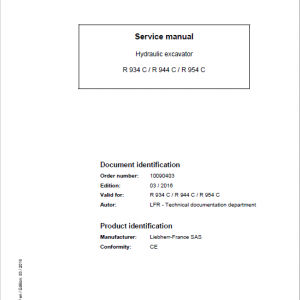

Liebherr D934 A7 SCR, D936 A7 SCR, D946 A7 SCR Diesel Engine Service Repair Manual

$30.00

Manual Included:

- Service Repair Manual: 102 Pages

- Operators Manual: 112 Pages

Specifications:

- Brand: Liebherr

- Model: D934 A7 SCR, D936 A7 SCR, D946 A7 SCR

- Type: Engine

- Manuals: Service Repair Manual & Operators Manual

- Language: English

- Format: PDF

- Description

- Reviews (0)

Description

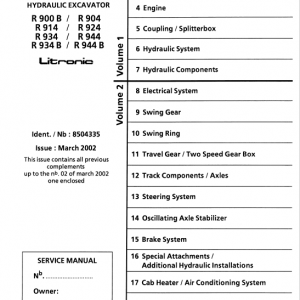

Table of Content of the D934 A7 SCR, D936 A7 SCR, D946 A7 SCR Service Manual:

1 General information

1.1 Structure of this manual

1.2 Important notes within this manual

1.2.1 Designation of activity-related notes on safety

1.2.2 Further designations

1.3 Symbols in this manual

1.4 Notes on safety

1.4.1 General notes on safety

1.4.2 Preventing injury to persons

1.4.3 Preventing damage to property

1.5 Notes regarding working on the fuel system and injection system

1.5.1 General notes on safety

1.5.2 Preventing injury to persons

1.5.3 Preventing damage to property

1.6 Notes on safety for working on the exhaust after-treatment system (SCR system)

1.6.1 Carbamide solution

1.6.2 General notes on safety

1.6.3 Preventing injury to persons

1.6.4 Preventing damage to property

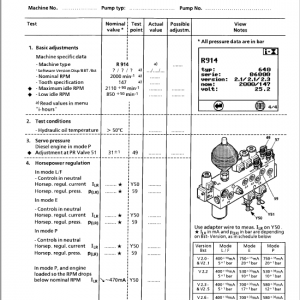

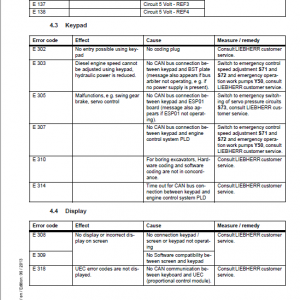

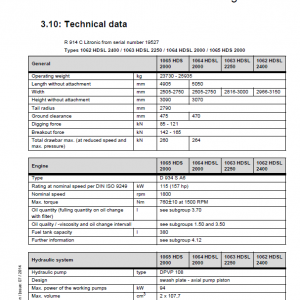

1.7 Technical Data

1.7.1 Engine in general

1.7.2 Standard tightening torques for screw connections

1.7.3 Standard torques for locking screws and banjo bolts

1.7.4 Standard torques for metric threaded unions

1.7.5 Standard torques for imperial threaded unions

1.7.6 Standard torques for cutting ring threaded unions

1.7.7 Standard torques for Triple Lock threaded unions

1.7.8 Standard torques for VSTI screw plugs

1.7.9 Special torques, tightening specifications, installation specifications and installation instructions

General notes

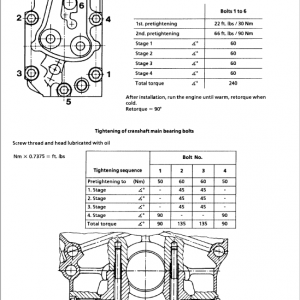

Tightening specification for main bearing

Tightening specification for aggregate carrier

Tightening specification for piston cooling nozzle

Tightening specification for final regulating valve and cold start valve

Tightening specification for oil intake

Tightening specification for oil drain valve

Tightening specification for oil sump (D934)

Tightening specification for oil sump (D936 / D946)

Tightening specification for crankshaft accessories

Tightening specification for connecting rod

Tightening specification for cylinder head

Installation and tightening specification for counterbalancing shafts (D934)

Tightening specification for rocker arm support

Installation and tightening specification for camshaft

Tightening specification for oil cooler

Tightening specification for oil cooler housing (D934)

Tightening specification for oil cooler housing (D936 / D946)

Tightening specification for fitting in oil filter bracket

Installation and tightening specification for high-pressure pump

Installation and tightening specification for injector and pressure pipe tube

Installation instruction for cable harness on injector

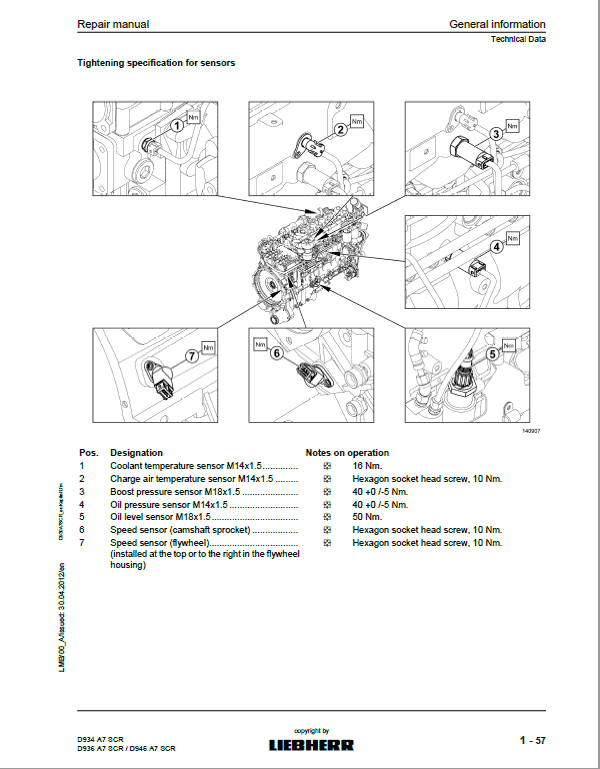

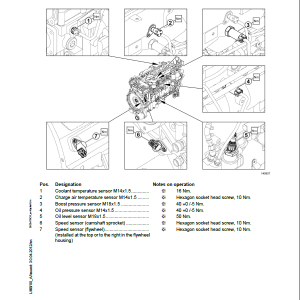

Tightening specification for sensors

Installation instruction for cable harness

Installation instruction for throttle valve

Tightening specification for heater flange

Tightening specification for idler

Tightening specification for air compressor gear

Installation instruction for coolant pump

Tightening specification for exhaust manifold (D934)

Tightening specification for thermal protection plate (D934)

Tightening specification for exhaust manifold (D936 / D946)

Tightening specification for thermal protection plate (D936 / D946)

Tightening specification for coolant pump

Tightening specification for turbocharger and flange on turbocharger

Tightening specification for generator belt pulley

Tightening specification for flywheel housing

Tightening specification for flywheel

Tightening specification for control unit-mount

Tightening specification for power take-off

Tightening specification for SCR module (installed machine side)

1.7.10 Cleaning agents, thread-locking adhesives and greases

1.8 Representations of the engine and engine components

1.8.1 Gear train (D934)

1.8.2 Gear train (D936 / D946)

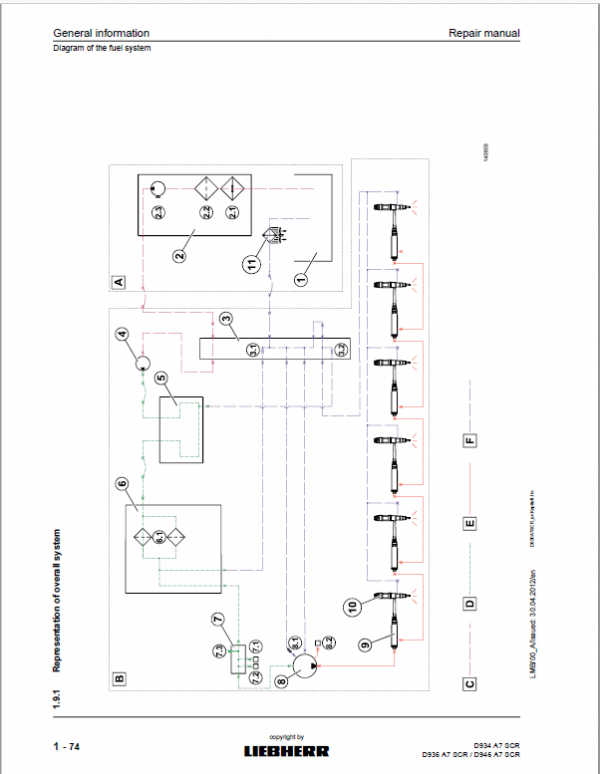

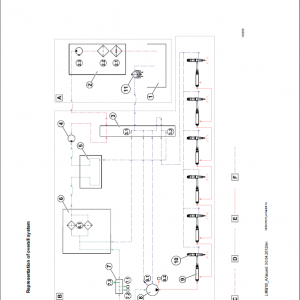

1.9 Diagram of the fuel system

1.9.1 Representation of overall system

1.10 Diagram of lube oil system

1.11 Diagram of coolant system

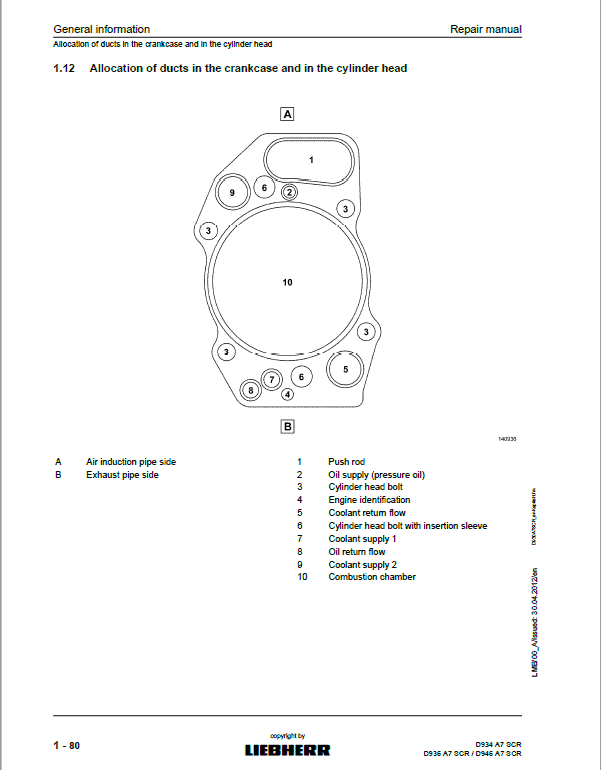

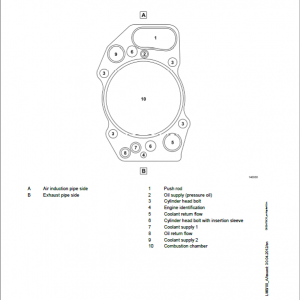

1.12 Allocation of ducts in the crankcase and in the cylinder head

1.13 Tools

1.13.1 Special tools

Lifting beam

Engine assembly stand

Lifting device for flywheels (SAE0, SAE1, SAE2)

Turning gears

Mounting bolts

Angle of rotation devices

Torx tools

Installing and dismantling the cylinder liner

Checking excess length of the cylinder liners

Installing and dismantling the front crankshaft seal

Installing and dismantling the crankshaft

Installing and dismantling the piston with connecting rod and piston rings

Installing and dismantling the piston rings

Installing and dismantling valve stem seals, valve springs and valves

Installing and dismantling the counterbalancing shafts

Dismantling and installing the camshafts

Installing and dismantling the injection lines

Installing and dismantling the pressure pipe tube and injector

Installing and dismantling the flywheel

Installing and dismantling the rear crankshaft seal

Target group

This repair manual has been compiled specifically for the mechanics and the workshop personnel of the LIEBHERR Owners and LIEBHERR subsidiaries, whose task it is to ensure that the diesel engines are in perfect working order.

Be the first to review “Liebherr D934 A7 SCR, D936 A7 SCR, D946 A7 SCR Diesel Engine Service Repair Manual”

You must be logged in to post a review.

Reviews

There are no reviews yet.