Liebherr D934 A7, D936 A7, D946 A7 Diesel Engine Operators Manual

$27.00

Manual Included:

- Operators Manual: 122 Pages

Specifications:

- Brand: Liebherr

- Model: D934 A7, D936 A7, D946 A7

- Type: Diesel Engine

- Manuals: Operators Manual

- Language: English

- Format: PDF

- Description

- Reviews (0)

Description

Table of Content (Operating manual D934 A7, D936 A7, D946 A7 DPF)

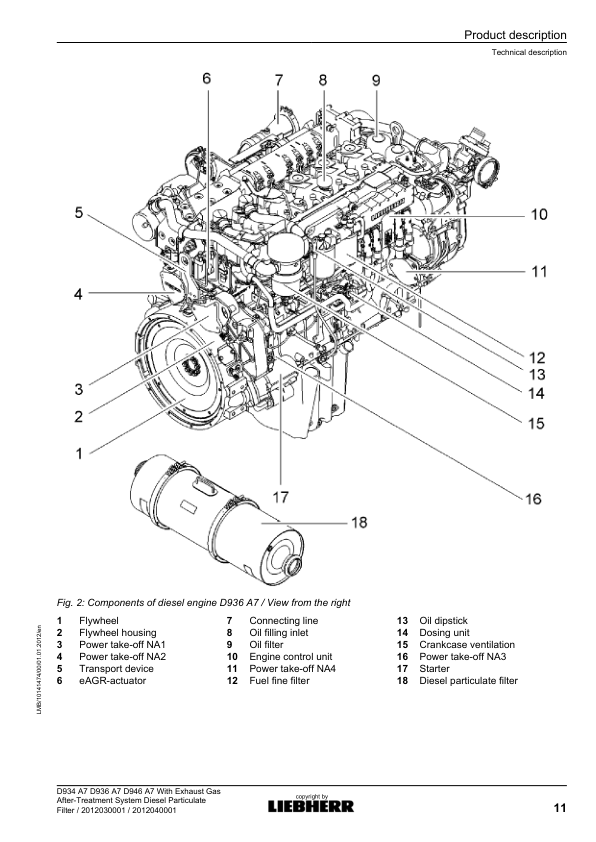

1 Product description

– 1.1 Technical description

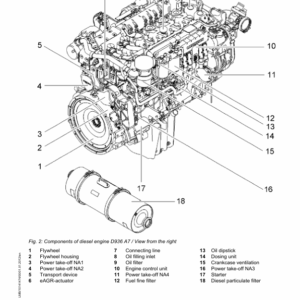

–– Overview of assembly

–– Explanation of type description

–– Design features

–– Special equipment for the diesel engine

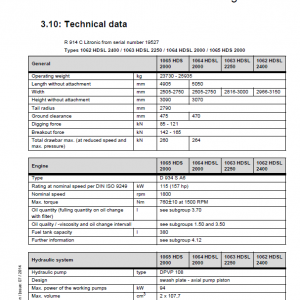

– 1.2 Technical data

–– Diesel engine

–– Cylinder head, standard

–– Cylinder head with engine auxiliary brake system (ZBS)

–– Coolant pump D934 1-stage

–– Coolant pump D934 2-stage

–– Coolant pump D936 / D946

–– Coolant thermostat

–– Generator

–– Starter

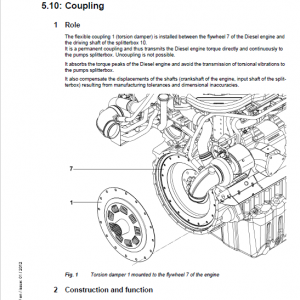

–– Flywheel housing

–– Air compressor Wabco 293 cm³

–– Air compressor Wabco 352 cm³

–– Air compressor Knorr 300 cm³

–– Diesel particulate filter

2 Notes on safety

2.2 General notes on safety

2.3 Use as directed

2.4 Notes on the prevention of crushing and burns

2.5 Notes on the prevention of fire and explosions

2.6 Observe safety precautions when starting

2.7 Measures for safe maintenance

2.8 Safety precautions for diesel engines with ECU

2.9 Safety and emergency run program for diesel engines with ECU

2.10 Special notes on Common Rail System

2.11 Particularly hazardous

2.12 Disposing of fuels and lubricants

2.13 Diesel particulate filter

– Measures for safe maintenance and repair

– Information on prevention of burns

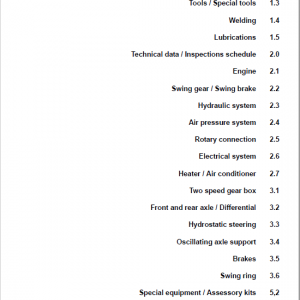

3 Operation, Servicing

3.1 Control and operating elements

3.2 Operation

– Preparations before initial start-up

– Initial start-up / test run

– Start the diesel engine

– Starting in frosty temperatures

– Switching off the diesel engine

– Exhaust gas after-treatment for DPF

4 Malfunctions

4.1 Faults – Cause – Remedy

5 Maintenance

5.1 Maintenance and inspection chart

5.2 Filling amounts

– Table for filling amounts

– Lubrication chart

5.3 Fuels and lubricants

– Handling fuels and lubricants

– Environmental-protection guidelines

– Disposing of used materials

– Diesel fuels

– Lube-oils for the diesel engine

– Coolant for diesel engine

5.4 Special tools for maintenance tasks

5.5 Preparatory maintenance tasks

5.6 Maintenance tasks (daily) / every 10 operating hours

– Check engine oil level

– Visual inspection (leaks, contamination, damages)

– Check coolant level

– Check or drain water separator of fuel prefilter

– Check low-pressure display of air filter

– Visual inspection of diesel particulate filter system

5.7 Maintenance tasks (weekly) / every 50 operating hours

– Drain water and sediment in fuel tank

– Clean dust-discharge valve of air filter

5.8 Maintenance tasks / every 500 operating hours

– Check flap of diesel engine brake

– Change engine oil and replace oil filter

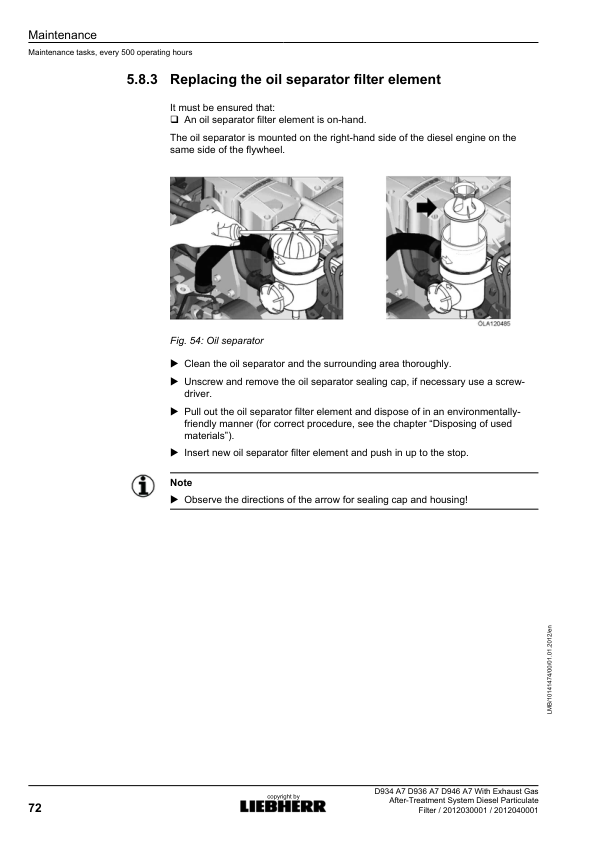

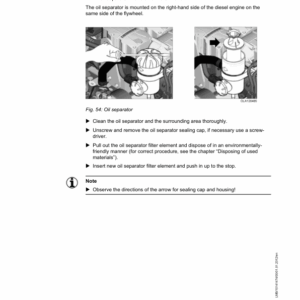

– Replace oil separator filter element

– Check and replace ribbed V-belt

– Check induction and exhaust gas system for leaks and condition

– Check cooling and heating systems for leaks and condition

– Check lubrication and fuel system for leaks and condition

– Check batteries and cable connections

– Check control unit mounting

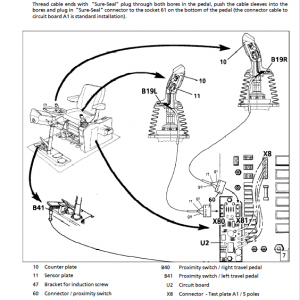

– Check sensors, actuators, cable fittings and plugs

– Check DPF profile clamps

5.9 Maintenance tasks / every 1000 operating hours

– Check oil sump, engine mount and brackets

– Check and adjust valve clearance

– Replace fuel prefilter element

– Replace fuel fine-filter

5.10 Maintenance tasks / every 2000 operating hours

– Check anticorrosive / antifreeze concentration in coolant

5.11 Maintenance tasks / every 3000 operating hours

– Grease flywheel starter ring gear

– Replace coolant

– Clean diesel particulate filter

5.12 Maintenance tasks / every 4500 operating hours

– Clean diesel particulate filter

5.13 Maintenance tasks / every 10000 operating hours

– Replace heater flange

5.14 Maintenance tasks as required

5.15 Check heater flange

5.16 Bleed fuel system

5.17 Replace dry air filter main element

5.18 Replace dry air filter safety element

5.19 Transport and storage

– Lifting gear

– Storage up to 6 months

– Storage for 6–24 months

5.20 Packaging and transport of DPF

– Protective caps for DPF

– Packaging of DPF module

– Authorized Liebherr service points

– Sending DPF module

– Recycling of used/damaged filters

– Hotline

6 Supplemental Information USA

6.3 Emission control warranty statement – rights and obligations

– Manufacturer’s warranty coverage

– Owner’s warranty responsibilities

– Warranty coverage

– Warranted parts

Be the first to review “Liebherr D934 A7, D936 A7, D946 A7 Diesel Engine Operators Manual”

You must be logged in to post a review.

Reviews

There are no reviews yet.