John Deere 6076 Engines CTM6 Repair Manual

$34.00

John Deere 6076 Engines CTM6

Model: 6076 (CTM6)

Language: English

Format: PDF

No of Pages: 437

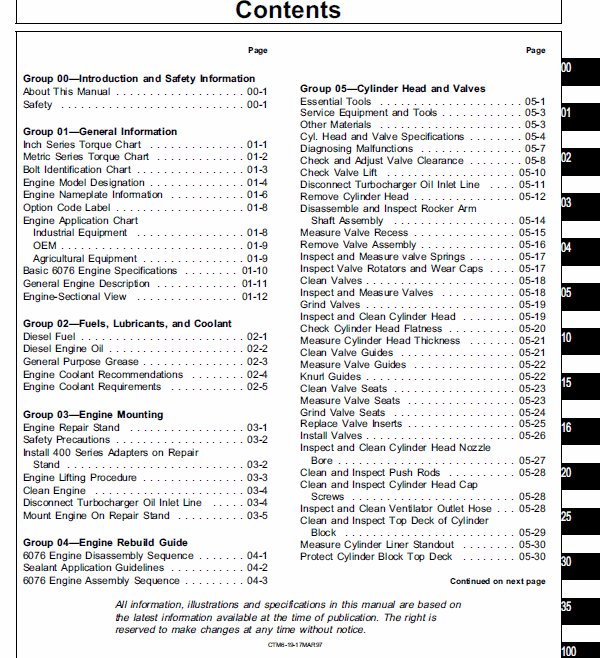

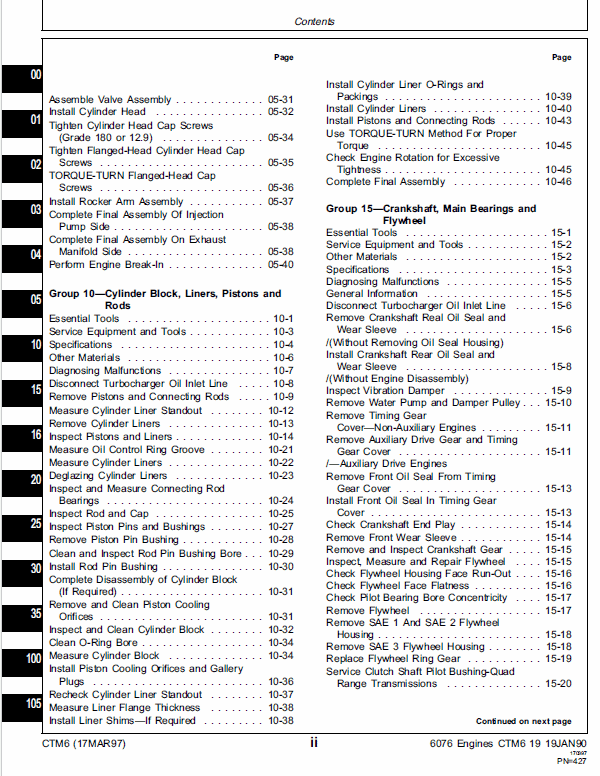

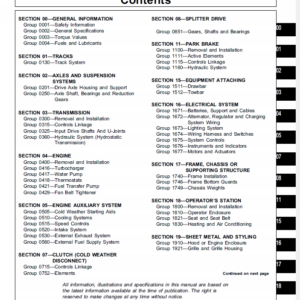

See pictures for the table of content.

- Description

- Reviews (0)

Description

John Deere 6076 Engines CTM6 Repair Manual

Model: 6076 (CTM6)

Type: Engines

Language: English

Format: PDF

No of Pages: 437

See pictures for the table of content.

John Deere 6076 Engines CTM6 Manual Contents:

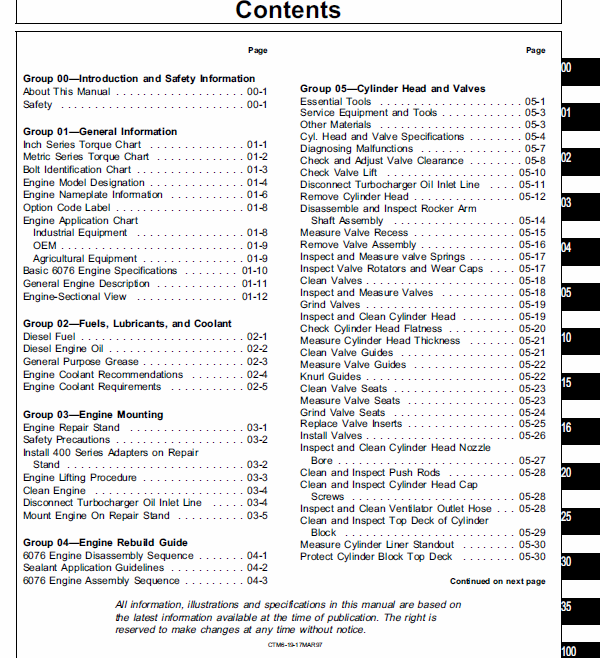

- Group 00 Introduction and Safety Information

- Group 01 General Information

- Group 02 Fuels, Lubricants, and Coolant

- Group 03 Engine Mounting

- Group 04 Engine Rebuild Guide

- Group 05 Cylinder Head and Valves

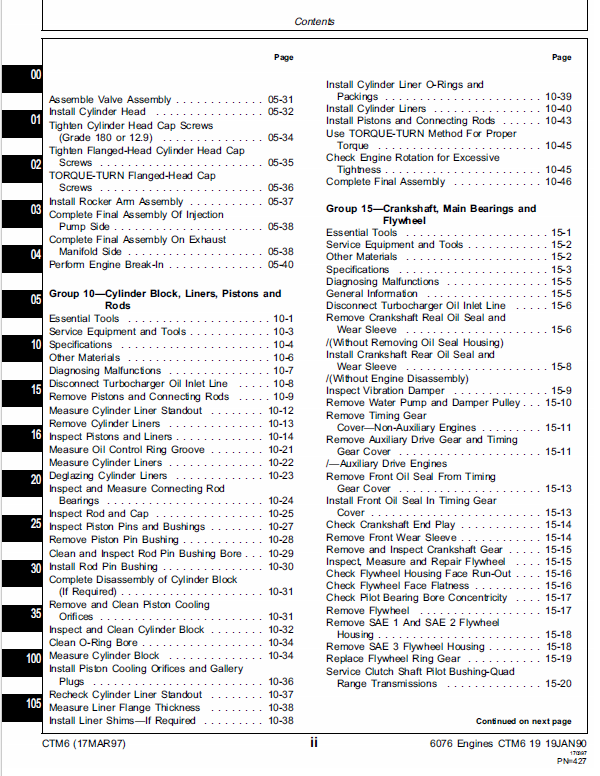

- Group 10 Cylinder Block, Liners, Pistons and Rods

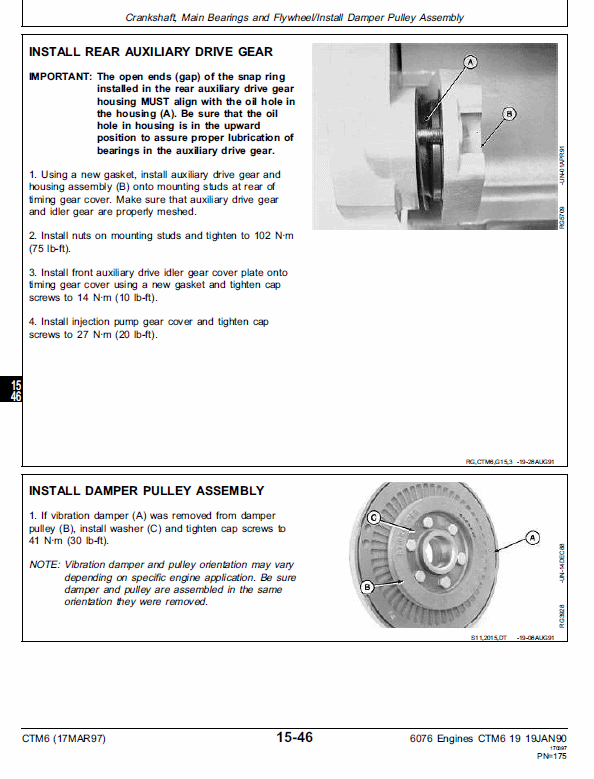

- Group 15 Crankshaft, Main Bearings and Flywheel

- Group 16 Camshaft and Timing Gear Train

- Group 20 Lubrication System

- Group 25 Cooling System

- Group 30 Air Intake And Exhaust System Essential Tools

- Group 35 Fuel System

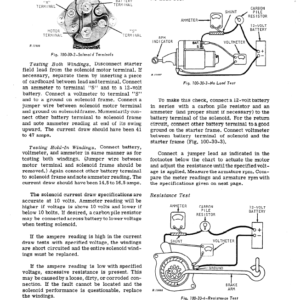

- Group 100 Tune-Up Preliminary Engine Testing

- Group 105 Engine System Operation and Test

- Group 110 Air Intake System Operation and Test

- Group 115 Fuel System Operation and Tests

- Group 199 Dealer Fabricated Tools

You can also buy this John Deere 6076 Engines CTM6 Manual at our Sellfy Store:

https://sellfy.com/p/CmZJ/

Be the first to review “John Deere 6076 Engines CTM6 Repair Manual”

You must be logged in to post a review.

Reviews

There are no reviews yet.