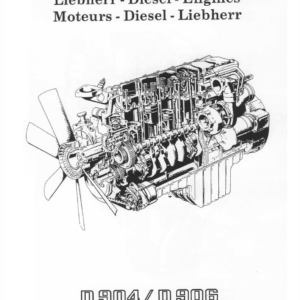

Liebherr D934 A7 DPF, D936 A7 DPF, D946 A7 DPF Diesel Engine Service Repair Manual

$26.00

Manual Included:

- Service Repair Manual: 126 Pages

Specifications:

- Brand: Liebherr

- Model: D934 A7 DFP, D936 A7 DFP, D946 A7 DFP

- Type: Engine

- Manuals: Service Repair Manual

- Publication Numbers: 11160823

- Language: English

- Format: PDF

- Description

- Reviews (0)

Description

Table of Content of the Engine Repair Service Manual

1 General Information

-

Structure of this Manual

-

Important Notes Within This Manual

-

Designation of Activity-Related Notes on Safety

-

Further Designations

-

-

Symbols in This Manual

-

Notes on Safety

-

General Notes on Safety

-

Preventing Injury to Persons

-

Preventing Damage to Property

-

-

Notes Regarding Working on the Fuel System and Injection System

-

General Notes on Safety

-

Preventing Injury to Persons

-

Preventing Damage to Property

-

-

Technical Data

-

Engine in General

-

Standard Tightening Torques for Screw Connections

-

Standard Torques for Locking Screws and Banjo Bolts

-

Standard Torques for Metric Threaded Unions

-

Standard Torques for Imperial Threaded Unions

-

Standard Torques for Cutting Ring Threaded Unions

-

Standard Torques for Triple Lock Threaded Unions

-

Standard Torques for VSTI Screw Plugs

-

Special Torques, Tightening Specifications, Installation Specifications and Installation Instructions

-

General Notes

-

Tightening Specification for Main Bearing

-

Tightening Specification for Aggregate Carrier

-

Tightening Specifications for Piston Cooling Nozzle

-

Tightening Specification for Final Regulating Valve and Cold Start Valve

-

Tightening Specification for Oil Intake

-

Tightening Specification for Oil Drain Valve

-

Tightening Specification for Oil Sump (D934)

-

Tightening Specification for Oil Sump (D936 / D946)

-

Tightening Specification for Crankshaft Accessories

-

Tightening Specification for Connecting Rod

-

Tightening Specification for Cylinder Head

-

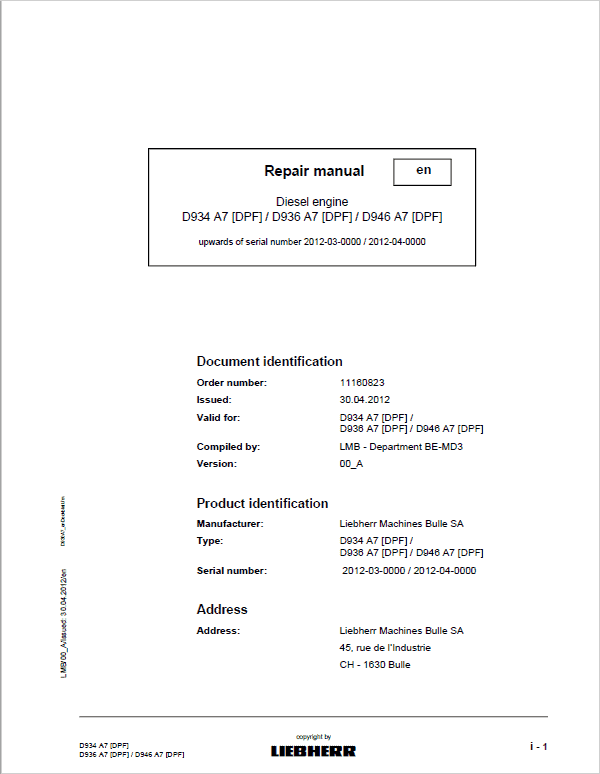

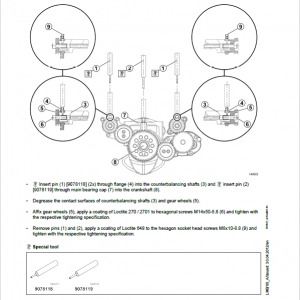

Installation and Tightening Specification for Counterbalancing Shafts (D934)

-

Tightening Specification for Rocker Arm Support

-

Installation and Tightening Specification for Camshaft

-

Tightening Specification for Camshaft Sprocket on Aggregate Carrier and Flywheel Side

-

Tightening Specification for Oil Cooler

-

Tightening Specification for Oil Cooler Housing (D934)

-

Tightening Specification for Oil Cooler Housing (D936 / D946)

-

Tightening Specification for Fitting in Oil Filter Bracket

-

Installation and Tightening Specification for High-Pressure Pump

-

Installation and Tightening Specification for Injector and Pressure Pipe Tube

-

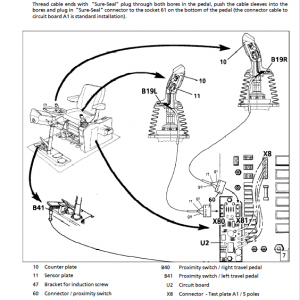

Installation Instruction for Cable Harness on Injector

-

Tightening Specification for Sensors

-

Installation Instruction for Cable Harness

-

Installation Instruction for Air Intake

-

Installation Instruction for Intercooler

-

Tightening Specification for Heater Flange

-

Tightening Specification for Idler

-

Tightening Specification for Air Compressor Gear

-

Installation Instruction for Coolant Pump

-

Installation Instruction for Thermostat Housing and Thermostat (3rd Thermostat)

-

Installation Instruction for Thermostat Housing and Thermostat

-

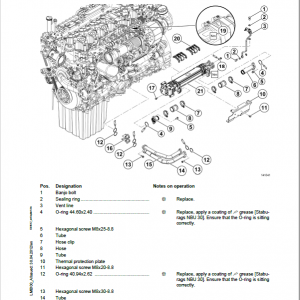

Installation Instruction for Water Manifold

-

Installation Instruction for Charge Air Duct

-

Installation Instruction for Exhaust Stack

-

Tightening Specification for Coolant Pump

-

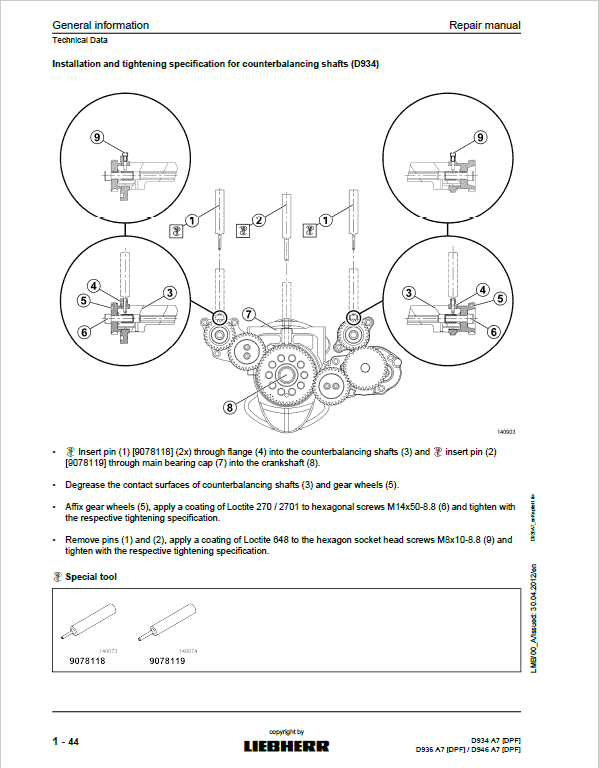

Installation Instruction for Exhaust Gas Recirculation Module

-

Tightening Specification for Exhaust Gas Recirculation

-

Installation Instruction for Exhaust Gas Recirculation Housing

-

Tightening Specification for Thermal Protection Plate

-

Installation Instruction for Actuator

-

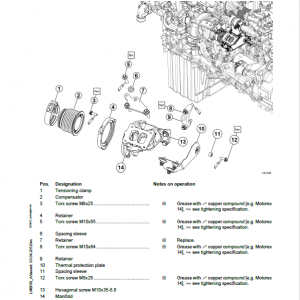

Installation Instruction for Turbocharger (Low Pressure)

-

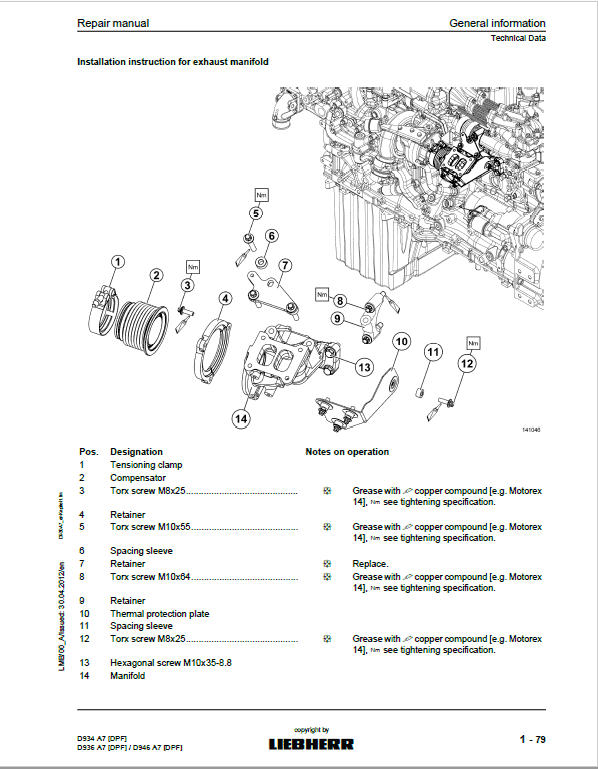

Installation Instruction for Exhaust Manifold

-

Installation Instruction for Exhaust Manifold

-

Tightening Specification for Exhaust System

-

Installation Instruction for Turbocharger (High Pressure)

-

Tightening Specification for Generator Belt Pulley

-

Tightening Specification for Flywheel Housing

-

Tightening Specification for Flywheel

-

Tightening Specification for Mounting of Control Units and Mounting of Sensor

-

Tightening Specification for Power Take-Off

-

Installation and Tightening Specification for Fuel Line Between Injection and Dosing Unit (D936)

-

Installation and Tightening Specification for Injection Unit

-

Installation and Tightening Specification for Dosing Unit

-

Tightening Specification for Particle Filter (Installed on the Machine Side)

-

-

Cleaning Agents, Thread-Locking Adhesives and Greases

-

-

Representations of the Engine and Engine Components

-

Gear Train (D934)

-

Gear Train (D936 / D946)

-

-

Diagram of the Fuel System

-

Representation of Overall System

-

-

Diagram of Lube Oil System

-

Diagram of Coolant System

-

Allocation of Ducts in the Crankcase and in the Cylinder Head

-

Tools

-

Special Tools

-

Lifting Beam

-

Engine Assembly Stand

-

Lifting Device for Flywheels (SAE0, SAE1 and SAE2)

-

Turning Gears

-

Mounting Bolts

-

Angle of Rotation Devices

-

Torx Tools

-

Installing and Dismantling the Cylinder Liner

-

Checking Excess Length of the Cylinder Liners

-

Installing and Dismantling the Front Crankshaft Seal

-

Installing and Dismantling the Crankshaft

-

Installing and Dismantling the Piston with Connecting Rod and Piston Rings

-

Installing and Dismantling the Piston Rings

-

Installing and Dismantling Valve Stem Seals, Valve Springs and Valves

-

Installing and Dismantling the Counterbalancing Shafts

-

Dismantling and Installing the Camshafts

-

Installing and Dismantling the Injection Lines

-

Installing and Dismantling the Pressure Pipe Tube and Injector

-

Installing and Dismantling the Flywheel

-

Installing and Dismantling the Rear Crankshaft Seal

-

-

Be the first to review “Liebherr D934 A7 DPF, D936 A7 DPF, D946 A7 DPF Diesel Engine Service Repair Manual”

You must be logged in to post a review.

Reviews

There are no reviews yet.