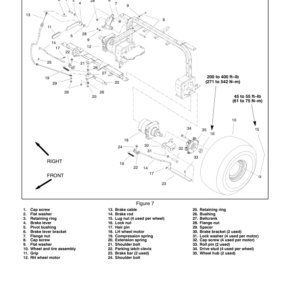

- Servicing the Brakes

- Rear Axle Motor Housings

- Rear Axle

- Control Arm

- Operator Seat

- Mechanical Seat Suspension

- Front Lift Arms

- Rear Lift Arms

- Hood

- Chapter 7 : Cutting Deck

- 1 Specifications

- Cutting Deck

- General Information

- Cutting Deck Operator's Manual

- Troubleshooting

- Factors That Can Affect Cutting Performance

- Special Tools

- Rear Roller Bearing and Seal Installation Tools

- Spindle Plug

- Adjustments

- Blade Stopping Time

- Cutting Deck

- Service and Repairs

- Blade Spindle Assembly

- Servicing the Blade Spindle

- Rear Roller

- Servicing the Rear Roller

- Servicing the Front Roller

- Cutting Deck Carrier Frame

- Appendix A: Foldout Drawings

- Electrical Drawing Designations

- Hydraulic Schematic

- Electrical Schematic (Serial numbers below 403430000)

- Electrical Schematic (Serial numbers above 403430001)

- NO TITLE

- Wire Harness Drawing – Seat (sheet 1 of 2)

- Wire Harness Drawing – Seat (sheet 2 of 2)

- Wire Harness Drawing – Engine (sheet 1 of 2)

- Wire Harness Drawing – Engine (sheet 2 of 2)

- Wire Harness Drawing – Main (sheet 1 of 2) (Serial numbers below 403430000)

- Wire Harness Drawing – Main (sheet 2 of 2) (Serial numbers below 403430000)

- Wire Harness Drawing – Main (sheet 1 of 2) (Serial numbers 403430001 to 405699999)

- Wire Harness Drawing – Main (sheet 2 of 2) (Serial numbers 403430001 to 405699999)

- Wire Harness Drawing – Main (sheet 1 of 2) (Serial numbers above 405700001)

- Wire Harness Drawing – Main (sheet 2 of 2) (Serial numbers above 405700001)

- Wire Harness Diagram − Two−Post ROPS Extension (sheet 1 of 2)

- Wire Harness Diagram − Two−Post ROPS Extension (sheet 2 of 2)

Be the first to review “Toro Groundsmaster 4300-D (Model 30864) (Serial No. 314000101 and Up) Service Repair Manual”

You must be logged in to post a review.

Reviews

There are no reviews yet.