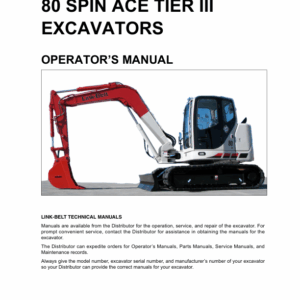

Linkbelt 80 Tier 3 Spin Ace Excavator Service Repair Manual

$39.00

Manual Included:

- Service Repair Manual: 753 pages

- Operators Manual: 122 pages

- Hydraulic and Electrical Schematics

Specifications:

- Brand: LinkBelt

- Model: 80 Tier 3 Spin Ace

- Type: Excavator

- Manuals: Repair and Operators Manual

- Language: English

- Format: PDF

- Description

- Reviews (0)

Description

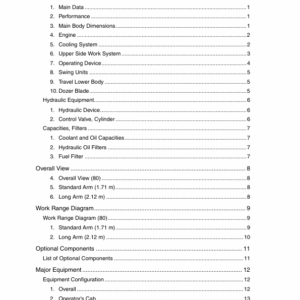

Table of Contents

Main Body Section

Specifications

- Main Data

- Performance

- Main Body Dimensions

- Engine

- Cooling System

- Upper Side Work System

- Operating Device

- Swing Units

- Travel Lower Body

- Dozer Blade

Hydraulic Equipment

- Hydraulic Device

- Control Valve, Cylinder

Capacities, Filters

- Coolant and Oil Capacities

- Hydraulic Oil Filters

- Fuel Filter

Overall View

- Overall View (80)

- Standard Arm (1.71 m)

- Long Arm (2.12 m)

Work Range Diagram

- Work Range Diagram (80)

- Standard Arm (1.71 m)

- Long Arm (2.12 m)

Optional Components

- List of Optional Components

Major Equipment

- Equipment Configuration

- Overall

- Operator’s Cab

Main Equipment Table

- Lower Mechanism

- Assembly Diagrams (with blade)

Lower Component

- Travel Unit

- Take-up Roller

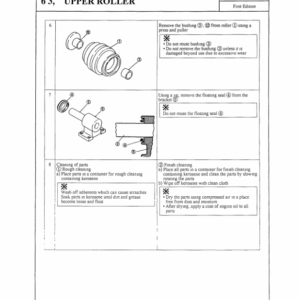

- Upper-roller

- Lower-roller

- Recoil Spring

- Shoes

Upper Component

- Swing Unit

Engine-related

- Engine

- Muffler

- Air Cleaner (double element)

- Radiator

Hydraulic Device

- Hydraulic pump

Control-related

- Control Valve

- Solenoid Valve (4 stack)

- Remote Control Valve (left/right, travel operations)

- Remote Control Valve Characteristic Diagram

- Center Joint

Backhoe Attachment

- Cylinder

- Attachments

Fuel Tank

Sump Tank

Hydraulic Section

Hydraulic Pump Operational Description

- Configuration and Principle of Operation

Flow Control

- Constant controlling of simultaneous output

- Power-down control by discharge pressure of blade pump (blade shift)

Control Valve Operation

- Operation with All Spools in Neutral

- Main passage

- Signal passage

Independent Operation

- Travel spool switch-over (Figure 1)

- Backup spool switch-over (Figure 2)

- Swing spool switch-over (Figure 3)

- Bucket spool switch-over (Figure 3)

- Boom spool switch-over

- Arm spool switch-over

- Blade spool switch-over (Add-on) (Figure 9)

- Boom Swing spool switch-over (Add-on) (Figure 9A)

- Relief valve

- Anti-drift valve (Boom section)

Combined Operations

- Additional operation with travel (Figure 14)

Relief Valve

- Main relief valve

- Overload relief valve

Swing Unit Swing Motor

- Functional and Operational Description

- Swash Plate Motor

- Parking Brake (for models equipped with parking brakes)

- Principle of Relief Valve Operation

- Makeup Valve

- Reduction Gear (2-stage planetary gear)

Overview

- Features

- Operational Description

Travel Unit Travel Motor

- External Dimensional Drawing

- Basic Structure and Drawings

- Basic structure of GM motor

- Parts list

- Operational Description

- Reduction gear

- Hydraulic drive section

Hydraulic Circuit Section

Port Locations

- Hydraulic Pump

- Control Valve

Control Valve

Pilot Hose Connection Diagrams

- Pilot P & T Lines

- Pilot Control Lines

Functional Description

- List of Functions

- Control Valve Configuration Table

Overview

Explanation of Hydraulic Circuit and Operations (standard model)

- Travel Circuits

- High-speed Travel Circuit

- Low-speed Travel Circuit

- Straight-travel Circuit (Boom-Up and Travel-Forward)

- Swing Circuit

- Swing Parking Circuit

- Swing Override Throttle Circuit

- Bucket Circuit

- Bucket-Opening Circuit

- Arm Circuits

- Arm-in / Arm-out 2-speed Circuit

- Boom Circuits

- Boom Circuit 1: Boom-up 2-speed Circuit

- Boom Circuit 2: Boom-down Load Holding Valve Circuit

- Boom Swing Circuit

- Boom Swing Circuit

- Blade Circuits

- Blade Circuits

Explanation of Hydraulic Circuit and Operations (option)

- Backup Circuits

- Breaker and Crusher Circuit (2-speed confluence crusher circuit)

- Breaker and Crusher Circuit (breaker circuit)

- Ultra Small Tail Swing Hydraulic Excavator

- Backup Reciprocating Circuit (ultra small swing hydraulic excavator)

- Secondary Backup Reciprocating Circuit (ultra small tail swing hydraulic excavator)

Electric Circuits Section

Operational Description

- Monitor Display

- Monitor switch panel

- List of Functions

- Engine Control

- Engine start-up control

- Engine Start-up Circuit

- Monitor Output Control

- Monitor Display Control

Electric Circuit Diagrams

- Electric Circuit Diagram 1

- Electric Circuit Diagram 2

- Electric Circuit Diagram: Air Conditioner 1

- Electric Circuit Diagram: Air Conditioner 2

Harness Diagrams

- Upper Frame

- Frame Wiring Main Harness

- Inside Cab

- Cab Wiring Main Harness

Wiring Diagrams

- Electrical Components and Wiring for Upper Frame (frame)

- Electrical Components and Wiring for Cab

- Electrical Components and Wiring for Upper Frame (engine)

- Electrical Components and Wiring for Upper Frame (battery)

- Heater

- Air Conditioner

- Inside Frame

- Inside Cab

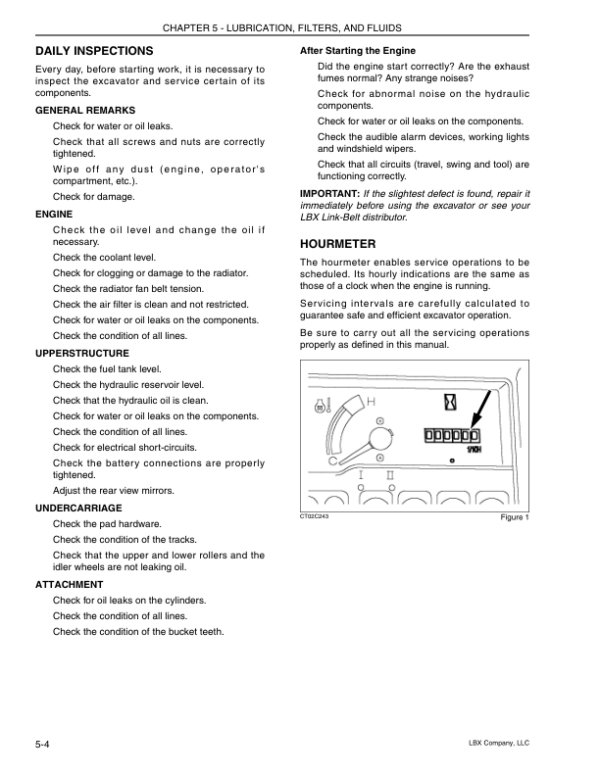

Maintenance Section

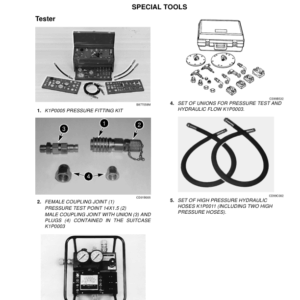

Measuring / Adjusting Pressure

- Measuring Pressure

- Basic conditions

- Pressure settings

- Ports for measuring pressure

- Preparation for Measuring Pressure

- Measuring Pressure

- Pressure adjustment

- Pressure adjusting points

- Bleeding Air

Attachments Dimensions

- Attachment Installation Methods

Appendix

- Unit Conversion Table

- New Hydraulic Oil

- Long-life hydraulic oil (IDEMITSU Daphne Super Hydro 46SX)

- Compatibility

- List of Common Features and Compatibility of Major Parts

Be the first to review “Linkbelt 80 Tier 3 Spin Ace Excavator Service Repair Manual”

You must be logged in to post a review.

Reviews

There are no reviews yet.