Massey Ferguson 2605, 2615 Tractor Service Manual

$35.00

Model: Tractor 2605, 2615

Format PDF

Type: Workshop Repair Manual

Publication No: 4283072M2

- Massey Ferguson 2605, 2615 Tractors Workshop Manual – 673 Pages

- Massey Ferguson 2605, 2615 Tractors Parts Catalog Manual – 75 Pages & 78 Pages

- Description

- Reviews (1)

Description

Massey Ferguson 2605, 2615 Tractor Service Manual

Manual for Tractor 2605, 2615

Format PDF

Type: Workshop Service Manual

Publication No: 4283072M2

- Massey Ferguson 2605, 2615 Tractors Workshop Manual – 673 Pages

- Massey Ferguson 2605, 2615 Tractors Parts Catalog Manual – 75 Pages & 78 Pages

This service manual has been prepared with the latest service information available at the time of publication. Read the service manual carefully before doing any service on the Massey Ferguson tractors. This manual is one of the most important tools available to the service technician.

This Massey Ferguson 2605, 2615 Tractors Service Manual was develope to provide the best possible information, technical support and service to the customer. Review the Table of Contents and basic layout to become familiar with locations of pertinent information such as maintenance table, specifications and etc.

Extract of the Manual Procedure for Eliminating Air from Fuel system (SJ327E with VE type Fuel Pump)

Following procedure describes eliminating air from the fuel line system in SJ 327 E engine fitted with MICO VE

type fuel injection pump applicable to tractors

1. Ensure diesel flows freely at feed pump inlet and tighten the banjo bolt.

2. Operate hand primer

• Release air at vent screw from primary bowl of fuel filter. Ensure fuel flows without air and tighten the vent screw.

• Release air at vent screw from secondary bowl of fuel filter. Ensure fuel flows without air and tighten the vent screw

• Release air at over flow banjo bolt (marked OUT on banjo bolt top) of fuel injection pump. Ensure fuel flows without air and tighten the overflow banjo bolt.

3. Then loosen the three nuts of high pressure fuel pipe at atomiser.

• Crank the engine with the help of battery until fuel flows free of air.

4. Tighten the three nuts of high pressure pipe at atomiser.

5. Engine is now ready to start.

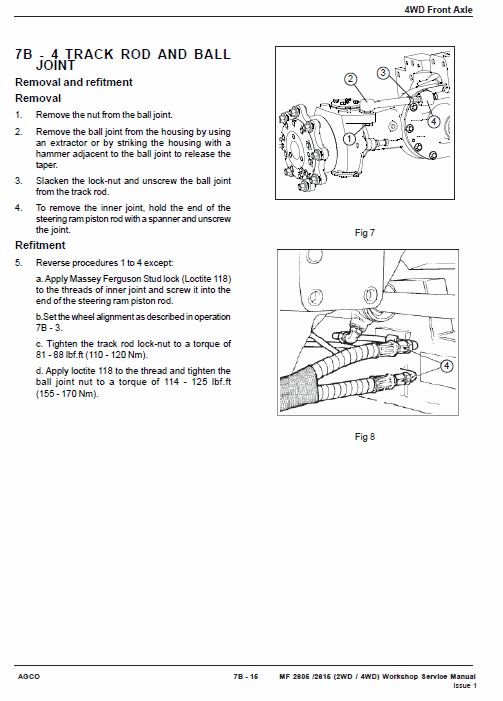

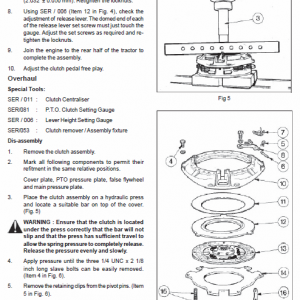

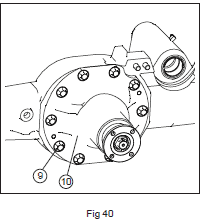

7B – 12 DIFFERENTIAL CARRIER ASSEMBLY

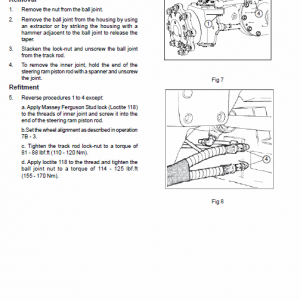

Removal and refitment

Removal

1. Secure the tractor by applying the parking brake.

2. Jack up the front of the tractor and support under the engine.

3. Slide back the propeller shaft guard and disconnect the propeller shaft.

4. Remove the axle from the tractor, see operation 7B – 5.

5. Remove both front wheels.

6. Drain the oil from the axle housing.

7. Remove both swivel housings, see operation 7B – 9 .It is not necessary to dismantle the planetary hubs.

8. Remove the steering ram, see operation 7B – 16.

9. Remove the ten bolts holding the differential carrier to the axle casing.

WARNING: Take care when removing the differential carrier assembly, it is uncomfortable and heavy to handle.

10. The differential is located by dowels in the axle casing. Carefully pry it away from the axle housing supporting the weight at all times.

Refitment

11. Reverse procedures 1 to 10 except: a. Apply Massey Ferguson Instant Gasket (Loctite 596) to the joint face of the differential case.

b. Apply loctite 118 to the differential carrier bolts and tighten them to a torque of 95 – 103 lbf.ft (130 – 140 Nm)

This was an extract from the actual manual.

Table of Content Massey Ferguson 2605, 2615 Tractor Service Manual

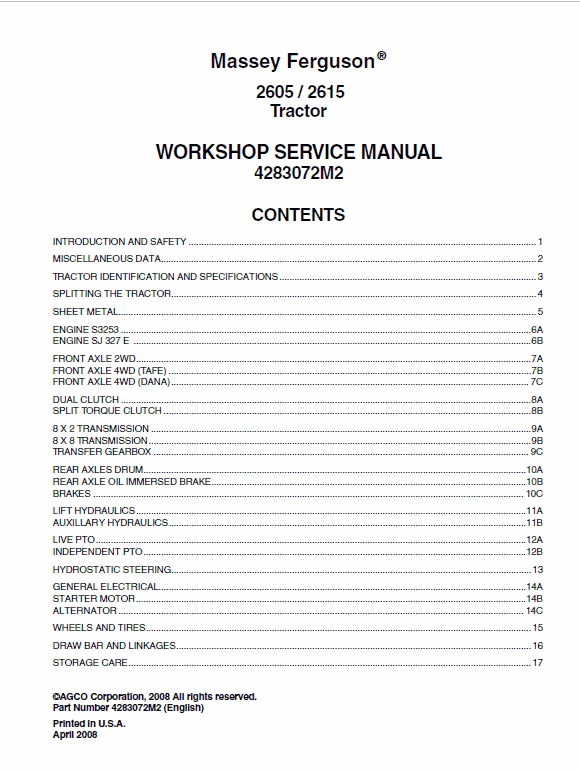

INTRODUCTION AND SAFETY ………………………………………………………………………………………………………………………… 1

MISCELLANEOUS DATA………………………………………………………………………………………………………………………………….. 2

TRACTOR IDENTIFICATION AND SPECIFICATIONS………………………………………………………………………………………… 3

SPLITTING THE TRACTOR………………………………………………………………………………………………………………………………. 4

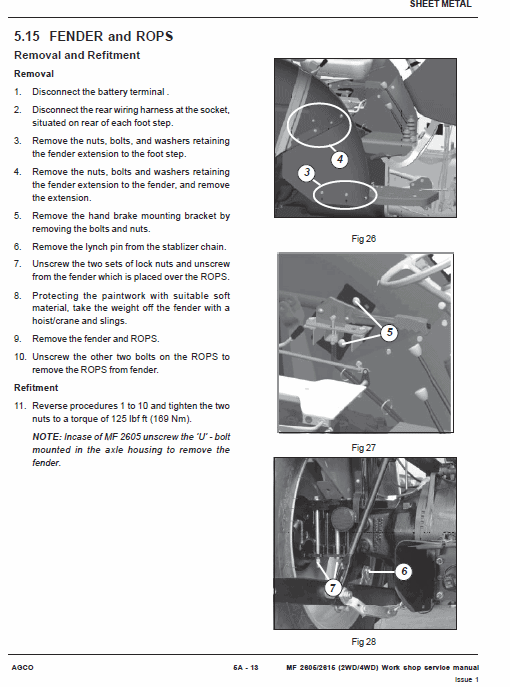

SHEET METAL…………………………………………………………………………………………………………………………………………………. 5

ENGINE S3253 ……………………………………………………………………………………………………………………………………………….6A

ENGINE SJ 327 E …………………………………………………………………………………………………………………………………………..6B

FRONT AXLE 2WD………………………………………………………………………………………………………………………………………….7A

FRONT AXLE 4WD (TAFE) ………………………………………………………………………………………………………………………………7B

FRONT AXLE 4WD (DANA)……………………………………………………………………………………………………………………………. 7C

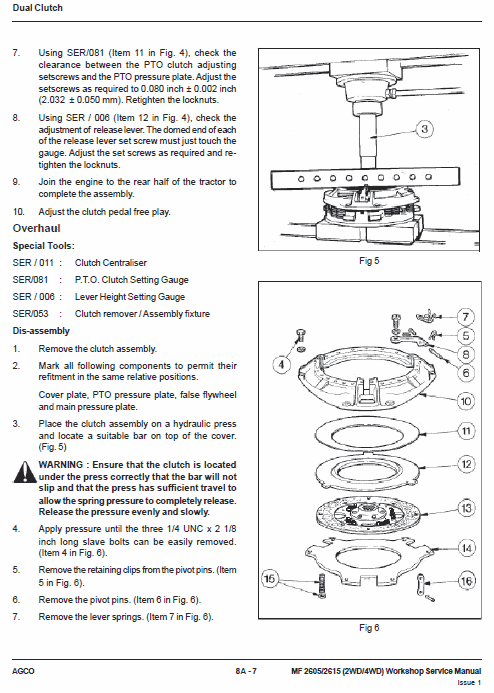

DUAL CLUTCH ……………………………………………………………………………………………………………………………………………….8A

SPLIT TORQUE CLUTCH ………………………………………………………………………………………………………………………………..8B

8 X 2 TRANSMISSION …………………………………………………………………………………………………………………………………….9A

8 X 8 TRANSMISSION……………………………………………………………………………………………………………………………………..9B

TRANSFER GEARBOX ………………………………………………………………………………………………………………………………….. 9C

REAR AXLES DRUM……………………………………………………………………………………………………………………………………..10A

REAR AXLE OIL IMMERSED BRAKE……………………………………………………………………………………………………………..10B

BRAKES ……………………………………………………………………………………………………………………………………………………… 10C

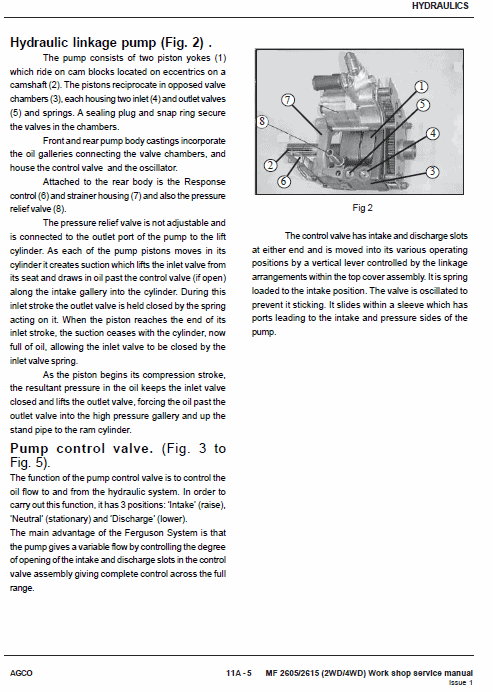

LIFT HYDRAULICS………………………………………………………………………………………………………………………………………..11A

AUXILLARY HYDRAULICS…………………………………………………………………………………………………………………………….11B

LIVE PTO………………………………………………………………………………………………………………………………………………………12A

INDEPENDENT PTO……………………………………………………………………………………………………………………………………..12B

HYDROSTATIC STEERING……………………………………………………………………………………………………………………………..13

GENERAL ELECTRICAL………………………………………………………………………………………………………………………………..14A

STARTER MOTOR………………………………………………………………………………………………………………………………………..14B

ALTERNATOR…………………………………………………………………………………………………………………………………………….. 14C

WHEELS AND TIRES………………………………………………………………………………………………………………………………………15

DRAW BAR AND LINKAGES……………………………………………………………………………………………………………………………16

STORAGE CARE…………………………………………………………………………………………………………………………………………….17

1 review for Massey Ferguson 2605, 2615 Tractor Service Manual

Add a review

You must be logged in to post a review.

Best Parts (verified owner) –

Just as described.