John Deere 690C, 693C Excavator Service Manual

$35.00

John Deere 690C, 693C Excavator Service Repair Manual TM1323 & TM1329

Model: John Deere 690C and John Deere 693C (TM1323)

Type: Excavator

Language: English

Format: PDF

No of Pages: 1104 – Operation and Tests

No of Pages: 402 – Repair

- Description

- Reviews (0)

Description

John Deere 690C, 693C Excavator Service Manual TM1323 & TM1329

Model: John Deere 690C, John Deere 693C (TM1323)

Type: Excavator

Language: English

Format: PDF

No of Pages: 1104 – Operation and Tests

No of Pages: 402 – Repair

Technical Manuals or Service Manuals for actual service

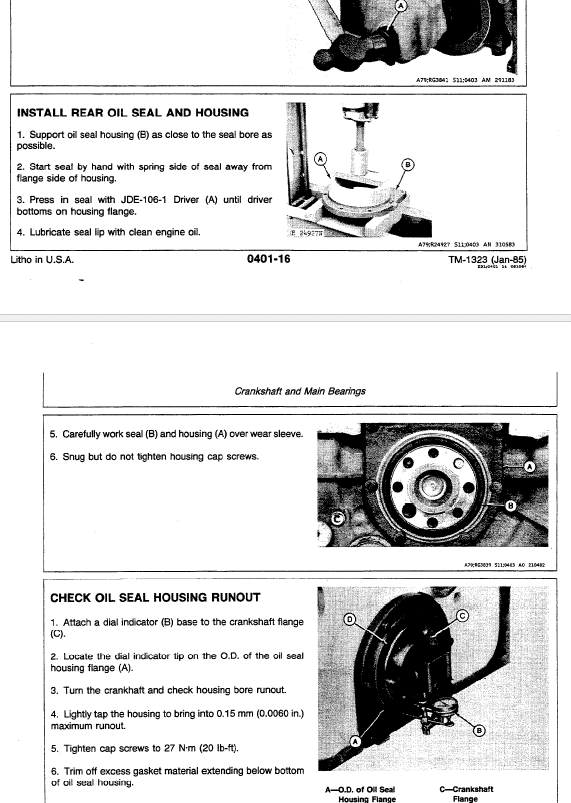

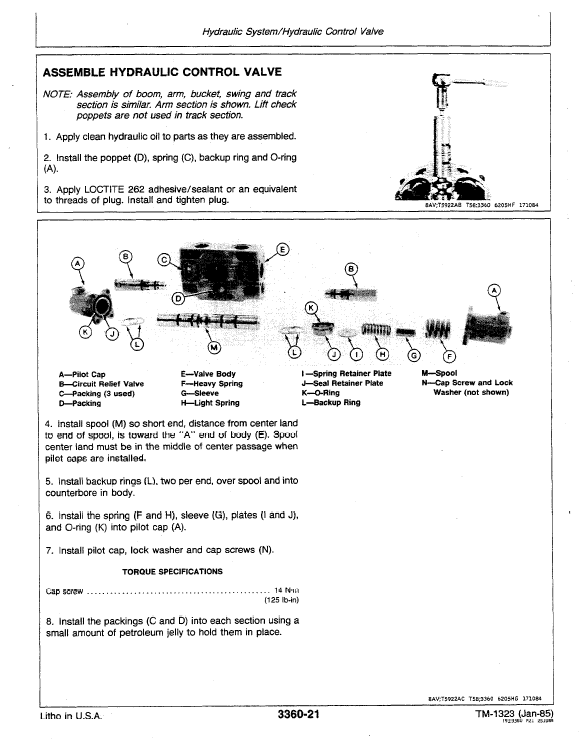

This Technical manual also known as Service Manual for John Deere 690C, 693C Excavator includes repair and maintenance information, detailed description of service and troubleshoot procedures, installation instructions, special instructions, other additional information. This manual includes illustrations like pictures and diagrams which you can help you determine the installation location spare parts, etc.

Technical (Repair) Manual or Service Manual are concise service guides for a specific machine and are on-the-job guides containing only the vital information needed by a technician.

Manual covers:

John Deere 690C Excavator,

John Deere 693C Feller-Buncher

and

John Deere 693C Delimber.

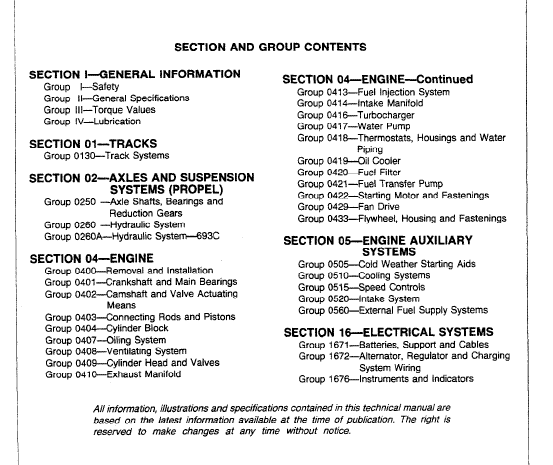

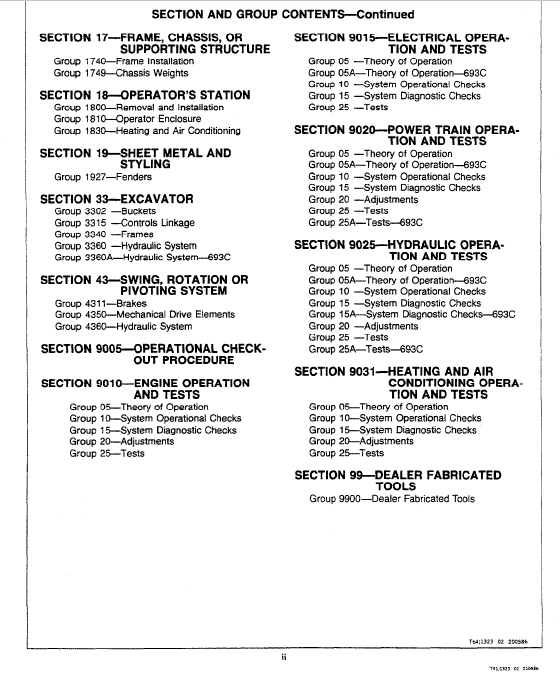

John Deere 690C, 693C Excavator Service Manual TM1323 Sections:

- I – GENERAL INFORMATION

- 01 – TRACKS

- 02 – AXLES AND SUSPENSION SYSTEMS (PROPEL)

- 04 – ENGINE

- 05 – EGINE AUXILIARY SYSTEMS

- 16 – ELECTRICAL SYSTEMS

- 17 – FRAME, CHASSIS, OR SUPPORTING STRUCTURE

- 18 – OPERATOR’S STATION

- 19 – SHEET METAL AND STYLING

- 33 – EXCAVATOR

- 43 – SWING, ROTATION OR PIVOTING SYSTEM

- 9005 – OPERATIONAL CHECKOUT PROCEDURE

- 9010 – ENGINE OPERATION AND TESTS

- 9015 – ELECTRICAL OPERATION AND TESTS

- 9020 – POWER TRAIN OPERATION AND TESTS

- 9025 – HYDRAULIC SYSTEM OPERATION AND TESTS

- 9031 – HEATING AND AIR CONDITIONING OPERATION AND TESTS

- 99 – DEALER FABRICATED TOOLS

John Deere 690C, 693C Excavator Service Manual TM1329 Sections::

- I – GENERAL INFORMATION

- 01 – WHEELS

- 02 – AXLES AND SUSPENSION SYSTEMS (PROPEL)

- 04 – ENGINE

- 05 – ENGINE AUXILIARY SYSTEM

- 16 – ELECTRICAL SYSTEMS

- 17 – FRAME, CHASSIS, OR SUPPORTING STRUCTURE

- 18 – OPERATOR’S STATION

- 19 – SHEET METAL AND STYLING

- 32 – DOZERS

- 33 – John Deere 690C, 693C EXCAVATOR

- 43 – SWING, ROTATION OR PIVOTING SYSTEM

- 9005 – OPERATIONAL CHECKOUT PROCEDURE

- 9010 – ENGINE OPERATION AND TESTS

- 9015 – ELECTRICAL OPERATION AND TESTS

- 9020 – POWER TRAIN OPERATION AND TESTS

- 9025 – HYDRAULIC OPERATION AND TESTS

- 9031 – HEATING & AIR CONDITIONING SYSTEM OPERATION AND TEST

- 99 – DEALER FABRICATED TOOLS

If you are interested in any other models of John Deere Service Manual click here.

You can also buy this John Deere 690C, 693C Excavator Manual at our Sellfy Store:

https://sellfy.com/p/9oki/

Be the first to review “John Deere 690C, 693C Excavator Service Manual”

You must be logged in to post a review.

Reviews

There are no reviews yet.