New Holland E16 and E18 Mini Excavator Service Manual

$34.00

Manual Included:

- Workshop Manual: 636 Pages

Specifications:

- Brand: New Holland

- Model: E16 and E18

- Type: Mini Excavator

- Manuals: Workshop Manual

- Publication Numbers: 604.13.396 (01/2005)

- Language: English

- Format: PDF

- Description

- Reviews (0)

Description

Table of Content (Workshop Manual)

INDEX

SPECIFICATIONS

1 – Preliminary remarks

2 – Specifications

3 – Attachment dimensions

MAINTENANCE

11 – Tools

12 – Standard maintenance time table

13 – Maintenance standards and tests procedures

SYSTEM

22 – Hydraulic system

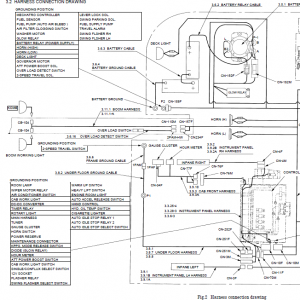

23 – Electrical system

24 – Components system

DISASSEMBLING

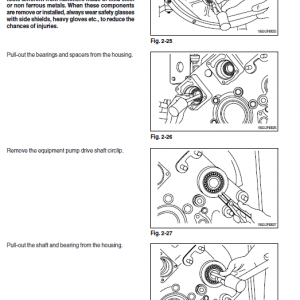

31 – Whole disassembly and assembly

32 – Attachments

33 – Upper slewing structure

34 – Travel system

TROUBLESHOOTING

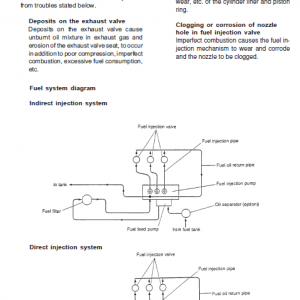

42 – Hydraulic system

43 – Electrical system

44 – Engine

ENGINE

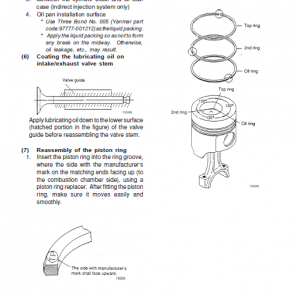

51 – Engine

The Manual Preface

This Manual has been written for the repair specialist. It provides important information on carrying out repair work expertly. Please go carefully through the Workshop Manual of the mini excavator before starting any repair work. Use the Workshop Manual of the E16 and E18 Excavator as a reference book and source of information even if you are familiar with mini excavator technology. Using this the experience construction machine mechanic can carry out any necessary repairs expertly.

Sections of the Manual

The Manual is into main groups and subgroups, and covers any previous version of the machine. Any additions or modifications which can happen at a later date are not describe in this manual. The require information can easily be found by referring to the table of contents. For reasons of clarity, some of the illustrations are present in simplified form. Differences from the actual version at the E16 and E18 mini excavator are therefore possible if this adds to the clarity of the information.

Repair and Parts

Carry out any necessary repair work as soon as possible. This reduces repair costs and increases the availability of your mini excavator When doing any work on the mini excavator, always observe the instructions given in the Workshop Manual. Extensive works not described in this Workshop Manual will gladly be executed for you by your dealer. Always use original spare parts only.

Be the first to review “New Holland E16 and E18 Mini Excavator Service Manual”

You must be logged in to post a review.

Reviews

There are no reviews yet.