John Deere LX280, LX280AWS and LX289 Garden Tractors Service Manual TM2046

$34.00

John Deere LX280, LX280AWS and LX289 Garden Tractors Service Repair Manual TM2046

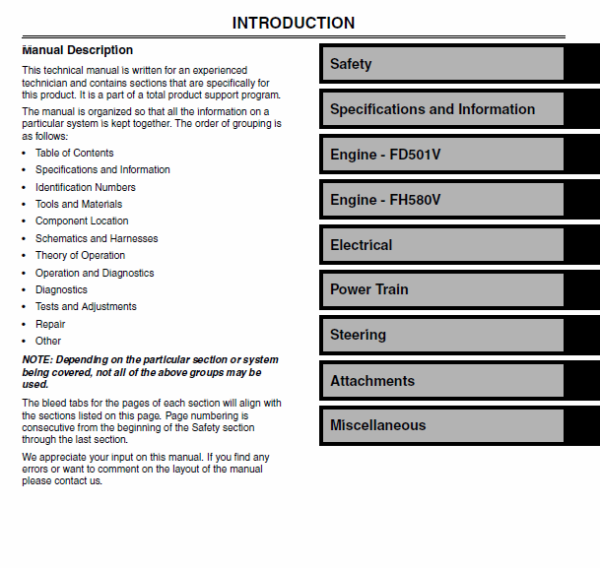

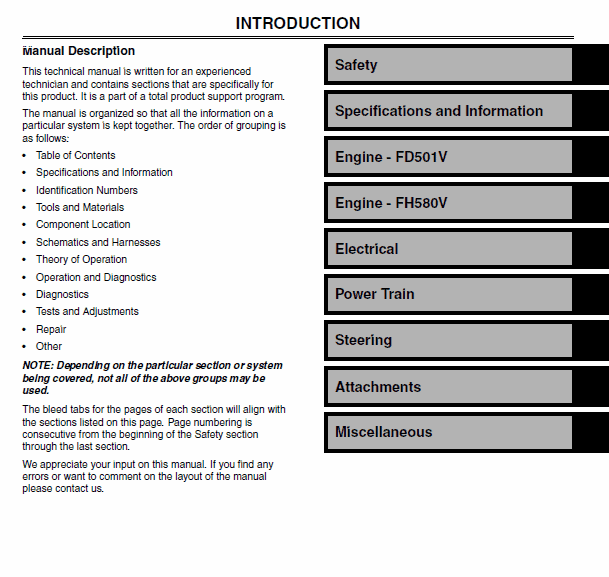

See pictures for the table of content.

Language: English

Format: PDF

Technical Manual: 446 Pages

Operator’s manual: 84 Pages

Models covered:

LX280 Garden Tractors,

LX280AWS Garden Tractors,

LX289 Garden Tractors.

- Description

- Reviews (0)

Description

John Deere LX280, LX280AWS and LX289 Garden Tractors Service Manual TM2046

See pictures for the table of content.

Language: English

Type: Tractors

Format: PDF

Service manual: 446 Pages (TM2046)

Operator’s manual: 84 Pages ( OMM152799)

Models covered:

LX280 Garden Tractors,

LX280AWS Garden Tractors,

LX289 Garden Tractors.

Service Manuals for actual service

Service Manuals are concise service guides for a specific machine and are on-the-job guides containing only the vital information needed by a technician.

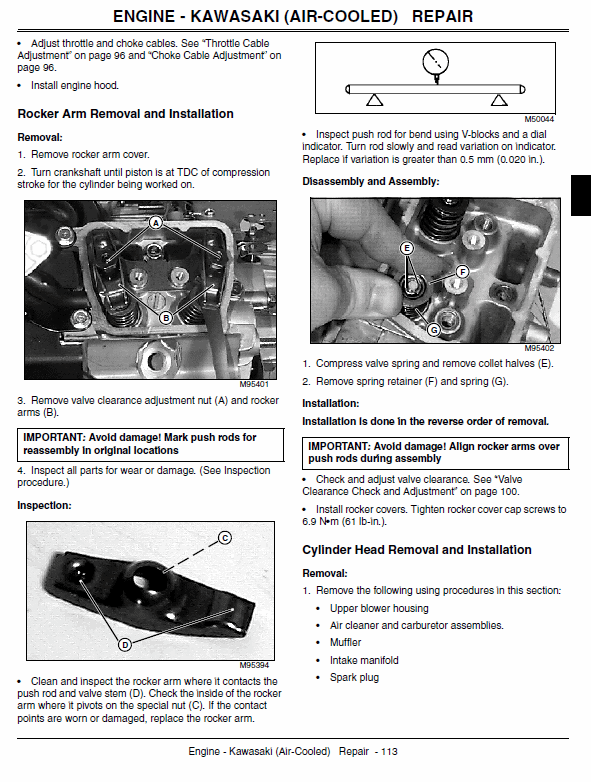

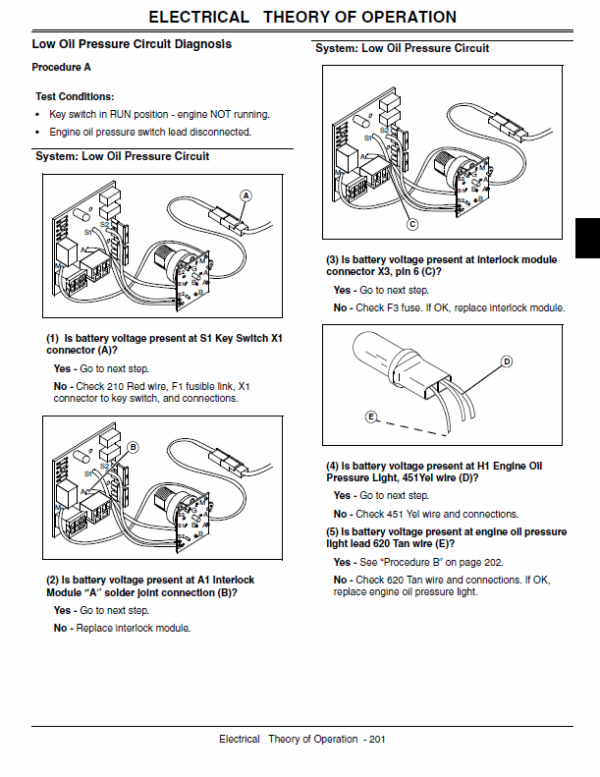

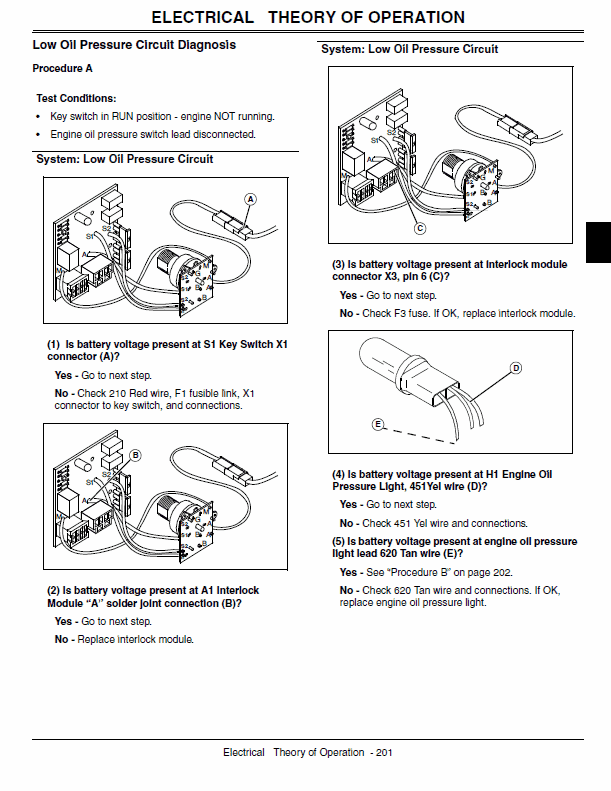

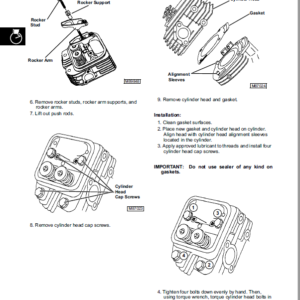

This Service Manual includes repair and maintenance information, detailed description of service and troubleshoot procedures, installation instructions, special instructions, other additional information for John Deere LX280, LX280AWS and LX289 Garden Tractors.

This manual includes illustrations like pictures and diagrams which you can help you determine the installation location spare parts, etc.

Using Your Operator s Manual

This manual is an important part of your machine and should remain with the machine when you sell it.

Reading your operator s manual will help you and others avoid personal injury or damage to the machine.

Information given in this manual will provide the operator with the safest and most effective use of the machine.

Knowing how to operate this machine safely and correctly will allow you to train others who may operate this machine.

If you have an attachment, use the safety and operating information in the attachment operator s manual along with

the machine operator s manual to operate the attachment safely and correctly.

John Deere LX280, LX280AWS and LX289 Garden Tractors Service Manual TM2046 Contents:

Safety

Specifications and Information

Engine – FD501V

Engine – FH580V

Electrical

Power Train

Steering

Attachments

Miscellaneous

We offer a wide range of manuals for different Brands be sure to check our collections.

You can also buy the John Deere LX280, LX280AWS and LX289 item at our Sellfy Store:

https://sellfy.com/p/Ro6z/

Be the first to review “John Deere LX280, LX280AWS and LX289 Garden Tractors Service Manual TM2046”

You must be logged in to post a review.

Reviews

There are no reviews yet.