Toro Greensmaster Triflex Hybrid 3320, 3420 (Models 04530, 04540) Service Repair Manual

$34.00

Manual Included:

- Service Repair Manual: 406 Pages

Specifications:

- Brand: Toro

- Model: Greensmaster Triflex Hybrid 3320, 3420 (Models 04530, 04540)

- Type: Greens Reel Mowers

- Manuals: Service Repair Manual

- Publication Numbers: 12190SL

- Language: English

- Format: PDF

- Description

- Reviews (0)

Description

Table of Content – Greensmaster Triflex Hybrid 3320, 3420 (Models 04530, 04540)

- Title Page

- Revision History

- Reader Comments

- Preface

- Table Of Contents

- 1 – Safety

- Table of Contents

- General Safety Instructions

- Before Operating

- While Operating

- Maintenance and Service

- Jacking Instructions

- Safety and Instruction Decals

- 2 – Product Records and Maintenance

- Table of Contents

- Product Records

- Maintenance

- Equivalents and Conversions

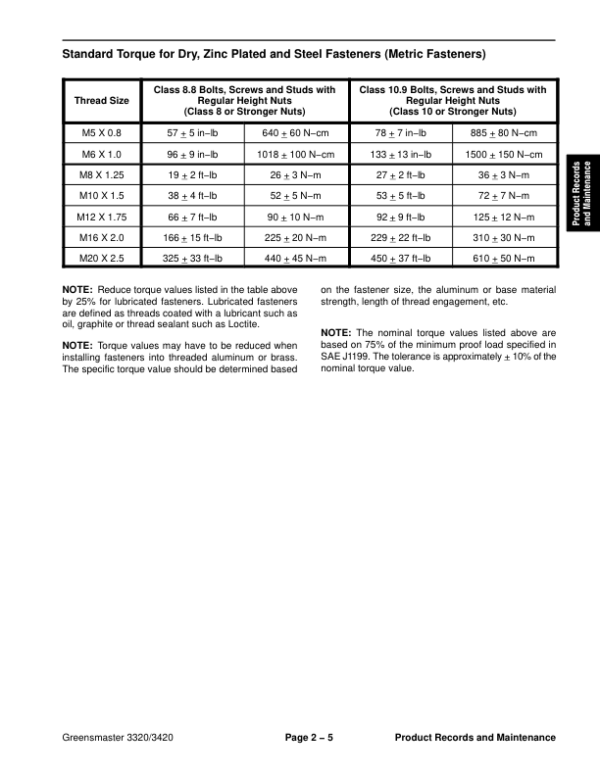

- Torque Specifications

- Fastener Identification

- Using a Torque Wrench with an Offset Wrench

- Standard Torque for Dry, Zinc Plated and Steel Fasteners (Inch Series)

- Standard Torque for Dry, Zinc Plated and Steel Fasteners (Metric Fasteners)

- Other Torque Specifications

- Conversion Factors

- 3 – Gasoline Engine

- Table of Contents

- Specifications

- General Information

- Operator's Manual

- Fuel Evaporative Control System

- Adjustments

- Choke Cable Adjustment

- Throttle Cable Adjustment

- Service and Repairs

- Fuel Evaporative Control System (Serial Number Below 312000000)

- Fuel Evaporative Control System (Serial Number Above 312000000)

- Fuel Tank

- Engine

- BRIGGS & STRATTON VANGUARD V−TWIN OHVREPAIR MANUAL

- 4 – Diesel Engine

- Table of Contents

- Specifications

- General Information

- Operator's Manual

- Adjustments

- Adjust Throttle Control

- Service and Repairs

- Air Cleaner Assembly

- Exhaust System

- Fuel Tank

- Radiator

- Starter Motor

- Engine

- KUBOTA WORKSHOP MANUAL, DIESEL ENGINE,SM−E3B SERIES

- 5 – Hydraulic System

- Table of Contents

- Specifications

- General Information

- Operator's Manuals

- Check Hydraulic Fluid Level

- Pushing Traction Unit

- Relieving Hydraulic System Pressure

- Opening Electrical Circuit to Cutting Units

- Traction Circuit Component Failure

- Hydraulic Hoses

- Hydraulic Hose and Tube Installation (O-Ring Face Seal Fitting)

- Hydraulic Fitting Installation (SAE Straight Thread O-Ring Fitting into Component Port)

- Hydraulic Schematic

- Hydraulic Flow Diagrams

- Traction Circuit

- Lower Cutting Units

- Raise Cutting Units

- Right and Left Turn

- Special Tools

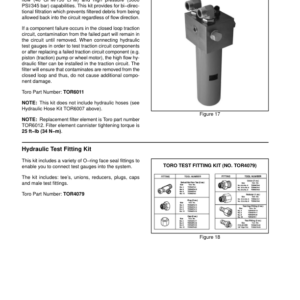

- Hydraulic Pressure Test Kit

- Hydraulic Tester (Pressure and Flow)

- 40 GPM Hydraulic Tester (Pressure and Flow)

- Hydraulic Hose Kit

- O-ring Kit

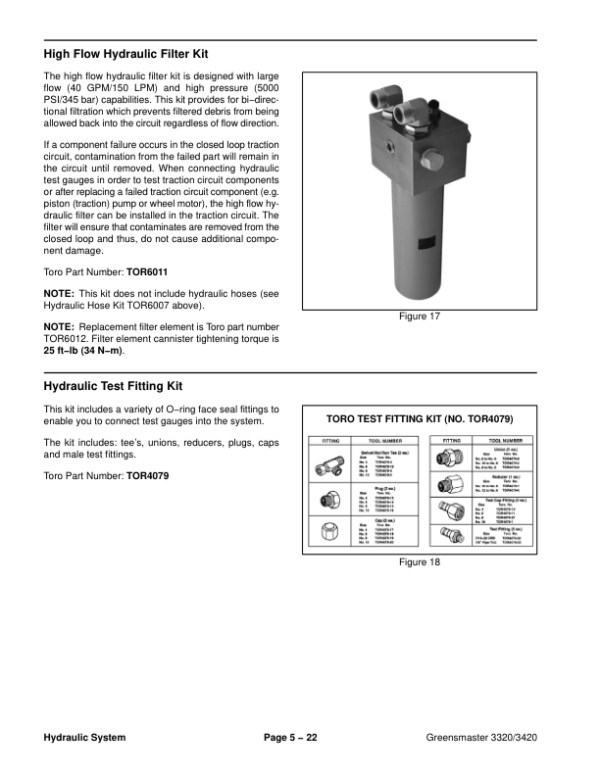

- High Flow Hydraulic Filter Kit

- Hydraulic Test Fitting Kit

- Measuring Container

- Wheel Hub Puller

- Troubleshooting

- Testing

- Charge Relief Valve Pressure Test (Using Pressure Gauge)

- Piston (Traction) Pump Flow Test (Using Tester with Flowmeter and Pressure Gauge)

- Wheel Motor Efficiency Test (Using Tester with Flowmeter and Pressure Gauge)

- Steering, Lift Relief Valve Pressure Test (Using Pressure Gauge)

- Lower Cutting Units Relief Valve (RV) Pressure Test (Using Pressure Gauge)

- Steering, Lift Circuit Gear Pump Flow Test (Using Tester with Flowmeter and Pressure Gauge)

- Power Steering Valve Test

- Adjustments

- Adjust Manifold Relief Valves

- Adjust Traction Control Assembly

- Service and Repairs

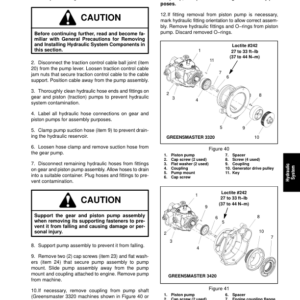

- General Precautions for Removing and Installing Hydraulic System Components

- Flush Hydraulic System

- Filtering Closed-Loop Traction Circuit

- Hydraulic System Start-up

- Gear Pump

- Gear Pump Service

- Piston (Traction) Pump Neutral Assembly

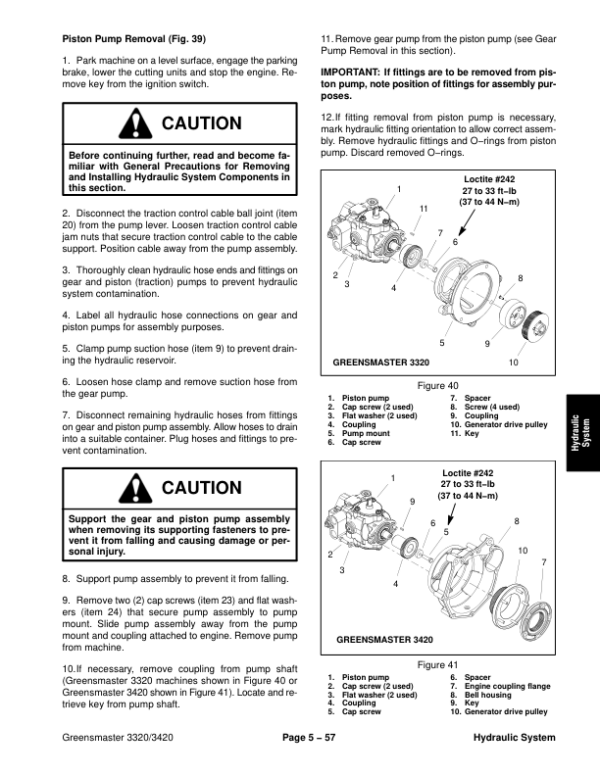

- Piston (Traction) Pump

- Piston (Traction) Pump Service

- Piston Pump Crush Ring Replacement

- Front Wheel Motors

- Rear Wheel Motor (Optional 3WD)

- Wheel Motor Service

- Lift Cylinders

- Lift Cylinder Service

- Lift Control Manifold

- Lift Control Manifold Service

- Control Manifold Cartridge Valve Service

- Power Steering Valve

- Power Steering Valve Service

- Steering Cylinder

- Steering Cylinder Service

- Hydraulic Reservoir

- Leak Detector Tank (Machines Equipped with Optional Turf GuardianTM Leak Detector System)

- Leak Detector Solenoid Valve Assembly (Machines Equipped with Optional Turf GuardianTM Leak Detector System)

- EATON, MEDIUM DUTY PISTON PUMP, REPAIRINFORMATION

- PARKER TORQMOTORTM SERVICE PROCEDURE(TC, TB, TE, TJ, TF, TG, TH AND TL SERIES)

- DANFOSS STEERING UNIT TYPE OSPM SERVICEMANUAL

- 6 – Electrical System

- Table of Contents

- General Information

- Operator's Manual

- Toro Electronic Controller (TEC)

- CAN-bus Communications

- Opening Electrical Circuit to Cutting Units

- Electrical Drawings

- Electrical System Operation

- 12 Volt DC System Operation

- Electric Reel Drive System (48 Volt DC) Operation

- Turf GuardianTM Leak Detector System Operation (Optional Kit)

- Before Start‐Up (Cold Oil)

- Normal Operation (Warm Oil)

- Leak Alert!

- Special Tools

- Multimeter

- Hand Held Diagnostic Display

- Battery Terminal Protector

- Dielectric Lubricant, Sealant

- Battery Hydrometer

- Generator Rotor Tool Set

- Cutting Reel Motor Rotor Tool Set

- InfoCenter Display (Serial Number Above 312000000)

- Splash Screen

- Main Information Screen

- Main Menu Screen

- Faults Screen

- Service Screen

- Diagnostics Screen

- About Screen

- Settings Screen

- Troubleshooting

- Diagnostic Light (Serial Number Below 312000000)

- Fault Codes

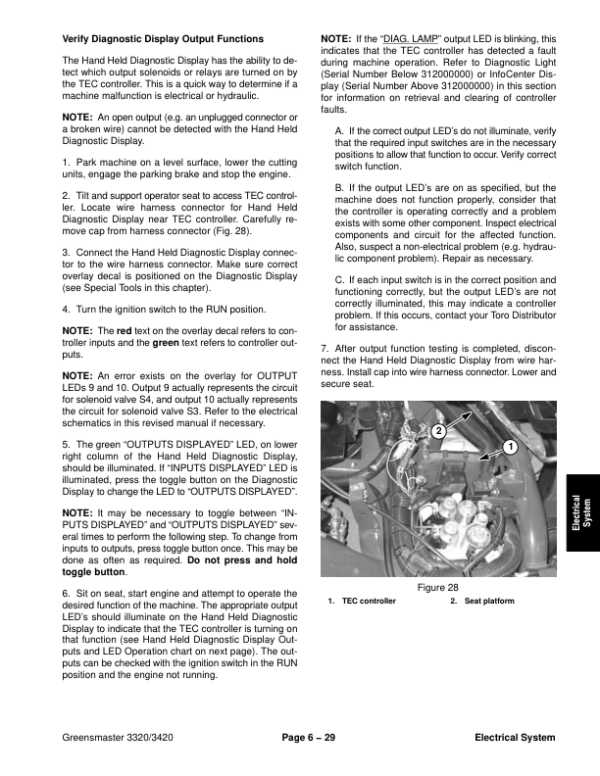

- Hand Held Diagnostic Display

- Electrical System Quick Checks

- 12 Volt Battery Test

- Engine Charging System Test

- Glow Plug System Test (Greensmaster 3420)

- Adjustments

- Parking Brake Switch

- Neutral and Mow Switches

- Component Testing

- Ignition Switch (Serial Number Below 312000000)

- Ignition Switch (Serial Number Above 312000000)

- Engine Oil Pressure Indicator Light (Greensmaster 3320 with Serial Number Below 312000000)

- Indicator Lights (Greensmaster 3420 with Serial Number Below 312000000)

- Fuse Block (Greensmaster 3320)

- Fuse Block (Greensmaster 3420 with Serial Number Below 312000000)

- Fuse Block (Greensmaster 3420 with Serial Number Above 312000000)

- Electric Reel Drive System (48 Volt DC) Fuses

- Fusible Links

- Hour Meter

- Seat Switch

- Neutral and Mow Switches

- Parking Brake Switch

- Joystick Raise and Lower Switches

- Backlap Switch

- Electric Reel Contactor

- Reel Speed Potentiometer (Serial Number Below 312000000)

- Toro Electronic Controller (TEC)

- Hydraulic Solenoid Valve Coils

- Main Power, Electric Cutting Reels Enable, Charge Circuit (Greensmaster 3320), Glow (Greensmaster 3420) and Fan (Greensmas…

- Kill (Greensmaster 3320) and Start (Greensmaster 3420) Relays

- CAN-bus Termination Resistors

- Electric Reel Circuit Protection Diode

- Location ID Module

- Cutting Reel Motors

- Starter Solenoid (Greensmaster 3320)

- Fuel Pump (Greensmaster 3420)

- Fuel Solenoid (Greensmaster 3420)

- Temperature Sender (Greensmaster 3420)

- Diode Assembly (Greensmaster 3420)

- Turf GuardianTM Leak Detector Oil Level Sensor (If Equipped)

- Turf GuardianTM Leak Detector Alarm (If Equipped)

- Service and Repairs

- Verify Interlock System Operation

- 12 Volt Battery Care

- 12 Volt Battery Storage

- 12 Volt Battery Service

- Electric Reel Drive System (48 Volt DC) Battery Pack Service

- Generator Drive Belt (Greensmaster 3320)

- Generator Drive Belt (Greensmaster 3420)

- Generator Assembly (Greensmaster 3320)

- Generator Assembly (Greensmaster 3420)

- Generator Assembly Service

- Cutting Reel Motor

- Cutting Reel Motor Service

- 7 – Chassis

- Table of Contents

- Specifications

- General Information

- Operator's Manuals

- Opening Electrical Circuit to Cutting Units

- Special Tools

- Wheel Hub Puller

- Grease Fitting

- Adjustments

- Parking Brake Adjustment

- Service and Repairs

- Wheels

- Brake Service

- Brake Cables

- Rear Wheel Spindle Assembly

- Rear Steering Fork

- Control Console

- Tank Mount Plate Assembly

- Cutting Unit Suspension Crossarm Assembly

- Cutting Unit Suspension Assembly

- Cutting Unit Suspension Service

- Frame Assembly

- 8 – DPA Cutting Units

- Table of Contents

- Specifications

- General Information

- Cutting Unit Operator's Manual

- Supporting Cutting Unit when Servicing

- Opening Electrical Circuit to Cutting Units

- Special Tools

- Gauge Bar Assembly

- Bedknife Screw Tool

- Long Handle Brush Assembly

- Roller Bearing Installation Tools

- Diameter, Circumference Measuring Tape

- Turf Evaluator Tool

- Factors That Can Affect Cutting Performance

- Set Up and Adjustments

- Characteristics

- Leveling Rear Roller

- Service and Repairs

- Backlapping

- Bedbar Assembly

- Bedbar Adjuster Service

- Bedknife Replacement and Grinding

- Cutting Reel Assembly Removal and Installation

- Cutting Reel Assembly Service

- Preparing Reel for Grinding

- Reel Motor Adapter

- Front Roller

- Rear Roller

- Roller Service

- Rear Roller Brush (Optional)

- 9 – Groomer

- Table of Contents

- Specifications

- General Information

- Installation Instructions

- Opening Electrical Circuit to Cutting Units

- Troubleshooting

- Factors Affecting Grooming

- Grooming Reel Mechanical Problems

- Adjustments

- Height, Depth of Groomer Adjustment

- Service and Repairs

- Groomer Belt Replacement (Forward Rotating Groomer Drive)

- Groomer Cover (Counter Rotating Groomer Drive)

- Grooming Reel (Forward Rotating Groomer Drive)

- Grooming Reel (Counter Rotating Groomer Drive)

- Grooming Reel Service

- Grooming Reel Bearing Replacement

- Idler Assembly (Forward Rotating Groomer Drive)

- Idler Assembly (Counter Rotating Groomer Drive)

- Lift Arm Assembly

- Groomer Brush

- 10 – Universal Groomer (Optional)

- Specifications

- Universal Groomer

- General Information

- Installation Instructions

- Grooming Performance

- Troubleshooting

- Service and Repairs

- The Gear Box Assembly

- The Idler Assembly

- The Groomer Reel

- The Height Adjuster Assembly

- The Grooming Brush (Optional)

- 11 – Foldout Drawings

- Table of Contents

- Hydraulic Schematic

- Electrical Schematic GR3320

- Electrical Schematic GR3320

- Greensmaster 3320Electrical Schematic(Serial Numbers 314000001 to 316000000)

- Greensmaster 3320Electrical Schematic(Serial Numbers 316000001 to 403410000)

- Greensmaster 3320Electrical Schematic(Serial Numbers above 403410001)

- Electrical Schematic GR3420

- Electrical Schematic GR3420

- Greensmaster 3420Electrical Schematic(Serial Numbers 314003001 to 316000000)

- Greensmaster 3420Electrical Schematic(Serial Numbers 316000001 to 403420000)

- Greensmaster 3420Electrical Schematic(Serial Numbers above 403420001)

- E−Reels Electrical Schematic

- E−Reels Electrical Schematic

- Wire Harness Drawing GR3320

- Wire Harness Diagram GR3320

- Wire Harness Drawing GR3320

- Wire Harness Diagram GR3320

- Wire Harness DrawingGreensmaster 3320(Serial Numbers 316000001 to 403410000)

- Wire Harness DrawingGreensmaster 3320(Serial Numbers 316000001 to 403410000)

- Wire Harness DrawingGreensmaster 3320(Serial Numbers 403410001 to 406000000)

- Wire Harness DiagramGreensmaster 3320(Serial Numbers 403410001 to 406000000)

- Wire Harness DrawingGreensmaster 3320(Serial Numbers above 406000001)

- Wire Harness DiagramGreensmaster 3320(Serial Numbers above 406000001)

- Wire Harness Drawing GR3420

- Wire Harness Diagram GR3420

- Wire Harness Drawing GR3420

- Wire Harness Diagram GR3420

- Wire Harness DrawingGreensmaster 3420(Serial Numbers 314000001 to 316000000)

- Wire Harness DiagramGreensmaster 3420(Serial Numbers 314000001 to 316000000)

- Wire Harness DrawingGreensmaster 3420(Serial Numbers 316000001 to 316000500)

- Wire Harness DiagramGreensmaster 3420(Serial Numbers 316000001 to 316000500)

- Wire Harness DrawingGreensmaster 3420(Serial Numbers 316000501 to 403420000)

- Wire Harness DiagramGreensmaster 3420(Serial Numbers 316000501 to 403420000)

- Wire Harness DrawingGreensmaster 3420(Serial Numbers 403420000 to 405700000)

- Wire Harness DiagramGreensmaster 3420(Serial Numbers 403420000 to 405700000)

- Wire Harness DrawingGreensmaster 3420(Serial Numbers above 405700001)

- Wire Harness DiagramGreensmaster 3420(Serial Numbers above 405700001)

- E−Reels Wire Harness Drawing

- E−Reels Wire Harness Diagram

- E−Reels Wire Harness Drawing

- E−Reels Wire Harness Diagram

- E−Reels Wire Harness Drawing

- E−Reels Wire Harness Diagram

Be the first to review “Toro Greensmaster Triflex Hybrid 3320, 3420 (Models 04530, 04540) Service Repair Manual”

You must be logged in to post a review.

Reviews

There are no reviews yet.