JCB Vibromax 1103 Single Drum Roller Service Manual

$26.50

Model: Vibromax 1103

Language: English

Format PDF

Type: Service Repair Manual

JCB Vibromax 1103 Single Drum Roller Service Repair Manual – 222 Pages

- Description

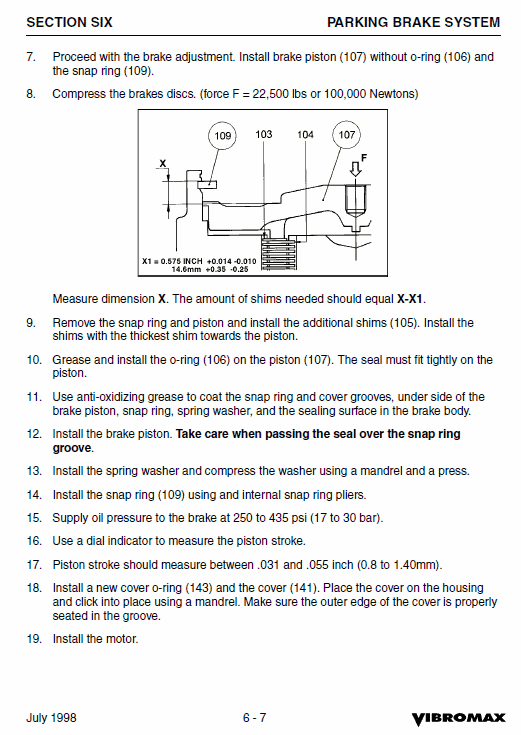

- Reviews (0)

Description

JCB Vibromax 1103 Single Drum Roller Service Manual

Model: Vibromax 1103

Language: English

Format PDF

Type: Service Manual

JCB Vibromax 1103 Single Drum Roller Service Manual – 222 Pages

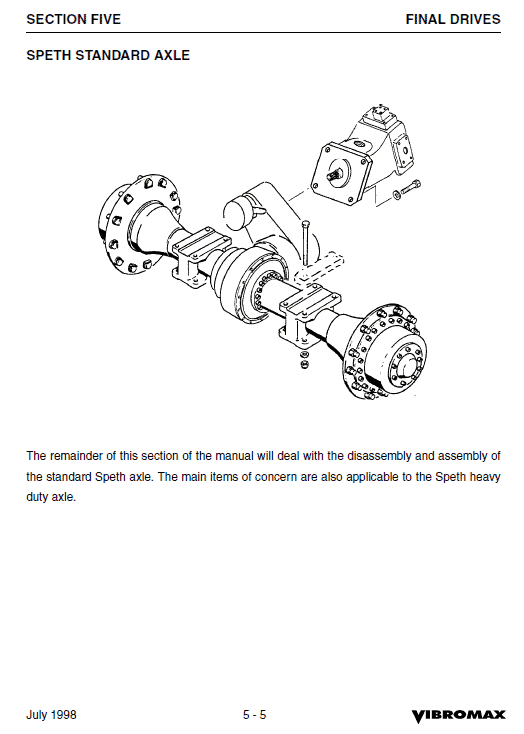

The Vibromax 1103 Vibratory Roller is the replacement for the 1102. Like the 1102, the 1103 is available in smooth drum or pad foot drum configuration. The 1103 however, is offer with a standard Speth axle or a heavy duty Speth axle for high gradeability applications. The 1103 uses the Cummins 5.9 liter 6 cylinder turbocharged engine at 130 gross horsepower. Changes in the drive pump and the addition of a heavy duty axle drive motor result in improved machine performance. The vibratory drum diameter remains the same and drum width is two inches narrower. The drum s centrifugal force has been increased 22%.

A Sauer Sundstrand Series 90 variable displacement, axial piston hydrostatic pump, used for machine propulsion, mounts to the flywheel end of the engine. It provides oil to a Poclain MS25 drum drive motor and a Sauer Sundstrand 2 speed axle drive motor in a parallel path. The Poclain motor is mounted on the left side of the drum and is isolated from the drum by rubber buffers. The axle drive motor on the standard axle has a displacement of 80 cc while the motor on the heavy duty axle displaces 110cc.

See the other Tab for JCB Vibromax 1103 Single Drum Roller Service Manualthe table of content.

The vibration system uses a Sauer Sundstrand Series 90 hydrostatic pump similar to the propulsion pump and mounted directly behind the propulsion pump.

The vibratory pump supplies oil to a Sauer Sundstrand hydrostatic motor mounted at the right side of the drum. The Vibromax 1103 single drum roller smooth drum operates at frequencies of 1680 or 2160 vibrations per minute, while the pad foot version operates only at the lower frequency. A steering pump, mounted to the rear of the vibration pump, provides the oil needed for steering.

The steering pump is also a second charge pump in the propulsion/vibration circuit. The steering pump draws oil from the reservoir, passes it through the steering control valve, through the inline hydraulic filter, and into the charge circuit. The charge pump draws oil from reservoir, joins the steering oil at the filter, passes it through the filter and into the charge circuit.

The Vibromax 1103 has brakes at both the front drum and the rear axle. A spring applied-hydraulically released multi disc brake is part of the drum drive motor. The standard axle machine uses a spring applied-hydraulically released band brake at the intermediate gearbox while the heavy duty axle incorporates multiple disc brakes at the intermediate gearbox.

Be the first to review “JCB Vibromax 1103 Single Drum Roller Service Manual”

You must be logged in to post a review.

Reviews

There are no reviews yet.