Toro Groundsmaster 3200, 3300, 3310 (31900, 31901, 31902, 31903, 31907, 31709) Service Repair Manual

$34.00

Manual Included:

- Service Repair Manual: 359 Pages

Specifications:

- Brand: Toro

- Model: Groundsmaster 3200, 3300, 3310 (31900, 31901, 31902, 31903, 31907, 31709)

- Type: Rotary Mowers

- Manuals: Service Repair Manual

- Publication Numbers: 19240SL

- Language: English

- Format: PDF

- Description

- Reviews (0)

Description

Table of Content – Groundsmaster 3200, 3300, 3310 (31900, 31901, 31902, 31903, 31907, 31709)

- Title Page

- Revision History

- Reader Comments

- Preface

- Service Procedure Icons

- Chapter 1 : Safety

- Safety Instructions

- Think Safety First

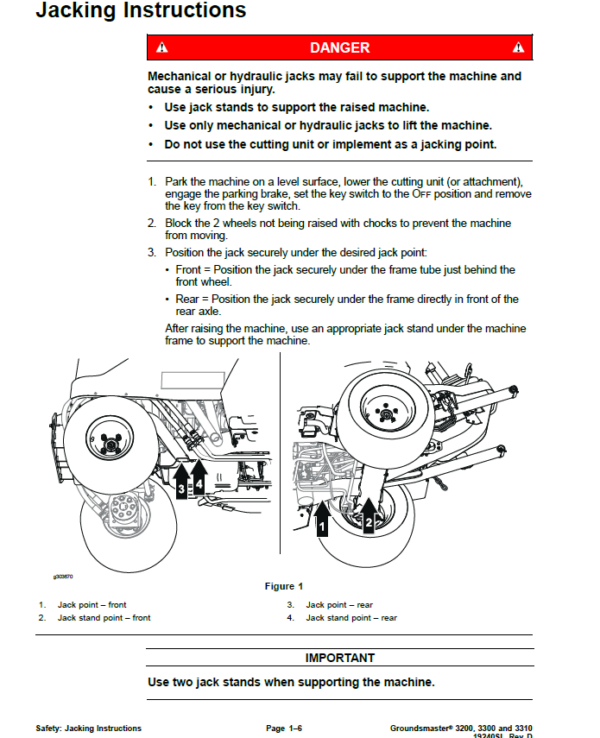

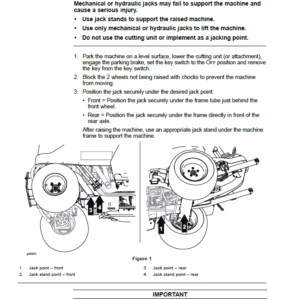

- Jacking Instructions

- Safety and Instructional Decals

- Chapter 2 : Specifications and Maintenance

- Specifications

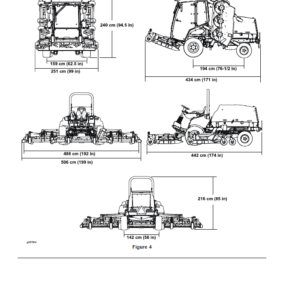

- Overall Dimensions

- Engine (Model 31900 & 31901)

- Engine (Model 31902 & 31903)

- Engine (Model 31907 & 31909)

- Hydraulic System

- Chassis

- Cutting Unit

- Torque Specifications

- Calculating the Torque Values When Using a Drive-Adapter Wrench

- Identifying the Fastener

- Standard Torque for Dry, Zinc Plated, and Steel Fasteners (Inch)

- Standard Torque for Dry, Zinc Plated, and Steel Fasteners (Metric Fasteners)

- Other Torque Specifications

- Conversion Factors

- Shop Supplies

- Special Tools

- Chapter 3 : Troubleshooting

- GEARS – The Systematic Approach to Defining, Diagnosing and Solving Problems

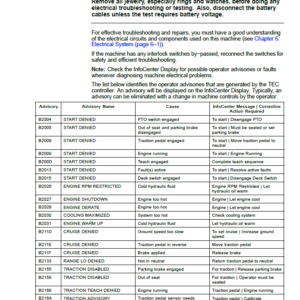

- Operator Advisories

- Machine and Engine Faults

- Machine Faults

- Engine Faults (Models 31902 and 31903)

- Using the TDM Display, Controller Screens for Troubleshooting

- Troubleshooting – Hydraulic

- General Hydraulic System Problems

- Traction System Problems

- Steering System Problems

- Cutting Unit (or attachment) Lift, Lower Problems

- Troubleshooting – Electrical

- Starting Problems

- General Run and Transport Problems

- Cutting Unit (or attachment) Problems

- Factors That Can Affect Quality of Cut

- Chapter 4 : Engine

- General Information

- Traction Unit Operator’s Manual

- Yanmar Service and Troubleshooting Manuals

- Engine Electronic Control Unit (ECU) (Models 31902 and 31903)

- Yanmar Engines

- Diesel Particulate Filter

- Service and Repairs

- Air Cleaner Assembly

- Exhaust System

- Radiator

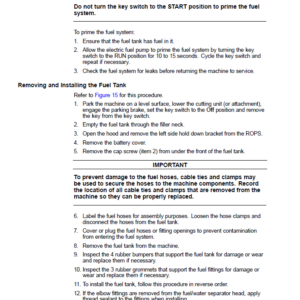

- Fuel System

- Engine

- Yanmar Service Repair Manual for 3TNV80F engines

- Yanmar Service Repair Manual for 3TNV88 engines

- Yanmar Troubleshooting Manual for 3TNV88 engines

- Yanmar Service Repair Manual for 3TNV88C engines

- Yanmar Troubleshooting Manual for 3TNV88C engines

- Chapter 5 : Hydraulic System

- General Information

- Traction Unit Operator’s Manual and Accessory Installation Instructions

- Relieving Pressure from the Hydraulic System

- Towing the Traction Unit

- Traction Circuit Component Failure

- Hydraulic Hoses

- Installing Hydraulic Hoses and Tubes (O-Ring Face Seal Fitting)

- Installing the Hydraulic Fittings (SAE Straight Thread O-Ring Fittings)

- Hydraulic Schematics

- Hydraulic Flow Diagrams

- Traction Circuit

- Steering Circuit

- Lift Circuit

- Auxiliary Valve Circuit (Optional)

- Testing the Hydraulic System

- Hydraulic Test Selection

- Testing the Traction Circuit – Charge Pressure

- Testing the Traction Circuit – Wheel Motor Efficiency

- Testing the Traction Circuit – Piston (traction) Pump (P1) Flow and Relief Pressure

- Testing the Steering and Lift Circuit – Gear Pump (P2) Flow and Circuit Relief Valve

- Testing the Steering and Lift Circuit – Steering Cylinder and Circuit Relief Valve

- Testing the Steering and Lift Circuit – Lift Cylinder Internal Leakage

- Adjustments

- Adjusting the Traction System for Neutral

- Service and Repairs

- General Precautions for Removing and Installing the Hydraulic System Components

- Checking the Hydraulic Lines and Hoses

- Flushing the Hydraulic System

- Filtering the Closed-loop Traction Circuit

- Priming the Hydraulic Pumps

- Charging the Hydraulic System

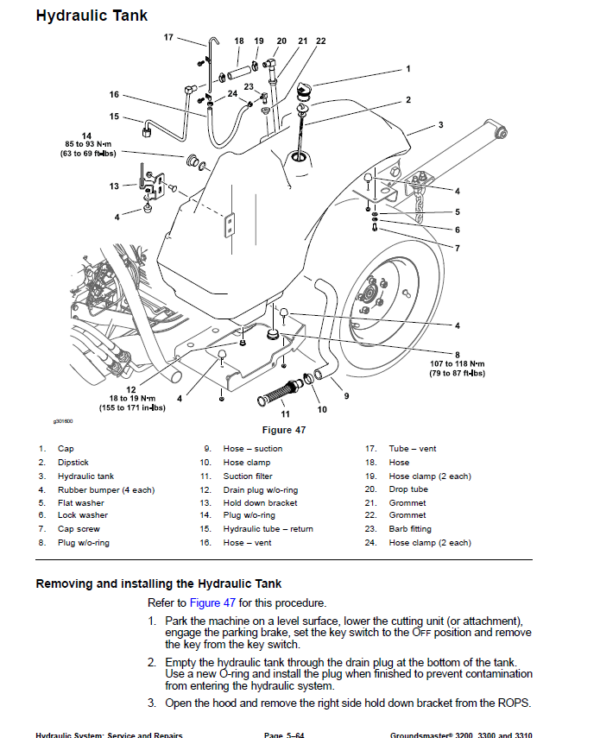

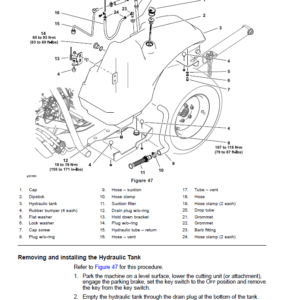

- Hydraulic Tank

- Hydraulic Fluid Cooler

- Traction Pump Drive

- Piston (traction) Pump (P1)

- Servicing the Traction (piston) Pump (P1)

- Gear Pump (P2)

- Gear Pump (P2) Service

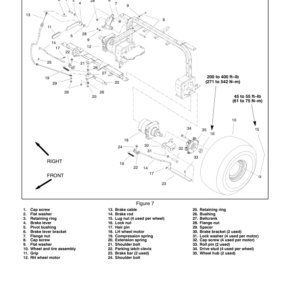

- Wheel Motors

- Wheel Motor Service

- Hydraulic Manifold

- Hydraulic Manifold Service

- Cartridge Valve Service

- Steering Control Valve

- Steering Control Valve Service

- Steering Cylinder

- Steering Cylinder Service

- Lift Cylinder

- Lift Cylinder Service

- Auxiliary Hydraulic Valve Manifold (optional)

- Danfoss LPV Axial Piston Pump Service Repair Manual

- Danfoss LPV Axial Piston Pump Repair Manual

- Parker Torqmotor™ Service Procedure (TF, TG, TH, and TL Series)

- Danfoss OSPM Steering Unit Service Repair Manual

- Chapter 6 : Electrical System

- General Information

- Traction Unit Operator’s Manual and Accessory Installation Instructions

- Yanmar Engine Electrical Components

- TDM Display, Controller

- CAN bus Communications

- Electrical Schematics and Wire Harness Drawings, Diagrams

- Electrical System Quick Checks

- Testing the Charging System

- Checking the Operation of the Interlock Switches

- Testing the Electrical Components

- Fusible Link Harness

- Fuses

- CAN bus

- TDM Display, Controller

- Key Switch

- PTO Switch

- Lift, Lower Switch

- Glow Plug Switch (Model 31900, 31901, 31907 and 31909)

- Throttle Switch (Model 31902 and 31903)

- Seat Switch

- Traction Neutral Switch

- Parking Brake Switch

- Cutting Unit High Trim Height Switch

- Windshield Washer, Wiper Switch (Model 31903 and 31909)

- Air Conditioning On, Off Switch (Model 31903 and 31909)

- Fan Speed Switch (Model 31903 and 31909)

- Multifunction Switch (Optional)

- Hazard Switch (Optional)

- Relays with 4 Terminals

- Relays with 5 Terminals

- PTO Clutch

- Fuel Pump

- Transient Voltage Suppression (TVS) Diode

- Diode Assemblies (Model 31902 and 31903)

- Resistor Assemblies

- CAN bus Terminator Resistors

- Hydraulic Solenoid Valve Coils

- Slope Sensor (Optional)

- Slope Sensor Alarm (Optional)

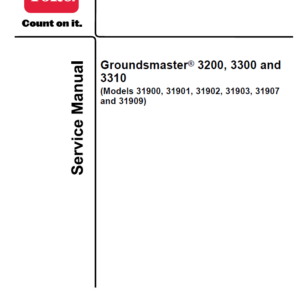

- Service and Repairs

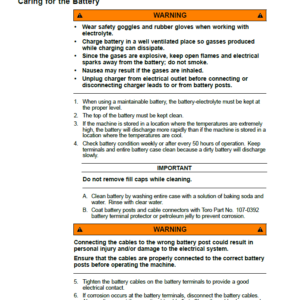

- Caring for the Battery

- Storing the Battery

- Servicing the Battery

- Chapter 7 : Chassis

- General Information

- Traction Unit Operator’s Manual and Accessory Installation Instructions

- Adjustments

- Adjusting the Parking Brake

- Adjusting the Traction Cable

- Adjusting the Tie Rod Length (Rear Wheel Toe-In)

- Adjusting the PTO Clutch

- Service and Repairs

- Wheels

- Parking Brakes

- Traction Pedal, Cable, and Control Assembly

- Steering Column

- Rear Axle and Spindles

- PTO Shaft

- Servicing the PTO Shaft Cross and Bearing

- PTO Clutch

- Operator’s Console

- Hood

- Operator Seat

- Mechanical Suspension Seat (Model 31981)

- Air Ride Suspension Seat (Model 31982)

- Lift Arms

- Chapter 8 : Cutting Units

- General Information

- Cutting Unit Operator's Manual

- Blade Stopping Time

- Service and Repairs

- Rotary Cutting Units

- Flail Cutting Unit (Model 02835) Additional Information Pending

- Chapter 9 : Operator Cab

- General Information

- Traction Unit Operator’s Manual and Accessory Installation Instructions

- Electrical Components, Schematics and Wire Harness Drawings

- Air Conditioning System

- Cab Heater System

- Adjustments

- Adjusting the Compressor Belt Tension

- Adjusting the Doors

- Service and Repairs

- General Precautions for Removing and Installing Air Conditioning System Components

- Air Conditioning Compressor

- Heating and Air Conditioning Components

- Control Panel and Windshield Wiper Assembly

- Doors

- Sanden SD Compressor Service Guide

- Appendix A: Foldout Drawings

- Electrical Drawing Designations

- Hydraulic Schematic – 3200 2WD

- Hydraulic Schematic – 3200 4WD

- Hydraulic Schematic – 3300, 3310

- Electrical Schematic – 3200, 3300, 3310

- Electrical Schematic – 3300, 3310

- Electrical Schematic – 3300, 3310 (continued)

- Electrical Schematic-Operator Cab

- Wire Harness Drawing – 3200, 3300, 3310

- Wire Harness Diagram – 3320, 3300, 3310

- Wire Harness Drawing – Main 3300, 3310

- Wire Harness Diagram – Main 3300, 3310

- Wire Harness Diagram – Main 3300, 3310 (continued)

- Wire Harness – Cab Power

- Wire Harness – Cab Rooftop

- Wire Harness – Cab Control Panel

- Wire harness – Cab HVAC Adapter

- Wire Harness – Cab Work Light Kit (optional)

- Wire Harness – Road Light Kits, Lights (optional)

- Wire Harness – Road Light Kit, Controls (optional)

- Slope Sensor Kit (optional)

Be the first to review “Toro Groundsmaster 3200, 3300, 3310 (31900, 31901, 31902, 31903, 31907, 31709) Service Repair Manual”

You must be logged in to post a review.

Reviews

There are no reviews yet.