Case CX16B and CX18B Mini Excavator Service Manual

$34.00

Manufacturer: Case

Manual For: CX16B and CX18B Mini Excavator

Format: PDF

Language: English

No: 9-88670

Case CX16B and CX18B Excavator Service Repair Manual – 636 Pages

- Description

- Reviews (0)

Description

Case CX16B and CX18B Mini Excavator Service Manual

Manufacturer: Case

Manual For: CX16B and CX18B Mini Excavator

Format: PDF

Language: English

No: 9-88670

Case CX16B and CX18B Excavator Service Manual – 636 Pages

How to Use this Manual

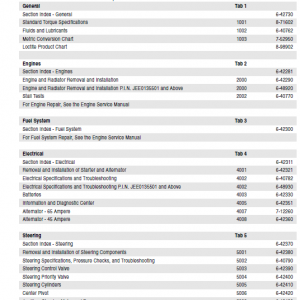

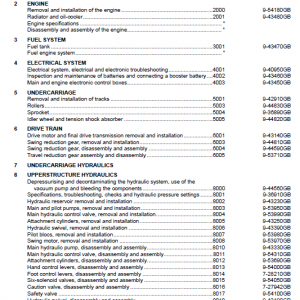

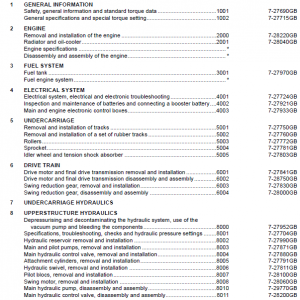

The Case CX16B and CX18B Excavator manual is in different Sections. Each Section is then divided into Chapters. Contents pages are available at the beginning of the manual, then inside every Section and inside every Chapter. An alphabetical Index is use as guide at the end of a Chapter. Page number references are present for every piece of technical information mention in the Chapter Contents or Chapter Index.

Each Chapter details are into four Information types:

- Technical Data (specifications) for all the mechanical, electrical or hydraulic devices, components and, assemblies.

- Functional Data (how it works) for all the mechanical, electrical or hydraulic devices, components and assemblies.

- Diagnostic Data (fault codes, electrical and hydraulic troubleshooting) for all the mechanical, electrical or hydraulic devices, components and assemblies.

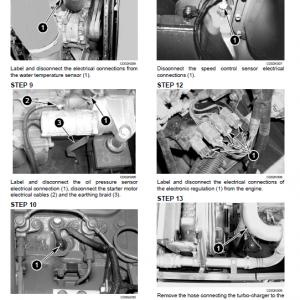

- Service data (remove disassembly, assemble, install) for all the mechanical, electrical or hydraulic devices, components and assemblies.

All maintenance and repair interventions listed in this Case CX16B and CX18B Service Manual must be performed exclusively by the Service Network of the Manufacturer or a repair professional who will comply strictly with the indications herein and using, when required, the prescribed special tools. Whoever performs service operations described herein without complying strictly with the instructions becomes solely responsible for any consequential damage that could occur.

Be the first to review “Case CX16B and CX18B Mini Excavator Service Manual”

You must be logged in to post a review.

Reviews

There are no reviews yet.