Linkbelt 800LX Excavator Service Repair Manual

$45.00

Manual Included:

- Service Repair Manual: 626 pages

- Operators Manual: 227 pages

- Parts Catalog: 587 pages

- Hydraulic and Electrical Schematics

Specifications:

- Brand: LinkBelt

- Model: 800LX

- Type: Excavator

- Manuals: Repair and Operators Manual

- Publication Numbers: 1061 & 1047

- Language: English

- Format: PDF

- Description

- Reviews (0)

Description

Table of Contents

1. General Information

- General Information

- Safety

- Standard Torque Data

- Serial Number Information

- Ingredients

- Engine Oil

- Engine Specifications

- Hydraulic System Specifications

- Attachment Specifications

- Sprocket Dimensions and Wear Limits

- Idler Wheel Dimensions

- Upper Roller Dimensions

- Lower Roller Dimensions

- Attachment Dimensions

- Special Torque Settings

- Machine Overall Dimensions

2. Engine

- Engine Removal and Installation

- Radiator/Oil Cooler Removal and Installation

3. Fuel System

- Fuel Tank Removal and Installation

4. Electrical System

- General Location of Components (Outside the Cab)

- Relay and Main Fuses

- General Location of Components (Inside the Cab)

- Fuse Box

- Instrument Panel

- Operating Principles

- Work Mode Selection

- H/S/L Mode Checking

- Auto Mode Checking

- Anti-Pollution System

- Acceleration Checking

- Engine Idle Checking

- Breaker Mode Checking

- Automatic Engine Preheat

- Auto Engine Warm-Up

- Idle Checking Using Battery Voltage

- Engine Emergency Stop

- Back-Up Mode

- Function Locking

- Power Boost

- Swing Brake

- Free Swing

- Travel Mode

- Travel Alarm

- Supply Cut-Off Delayed

- Hydraulic Oil Temperature Indicator

- Fuel Level

- Engine Fuel Injection Pump

- Counterweight Removal Circuit

- Access to Monitor Displays

- Machine History

- Machine Condition

- Diagnostic Code

- Warning Messages

- Excavator Model Selection Panel

- Troubleshooting

- Electrical System Troubleshooting

- Electrical Inspection of Components

- Battery Maintenance

- Maintenance of Battery

- Inspecting Battery

- Charging Battery

- Battery Charging Guide

- Connecting a Booster Battery

- Computer and Engine Controller Removal and Installation

5. Undercarriage

- Track Sets Removal and Installation

- Lower Roller Removal and Installation

- Upper Roller Removal and Installation

- Checking for Leaks

- Sprocket Removal and Installation

- Idler Wheel and Tension Shock Absorber Removal and Installation

6. Drive Train

- Travel Motor/Reduction Gear Assembly Removal and Installation

- Travel Drive Motor and Reduction Gear Disassembly and Assembly

- Swing Reduction Gear Removal and Installation

- Swing Reduction Gear Disassembly and Assembly

7. Hydraulics

- Releasing Pressure in Hydraulic System

- Bleeding Air from Hydraulic System

- Vacuum Pump

- Cleaning Hydraulic System

- Identification of Hydraulic Components

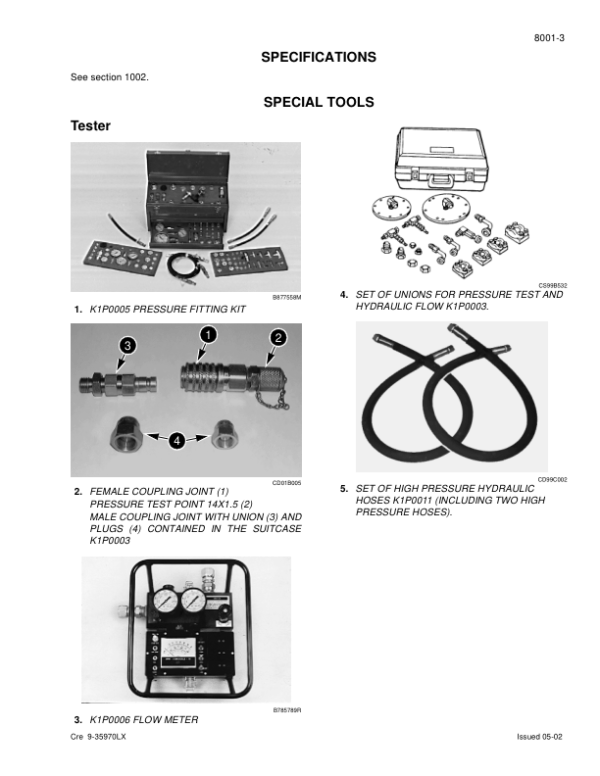

- Preparation Before Inspection

- Checking and Setting Procedure

- Troubleshooting

- Hydraulic Reservoir Removal and Installation

- Main Hydraulic Pump Removal and Installation

- Pilot Pump Removal and Installation

- Hydraulic Pump Coupling Removal and Installation

- Main Control Valve Removal and Installation

- Boom Cylinder Removal and Installation

- Arm Cylinder Removal and Installation

- Bucket Cylinder Removal and Installation

- Hydraulic Swivel Removal and Installation

- Pilot Function Blocks Removal and Installation

- Swing Motor Removal and Installation

- Free Swing Valve Disassembly and Assembly

- Hydraulic Pump Components

- Locating the Ports

- Regulation Control

- Removing the Controller

- Removing the Pump

- Installing the Controller

- Inspection

- Installing the Hydraulic Pump

- Control Valve Disassembly and Assembly

- Attachment Cylinders Disassembly and Assembly

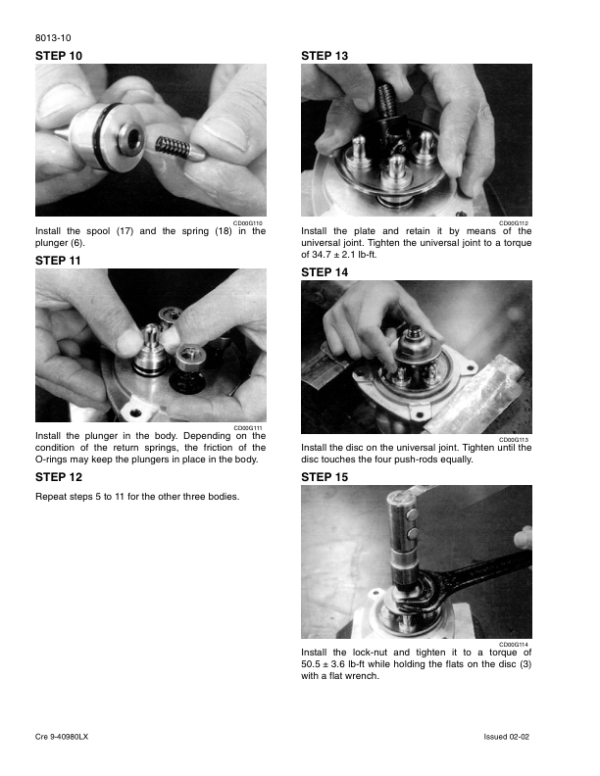

- Control Lever Disassembly and Assembly

- Control Pedals Disassembly and Assembly

- Eight Solenoid Valve Bank Disassembly and Assembly

- Cushion Control Valve Disassembly and Assembly

- Boom and Safety Valves Disassembly and Assembly

- Hydraulic Swivel Disassembly and Assembly

- Hydraulic Swing Motor Disassembly and Assembly

- Hydraulic Functions

8. Upper Structure

- Upper Structure Removal and Installation

- Counterweight Removal and Installation

- Bucket Removal and Installation

- Arm Removal and Installation

- Boom Removal and Installation

- Operator’s Seat Removal and Installation

- Safety Belt Removal and Installation

- Cab Removal and Installation

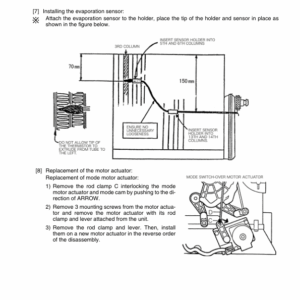

- Heating Block/AC Block Removal and Installation

- Windshield Wiper Motor Removal and Installation

- Attachment Installation

- Attachment Removal and Installation

- Connecting Lower Side Frames to Upper Structure

- Procedure for Mounting Counterweight

- Operational Testing

Be the first to review “Linkbelt 800LX Excavator Service Repair Manual”

You must be logged in to post a review.

Reviews

There are no reviews yet.