Toro Groundsmaster 3280-D, 3320 Service Repair Manual

$34.00

Manual Included:

- Service Repair Manual: 508 Pages

Specifications:

- Brand: Toro

- Model: Groundsmaster 3280-D, 3320

- Type: Rotary Mowers

- Manuals: Service Repair Manual

- Publication Numbers: 05138SL

- Language: English

- Format: PDF

- Description

- Reviews (0)

Description

Table of Content – Groundsmaster 3280-D, 3320

- Title Page

- Revision History

- Reader Comments

- Preface

- Service Procedure Icons

- Table of Contents

- Chapter 1 : Safety

- Safety Instructions

- Supervisor’s Responsibilities

- Before Operating the Machine

- While Operating the Machine

- Before starting the machine

- Before stopping the machine

- Maintenance and Service

- Jacking Instructions

- Raising the Front of the Machine

- Raising the Rear of the Machine

- Safety and Instructional Decals

- Chapter 2 : Specifications and Maintenance

- Specifications

- Decimal and Millimeter Equivalents

- U.S. to Metric Conversions

- Torque Specifications

- Identifying the Fastener

- Fasteners with a Locking Feature

- Calculating the Torque Values When Using a Drive-Adapter Wrench

- Standard Torque for Dry, Zinc Plated, and Steel Fasteners (Inch Series)

- Standard Torque for Dry, Zinc Plated, and Steel Fasteners (Metric Fasteners)

- Other Torque Specifications

- Conversion Factors

- Shop Supplies

- Special Tools

- Hydraulic Pressure Testing Kit

- 57 LPM (15 GPM) Hydraulic Tester Kit

- 150 LPM (40 GPM) Hydraulic Tester

- Hydraulic O-Ring Kit

- Hydraulic Hose Kit

- Hydraulic Test Fitting Kit

- High Flow Hydraulic Filter Kit

- Remote Starter Switch

- Multimeter

- Battery Terminal Protector

- Chapter 3 : Gasoline Engine

- 1 Specifications

- Engine – Groundsmaster 3320-G

- General Information

- Adding Oil to Engine

- Adjustments

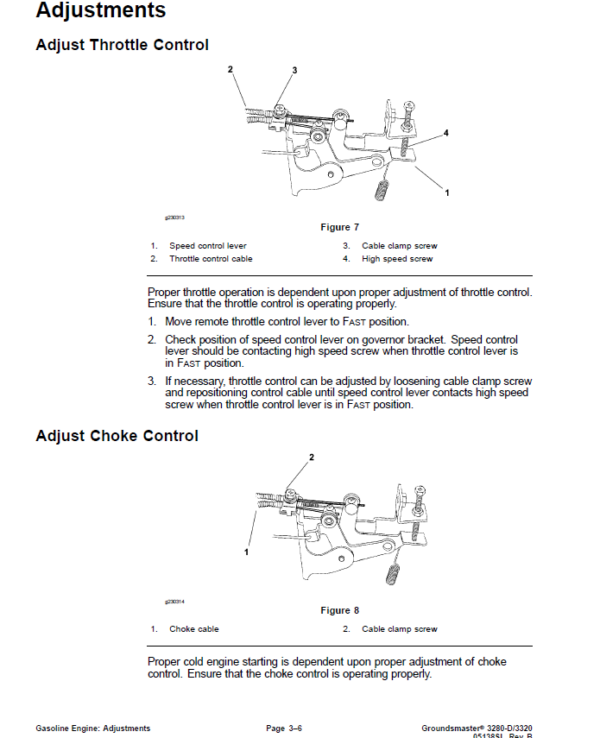

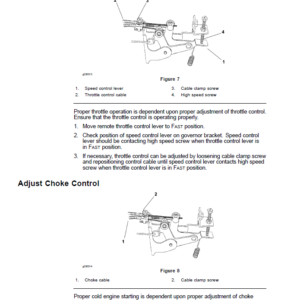

- Adjust Throttle Control

- Adjust Choke Control

- Adjust Engine Speed

- Service and Repairs

- Fuel System

- Check Fuel Lines and Connections

- Drain and Clean Fuel Tank

- Removing the Fuel Tank

- Installing the Fuel Tank

- Air Cleaner

- Removing the Air Cleaner

- Installing the Air Cleaner

- Radiator

- Removing the Radiator

- Installing the Radiator

- Engine

- Removing the Engine

- Installing the Engine

- BRIGGS AND STRATTON, DAIHATSU REPAIR MANUAL FOR 3-CYLINDER, LIQUID-COOLED,GASOLINE ENGINES

- Chapter 4 : Diesel Engine

- 1 Specifications

- Engine – Groundsmaster 3280-D

- General Information

- Traction Unit Operator’s Manual

- Engine Identification

- Kubota Engine Workshop Manuals

- Engine Group Code

- Adjustments

- Adjusting the Throttle Control

- Service and Repairs

- Air Cleaner System

- Removing the Air Cleaner System

- Installing the Air Cleaner System

- Exhaust System

- Removing the Exhaust System

- Installing the Exhaust System

- Radiator

- Removing the Radiator

- Installing the Radiator

- Fuel System

- Checking the Fuel Lines and Connections

- Draining and Cleaning the Fuel Tank

- Priming the Fuel System

- Removing the Fuel Tank

- Installing the Fuel Tank

- Engine

- Removing the Engine

- Installing the Engine

- KUBOTA 05-E2B SERIES WORKSHOP MANUAL

- KUBOTA 05-E3B SERIES WORKSHOP MANUAL

- KUBOTA 05-E4B SERIES WORKSHOP MANUAL

- Chapter 5 : Hydraulic System

- 1 Specifications

- Groundsmaster 3280-D and 3320-G

- General Information

- Checking the Hydraulic Fluid

- Pushing or Towing the Traction Unit

- Releasing Pressure from the Hydraulic System

- Releasing the Hydraulic Pressure from the Traction Circuit

- Releasing the Hydraulic Pressure from the Lift Circuit

- Releasing the Hydraulic Pressure from the Steering Circuit

- Traction Circuit Component Failure

- Hydraulic Hoses

- Installing the Hydraulic Hose and Tube (O-Ring Face Seal Fitting)

- Hose, Tube Installation Torque Table

- Flats From Wrench Resistance Table

- Installing the Hydraulic Fittings (SAE Straight Thread O-Ring Fitting into the Component Port)

- Installing the Non-Adjustable Fittings

- Fitting Installation Torque Table

- Flat From Finger Tight Table

- Installing an Adjustable Fitting

- Flat From Finger Tight Table

- Hydraulic Schematics

- Hydraulic Flow Diagrams

- Traction Circuit (Machine Serial Number below 316000000)

- Forward Direction

- Reverse Direction

- Traction Circuit (Machine Serial Number above 316000000)

- Forward Direction

- Reverse Direction

- Lift Circuit (Machine Serial Number below 311000000)

- Raise Cutting Deck (or Implement)

- Lower Cutting Deck (or Implement)

- Counterbalance

- Lift Circuit (Machine Serial Number above 311000000)

- Raise the Cutting Deck (or Implement)

- Lower the Cutting Deck (or Implement)

- Steering Circuit (Machine Serial Number below 316000000)

- Left Turn

- Right Turn

- Steering Circuit (Machine Serial Number above 316000000)

- Left Turn

- Right Turn

- Special Tools

- Hydraulic Pressure Testing Kit

- 15 GPM Hydraulic Tester Kit (Pressure and Flow)

- 40 GPM Hydraulic Tester (Pressure and Flow)

- Hydraulic Hose Kit

- Hydraulic Test Fitting Kit

- O-Ring Kit

- High Flow Hydraulic Filter Kit

- Remote Starter Switch

- Troubleshooting

- General Hydraulic System Problems

- Traction Circuit Problems

- Lift, Lower Circuit Problems

- Steering Circuit Problems

- Testing the Hydraulic System

- Charge Pressure Test (Using Pressure Gauge) (Machine Serial Numbers below 316000000)

- Implement Relief Pressure Test (Using Pressure Gauge) (Machine Serial Numbers below 316000000)

- Lift Cylinder Internal Leakage Test (Machine Serial Numbers below 316000000)

- Test Procedure

- Steering Cylinder Internal Leakage Test (Machine Serial Numbers below 316000000)

- Test Procedure

- Charge Pump Flow Test (Using Tester With Pressure Gauges and Flow Meter) (Machine Serial Numbers below 316000000)

- Testing the Traction Circuit–Charge Pressure (Machine Serial Numbers above 316000000)

- Test Procedure

- Testing the Traction Circuit–Hydraulic Pump Flow and Relief Pressure (Machine Serial Numbers above 316000000)

- Test Procedure

- Testing the Steering Circuit–Steering Control Valve, Relief Valve Pressure, and Steering Cylinder (Machine Serial Numbers above 316000000)

- Test Procedure

- Testing the Steering Circuit–Charge Pump Flow (Machine Serial Numbers above 316000000)

- Test Procedure

- Testing the Lift Circuit–Lift Cylinder Internal Leakage (Machine Serial Numbers above 316000000)

- Test Procedure

- Adjustments

- Traction Pedal Friction Wheel (Machine Serial Number below 316000000)

- Adjusting the Traction Pedal Friction Wheel

- Service and Repairs

- General Precautions for Removing and Installing the Hydraulic System Components

- Before Repairing or Replacing the Components

- After Repairing or Replacing the Components

- Checking the Hydraulic Lines and Hoses

- Priming the Hydraulic Pump

- Flushing the Hydraulic System

- Filtering the Closed-Loop Traction Circuit (Machine Serial Number above 316000000)

- Charging the Hydraulic System

- Transmission Driveshaft (Machine Serial Numbers below 316000000)

- Removing the Transmission Driveshaft

- Aligning the Transmission Driveshaft

- Installing the Transmission Driveshaft

- Hydrostatic Transmission (Machine Serial Numbers below 316000000)

- Removing the Hydrostatic Transmission

- Installing the Hydrostatic Transmission

- Servicing the Hydrostatic Transmission (Machine Serial Numbers below 316000000)

- Hydrostatic Transmission Neutral Arm Assembly (Machine Serial Number below 316000000)

- Disassembling the Hydrostatic Transmission Neutral Arm Assembly

- Assembling the Hydrostatic Transmission Neutral Arm Assembly

- Hydraulic Pump Driveshaft (Machine Serial Number above 316000000)

- Removing the Hydraulic Pump Driveshaft

- Servicing the Driveshaft Cross and Bearing

- Installing the Hydraulic Pump Driveshaft

- Hydraulic Pump (Machine Serial Number above 316000000)

- Removing the Hydraulic Pump

- Installing the Hydraulic Pump

- Servicing the Hydraulic Pump (Machine Serial Number above 316000000)

- Traction Neutral Arm Assembly (Machine Serial Number above 316000000)

- Disassembling the Traction Neutral Arm Assembly

- Assembling the Traction Neutral Arm Assembly

- Front Axle Drive Motor (Machine Serial Number above 316000000)

- Removing the Front Axle Drive Motor

- Installing the Front Axle Drive Motor

- Servicing the Front Axle Drive Motor (Machine Serial Number above 316000000)

- Lift Cylinder

- Removing the Lift Cylinder

- Installing the Lift Cylinder

- Steering Control Valve

- Removing the Steering Control Valve

- Installing the Steering Control Valve

- Servicing the Steering Control Valve

- Steering Cylinder (2-Wheel Drive)

- Removing the Steering Cylinder (2-Wheel Drive)

- Installing the Steering Cylinder (2-Wheel Drive)

- Servicing the Steering Cylinder (2-Wheel Drive)

- Disassembling the Steering Cylinder (2-Wheel Drive)

- Inspecting the Steering Cylinder

- Assembling the Steering Cylinder (2-Wheel Drive)

- Steering Cylinder (4-Wheel Drive)

- Removing the Steering Cylinder (4-Wheel Drive)

- Installing the Steering Cylinder (4-Wheel Drive)

- Servicing the Steering Cylinder (4-Wheel Drive)

- Disassembling the Steering Cylinder (4-Wheel Drive)

- Inspecting the Steering Cylinder

- Assembling the Steering Cylinder (4-Wheel Drive)

- Lift Control Valve (Machine Serial Numbers below 316000000)

- Removing the Lift Control Valve

- Installing the Lift Control Valve

- Servicing the Lift Control Valve (Machine Serial Numbers below 311000000)

- Disassembly the Lift Control Valve

- Inspecting the Lift Control Valve

- Assembling the Lift Control Valve

- Counterbalance Valve Manifold (Machine Serial Numbers below 311000000) (If Equipped)

- Removing the Counterbalance Valve Manifold

- Servicing the Manifold

- Installing the Counterbalance Valve Manifold

- Lift Control Valve (Machine Serial Number above 311000000)

- Removing the Lift Control Valve

- Installing the Lift Control Valve

- Servicing the Lift Control Valve (Machine Serial Number above 311000000)

- Servicing the Control Manifold Cartridge Valve

- Oil Cooler (Groundsmaster 3280-D)

- Removing the Oil Cooler

- Inspecting the Oil Cooler

- Installing the Oil Cooler

- DANFOSS DDC20 AXIAL PISTON PUMP SERVICE MANUAL

- DANFOSS SERIES 15 AXIAL PISTON PUMPS, MOTORS AND TRANSMISSIONS REPAIR MANUAL

- DANFOSS SERIES 15 AXIAL PISTON PUMPS, MOTORS AND TRANSMISSIONS SERVICE MANUAL

- EATON MODEL 74111 AND 74118 FIXED AXIAL PISTON MOTOR REPAIR INFORMATION

- DANFOSS STEERING UNIT TYPE OSPM SERVICE MANUAL

- Chapter 6 : Electrical System

- General Information

- Electrical Schematics and Wire Harness Drawings, Diagrams

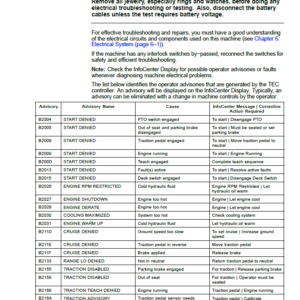

- Standard Control Module (SCM)

- SCM Inputs

- SCM Outputs

- Standard Control Module Logic Chart

- Special Tools

- Multimeter

- Terminal Protector

- Battery Hydrometer

- Dielectric Gel

- Troubleshooting

- Starting Problems

- General Run and Transport Problems

- Cutting Deck Operating Problems

- Cutting Deck Lift, Lower Problems

- Electrical System Quick Checks

- Testing the Battery (Open Circuit Test)

- Battery Test Table

- Testing the Charging System

- Battery Voltage Table

- Testing the Glow Plug System (Groundsmaster 3280-D)

- Checking the Operation of the Interlock Switches

- Adjustments

- Traction Neutral Sensor (Machine Serial Number above 316000000)

- Adjusting the Traction Neutral Sensor

- Parking Brake Switch

- Adjusting the Parking Brake Switch

- Testing the Electrical Components

- Fusible Link Harness

- Testing the Fusible Link Harness

- Fuses (Machine Serial Number below 400000000)

- Identification and Function

- Testing the Fuses

- Fuses (Machine Serial Number above 400000000)

- Identification and Function

- Testing the Fuses

- Operator Cab Fuses (Machines with Operator Cab)

- Identification and Function

- Testing the Fuses

- Key Switch

- Testing the Key Switch

- Circuit Logic Table

- Indicator Lights

- Charge Indicator Light

- Engine Oil Pressure Light

- High Temperature Warning Light

- Glow Plug Indicator Light

- Testing the Indicator Lights

- Hour Meter

- Testing the Hour Meter

- PTO Switch

- Testing the PTO Switch

- Circuit Logic Table

- Deck Lift Switch (Machine Serial Numbers above 311000000)

- Testing the Deck Lift Switch

- Circuit Logic Table

- Seat Switch

- Testing the Seat Switch

- Windshield Washer, Wiper Switch (Machines with Operator Cab)

- Testing the Windshield Washer, Wiper Switch

- Circuit Logic Table

- Accessory Power Switch (Machines with Operator Cab)

- Testing the Accessory Power Switch

- Circuit Logic Table

- Fan Speed Switch (Machines with Operator Cab)

- Testing the Fan Speed Switch

- Circuit Logic Table

- Work Light Switch (Machines with Operator Cab–Optional)

- Testing the Work Light Switch

- Circuit Logic Table

- Traction Neutral Switch (Machine Serial Numbers below 316000000)

- Testing the Traction Neutral Switch

- Adjusting the Traction Neutral Switch

- Traction Neutral Sensor (Machine Serial Number above 316000000)

- Testing the Traction Neutral Sensor

- Parking Brake Switch

- Testing the Parking Brake Switch

- High Temperature Warning Switch

- Testing the High Temperature Warning Switch

- High Temperature Shutdown Switch

- Testing the High Temperature Shutdown Switch

- Engine Oil Pressure Switch

- Testing the Engine Oil Pressure Switch

- Relays (Groundsmaster 3280-D)

- Testing the Relays

- Lift Control Valve Solenoid Valve Coil (Machine Serial Number above 311000000)

- Testing the Lift Control Valve Solenoid Valve Coil

- Solenoid Valve Coil Specifications Table

- PTO Electric Clutch

- Testing the PTO Electric Clutch

- Fuel Stop Solenoid (Groundsmaster 3280-D)

- Testing the Fuel Stop Solenoid (In Place)

- Testing the Fuel Stop Solenoid (Live)

- Glow Controller (Groundsmaster 3280-D)

- Controller Operation

- Controller Checks

- Fuel Pump (Groundsmaster 3280-D)

- Testing the Fuel Pump Capacity

- Fuel Pump Specifications (for Models 30344 and 30345)

- Fuel Pump Specifications (except Models 30344 and 30345)

- Fuel Pump (Groundsmaster 3320)

- Testing the Fuel Pump Capacity

- Fuel Pump Specifications

- Fuel Pump Relay (Groundsmaster 3320)

- Testing the Fuel Pump Relay

- Service and Repairs

- Lift Control Valve Solenoid Valve Coils (Machine Serial Number above 311000000)

- Removing the Lift Control Valve Solenoid Valve Coils

- Installing the Lift Control Valve Solenoid Valve Coils

- PTO Electric Clutch

- Removing the PTO Electric Clutch

- Installing the PTO Electric Clutch

- Battery Storage

- Battery Care

- Servicing the Battery

- Battery Specifications

- Removing and Installing the Battery

- Inspecting, Maintaining, and Testing the Battery

- Cell Specific Gravity Example

- Minimum Voltage Table

- Charging the Battery

- Battery Charge Level Table

- Chapter 7 : Chassis

- Specifications

- NO TITLE

- General Information

- Service and Repairs

- Wheels

- Removing the Wheel

- Installing the Wheel

- Steering Column

- Removing the Steering Column

- Installing the Steering Column

- Rear Frame and Axle Assembly

- Removing the Rear Frame and Axle Assembly

- Installing the Rear Frame and Axle Assembly

- Rear Axle (2-Wheel Drive)

- Removing the Rear Axle

- Installing the Rear Axle

- Servicing the Rear Axle (2-Wheel Drive)

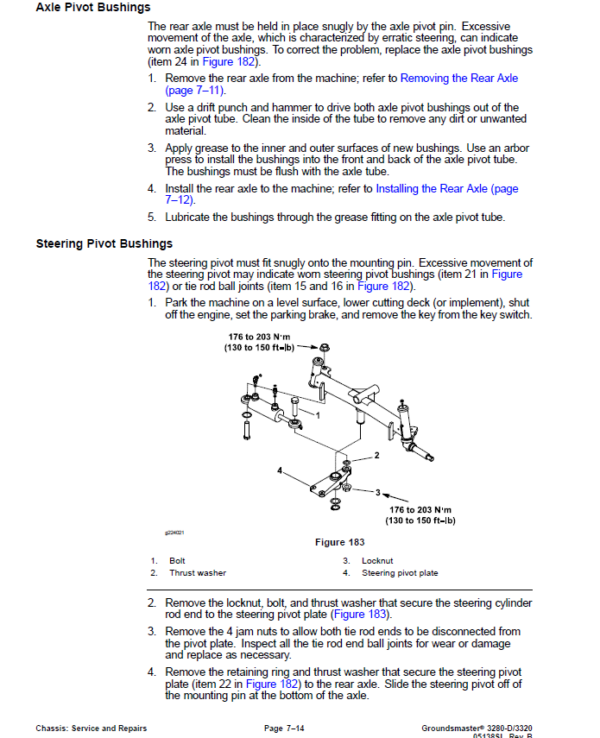

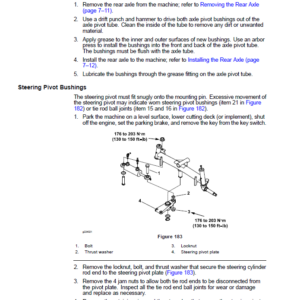

- Axle Pivot Bushings

- Steering Pivot Bushings

- Rear Axle Spindle Bushings

- Rear Wheel Bearings (2-Wheel Drive)

- Disassembling the Rear Wheel Bearings

- Assembling the Rear Wheel Bearings

- Operator Seat

- Removing the Operator Seat

- Installing the Operator Seat

- Mechanical Seat Suspension

- Removing the Mechanical Seat Suspension

- Installing the Mechanical Seat Suspension

- Pneumatic Seat Suspension

- Removing the Pneumatic Seat Suspension

- Installing the Pneumatic Seat Suspension

- Lift Arms

- Removing the Lift Arms

- Installing the Lift Arms

- Chapter 8 : Drive Axles

- Specifications

- NO TITLE

- General Information

- Front Axle

- 4-Wheel Drive Rear Axle

- Special Tools

- Differential Gear Holder

- Service and Repairs

- Servicing the Brake

- Disassembling the Brake

- Assembling the Brake

- Front Axle Shafts and Bearings

- Disassembling the Front Axle Shafts and Bearings

- Assembling the Front Axle Shafts and Bearings

- Front Axle (Machine Serial Number before 316000000)

- Removing the Front Axle

- Installing the Front Axle

- Front Axle (Machine Serial Number after 316000000)

- Removing the Front Axle

- Installing the Front Axle

- Servicing the Front Axle

- Disassembling the Front Axle

- Assembling the Front Axle

- Ring to Pinion Gear Engagement (Front Axle)

- Gear Pattern Movement Summary

- Rear Axle Driveshaft (4-Wheel Drive)

- Removing the Rear Axle Driveshaft (4-Wheel Drive)

- Installing the Rear Axle Driveshaft (4-Wheel Drive)

- Servicing the Rear Axle Driveshaft Cross and Bearing (4-Wheel Drive)

- Rear Axle (4-Wheel Drive)

- Removing the Rear Axle (4-Wheel Drive)

- Installing the Rear Axle (4-Wheel Drive)

- Bevel Gear Case and Axle Case (4-Wheel Drive Axle)

- Removing the Bevel Gear Case and Axle Case (4-Wheel Drive Axle)

- Inspecting the Bevel Gear Case and Axle Case

- Installing the Bevel Gear Case and Axle Case (4-Wheel Drive Axle)

- Differential Shafts (4-Wheel Drive Axle)

- Removing the Differential Shaft (4-Wheel Drive Axle)

- Installing the Differential Shaft (4-Wheel Drive Axle)

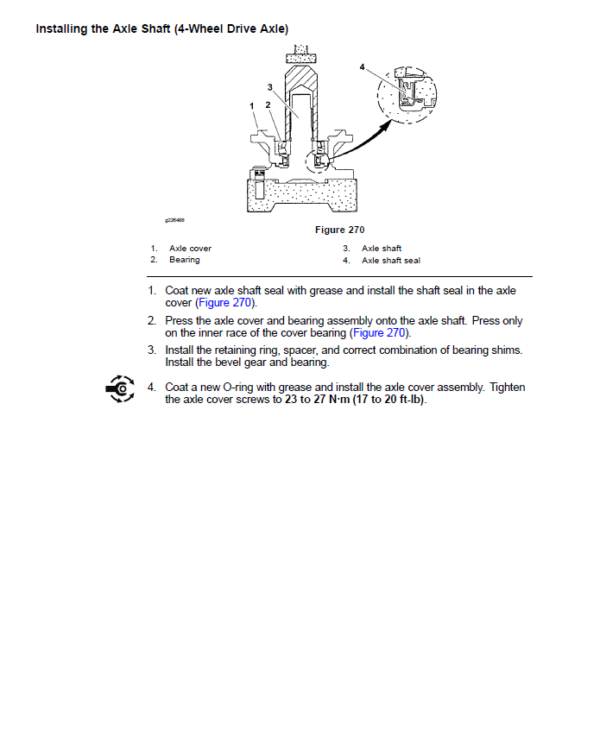

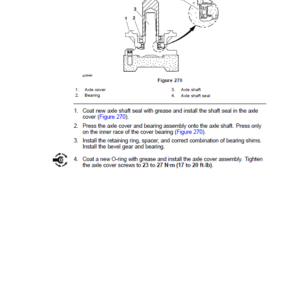

- Axle Shafts (4-Wheel Drive Axle)

- Removing the Axle Shaft (4-Wheel Drive Axle)

- Installing the Axle Shaft (4-Wheel Drive Axle)

- Input Shaft, Pinion Gear (4-Wheel Drive Axle)

- Removing the Input Shaft, Pinion Gear (4-Wheel Drive Axle)

- Installing the Input Shaft, Pinion Gear (4-Wheel Drive Axle)

- Differential Gear Assembly (4-Wheel Drive Axle)

- Removing the Differential Gear Assembly (4-Wheel Drive Axle)

- Inspecting the Differential Gear Assembly

- Installing the Differential Gear Assembly (4-Wheel Drive Axle)

- Pinion Gear to Ring Gear Engagement (4-Wheel Drive Axle)

- Gear Pattern Movement Summary

- Bi-Directional Clutch (4-Wheel Drive)

- Removing the Bi-Directional Clutch (4-Wheel Drive)

- Installing the Bi-Directional Clutch (4-Wheel Drive)

- Servicing the Bi-Directional Clutch (4-Wheel Drive)

- Disassembling the Bi-Directional Clutch (4-Wheel Drive)

- Assembling the Bi-Directional Clutch (4-Wheel Drive)

- Chapter 9 : PTO System

- General Information

- Service and Repairs

- PTO Drive Belt

- PTO Driveshaft

- Removing the PTO Driveshaft

- Installing the PTO Driveshaft

- Servicing the PTO Driveshaft Cross and Bearing

- PTO Shaft

- Removing the PTO Shaft

- Installing the PTO Shaft

- Aligning the PTO Pulley to the Electric Clutch Pulley

- Checking the Pulley Alignment

- Adjusting the Pulley Alignment

- Chapter 10 : Cutting Units

- General Information

- Specifications

- Cutting Unit Operator's Manual

- Troubleshooting

- Factors That Can Affect Quality of Cut

- Adjustments

- Castor Wheel Tire Pressure

- Service and Repairs

- Cutting Deck

- Idler Assembly

- Removing the Idler Assembly

- Installing the Idler Assembly

- Blade Spindle

- Removing the Blade Spindle

- Installing the Blade Spindle

- Servicing the Blade Spindle

- Disassembling the Blade Spindle

- Assembling the Blade Spindle

- Gearbox

- Removing the Gearbox

- Installing the Gearbox

- Castor Forks and Wheels

- Disassembling the Castor Forks and Wheels

- Assembling the Castor Forks and Wheels

- Cutting Deck Rollers and Skids

- Removing the Cutting Deck Rollers and Skids

- Installing the Cutting Deck Rollers and Skids

- Chapter 11 : Operator Cab

- General Information

- Operator’s Manual

- Electrical Components and Schematics

- Cab Heater System

- Service and Repairs

- Roof Assembly

- Removing the Roof Assembly

- Installing the Roof Assembly

- Heating Components

- Mixing Box Assembly

- Removing the Mixing Box Assembly

- Installing the Mixing Box Assembly

- Heater Core

- Removing the Heater Core

- Installing the Heater Core

- Blower Fan

- Removing the Blower Fan

- Installing the Blower Fan

- Windshield Wiper Assembly

- Disassembling the Windshield Wiper Assembly

- Assembling the Windshield Wiper Assembly

- Appendix A: Foldout Drawings

- Electrical Drawing Designations

- Hydraulic Schematic-3280-D (Serial Numbers below 270000400) and 3320 (Serial Numbers below 280000000)

- Hydraulic Schematic-3280-D (Serial Numbers 270000400 to 311000000) and 3320 (Serial Numbers 280000000 to 311000000)

- Hydraulic Schematic-3280-D (Serial Numbers 311000001 through 316000000)

- Hydraulic Schematic-3280-D (Machine Serial Numbers after 316000000)

- Electrical Schematic-3320

- Electrical Schematic (Machine Serial Number before 311000000)

- Electrical Schematic (Machine Serial Number 311000000 and Up)

- Electrical Schematic-Operator Cab

- Electrical Schematic-Operator Cab

- Wire Harness Drawing-Main-3320 (Serial Numbers below 260000000)

- Wire Harness Diagram-Main-3320 (Serial Numbers below 260000000)

- Wire Harness Drawing-Main-3320 (Serial Numbers above 260000000)

- Wire Harness Diagram-Main-3320 (Serial Numbers above 260000000)

- Wire Harness Drawing-Main-3280-D (Serial Numbers below 260000000)

- Wire Harness Diagram-Main-3280-D (Serial Numbers below 260000000)

- Wire Harness Drawing-Main-3280-D (Machine Serial Number 260000000 to 270000600)

- Wire Harness Diagram-Main-3280-D (Machine Serial Number 260000000 to 270000600)

- Wire Harness Drawing-Main-3280-D (Machine Serial Number 270000601 to 311000000)

- Wire Harness Diagram-Main-3280-D (Machine Serial Number 270000601 to 311000000)

- Wire Harness Drawing-Main-3280-D (Machine Serial Number 311000000 to 316000000)

- Wire Harness Diagram-Main-3280-D (Machine Serial Number 311000000 to 316000000)

- Wire Harness Drawing-Main-3280-D (Machine Serial Number 316000000 to 400000000)

- Wire Harness Diagram-Main-3280-D (Machine Serial Number 316000000 to 400000000)

- Wire Harness Drawing-Main-3280-D (Machine Serial Number 400000000 and Up)

- Wire Harness Diagram-Main-3280-D (Machine Serial Number 400000000 and Up)

- Wire Harness Drawing-Cab Model 30298 Power

- Wire Harness Diagram-Cab Model 30298 Power

- Wire Harness Drawing-Cab Model 30298 Headliner

- Wire Harness Diagram-Cab Model 30298 Headliner

- Wire Harness Drawing-Cab Model 30298 Front Mount Accessory Power Supply

- Wire Harness Diagram-Cab Model 30298 Front Mount Accessory Power Supply

- Wire Harness Drawing-Cab Model 30298 Heat, Air Conditioning Blower

- Wire Harness Diagram-Cab Model 30298 Heat, Air Conditioning Blower

- Wire Harness Drawing-Light Kit Model 30405 (Machines without Cab)

- Wire Harness Diagram-Light Kit Model 30405 (Machines without Cab)

- Wire Harness Drawing-North American Light Kit Model 30701 (Machines Serial Number 315000000 and Up)

- Wire Harness Diagram-North American Light Kit Model 30701 (Machines Serial Number 315000000 and Up)

Be the first to review “Toro Groundsmaster 3280-D, 3320 Service Repair Manual”

You must be logged in to post a review.

Reviews

There are no reviews yet.