Toro Groundsmaster 3200, 3300, 3310 (31900, 31901, 31902, 31903, 31907, 31709) Service Repair Manual

$34.00

Type: Groundsmaster

Language: English

Format: PDF Download

- Toro Groundsmaster 3200, 3300, 3310 (31900, 31901, 31902, 31903, 31907, 31709) Service Repair Manual – 359 Pages

- Description

- Reviews (0)

Description

Toro Groundsmaster 3200, 3300, 3310 (31900, 31901, 31902, 31903, 31907, 31709) Service Repair Manual

Type: Groundsmaster

Language: English

Format: PDF Download

- Toro Groundsmaster 3200, 3300, 3310 (31900, 31901, 31902, 31903, 31907, 31709) Service Repair Manual – 359 Pages

Table of Content of the Groundsmaster 3200, 3300, 3310

Preface …………………………………………………………………………………………………. 5

Chapter 1: Safety ……………………………………………………………………………….. 1–1

Safety Instructions …………………………………………………………………………… 1–2

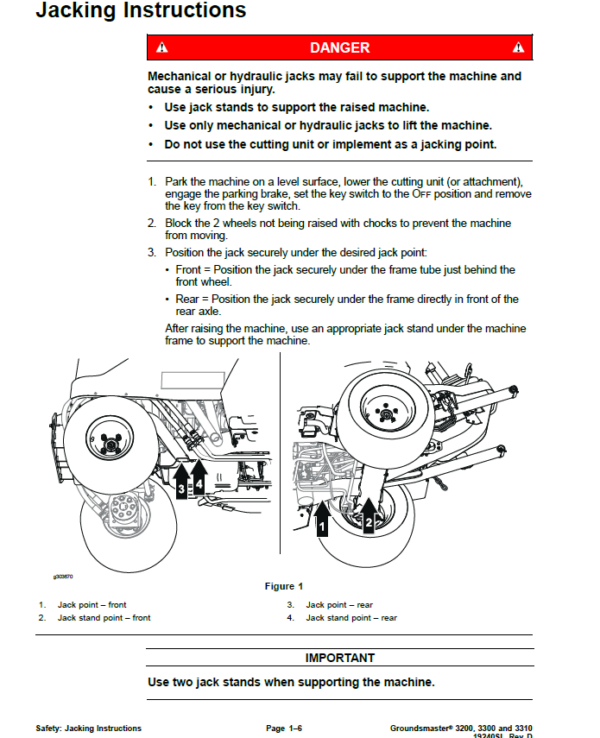

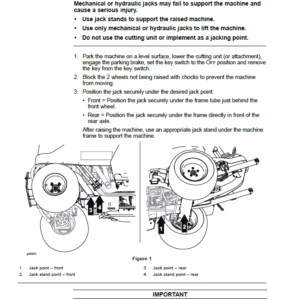

Jacking Instructions …………………………………………………………………………. 1–6

Safety and Instructional Decals ………………………………………………………….. 1–7

Chapter 2: Specifications and Maintenance ……………………………………………. 2–1

Specifications ………………………………………………………………………………….. 2–2

Torque Specifications ……………………………………………………………………….. 2–7

Shop Supplies ……………………………………………………………………………….. 2–14

Special Tools …………………………………………………………………………………. 2–16

Chapter 3: Troubleshooting ………………………………………………………………….. 3–1

GEARS – The Systematic Approach to Defining, Diagnosing and Solving

Problems ………………………………………………………………………………………… 3–2

Operator Advisories ………………………………………………………………………….. 3–3

Machine and Engine Faults………………………………………………………………… 3–5

Using the TDM Display/Controller Screens for Troubleshooting ……………… 3–12

Troubleshooting – Hydraulic …………………………………………………………….. 3–14

General Hydraulic System Problems …………………………………………………. 3–15

Traction System Problems ……………………………………………………………….. 3–17

Steering System Problems ………………………………………………………………. 3–19

Cutting Unit (or attachment) Lift/Lower Problems …………………………………. 3–20

Troubleshooting – Electrical……………………………………………………………… 3–21

Starting Problems …………………………………………………………………………… 3–22

General Run and Transport Problems………………………………………………… 3–24

Cutting Unit (or attachment) Problems ……………………………………………….. 3–25

Factors That Can Affect Quality of Cut ……………………………………………….. 3–26

Chapter 4: Engine ………………………………………………………………………………. 4–1

General Information …………………………………………………………………………. 4–2

Service and Repairs …………………………………………………………………………. 4–9

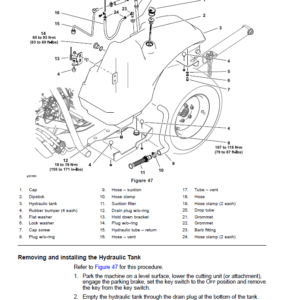

Chapter 5: Hydraulic System………………………………………………………………… 5–1

General Information …………………………………………………………………………. 5–3

Hydraulic Schematics ……………………………………………………………………… 5–12

Hydraulic Flow Diagrams …………………………………………………………………. 5–13

Testing the Hydraulic System……………………………………………………………. 5–22

Adjustments ………………………………………………………………………………….. 5–50

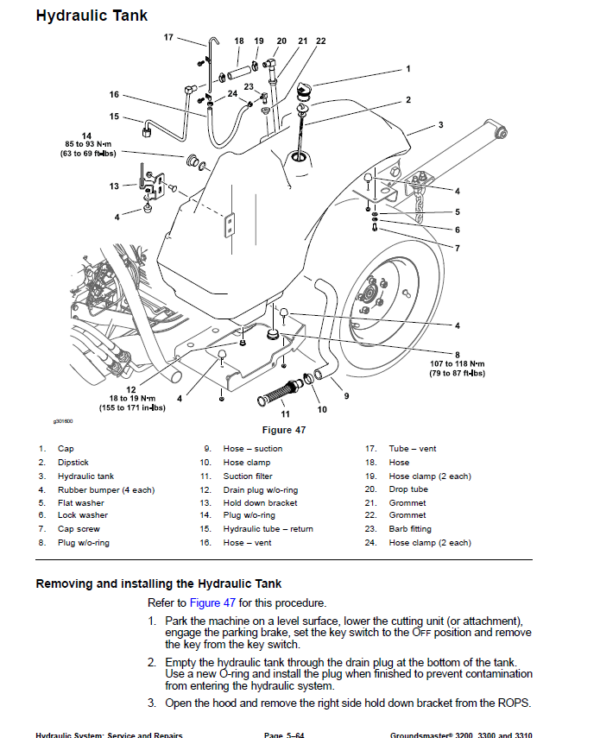

Service and Repairs ……………………………………………………………………….. 5–52

Chapter 6: Electrical System ………………………………………………………………… 6–1

General Information …………………………………………………………………………. 6–2

Electrical Schematics and Wire Harness Drawings/Diagrams………………….. 6–6

Electrical System Quick Checks………………………………………………………….. 6–7

Testing the Electrical Components ………………………………………………………. 6–9

Service and Repairs ……………………………………………………………………….. 6–66

Chapter 7: Chassis……………………………………………………………………………… 7–1

General Information …………………………………………………………………………. 7–2

Adjustments ……………………………………………………………………………………. 7–3

Service and Repairs …………………………………………………………………………. 7–5

Chapter 8: Cutting Units ………………………………………………………………………. 8–1

General Information …………………………………………………………………………. 8–2

Service and Repairs …………………………………………………………………………. 8–3

Chapter 9: Operator Cab ……………………………………………………………………… 9–1

General Information …………………………………………………………………………. 9–2

Adjustments ……………………………………………………………………………………. 9–5

Service and Repairs …………………………………………………………………………. 9–7

Appendix A …………………………………………………………………………………………A–1

Electrical Drawing Designations…………………………………………………………..A–2

Hydraulic Schematic – 3200 2WD………………………………………………………..A–3

Hydraulic Schematic – 3200 4WD………………………………………………………..A–4

Hydraulic Schematic – 3300/3310………………………………………………………..A–5

Electrical Schematic – 3200/3300/3310 ………………………………………………..A–6

Electrical Schematic – 3300/3310 ………………………………………………………..A–7

Electrical Schematic – 3300/3310 (continued) ……………………………………….A–8

Electrical Schematic-Operator Cab………………………………………………………A–9

Wire Harness Drawing – 3200/3300/3310……………………………………………A–10

Wire Harness Diagram – 3320/3300/3310 …………………………………………..A–11

Wire Harness Drawing – Main 3300/3310 ……………………………………………A–12

Wire Harness Diagram – Main 3300/3310……………………………………………A–13

Wire Harness Diagram – Main 3300/3310 (continued) …………………………..A–14

Wire Harness – Cab Power……………………………………………………………….A–15

Wire Harness – Cab Rooftop …………………………………………………………….A–16

Wire Harness – Cab Control Panel……………………………………………………..A–17

Wire harness – Cab HVAC Adapter…………………………………………………….A–18

Wire Harness – Cab Work Light Kit (optional)……………………………………….A–19

Wire Harness – Road Light Kits, Lights (optional)………………………………….A–20

Wire Harness – Road Light Kit, Controls (optional)………………………………..A–21

Slope Sensor Kit (optional) ……………………………………………………………….A–22

The purpose of this publication is to provide the service technician with information for troubleshooting, testing and repair of major systems and components on the Groundsmaster 3200, 3300, 3310.

This service manual was written expressly for service technicians. Basic shop safety knowledge and mechanical/electrical skills are assumed. The purpose of this publication is to provide the service technician with information about troubleshooting, testing, and repairing major systems and components. This manual may also be specified for use on numerous products.

Refer to the Table of Contents for a list of the systems and the related topics covered in this manual. The Toro Company has made every effort to make the information in this manual complete and correct.

Be the first to review “Toro Groundsmaster 3200, 3300, 3310 (31900, 31901, 31902, 31903, 31907, 31709) Service Repair Manual”

You must be logged in to post a review.

Reviews

There are no reviews yet.