Hitachi ZW65-6 , ZW75-6, ZW95-6 Wheel Loader Service Repair Manual

$35.00

Hitachi ZW65-6 , ZW75-6, ZW95-6 Workshop Manual – 294 Pages

Hitachi ZW65-6 , ZW75-6, ZW95-6 Service Repair Manual – 146 Pages

Deutz Engine Workshop Manual D2.9 L4, TD2.9 LD and TCD2.9 L4 – 358 Pages

Circuit diagram – 8 Pages

- Description

- Reviews (0)

Description

Hitachi ZW65-6 , ZW75-6, ZW95-6 Wheel Loader Service Manual

The manual is applicable for the Hitachi ZW65-6 , ZW75-6, ZW95-6 Wheel Loader Model

Format: PDF

Language: English

Service Manual consists of the following:

Hitachi ZW65-6 , ZW75-6, ZW95-6 Workshop Manual – 294 Pages

Hitachi ZW65-6 , ZW75-6, ZW95-6 Service Manual – 146 Pages

Deutz Engine Workshop Manual D2.9 L4, TD2.9 LD and TCD2.9 L4 – 358 Pages

Circuit diagram – 8 Pages

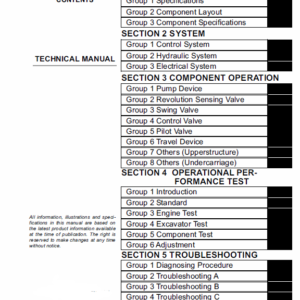

Table of Content of the Workshop Manual

1 Notes for the Reader………………………………………………………………………………………………. 6

2 Technical Data……………………………………………………………………………………………………….. 9

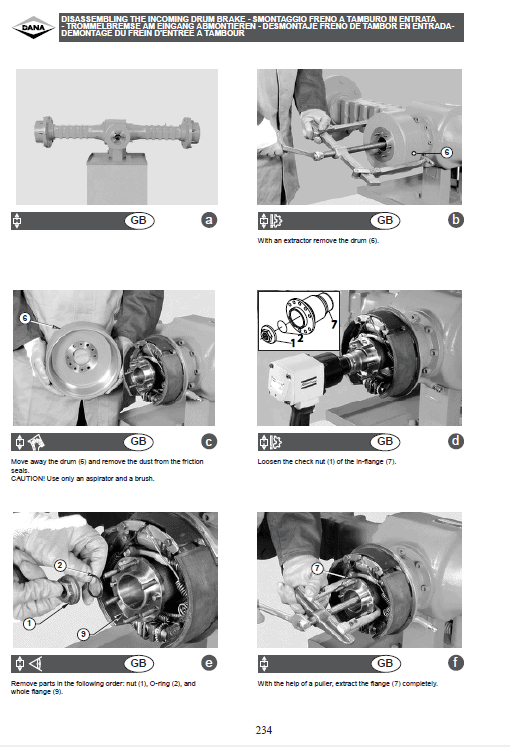

3 Axles …………………………………………………………………………………………………………………… 23

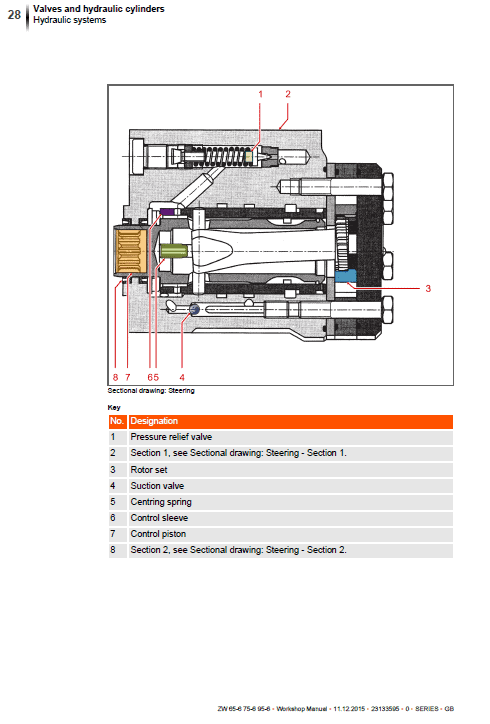

4 Hydraulic systems ………………………………………………………………………………………………..25

5 Hydrostatic drive…………………………………………………………………………………………………..53

6 Electrical system………………………………………………………………………………………………….. 91

7 System………………………………………………………………………………………………………………. 149

Manual guide composition

Hitachi ZAXIS ZW65-6 , ZW75-6, ZW95-6 service manual consists of the Troubleshooting and the Workshop Manual.

- Information included in the Service Manual: Technical information needed for redelivery and delivery, operation and activation of all devices and systems, operational performance tests, and troubleshooting procedures.

- Information included in the Workshop Manual: Technical information needed for maintenance and repair of the machine, tools and devices needed for maintenance and repair, maintenance standards, and removal / installation and assemble / disassemble procedures.

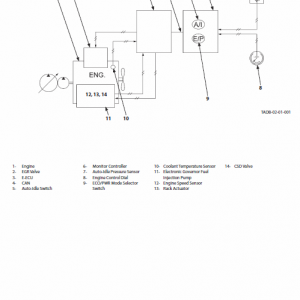

2.4.2 Central electrical system

With the implementation of the required emission directives of the Tier standard, a new generation of vehicle control system has been introduced in the AX product segment.

Electronic control of the power unit that is taken for granted in today’s automotive industry in order to achieve the required emission values, has been enhanced in this stage of development to include electronic control of the hydraulic movement function.

Furthermore, communication of the control signals has been optimised by the implementation of a CAN bus system between the control units in the vehicle.

4 – Adjust Spring

5 – Differential Piston

6 – Orifice

A- DA Valve Primary side (From Charging Pump) B- DA Valve Secondary side (To Control Circuit) C- DA Valve Secondary side (To Charging Circuit) D- DA Valve Drain

Be the first to review “Hitachi ZW65-6 , ZW75-6, ZW95-6 Wheel Loader Service Repair Manual”

You must be logged in to post a review.

Reviews

There are no reviews yet.