Toro Groundsmaster 3500-D, 3500-G (Model 30807, 30809) Service Repair Manual

$30.00

Manual Included:

- Service Repair Manual: 288 Pages

Specifications:

- Brand: Toro

- Model: Groundsmaster 3500-D, 3500-G (Model 30807, 30809)

- Type: Rotary Mowers

- Manuals: Service Repair Manual

- Publication Numbers: 14209SL

- Language: English

- Format: PDF

- Description

- Reviews (0)

Description

Table of Content – Groundsmaster 3500-D, 3500-G (Model 30807, 30809)

- Title Page

- Revision History

- Reader Comments

- Preface

- Table Of Contents

- 1 – Safety

- General Safety Instructions

- Before Operating

- While Operating

- Maintenance and Service

- Jacking Instructions

- Safety and Instruction Decals

- 2 – Product Records and Maintenance

- Product Records

- Maintenance

- Equivalents and Conversions

- Torque Specifications

- Fastener Identification

- Standard Torque for Dry, Zinc Plated, and Steel Fasteners (Inch Series)

- Standard Torque for Dry, Zinc Plated, and Steel Fasteners (Metric Fasteners)

- Other Torque Specifications

- Conversion Factors

- 3 – Kubota Diesel Engine (Model 30807)

- Specifications

- Introduction

- Operator's Manuals

- Kubota Workshop Manual

- Kubota Diesel Engine

- Service and Repairs

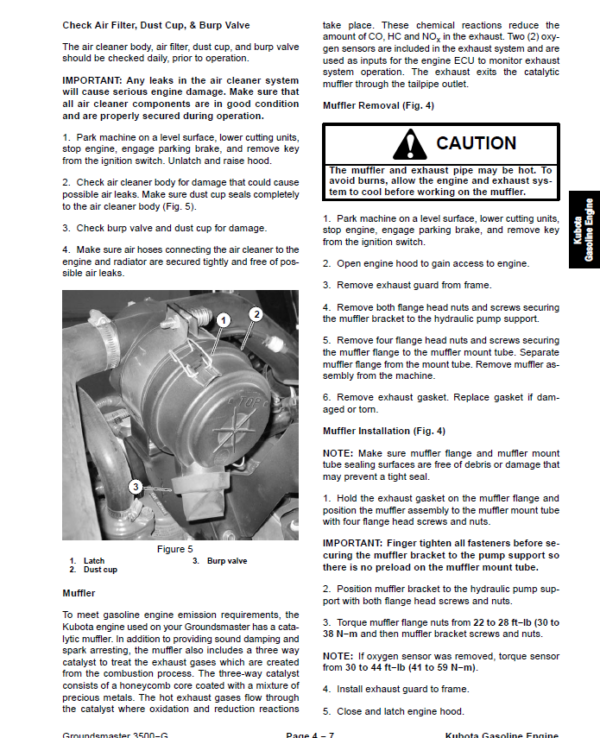

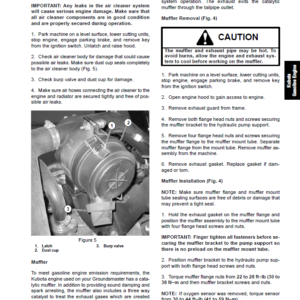

- Air Cleaner and Muffler

- Fuel System

- Radiator – Radiator, Hydraulic Fluid Cooler

- Diesel Engine

- Kubota Workshop Manual, Diesel Engine, 05−E3B Series (S.N Below 314000000)

- Kubota Workshop Manual, Diesel Engine, 05-E4B Series (S.N Above 314000000)

- 4 – Kubota Gasoline Engine (Model 30809)

- Specifications

- Introduction

- Traction Unit Operator's Manuals

- Kubota Workshop and Diagnostics Manuals

- Kubota Gasoline Engine

- Kubota Gasoline Engine Electronic Control Unit (ECU)

- Service and Repairs

- Air Cleaner and Muffler

- Fuel System

- Fuel Evaporative Control System (Unit Serial No. Prior to 315000001)

- Radiator, Hydraulic Fluid Cooler

- Engine

- Kubota Workshop Manual, Gasoline Engine, WG972−G−E3F

- Kubota Diagnostics Manual, Gasoline Engine, WG972−G−E3F

- 5 – Hydraulic System

- Specifications

- General Information

- Operator's Manual

- Relieving Hydraulic System Pressure

- Traction Circuit Component Failure

- Hydraulic Hoses

- Hydraulic Hose and Tube Installation (O-Ring Face Seal Fitting)

- Hydraulic Fitting Installation (SAE Straight Thread O-Ring Fitting into Component Port)

- Special Tools

- Hydraulic Schematics

- Units Prior to Serial No. 314000001

- Unit Serial No. 314000001 & Up

- Hydraulic Flow Diagrams

- Traction Circuit

- Cutting Unit Circuit

- Lift Circuit (Up)

- Lift Circuit (Down) & Counterbalance

- Sidewinder Circuit

- Steering Circuit

- Troubleshooting

- General Hydraulic System Problems

- Traction Circuit Problems

- Lift Circuit Problems

- Steering Circuit Problems

- Mow Circuit Problems

- Testing

- Traction Circuit Testing – Charge Pressure Test

- Traction Unit Testing – Wheel Motor Efficiency Tests

- Traction Circuit Testing – Piston Pump, Hydrostat (P3) Flow and Relief Pressure Test

- Cutting Deck Circuit Testing – Pressure Test

- Cutting Deck Circuit Testing – Deck Motor Efficiency, Case Drain Test

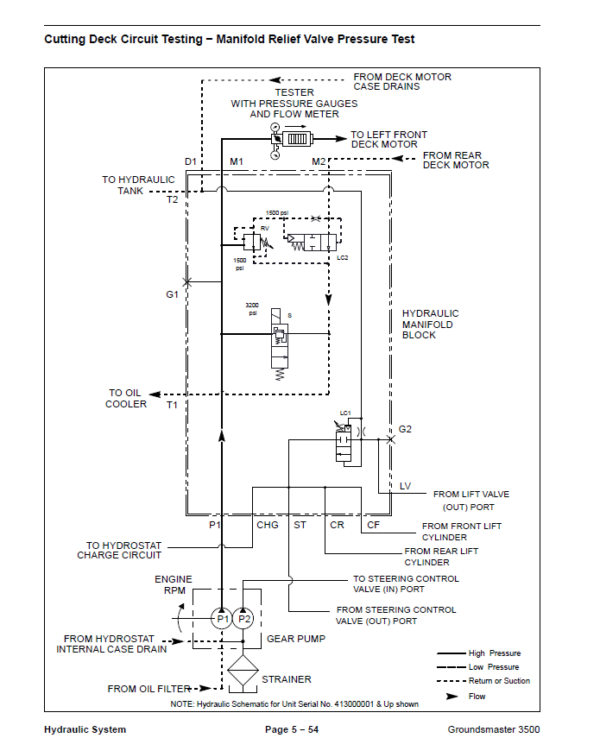

- Cutting Deck Circuit Testing – Manifold Relief Valve Pressure Test

- Cutting Deck Circuit Testing – Gear Pump (P1) Flow Test

- Steering, Lift, Sidewinder Circuit Testing – Gear Pump (P2) Flow Test

- Steering, Lift, Sidewinder Circuit Testing – Relief Valve Pressure Test

- Steering, Lift, Sidewinder Circuit Testing – Steering Control Valve and Steering Cylinder Test

- Adjustments

- Blade Braking Valve (BV) Adjustment (Traction Units Prior to No 314000001)

- Blade Braking Relief Valve (RV) Adjustment (Traction Units No 314000001 & Up)

- Counterbalance Logic Valve (LC1) Adjustment

- Service and Repairs

- General Precautions for Removing and Installing Hydraulic System Components

- Check Hydraulic Lines and Hoses

- Priming Hydraulic Pumps

- Flush Hydraulic System

- Filtering Closed-Loop Traction Circuit

- Charge Hydraulic System

- Hydraulic Tank and Hydraulic Fluid Filter

- Hydraulic Fluid Cooler

- Piston Pump, Hydrostat Assembly

- Piston Pump, Hydrostat Service

- Gear Pump Service

- Front Wheel Motors

- Rear Wheel Motor

- Wheel Motor Service

- Hydraulic Manifold

- Hydraulic Manifold Service

- Traction Units Prior to Serial No 314000001

- Traction Units Serial No 314000001 & Up

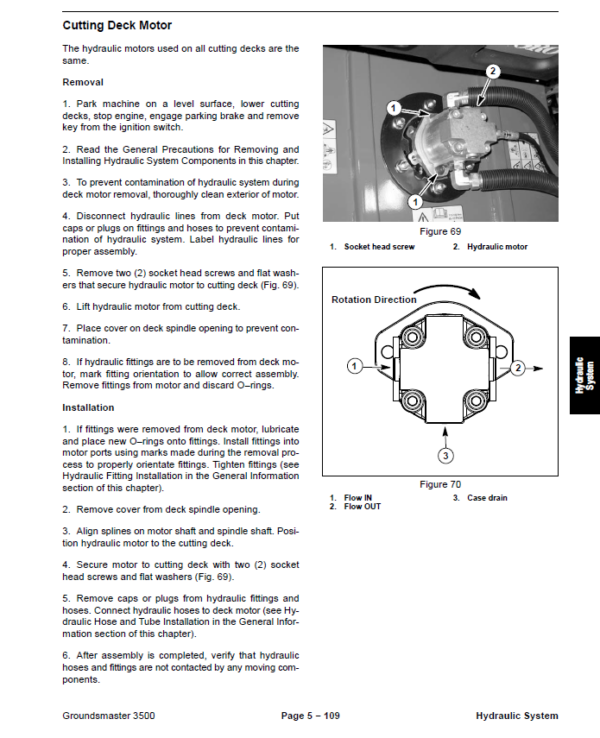

- Cutting Deck Motor

- Cutting Deck Motor Service

- Steering Control Valve

- Steering Control Valve Service

- Steering Cylinder

- Steering Cylinder Service

- Lift, Sidewinder Control Valve

- Lift, Sidewinder Control Valve Service

- Front Lift Cylinder

- Rear Lift Cylinder

- Lift Cylinder Service

- Sidewinder

- Parker Torqmotor TC, TB, TE, TJ, TF, TG,TH and TL Series Service Procedure

- Eaton Piston Pump Repair Information Model 70160

- Danfoss Steering Unit Type OSPM Service Repair Manual

- 6 – Electrical System

- General Information

- Operator's Manual

- Electrical Drawings

- Standard Control Module (SCM)

- Kubota Diesel Engine – Electrical Components

- Kubota Gasoline Engine – Electrical Components

- Special Tools

- Troubleshooting

- Starting Problems

- General Run and Transport Problems

- Cutting Deck Operating Problems

- Electrical System Quick Check

- Battery Test (Open Circuit Test)

- Charging System Test

- Glow Plug System Test (Diesel Engines Only)

- Check Operation of Interlock Switches

- Standard Control Module (SCM)

- Standard Control Module (SCM) Logic Chart

- Component Testing

- Ignition Switch

- Glow Controller (Diesel Engines Only)

- Glow Relay (Diesel Engine Only)

- Start, PWR, ETV Relays (Gasoline Engine Only)

- Hour Meter

- Diode Assemblies

- CAN-bus Termination Resistor (Gasoline Engines Only)

- Indicator Lights

- PTO Switch

- Neutral Switch

- Seat Switch

- Parking Brake and Transport, Mow Switches

- Fuses

- Fusible Links

- High Temperature Warning and Shutdown Switches (Diesel Engines Only)

- Oil Pressure Switch

- Fuel Pump (Diesel Engine Only)

- Fuel Pump (Gasoline Engine Only)

- Fuel Stop Solenoid (Diesel Engine Only)

- Electronic Throttle Control (Gasoline Engine Only)

- Hydraulic Cartridge Solenoid Valve Coils

- Service and Repairs

- Battery Care

- Battery Service

- Hydraulic Cartridge Solenoid Valve Coil

- 7 – Wheels, Brakes, and Chassis

- Specifications

- Special Tools

- Adjustments

- Adjust Brakes

- Adjust Front Lift Arms

- Adjust Front Lift Arm Carrier Stop Bracket Assembly

- Adjust Rear Lift Arm

- Service and Repairs

- Standard Seat

- Deluxe Seat

- Front Wheel and Brake

- Rear Fork and Wheel

- Brake Lever Linkages

- Steering Column

- Front Lift Arms

- Rear Lift Arm

- Sidewinder Carrier

- 8 – Cutting Decks

- Specifications

- General Information

- Operator's Manual

- Troubleshooting

- Factors That Can Affect Quality of Cut

- Special Tools

- Adjustments

- Blade Stopping Time

- Service and Repairs

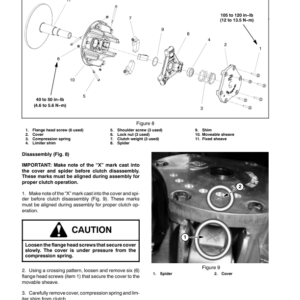

- Blade Spindle Assembly

- Blade Spindle Service

- Rear Roller

- Rear Roller Service

- Front Roller Service

- Cutting Deck Carrier Frame

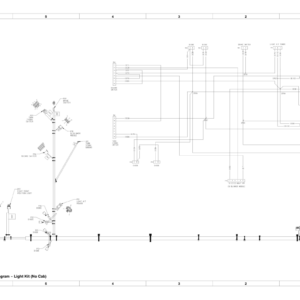

- 9 – Foldout Drawings

- Electrical Drawing Designations

- Groundsmaster 3500−D Hydraulic Schematic

(Units Prior to Serial No. 314000001) - Groundsmaster 3500−D Hydraulic Schematic

(Unit Serial No. 314000001 & Up) - Groundsmaster 3500−D Electrical Schematic (Serial Numbers Below 403440000)

- Groundsmaster 3500–DElectrical Schematic(Serial Numbers Above 403440001)

- Groundsmaster 3500−D Harness Diagram (Serial Numbers Below 403440000)

- Groundsmaster 3500−D Harness Drawing (Serial Numbers Below 403440000)

- Groundsmaster 3500–DHarness Diagram(Serial Numbers Above 403440001)

- Groundsmaster 3500–DWire Harness Diagram(Serial Numbers Above 403440001)

- Groundsmaster 3500−G Electrical Schematic (sheet 1 of 2)

- Groundsmaster 3500-G Electrical Schematic (sheet 2 of 2)

- Groundsmaster 3500−G Harness Diagram (Serial Numbers Below 402700000)

- Groundsmaster 3500−G Harness Drawing (Serial Numbers Below 402700000)

- Groundsmaster 3500–GHarness Drawing(Serial Numbers Above 402700001)

- Groundsmaster 3500–GWire Harness Drawing(Serial Numbers Above 402700001)

Be the first to review “Toro Groundsmaster 3500-D, 3500-G (Model 30807, 30809) Service Repair Manual”

You must be logged in to post a review.

Reviews

There are no reviews yet.